Guide to Glue Led Strip

- Introduction: Navigating the Global Market for glue led strip

- Understanding glue led strip Types and Variations

- Key Industrial Applications of glue led strip

- Strategic Material Selection Guide for glue led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for glue led strip

- Comprehensive Cost and Pricing Analysis for glue led strip Sourcing

- Spotlight on Potential glue led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for glue led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the glue led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of glue led strip

- Strategic Sourcing Conclusion and Outlook for glue led strip

Introduction: Navigating the Global Market for glue led strip

The global demand for high-quality glue LED strips is surging as industries across Africa, South America, the Middle East, and Europe seek versatile, energy-efficient lighting solutions for commercial, architectural, and retail applications. For international B2B buyers—from Kenya to France—sourcing the right glue LED strip is not merely a transaction but a strategic decision that influences product performance, installation efficiency, and long-term supply stability.

Glue LED strips, distinguished by their integrated adhesive backing, offer unparalleled ease of installation and durable mounting, making them indispensable in modern lighting projects. However, navigating the global marketplace requires a nuanced understanding of product variations, adhesive types, manufacturing standards, and quality control processes to ensure compatibility with diverse environmental conditions and regulatory requirements.

This comprehensive guide empowers buyers with actionable insights into:

- Types and materials of glue LED strips tailored for different applications

- Manufacturing and quality assurance benchmarks critical for reliability

- Supplier evaluation criteria to identify trustworthy long-term partners

- Cost factors and market dynamics influencing pricing and availability

- Logistics and delivery considerations for international procurement

- Frequently asked questions addressing common buyer challenges

By equipping you with this knowledge, the guide helps mitigate risks such as inconsistent product quality, supply chain disruptions, and hidden costs. Whether you are a distributor in Johannesburg, a contractor in São Paulo, or a reseller in Dubai, understanding these dimensions enables informed sourcing decisions that align with your business growth and operational excellence.

Understanding glue led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

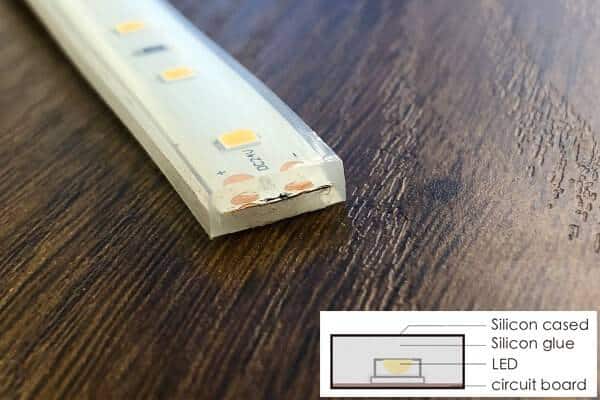

| Silicone-Based Glue LED Strip | Uses high-adhesion silicone glue, flexible and waterproof | Outdoor signage, architectural lighting, marine | Durable and weatherproof but higher cost and longer curing time |

| Acrylic Adhesive Glue LED Strip | Employs acrylic glue, strong initial tack, moderate flexibility | Indoor decoration, retail displays, office lighting | Cost-effective and quick installation; less resistant to moisture |

| Hot Melt Glue LED Strip | Features thermoplastic hot melt glue, fast bonding, moderate durability | Industrial lighting, temporary setups, exhibitions | Rapid application and repositionable; lower heat resistance |

| Epoxy Glue LED Strip | Uses epoxy resin glue, extremely strong bond, rigid | Automotive lighting, heavy-duty industrial uses | High strength and chemical resistance; difficult to remove or reposition |

| UV-Curable Glue LED Strip | Cured by UV light, fast setting, precise application | Electronics assembly, medical equipment lighting | Precision bonding and fast curing; requires UV curing equipment |

Silicone-Based Glue LED Strip

Silicone-based glue LED strips are prized for their flexibility and superior waterproofing, making them ideal for outdoor and marine environments where exposure to moisture and temperature changes is common. B2B buyers should consider the longer curing time and slightly higher price point but benefit from enhanced durability and reduced maintenance costs. These strips perform well in architectural and signage applications requiring longevity.

Acrylic Adhesive Glue LED Strip

Acrylic adhesive glue LED strips offer a strong initial bond and good flexibility, suited for indoor applications such as retail displays and office lighting. They provide a cost-effective solution with straightforward installation, appealing to buyers prioritizing budget and ease of use. However, they are less ideal in high-humidity or outdoor settings due to moderate moisture resistance, which buyers should evaluate based on end-use environments.

