Introduction: Navigating the Global Market for crown molding with led light

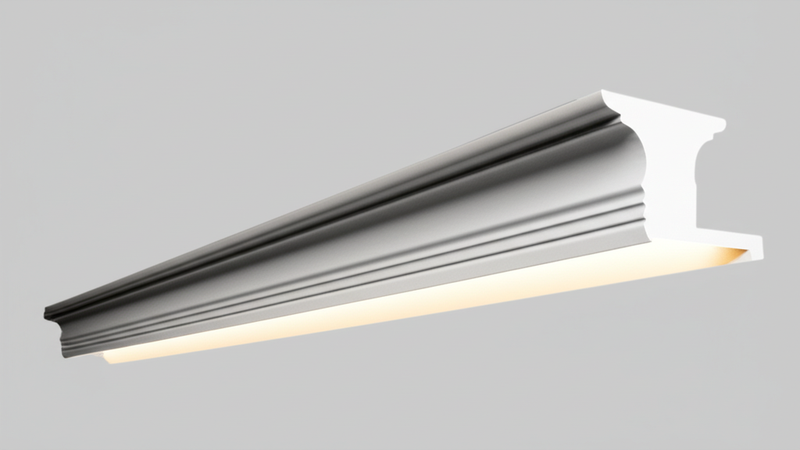

Crown molding integrated with LED lighting represents a transformative opportunity for businesses aiming to elevate interior spaces with elegance and modern functionality. This innovative product merges traditional architectural detailing with cutting-edge illumination technology, creating ambient environments that appeal to upscale residential, hospitality, and commercial markets worldwide. For B2B buyers in Africa, South America, the Middle East, and Europe—regions experiencing rapid growth in luxury construction and interior design—understanding the nuances of crown molding with LED lighting is essential to sourcing solutions that meet diverse aesthetic and technical demands.

This comprehensive guide is designed to equip international buyers with in-depth knowledge across the entire supply chain and product lifecycle. It covers a wide spectrum of topics including the various types and materials of crown molding, LED light technologies, manufacturing processes, and quality control standards. Additionally, it provides critical insights into selecting reliable suppliers, evaluating cost structures, and navigating regional market trends. Special attention is given to factors such as energy efficiency, lighting customization, and installation best practices that influence both product performance and buyer satisfaction.

By consolidating expert advice and market intelligence, this resource empowers procurement professionals and project managers to make informed decisions that optimize value, durability, and style. Whether sourcing for luxury hotels in Saudi Arabia, upscale residential developments in France, or commercial projects across emerging African and South American cities, buyers will find actionable strategies to identify high-quality products that align with their specific regional requirements and business objectives.

Understanding crown molding with led light Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Strip Crown Molding | Flexible LED strips installed inside or behind molding profiles; customizable color temperatures and brightness levels | Hospitality, luxury residential, office interiors | + Highly customizable and flexible – Requires precise installation and power management |

| LED Rope Light Crown Molding | Encased flexible rope lights ideal for curved or irregular molding shapes; moderate brightness | Retail spaces, entertainment venues, upscale homes | + Easy to install on curves – Lower brightness compared to strips; may require diffusers |

| LED Light Bar Crown Molding | Rigid linear LED bars offering uniform and intense illumination; often paired with aluminum channels for heat dissipation | Commercial offices, galleries, conference rooms | + High brightness and durability – Less flexible; limited to straight runs |

| Integrated LED Profile Molding | Crown molding with built-in LED channels and diffusers, designed for seamless installation and clean aesthetics | High-end residential, boutique hotels, showrooms | + Sleek integrated design; professional finish – Higher upfront cost; limited retrofitting options |

| Color-Changing RGB LED Molding | LED systems supporting multi-color and dynamic lighting effects, controllable via remote or smart systems | Event spaces, clubs, themed environments, modern offices | + Versatile ambiance control – Complex installation; higher maintenance and control system costs |

LED Strip Crown Molding is the most versatile and widely used type in international markets. These flexible strips allow B2B buyers to select from a broad range of color temperatures (2700K warm to 6500K cool) and brightness levels, making them suitable for diverse applications from upscale hotels in Europe to corporate offices in the Middle East. When sourcing, buyers should prioritize LED density (LEDs/meter) and ensure compatibility with local voltage standards. Installation requires expertise to manage wiring and power supplies, but offers excellent energy efficiency and customization.