Hot Melt Glue LED Strip

Hot melt glue LED strips utilize thermoplastic adhesives allowing for rapid bonding and easy repositioning. This makes them suitable for temporary installations like exhibitions or industrial lighting setups where flexibility is key. Buyers should weigh the benefits of quick application against the glue’s moderate heat resistance, which may limit suitability in high-temperature environments.

Epoxy Glue LED Strip

Epoxy glue LED strips provide an exceptionally strong and chemically resistant bond, suited for demanding applications such as automotive lighting and heavy-duty industrial uses. These strips offer long-term reliability but present challenges in removal or repositioning, which buyers must consider when planning installation and maintenance strategies. The rigidity of epoxy glue also limits flexibility in strip placement.

UV-Curable Glue LED Strip

UV-curable glue LED strips are bonded using adhesives that cure rapidly under UV light, enabling precise application and fast production cycles. This type is particularly advantageous in electronics and medical equipment lighting where accuracy and speed are critical. Buyers need access to UV curing equipment but gain from reduced lead times and high-quality adhesive performance, supporting efficient supply chain operations.

Key Industrial Applications of glue led strip

| Industry/Sector | Specific Application of glue led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent lighting for product displays and store interiors | Enhances product visibility, attracts customers | Adhesive strength for diverse surfaces, color consistency |

| Automotive | Interior ambient lighting and dashboard backlighting | Improves user experience and vehicle aesthetics | Heat resistance, flexible form factor, vibration durability |

| Architecture & Construction | Cove lighting and façade illumination | Energy-efficient, customizable lighting solutions | Waterproofing (IP rating), ease of installation, longevity |

| Hospitality & Entertainment | Mood lighting in hotels, restaurants, and theaters | Creates ambiance, enhances guest satisfaction | Dimming compatibility, color temperature options, durability |

| Electronics & Appliances | Backlighting for displays and control panels | Improves visibility and device appeal | Compact size, low power consumption, strong adhesive for plastics |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, glue LED strips are widely used for accentuating product displays and enhancing store interiors. These strips adhere firmly to various surfaces like glass, wood, and metal, delivering consistent brightness and vibrant color rendering. For B2B buyers, especially distributors and store fit-out companies, selecting glue LED strips with strong adhesive properties and uniform color temperature is critical to maintain high-quality visual merchandising. Reliable supply and product consistency ensure that large retail chains can roll out installations smoothly across multiple locations.

Automotive Sector Usage

Automotive manufacturers and aftermarket suppliers utilize glue LED strips primarily for interior ambient lighting and dashboard backlighting. The adhesive-backed strips must withstand heat generated inside vehicles and resist vibrations common on roads, making durability a top priority. Buyers from regions with hot climates, such as the Middle East and parts of Africa, should prioritize suppliers offering heat-resistant and flexible LED strips. This application enhances vehicle aesthetics and driver experience, supporting premium branding for automotive businesses.

Architecture & Construction Lighting

Glue LED strips are integral in architectural lighting projects, including cove lighting and façade illumination in commercial buildings and residential complexes. These strips provide energy-efficient, customizable lighting solutions that architects and contractors value for their flexibility and ease of installation. For international buyers, especially in Europe and South America, sourcing glue LED strips with high IP waterproof ratings and long lifespan is essential to withstand environmental exposure and meet local building codes. The adhesive quality must support secure mounting on diverse materials like concrete, metal, and wood.

Hospitality & Entertainment Industry

In hotels, restaurants, and theaters, glue LED strips create mood lighting that significantly enhances guest experience and ambiance. The ability to dim lights and select from a range of color temperatures allows hospitality businesses to tailor environments to different times of day or events. B2B buyers in this sector should focus on strips compatible with advanced dimming systems and with adhesives that maintain strong bonds despite frequent cleaning or humidity. This ensures long-term reliability and customer satisfaction, which are crucial in competitive hospitality markets across Africa and Europe.

Electronics & Appliances Integration

For electronics manufacturers, glue LED strips are used to backlight displays and control panels in consumer appliances and industrial devices. The strips must be compact, energy-efficient, and have adhesives suitable for plastic and metal surfaces to ensure seamless integration. Buyers in markets like France or Brazil should consider suppliers offering low-power consumption LEDs with consistent brightness and strong adhesive backing to reduce assembly complexity and improve product reliability. This application supports product differentiation and enhanced user interface visibility.

Related Video: How to Install LED Light Strips

Strategic Material Selection Guide for glue led strip

When selecting materials for glue LED strips, international B2B buyers must carefully evaluate the properties and performance characteristics of adhesive substrates and encapsulants used in the product. The choice of glue material directly influences durability, environmental resistance, and installation versatility, all critical for markets spanning Africa, South America, the Middle East, and Europe. Below is an analysis of four common material types used in glue LED strips, focusing on their suitability for diverse industrial and climatic conditions.

Silicone-Based Adhesives

Key Properties: Silicone adhesives offer excellent thermal stability, typically withstanding temperatures from -60°C up to 200°C. They exhibit outstanding UV resistance and maintain flexibility over time, making them ideal for outdoor and high-temperature environments. Silicone glue is also chemically inert, providing good resistance against moisture and many corrosive agents.

Pros & Cons: The major advantage of silicone glue is its durability under harsh environmental conditions, including exposure to sunlight and humidity, which is common in regions like the Middle East and parts of Africa. However, silicone adhesives tend to be more expensive and require precise curing conditions during manufacturing, which can increase production complexity.

Impact on Application: Silicone glue is particularly suitable for waterproof LED strips used in outdoor signage, architectural lighting, and marine applications. Its flexibility also allows for installation on curved or uneven surfaces without cracking.

B2B Considerations: Buyers in Europe and South America should verify compliance with standards such as DIN EN ISO 10993 for biocompatibility and ASTM D2000 for rubber properties. In Africa and the Middle East, suppliers offering silicone adhesives with certifications like RoHS and REACH ensure safer handling and environmental compliance.

Acrylic-Based Adhesives

Key Properties: Acrylic adhesives provide strong bonding strength and moderate temperature resistance, generally stable between -40°C and 120°C. They offer good resistance to UV light and weathering but are less flexible than silicone.

Pros & Cons: Acrylic glue is cost-effective and easier to process in manufacturing, with faster curing times compared to silicone. However, it may become brittle over time under extreme temperature fluctuations, which can be a concern in regions with high diurnal temperature ranges like parts of South America and Africa.

Impact on Application: Acrylic adhesives are commonly used in indoor LED strip applications or semi-outdoor environments where moderate moisture exposure occurs. They are suitable for retail lighting, office installations, and residential projects.

B2B Considerations: For buyers in Europe and the Middle East, acrylic adhesives should meet ASTM D1000 standards for pressure-sensitive tapes and adhesives. It is also important to confirm that the adhesive does not emit volatile organic compounds (VOCs) beyond regulated limits, especially for indoor use.

Polyurethane-Based Adhesives

Key Properties: Polyurethane adhesives combine strong mechanical properties with excellent abrasion and chemical resistance. They typically operate within -40°C to 150°C and offer good adhesion to a variety of substrates including metals and plastics.

Pros & Cons: These adhesives provide robust durability and are well-suited for industrial LED strip applications exposed to chemicals or mechanical stress. The downside is their sensitivity to moisture during curing, which can complicate manufacturing. Additionally, polyurethane adhesives can be more costly than acrylics but usually less than silicones.

Impact on Application: Polyurethane glue is ideal for automotive lighting, industrial machinery, and outdoor installations where chemical exposure is expected. Its toughness makes it suitable for environments like factories or coastal regions in Europe and South America.

B2B Considerations: Buyers should ensure suppliers comply with ISO 9001 quality management and check for certifications like UL 746C for polymeric materials. In Africa and the Middle East, verifying the adhesive’s resistance to local environmental contaminants (e.g., dust, salt) is critical.

Epoxy-Based Adhesives

Key Properties: Epoxy adhesives offer exceptional bonding strength and excellent resistance to heat and chemicals, withstanding temperatures up to 250°C. They cure to form a rigid, durable bond but lack flexibility.

Pros & Cons: Epoxy glue is highly durable and ideal for permanent installations requiring structural integrity. However, its rigidity can lead to cracking or delamination if the LED strip or substrate experiences mechanical stress or thermal expansion. Epoxy adhesives also require longer curing times and more complex handling.

Impact on Application: Best suited for fixed, industrial LED lighting solutions where maximum adhesion and chemical resistance are priorities, such as in manufacturing plants or heavy equipment lighting in Europe and South America.

B2B Considerations: Compliance with ASTM D695 for compressive properties and ISO 10993 for chemical safety is important. Buyers in the Middle East and Africa should confirm that epoxy adhesives are compatible with local temperature extremes and that manufacturers provide clear handling and safety documentation.

| Material | Typical Use Case for glue led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone-Based | Outdoor, waterproof, flexible LED strips for harsh climates | Excellent thermal & UV resistance; high flexibility | Higher cost; complex curing process | High |

| Acrylic-Based | Indoor or semi-outdoor LED strips with moderate exposure | Cost-effective; fast curing; good UV resistance | Less flexible; can become brittle under extreme temps | Low |

| Polyurethane-Based | Industrial, automotive, chemically exposed LED applications | Strong mechanical & chemical resistance | Sensitive to moisture during curing; moderate cost | Medium |

| Epoxy-Based | Fixed industrial LED installations requiring strong bonds | Exceptional strength and chemical resistance | Rigid, prone to cracking under stress; longer curing | Medium |

This guide enables international buyers to align their glue LED strip material choices with operational demands and regional compliance requirements, ensuring product longevity and customer satisfaction across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for glue led strip

Manufacturing glue LED strips involves a series of precision-driven stages designed to ensure durability, consistent performance, and ease of installation for end-users. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding these processes and the associated quality assurance protocols is crucial to sourcing reliable products that meet local regulations and consumer expectations.