LED Rope Light Crown Molding caters well to spaces with curved or intricate molding profiles, common in luxury retail or entertainment venues across South America and Africa. Rope lights offer easier installation on non-linear surfaces, though their brightness is generally lower than strip lights. Buyers should consider the need for diffusers or additional fixtures to achieve uniform lighting. This option is cost-effective and energy-efficient but may not suit projects demanding high-intensity illumination.

LED Light Bar Crown Molding provides a robust solution for environments requiring bright, consistent lighting such as galleries and commercial offices in Europe and the Middle East. These rigid bars often come with aluminum channels to dissipate heat, extending lifespan. For B2B buyers, the limitation lies in their inflexibility, making them ideal only for straight molding runs. They offer superior durability and brightness but may involve higher shipping costs due to their size and fragility.

Integrated LED Profile Molding represents a premium category where the crown molding itself is designed to house LED lighting seamlessly. This type is favored in high-end residential projects and boutique hospitality venues seeking a clean, modern aesthetic without visible fixtures. Buyers should expect higher upfront costs and limited retrofit capabilities but benefit from a professional finish and streamlined installation. This product type is ideal for markets prioritizing design sophistication, such as France and Saudi Arabia.

Color-Changing RGB LED Molding introduces dynamic lighting effects with multi-color capabilities controlled via remotes or smart systems. This variation is popular in event spaces, clubs, and modern office environments that require adaptable ambiance. B2B buyers must factor in the complexity of installation, integration with control systems, and potential maintenance costs. Despite higher initial investment, this option offers unmatched versatility for branding and experiential design in competitive markets.

Related Video: How to Make a Simple Modern CROWN MOLDING WITH LED LIGHTS💡

Key Industrial Applications of crown molding with led light

| Industry/Sector | Specific Application of crown molding with led light | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Leisure | Ambient and accent lighting in upscale hotels, restaurants, and clubs | Enhances guest experience with elegant, customizable lighting; energy-efficient and low maintenance | Durability under heavy use, compliance with local electrical standards, customizable color temperatures |

| Corporate & Commercial | Modern office interiors, boardrooms, and reception areas | Creates professional, inviting atmospheres while reducing energy costs; flexible lighting for branding | Compatibility with existing electrical infrastructure, dimmable options, ease of installation and maintenance |

| Retail & Showrooms | Product highlighting and creating immersive shopping environments | Draws customer attention to merchandise; improves visual merchandising effectiveness | High color rendering index (CRI), adjustable brightness, ability to retrofit existing crown moldings |

| Cultural & Public Spaces | Museums, galleries, and libraries for indirect illumination and artwork highlighting | Preserves artwork with low-heat lighting; enhances visitor engagement through subtle, uniform illumination | Low UV emission, long lifespan, precise color temperature control, compliance with conservation standards |

| Residential Developments | Luxury apartments and high-end residential interiors | Adds value with sophisticated lighting solutions; energy savings and customizable ambiance | Quality of materials, ease of installation, adaptability to various architectural styles, warranty support |

Hospitality & Leisure

In the hospitality sector, crown molding with LED lighting is extensively used to create an upscale ambiance in hotels, restaurants, and nightlife venues. These installations provide indirect, customizable lighting that enhances architectural features and sets the mood without intrusive fixtures. For international buyers, particularly in regions like the Middle East and Europe, sourcing solutions that comply with regional electrical safety standards and offer dimmable, color-tunable LEDs is critical. The long lifespan and energy efficiency of LEDs also reduce operational costs in high-traffic environments.

Corporate & Commercial Spaces

Corporate offices and commercial buildings leverage LED crown molding lighting to craft modern, professional interiors that impress clients and boost employee well-being. The flexibility to adjust brightness and color temperature supports branding strategies and creates comfortable work environments. Buyers from Africa and South America should prioritize LED systems compatible with local power grids and easy to maintain, considering factors like installation complexity and availability of local technical support to minimize downtime.

Retail & Showrooms

Retailers use crown molding with LED lighting to spotlight merchandise and design immersive shopping experiences that influence purchasing decisions. High CRI LEDs ensure products are presented in the best light, while adjustable lighting helps adapt displays for different promotions or seasons. For international B2B buyers, particularly in fast-growing markets, sourcing lighting that can retrofit existing moldings and withstand frequent use is essential for cost-effective upgrades and rapid rollouts.

Cultural & Public Spaces

Museums, galleries, and libraries require lighting that protects delicate artifacts and books while enhancing visitor experience. Crown molding with LED lighting provides soft, indirect illumination that minimizes heat and UV exposure, critical for preservation. Buyers in Europe and the Middle East, where cultural heritage is paramount, should seek LED solutions with precise color temperature control and certifications for conservation compliance. Longevity and low maintenance reduce disruptions in these sensitive environments.

Residential Developments

In luxury residential projects across Africa, Europe, and the Middle East, crown molding with LED lighting adds a layer of sophistication and comfort. It allows developers and interior designers to offer customizable lighting moods that appeal to discerning homeowners. Key considerations for B2B buyers include sourcing high-quality materials compatible with various architectural styles, ease of installation to meet tight project timelines, and strong warranty support to ensure lasting performance and client satisfaction.

Related Video: How to install foam crown molding with LED indirect strip lighting.

Strategic Material Selection Guide for crown molding with led light

When selecting materials for crown molding integrated with LED lighting, international B2B buyers must carefully evaluate options based on performance, cost, manufacturing complexity, and regional compliance standards. The right material ensures durability, ease of installation, and optimal lighting effects, while also meeting local market expectations and regulatory requirements. Below is an analysis of four common materials used for crown molding with LED lighting.

1. Medium-Density Fiberboard (MDF)

Key Properties: MDF is a composite wood product made from wood fibers bonded with resin under heat and pressure. It offers a smooth surface ideal for painting and finishing. MDF has moderate moisture resistance but is prone to swelling if exposed to high humidity or water.

Pros & Cons: MDF is cost-effective and widely available, making it a popular choice for budget-conscious projects. It is easy to machine and shape, allowing intricate molding profiles. However, MDF is less durable in humid environments and can be heavier than alternatives. It also requires sealing to prevent moisture damage.

Impact on Application: MDF’s smooth surface enhances LED light diffusion when painted with reflective finishes, improving ambient lighting effects. However, in regions with high humidity—such as parts of South America and the Middle East—MDF may require additional protective coatings or may not be suitable for exterior or damp interior applications.

International Considerations: MDF products often comply with ASTM standards in the US and EN standards in Europe. Buyers in Europe (e.g., France) should verify compliance with E1 or E0 formaldehyde emission standards for indoor air quality. In Africa and the Middle East, sourcing MDF with moisture-resistant treatments is advisable due to local climate conditions.

2. Polyurethane (PU) Foam

Key Properties: Polyurethane crown molding is a lightweight, closed-cell foam material with excellent moisture and impact resistance. It is dimensionally stable and can be molded into detailed profiles with smooth surfaces.

Pros & Cons: PU foam is highly durable, resistant to cracking, and ideal for humid or wet environments. Its lightweight nature simplifies transportation and installation, reducing labor costs. However, it is generally more expensive than MDF and requires specialized manufacturing processes.

Impact on Application: PU foam’s resistance to moisture makes it suitable for installations in tropical climates (e.g., parts of Africa and South America) and humid indoor environments. Its smooth finish enhances LED light reflection, contributing to uniform illumination. The material also withstands temperature fluctuations common in Middle Eastern markets.

International Considerations: PU foam moldings often meet ASTM D1622 for density and DIN standards for dimensional stability. European buyers should ensure compliance with REACH and RoHS directives for chemical safety. In Saudi Arabia and other Gulf countries, PU foam’s fire retardancy ratings must meet local fire safety codes.

3. PVC (Polyvinyl Chloride)

Key Properties: PVC crown molding is a rigid plastic material known for its excellent water resistance, chemical stability, and ease of maintenance. It is lightweight and can be extruded into various profiles.