Key Stages in the Manufacturing Process of Glue LED Strips

-

Material Preparation

– Raw Material Selection: High-quality LEDs, flexible PCBs (Printed Circuit Boards), adhesives, resistors, and protective coatings form the core components. Suppliers must ensure materials come from reputable sources to maintain consistency.

– Adhesive Formulation: The glue used on the LED strip is often a specialized acrylic or silicone-based adhesive, tailored for strong bonding on various surfaces and environmental resistance (humidity, heat).

– Component Inspection: Incoming materials undergo initial checks for specifications such as LED brightness, PCB thickness, and adhesive tackiness. -

Forming and Circuit Assembly

– PCB Fabrication: Flexible PCBs are cut and shaped to precise dimensions, accommodating the LED layout and circuitry.

– LED Placement and Soldering: LEDs and electronic components are mounted onto the PCB using automated pick-and-place machines, followed by precise soldering techniques (e.g., reflow soldering) to ensure electrical reliability.

– Adhesive Application: The glue layer is applied either on the back of the PCB or integrated as a peel-and-stick layer, ensuring uniform thickness and strong adhesion without compromising flexibility. -

Encapsulation and Finishing

– Protective Coating: For waterproof or dustproof variants, a silicone or epoxy resin coating is applied. This step enhances durability, especially critical for outdoor or industrial applications.

– Cutting and Packaging: Strips are cut into standard or customized lengths, tested for electrical continuity, and packaged with protective films or reels to prevent damage during transport. -

Customization and R&D Support

– Many manufacturers offer tailored adhesive strengths, color temperatures, and strip widths to meet specific application needs. Buyers should inquire about R&D capabilities to align products with regional market demands.

Quality Assurance: International Standards and Industry-Specific Certifications

For B2B buyers, verifying that glue LED strips conform to recognized quality standards is non-negotiable. These standards assure product safety, performance, and regulatory compliance across different markets.

- ISO 9001: A fundamental international quality management system standard that governs the manufacturer’s processes. It ensures consistent production quality and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, vital for environmental regulations in Europe and increasingly adopted worldwide.

- UL Certification: Recognized primarily in North America but valued globally for electrical safety.

- API and IEC Standards: Relevant for industrial or specialized lighting applications, ensuring performance under specific operational conditions.

Quality Control Checkpoints and Testing Methodologies

Quality control (QC) in glue LED strip manufacturing typically involves multiple inspection stages to catch defects early and maintain batch consistency:

- Incoming Quality Control (IQC): Verification of raw materials such as LEDs, PCBs, and adhesives for defects or deviations from specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly stages, including solder joint inspections, adhesive application uniformity, and electrical testing of circuit integrity.

- Final Quality Control (FQC): Comprehensive testing of finished products, including:

- Illumination Consistency: Measuring brightness and color temperature uniformity.

- Adhesion Strength Testing: Peel tests to ensure glue effectiveness on various substrates.

- Waterproof Testing: Submersion or spray tests for strips with protective coatings.

- Thermal Performance: Heat dissipation tests to prevent premature LED failure.

- Electrical Safety: Insulation resistance and short-circuit tests.

How B2B Buyers Can Verify Supplier Quality Assurance

- Factory Audits

– Conduct on-site or third-party audits focusing on manufacturing capabilities, QC procedures, and compliance with international standards.

– For buyers in Kenya, Brazil, UAE, or France, partnering with local inspection agencies or international firms like SGS or Bureau Veritas can provide credible assessments.

Illustrative Image (Source: Google Search)

-

Review of QC Documentation

– Request batch-specific QC reports, including test results for adhesion, brightness, and waterproofing.

– Evaluate certificates such as ISO 9001, CE, RoHS, and UL, ensuring they are up to date and issued by accredited bodies. -

Third-Party Inspections

– Independent lab testing for performance verification, especially when launching new product lines or entering highly regulated markets.

– Consider random sample inspections to validate ongoing production quality. -

Pilot Orders and Sample Testing

– Before scaling purchases, test samples in real-world conditions relevant to your region’s climate and installation environments.