Pros & Cons: PVC is highly durable in moist and corrosive environments, making it ideal for bathrooms and kitchens. It is low maintenance and resistant to insects and rot. However, PVC can be less environmentally friendly due to its chemical composition and may emit odors if exposed to high heat. It also has a lower heat tolerance compared to PU foam.

Impact on Application: PVC moldings are well-suited for LED installations in humid or coastal regions, such as parts of Africa and the Middle East, where resistance to moisture and corrosion is critical. Its rigidity supports the secure mounting of LED strips but may require careful handling to avoid cracking during installation.

International Considerations: PVC products typically comply with ASTM D1784 and ISO standards. European buyers should verify compliance with EU directives on plastic additives and recycling. In South America, PVC’s affordability and durability make it a preferred choice, but buyers should ensure UV stabilization for outdoor or sun-exposed applications.

4. Wood (Hardwood or Softwood)

Key Properties: Traditional wood moldings offer natural aesthetics and can be crafted from various species, each with distinct grain patterns and hardness. Wood is breathable but susceptible to moisture, warping, and insect damage without proper treatment.

Pros & Cons: Wood provides a premium, classic look that can be stained or painted to match interior designs. It is strong and can support heavier LED fixtures. However, wood is generally more expensive, requires skilled craftsmanship, and demands maintenance to prevent deterioration in humid or variable climates.

Impact on Application: Wood crown molding with integrated LED lighting is favored in upscale projects, especially in Europe and parts of the Middle East where natural materials are valued. However, in tropical or humid regions, wood must be treated or sealed to prevent damage, which adds to cost and complexity.

International Considerations: Wood moldings should comply with regional forestry and sustainability certifications such as FSC or PEFC. European buyers prioritize eco-friendly sourcing and compliance with EN 15285 for wood products. In Saudi Arabia and Africa, termite-resistant treatments and fire retardants are often required.

Summary Table

| Material | Typical Use Case for crown molding with led light | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| MDF | Indoor residential and commercial spaces with controlled humidity | Smooth finish, cost-effective, easy to machine | Susceptible to moisture damage, heavier | Low |

| Polyurethane | Humid or tropical environments, upscale commercial and residential | Moisture resistant, lightweight, durable | Higher cost, requires specialized manufacturing | High |

| PVC | Moist or corrosive environments like bathrooms, coastal regions | Excellent water and chemical resistance | Lower heat tolerance, environmental concerns | Medium |

| Wood | High-end interiors valuing natural aesthetics and strength | Premium look, strong, customizable | Expensive, requires maintenance, moisture prone | High |

In-depth Look: Manufacturing Processes and Quality Assurance for crown molding with led light

Manufacturing Processes for Crown Molding with LED Light

The production of crown molding integrated with LED lighting involves a series of carefully orchestrated stages to ensure both aesthetic appeal and functional performance. Understanding these stages helps international B2B buyers evaluate suppliers effectively and ensure product reliability.

1. Material Preparation

- Base Material Selection: Common materials include MDF (medium-density fiberboard), polyurethane, PVC, or wood composites. MDF is favored for its smooth finish and ease of machining, while polyurethane offers flexibility and moisture resistance.

- LED Component Sourcing: High-quality LED strips, drivers, connectors, and wiring are sourced separately, often from specialized electronics manufacturers. Buyers should verify LED specifications such as lumen output, color temperature, power consumption, and IP rating for moisture resistance.

- Raw Material Inspection: Incoming materials undergo visual and dimensional checks to confirm compliance with specifications, ensuring a defect-free starting point.

2. Forming and Shaping

- Molding Fabrication: The base molding is shaped using CNC routers or molding machines for precise profiles. This step defines the decorative contours and dimensions.

- Channel Milling: An integral part of the process is the creation of a recessed channel or groove within the molding profile to house the LED strips securely and discreetly.

- Surface Preparation: Surfaces are sanded and smoothed to remove imperfections and prepare for finishing.