– This is particularly important for African and Middle Eastern markets, where temperature and humidity extremes can impact adhesive and LED performance.

QC and Certification Nuances for International Markets

- Africa and the Middle East: Environmental conditions such as high heat and dust require glue LED strips with robust adhesives and protective coatings. Look for suppliers who can demonstrate field-tested durability and offer certifications recognized by local authorities.

- South America: Import regulations may demand compliance with regional standards alongside international certifications. Buyers should clarify documentation requirements upfront to avoid customs delays.

- Europe: The CE mark and RoHS compliance are mandatory. Additionally, energy efficiency ratings and eco-labels can influence purchasing decisions, especially for government or large-scale infrastructure projects.

- Cross-Market Logistics: Understand that adhesives can degrade if exposed to extreme temperatures during shipping. Confirm that suppliers use appropriate packaging and shipping methods to preserve product integrity.

By gaining a comprehensive understanding of the glue LED strip manufacturing process and quality assurance frameworks, international B2B buyers can make informed sourcing decisions. Prioritizing manufacturers with transparent QC systems, relevant certifications, and proven supply chain reliability will help secure products that perform consistently and comply with diverse market requirements across Africa, South America, the Middle East, and Europe.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for glue led strip Sourcing

When sourcing glue LED strips for international B2B purposes, especially across diverse regions such as Africa, South America, the Middle East, and Europe, understanding the comprehensive cost and pricing structure is crucial for making informed purchasing decisions. This analysis breaks down the core cost components, key price influencers, and practical buyer strategies to optimize procurement.

Key Cost Components in Glue LED Strip Manufacturing

-

Materials

The primary materials include high-quality LEDs, flexible PCB substrates, adhesives (glue), resistors, and protective coatings. Variations in LED chip brands, adhesive types (e.g., heat-resistant vs. standard), and waterproofing materials directly affect costs. Premium materials yield better durability and performance but come at a higher price. -

Labor

Labor costs depend on the manufacturing location and complexity of assembly. Precision is essential for proper adhesive application and LED placement, which can increase labor intensity. Regions with higher wage standards (e.g., Europe) typically incur higher labor costs than some Asian manufacturing hubs. -

Manufacturing Overhead

Overhead includes utilities, equipment depreciation, factory maintenance, and administrative expenses. Efficient factories with automated production lines can reduce overhead per unit, impacting final pricing favorably. -

Tooling and Setup Costs

Initial tooling—such as molds, adhesive dispensers, and assembly jigs—is a one-time or infrequent expense. For custom glue LED strips, tooling costs can be substantial but amortized over large production runs. -

Quality Control (QC)

Rigorous QC processes, including adhesive strength testing, electrical safety checks, and durability assessments, add to the cost but ensure product reliability. Certifications like CE, RoHS, or UL often require additional testing, influencing pricing. -

Logistics and Shipping

Costs vary significantly depending on shipping mode (air, sea, or land), distance, customs duties, and handling fees. Buyers from regions like Kenya or Brazil should factor in longer transit times and potential import tariffs when budgeting. -

Supplier Margin

Manufacturers and distributors include profit margins that reflect market positioning, brand reputation, and service quality. Long-term partnerships may allow negotiation on margins for volume buyers.

Influential Factors Affecting Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically benefit from economies of scale, reducing per-unit costs. However, some suppliers enforce high MOQs that may strain smaller buyers. Negotiating flexible MOQs can unlock better pricing. -

Product Specifications and Customization

Custom lengths, adhesive types, LED densities, and integrated features (e.g., dimming capability) increase production complexity and cost. Buyers requiring unique specifications should anticipate price premiums. -

Material Quality and Certifications

Certified materials and products that meet international standards command higher prices but reduce risks of failure and regulatory issues, vital for markets with strict compliance (e.g., EU). -

Supplier Reliability and Reputation

Trusted suppliers with proven track records and reliable supply chains may price higher but reduce risks related to delays, defects, and after-sales support. -

Incoterms and Delivery Terms

Pricing differs based on delivery terms such as FOB, CIF, or DDP. Buyers should understand their responsibilities for shipping, insurance, and customs clearance under each term to avoid unexpected costs.

Strategic Tips for International B2B Buyers

-

Negotiate Beyond Price

Focus on total value: quality guarantees, lead times, payment terms, and after-sales service. For example, a slightly higher unit price with reliable delivery and warranty often results in lower Total Cost of Ownership (TCO). -

Assess Total Cost of Ownership

Include installation ease, adhesive longevity, energy efficiency, and maintenance when comparing offers. Cheaper strips with poor adhesive or LED lifespan may lead to higher replacement and labor costs. -

Leverage Local Market Knowledge

Buyers from regions like Kenya or the Middle East should consider local import duties, VAT, and potential delays. Partnering with suppliers familiar with these markets can streamline logistics and reduce hidden expenses. -

Request Detailed Quotes and Samples

Transparent quotations breaking down costs help identify negotiation points. Insist on product samples to verify adhesive strength and LED performance before committing to large orders. -

Plan for Currency Fluctuations and Payment Terms

International transactions may be affected by currency volatility. Negotiate payment terms that mitigate financial risk, such as letters of credit or staged payments.

Indicative Pricing Disclaimer

Prices for glue LED strips vary widely based on specifications, order size, and supplier location. This overview provides a framework for cost consideration rather than fixed pricing. Buyers should conduct direct supplier engagement and market research to obtain current and region-specific pricing.

Understanding these cost drivers and pricing influencers equips international B2B buyers to negotiate effectively, optimize procurement budgets, and build resilient supply chains for glue LED strips tailored to their market needs.

Spotlight on Potential glue led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘glue led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for glue led strip

Understanding the key technical properties and trade terminology related to glue LED strips is essential for international B2B buyers aiming to make informed purchasing decisions. This knowledge ensures product suitability, optimizes supply chain communication, and supports long-term partnerships.

Critical Technical Properties of Glue LED Strips

-

Adhesive Quality and Material Grade

The adhesive backing on LED strips—often a pressure-sensitive acrylic—is crucial for secure installation on various surfaces. High-grade adhesives ensure strong, durable bonding even in humid or uneven environments common in regions like Africa or the Middle East. For B2B buyers, verifying adhesive type and material grade prevents installation failures and costly replacements. -

Waterproof Rating (IP Code)

The Ingress Protection (IP) rating defines the strip’s resistance to dust and water. Common ratings include IP20 (non-waterproof) and IP65/IP67 (waterproof). Buyers targeting outdoor or industrial applications in diverse climates must prioritize appropriate IP levels to guarantee longevity and safety compliance. -

LED Chip Type and Density

LED strips vary by chip models (e.g., SMD 3528, 5050, 2835) and LED density (LEDs per meter). These factors affect brightness, energy efficiency, and color uniformity. Knowing these specs helps buyers align product features with end-use needs, whether for decorative retail lighting in Europe or agricultural lighting in South America. -

Voltage and Power Consumption

Most glue LED strips operate at 12V or 24V DC. Power consumption, measured in watts per meter, impacts energy costs and power supply specifications. For international buyers, ensuring compatibility with local electrical standards is vital for installation safety and operational efficiency. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) ranges from warm white (2700K) to cool white (6500K). CRI indicates how accurately the light renders colors, with 80+ being standard for commercial use. Buyers should select appropriate color specs to meet client preferences and application requirements, such as retail displays or office lighting. -

Tolerance and Quality Control Parameters

Tolerance refers to the acceptable deviation in product dimensions or electrical performance. Tight tolerance ensures consistent quality across batches, critical for large-volume buyers who require uniformity in their projects. Confirming supplier quality control practices reduces risk of defects and returns.

Common Trade Terminology in Glue LED Strip Procurement

-

OEM (Original Equipment Manufacturer)

This term refers to manufacturers producing goods that other companies rebrand or sell under their own name. For B2B buyers, OEM partnerships can enable customization and branding flexibility while leveraging supplier expertise. -

MOQ (Minimum Order Quantity)

MOQ is the smallest order size a supplier is willing to accept. Understanding MOQ helps buyers balance inventory costs with supplier requirements, especially important for emerging markets or smaller distributors in Africa and South America. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers requesting price and delivery details for specified products. Mastery of RFQ processes enables buyers to compare offers efficiently and negotiate better terms. -

Incoterms (International Commercial Terms)

These standardized trade terms define responsibilities and risks between buyers and sellers during shipping. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms is crucial for controlling logistics costs and compliance in cross-border transactions. -

Lead Time

Lead time indicates the period between order placement and product delivery. Clear understanding of lead times helps buyers plan inventory and project timelines, minimizing operational disruptions. -

Batch Number / Lot Number

These identifiers track production batches for quality control and traceability. Buyers should request batch information to manage warranties and address any product recalls efficiently.

By grasping these essential technical properties and trade terms, international B2B buyers—from Kenya to France—can better evaluate glue LED strip suppliers, ensure product performance, and streamline procurement processes across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the glue led strip Sector

Market Overview & Key Trends

The global glue LED strip market is rapidly evolving, driven by increasing demand for versatile, energy-efficient lighting solutions across commercial, industrial, and residential sectors. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this market is critical to sourcing the right products that meet both functional and regulatory requirements.