3. Assembly of LED Components

- LED Installation: LED strips are carefully cut to length and adhered or clipped into the pre-milled channels. Aluminum channels or heat sinks may be incorporated to dissipate heat, prolonging LED lifespan.

- Wiring and Connectivity: Low-voltage wiring is routed through the molding, with connectors installed for power and control systems. This stage demands strict attention to electrical safety standards.

- Integration of Power Supplies and Controls: For some products, integrated dimmers or smart lighting controls are assembled within the molding system.

4. Finishing

- Painting and Coating: Molding surfaces are primed and painted or coated according to customer specifications, often with fire-retardant or anti-UV finishes for durability.

- Quality Sealing: Edges and joints are sealed to protect electrical components from dust and moisture.

- Packaging: Final products are carefully packed with protective materials to prevent damage during shipping.

Quality Assurance Protocols and Standards

Robust quality assurance (QA) is critical to delivering crown molding with LED lighting that meets international performance, safety, and durability expectations. Buyers should prioritize suppliers with documented QA systems aligned to global standards.

Key International and Industry Standards

- ISO 9001: The gold standard for quality management systems, ensuring consistent production processes, traceability, and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, confirming conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical components, essential for LED lighting products.

- IEC Standards: For electrical safety and performance of LED lighting (e.g., IEC 60598 for luminaires).

- Additional Regional Certifications: Buyers from the Middle East (e.g., Saudi Arabia) and Africa should verify compliance with local standards such as SASO (Saudi Standards, Metrology and Quality Organization) or SABS (South African Bureau of Standards).

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and LED components for defects, specifications, and certificates of conformity before production.

- In-Process Quality Control (IPQC): Continuous monitoring during molding shaping, LED installation, and wiring to catch defects early. This includes dimensional checks, adhesion tests for LEDs, and electrical continuity.

- Final Quality Control (FQC): Comprehensive inspection after assembly and finishing, including:

- Visual inspection for surface defects and paint quality.

- Functional testing of LED lighting (brightness, color temperature, flicker).

- Electrical safety tests (insulation resistance, voltage stability).

- Mechanical durability tests (impact resistance, vibration).

- Packaging integrity checks.

Common Testing Methods

- Photometric Testing: Measures light output (lumens), color rendering index (CRI), and color temperature (Kelvin) to ensure lighting meets design requirements.

- Electrical Safety Testing: Includes insulation resistance, dielectric strength, and grounding checks.

- Environmental Testing: Simulates humidity, temperature cycling, and UV exposure to assess long-term durability.

- Mechanical Testing: Verifies adhesion of LEDs to molding, resistance to impact, and robustness of wiring connections.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially in Africa, South America, the Middle East, and Europe, verifying supplier QA practices is essential to mitigate risks related to product failure, regulatory non-compliance, or delayed shipments.

Supplier Audits

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing capabilities, quality control systems, and compliance with international standards.

- Process Audits: Focus on critical stages like LED installation and electrical wiring to confirm adherence to best practices.

- Social and Environmental Audits: Evaluate compliance with labor laws and environmental regulations, increasingly important in Europe and among multinational buyers.

Documentation and Reports

- Certificates of Compliance: Request ISO 9001, CE, RoHS, and other relevant certifications.

- Test Reports: Obtain third-party lab test results for photometric performance, electrical safety, and environmental durability.

- Inspection Reports: Review IQC, IPQC, and FQC documentation to verify consistency and traceability.

- Sample Approvals: Before bulk orders, require samples with full QA documentation and conduct independent testing if needed.

Third-Party Inspection Services

- Engage reputable inspection agencies to perform random or pre-shipment inspections, verifying product conformity and packaging quality.

QC and Certification Nuances for International Markets

- Africa and South America: Buyers should consider the variability in local standards and infrastructure. Products with strong international certifications (ISO, CE, RoHS) and robust packaging for long-distance shipping are preferred. Clarify warranty terms and after-sales support, as local repair services may be limited.

- Middle East (e.g., Saudi Arabia): Compliance with SASO and GCC technical regulations is often required. Suppliers should demonstrate understanding of regional climate challenges, such as high temperatures and dust, which impact LED and molding durability.