Key Market Drivers:

– Energy Efficiency & Cost Savings: LED strips with strong adhesive backing simplify installation while reducing energy consumption compared to traditional lighting. This appeals to cost-conscious markets like Kenya and emerging economies in South America, where infrastructure modernization is ongoing.

– Customization & Flexibility: Manufacturers are increasingly offering customizable glue LED strips with adjustable lengths, color temperatures, and waterproof features. This flexibility enables buyers to tailor solutions for diverse applications, from retail lighting in France to outdoor architectural projects in the Middle East.

– Technological Advancements: Integration with smart controls, dimming capabilities, and improved adhesives designed for varied surfaces are setting new industry standards. B2B buyers benefit from partnering with manufacturers who invest in R&D and can scale production accordingly.

– Supply Chain Dynamics: Global supply chain disruptions have underscored the importance of stable, transparent sourcing channels. Buyers are focusing on manufacturers with proven track records, certifications, and strong communication to ensure consistent quality and timely delivery.

Emerging Sourcing Trends:

– Long-Term Partnerships: More buyers prioritize manufacturers with 10+ years of experience and established reputations to mitigate risks associated with quality and supply volatility.

– Sample Testing & Pilot Orders: Rigorous product sampling and trial runs before large-scale procurement are becoming standard practice to verify adhesive strength, durability, and light consistency.

– Regional Compliance: Meeting local certifications such as CE in Europe or regional safety standards is a prerequisite for market entry and helps avoid costly regulatory setbacks.

By aligning sourcing strategies with these trends, international buyers can secure reliable, innovative glue LED strip products that support growth and competitive differentiation.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional in the glue LED strip sector—it is a strategic imperative for B2B buyers aiming to future-proof their supply chains and meet growing environmental regulations across Africa, South America, the Middle East, and Europe.

Environmental Impact Considerations:

– LED strips inherently offer energy savings, but the production and disposal of electronic components and adhesives can generate significant environmental footprints. Selecting suppliers who utilize low-VOC (volatile organic compounds) adhesives and recyclable or biodegradable materials minimizes harmful emissions and waste.

– Waterproof and durable glue LED strips reduce replacement frequency, lowering material consumption and e-waste accumulation, a critical factor for markets with limited recycling infrastructure.

Ethical Supply Chain Importance:

– Transparency in sourcing raw materials such as phosphors, copper, and adhesives ensures compliance with conflict-free and labor standards, a growing concern for European and Middle Eastern buyers.

– Certifications like ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) provide buyers with assurance that suppliers adhere to stringent environmental and safety norms.

Green Certifications & Materials:

– Buyers should prioritize glue LED strip manufacturers offering products certified by recognized bodies such as Energy Star or TUV Rheinland, which validate energy efficiency and environmental safety.

– The adoption of bio-based adhesives and lead-free soldering techniques are emerging trends, reducing ecological impact and aligning with corporate social responsibility goals.

Integrating sustainability into procurement decisions not only aligns with global climate targets but also enhances brand reputation and meets the expectations of increasingly eco-conscious end customers.

Brief Evolution of Glue LED Strips

Glue LED strips emerged as a solution to the challenges of traditional LED strip installation, where mechanical fasteners or clips limited flexibility and increased labor costs. Early iterations relied on simple adhesive backings that often lacked durability, leading to product failures in demanding environments.

Over the past decade, advancements in adhesive technology—such as enhanced acrylic and silicone-based glues—have transformed these strips into highly reliable, easy-to-install lighting components. This evolution has been driven by increasing adoption in sectors ranging from automotive and retail to smart homes and architectural lighting.

For B2B buyers, understanding this progression underscores the importance of verifying adhesive quality and compatibility with intended surfaces, ensuring long-term performance and minimizing maintenance overhead. As the market matures, manufacturers continue to innovate with stronger adhesives, improved waterproofing, and integration with smart lighting systems, reflecting broader trends toward flexible, sustainable lighting solutions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of glue led strip

-

How can I effectively vet suppliers of glue LED strips for international trade?

Begin by verifying the supplier’s business license and certifications such as ISO, CE, RoHS, or UL, which indicate compliance with international standards. Check their industry reputation through customer reviews, case studies, and trade show participation. Request product samples to test adhesive strength, durability, and LED quality. Establish communication early to assess responsiveness and transparency. For buyers in Africa, South America, the Middle East, and Europe, prioritize suppliers with proven export experience and positive feedback in your region to reduce risks and ensure smoother transactions. -

Is customization of glue LED strips available, and how can I ensure it meets my market needs?

Many manufacturers offer customization, including length, adhesive type, LED color temperature, waterproofing, and voltage options. To ensure your specifications align with your target market’s requirements, provide detailed technical drawings or product briefs. Request prototypes or samples for approval before mass production. Collaborate closely with the supplier’s R&D team to adapt products for local environmental conditions and regulatory standards, especially important for diverse markets like Kenya or France. Clear communication on customization timelines and costs will help avoid surprises. -

What are typical Minimum Order Quantities (MOQs) and lead times for glue LED strip orders?

MOQs vary widely depending on the supplier and customization level, generally ranging from 500 to 5,000 meters per order. Lead times typically span 3 to 8 weeks, influenced by order size, complexity, and current production schedules. Buyers should negotiate MOQs aligned with their inventory capacity and market demand. Early engagement on lead times is essential to plan logistics effectively. For international buyers, factor in additional transit and customs clearance times to avoid stockouts or delays, especially in regions with longer shipping routes like South America or the Middle East. -

What payment terms are common in international B2B transactions for glue LED strips?

Standard payment terms include a 30%-50% deposit upfront with the balance paid before shipment or upon receiving the bill of lading. Letters of Credit (LC) and escrow services can provide added security for high-value orders. For new suppliers, start with smaller trial orders and safer payment methods to build trust. Negotiating payment terms that accommodate your cash flow while reassuring the supplier is crucial. Be aware of currency exchange risks and bank fees, especially when dealing with suppliers in different continents. -

How can I verify the quality assurance and certifications of glue LED strips?

Request documentation of quality control processes, including incoming material inspections, in-line testing, and final product checks. Certifications like CE, RoHS, UL, and IP ratings for waterproofing are critical indicators of product safety and compliance with international regulations. Insist on factory audit reports or third-party inspection certificates to verify claims. Testing product samples under your operating conditions (e.g., heat, humidity) helps validate adhesive durability and LED performance. This due diligence prevents costly returns and reputational damage in your local market. -

What logistics considerations should I plan for when importing glue LED strips internationally?

Understand the most efficient shipping methods—sea freight for large volumes or air freight for urgent orders. Confirm that your supplier can provide export documentation such as commercial invoices, packing lists, and certificates of origin. Plan for customs duties, taxes, and compliance with import regulations in your country. Work with freight forwarders experienced in handling electronics and adhesive products to avoid damage or delays. For markets like Europe or the Middle East, ensure compliance with REACH or other local chemical regulations related to adhesives. -

How should I handle disputes or quality issues with overseas glue LED strip suppliers?

Establish clear contractual terms covering product specifications, delivery schedules, and remedies for defects before placing orders. Maintain detailed records of communications, samples, and quality inspections. If issues arise, address them promptly with documented evidence and request corrective actions or replacements. Leveraging third-party inspection services during production or pre-shipment can reduce disputes. If disagreements persist, consider mediation or arbitration clauses in contracts to resolve conflicts without costly litigation, which is especially important for cross-border transactions. -

What strategies can help build a long-term partnership with a glue LED strip manufacturer?

Focus on suppliers with proven experience, stable production capacity, and strong after-sales support. Start with small trial orders to test reliability and product quality. Maintain open, regular communication about forecasts, market trends, and potential product innovations. Negotiate flexible pricing and lead times that accommodate growth in your region. Sharing feedback and collaborating on customization or marketing initiatives can foster mutual trust. Long-term partnerships enable better pricing, priority production slots, and smoother logistics, essential for scaling your business in diverse international markets.

Strategic Sourcing Conclusion and Outlook for glue led strip

Strategic sourcing of glue LED strips hinges on building trusted, long-term partnerships with manufacturers that deliver consistent quality, reliable supply, and responsive after-sales support. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, this means prioritizing suppliers with proven industry experience, robust certifications, and scalable production capabilities. Testing product samples thoroughly and verifying adhesive performance under local environmental conditions are critical steps to ensure durability and customer satisfaction.

Illustrative Image (Source: Google Search)

Moreover, understanding logistics, lead times, and local regulatory compliance will help avoid costly delays and facilitate smoother market entry. While competitive pricing is important, it should never overshadow the need for quality assurance and supplier reliability—especially when sourcing adhesive-backed LED strips that must perform flawlessly in diverse applications.

Looking ahead, the growing global demand for energy-efficient, customizable lighting solutions presents an excellent opportunity for buyers to leverage strategic sourcing as a competitive advantage. By cultivating strong supply chain relationships and staying informed on technological advances, businesses in Kenya, France, and beyond can confidently expand their product offerings and meet evolving market needs.

Take action now: conduct comprehensive supplier evaluations, request real-world product testing, and build partnerships that support your growth ambitions in the dynamic glue LED strip market.