- Europe (e.g., France): Strict adherence to CE marking and EU directives is mandatory. Environmental sustainability and energy efficiency certifications (e.g., Energy Star, EU Eco-label) can be differentiators. Detailed technical documentation and traceability are expected.

Summary for B2B Buyers

To ensure procurement of high-quality crown molding with LED lighting:

- Understand the manufacturing stages: from material prep through finishing, focusing on precision forming and safe LED integration.

- Demand compliance with international standards: ISO 9001, CE, RoHS, and region-specific certifications.

- Implement rigorous supplier verification: via audits, comprehensive documentation review, and independent inspections.

- Factor in local market requirements: including climate considerations, regulatory nuances, and after-sales service capabilities.

By applying these insights, international buyers can confidently select suppliers that deliver durable, visually appealing, and compliant crown molding with integrated LED lighting, optimized for their specific market needs.

Comprehensive Cost and Pricing Analysis for crown molding with led light Sourcing

When sourcing crown molding integrated with LED lighting, understanding the full cost and pricing dynamics is essential for international B2B buyers aiming to optimize procurement and ensure product quality. The pricing structure for these composite products involves multiple cost components and is influenced by various factors unique to LED-enhanced architectural elements.

Key Cost Components

-

Materials: This includes the raw crown molding material (commonly MDF, polyurethane, or wood) and the LED lighting components (LED strips, power supplies, wiring, and aluminum channels for heat dissipation). Higher-grade LEDs with superior color rendering or specialized features (e.g., dimmable, RGB) will increase material costs.

-

Labor: Skilled labor is required for both molding fabrication and the integration of LED lighting, including wiring and quality assurance. Labor costs vary significantly by manufacturing location and affect the final price.

-

Manufacturing Overhead: Overhead includes factory utilities, equipment depreciation, and indirect labor involved in assembly and finishing processes such as priming and painting the crown molding.

-

Tooling and Setup: Initial costs for creating molds, dies, or custom extrusion profiles for crown molding and LED housing can be substantial, especially for bespoke designs or low-volume orders.

-

Quality Control: Rigorous inspection protocols are vital to ensure LED functionality, uniform lighting, and adherence to safety standards. This contributes to cost but reduces returns and warranty claims.

-

Logistics and Shipping: Shipping bulky molding products with fragile LED components demands careful packaging and often incurs higher freight charges. International shipping costs fluctuate with fuel prices, route complexity, and customs handling.

-

Profit Margin: Suppliers factor in margins to cover business risks and generate profit, which can vary based on market demand, competition, and buyer-supplier relationships.

Influential Pricing Factors

-

Order Volume and Minimum Order Quantities (MOQ): Larger orders typically benefit from economies of scale, reducing per-unit cost. Buyers from regions like Africa or South America should negotiate MOQs that align with their market demand to avoid excess inventory costs.

-

Product Specifications and Customization: Custom profiles, specific LED color temperatures (e.g., warmer 2700K for residential markets in Europe or cooler 4000K-5000K preferred in commercial Middle Eastern projects), and integrated smart controls increase complexity and cost.

-

Material Quality and Certifications: Products with certifications such as CE (Europe), SASO (Saudi Arabia), or IEC standards assure compliance and often command premium pricing but reduce regulatory risks.

-

Supplier Factors: Established suppliers with proven track records may charge more but offer reliability, warranty, and after-sales support—crucial for international buyers managing remote supply chains.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF, DDP) influences who bears shipping, insurance, and customs costs, impacting total landed cost. Buyers must clarify terms early to accurately budget.

Actionable Buyer Tips for Cost Efficiency

-

Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, consider installation ease, product lifespan, energy efficiency of LEDs, and maintenance costs. A slightly higher upfront price may yield savings long-term.

-

Leverage Volume Consolidation: Buyers in emerging markets should collaborate with regional partners to consolidate orders, achieving better pricing and reducing shipping frequency.

-

Request Detailed Cost Breakdowns: Understanding how costs are allocated helps in targeted negotiations, such as requesting suppliers to optimize packaging or reduce non-essential customization.

-

Evaluate Alternative Materials: For cost-sensitive markets, discuss options like polyurethane molding instead of wood, balancing durability with budget constraints.

-

Account for Currency Fluctuations and Tariffs: Monitor exchange rates and import duties, especially relevant for buyers in South America and Africa, to avoid unexpected cost increases.

-

Audit Supplier Quality and Certifications: Insist on documented compliance to avoid costly product rejections or delays at customs.

-

Plan for Logistics Challenges: In regions with complex import regulations or infrastructure constraints, factor in additional lead times and buffer stock to prevent project delays.

Indicative Pricing Disclaimer

Prices for crown molding with integrated LED lighting vary widely depending on the above factors. For example, basic polyurethane crown molding with standard LED strips may start from approximately $15–$25 USD per linear meter FOB in major manufacturing hubs, while highly customized profiles with premium LEDs and smart controls can exceed $50 USD per meter. These figures are indicative; actual prices depend on specific project requirements, supplier capabilities, and market conditions.

By carefully analyzing cost components and pricing influencers, international B2B buyers—especially from Africa, South America, the Middle East, and Europe—can strategically source crown molding with LED lighting solutions that balance quality, aesthetics, and budget, ensuring successful project outcomes and competitive market positioning.

Spotlight on Potential crown molding with led light Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘crown molding with led light’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for crown molding with led light

Critical Technical Properties for Crown Molding with LED Light

When sourcing crown molding integrated with LED lighting, understanding key technical specifications is essential for ensuring product quality, compatibility, and durability in diverse international markets.

-

Material Grade and Composition

Crown molding materials commonly include PVC, polyurethane, MDF, or wood composites. For LED integration, PVC and polyurethane are preferred due to their moisture resistance, lightweight nature, and ease of cutting. Material grade impacts durability and finish quality. For B2B buyers in humid climates (e.g., coastal Africa or the Middle East), selecting moisture-resistant, fire-retardant grades is critical to meet safety standards and longevity expectations. -

LED Strip Specifications (Lumens and Color Temperature)

LED brightness is measured in lumens per meter/foot, indicating light intensity. Typical crown molding lighting requires between 800 to 2600 lumens depending on room size and ambiance. Color temperature, expressed in Kelvin (K), ranges from warm white (2700-3000K) for cozy environments to cool white (5000-6500K) for modern, vibrant spaces. Buyers should specify lumen output and Kelvin values to align with client design preferences and energy efficiency goals. -

Voltage and Power Consumption

Most LED strips operate at 12V or 24V DC. Low voltage ensures safety and ease of installation but requires compatible power supplies. Power consumption, measured in watts per meter, affects energy costs and heat generation. Opting for low-wattage, high-lumen LED strips maximizes efficiency—especially important in regions with higher electricity costs or unstable power grids. -

Dimensional Tolerance and Profile Design

Crown molding profiles must maintain tight dimensional tolerances (±0.5mm or better) to ensure seamless installation and consistent light diffusion. Profiles designed with integrated channels or grooves for LED strips facilitate clean wiring and optimal light distribution. Accurate dimensions are critical for modular construction and to meet architectural standards in European or Middle Eastern projects. -

Heat Dissipation and Lifespan

LED longevity depends on effective heat management. Molding designs incorporating aluminum channels or heat sinks help dissipate heat, extending LED lifespan (typically 30,000–50,000 hours). For B2B buyers, products with proven thermal management reduce maintenance costs and downtime in commercial applications like hotels or offices. -

Ingress Protection (IP) Rating

If crown molding with LEDs is intended for environments with moisture or dust (e.g., outdoor terraces or humid interiors), an IP rating (e.g., IP20 for indoor, IP65 for moisture-resistant) is essential. This rating certifies the product’s resistance level, ensuring safety and durability tailored to regional climate conditions.

Key Trade Terminology for International B2B Transactions

Understanding common industry terms facilitates clearer communication, smoother negotiations, and better contract management when purchasing crown molding with LED lights globally.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products or components that are rebranded and sold by other companies. For buyers, OEM partnerships often allow customization of molding profiles, LED specifications, and packaging to meet specific market needs or branding requirements. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. MOQ impacts pricing and inventory decisions. Buyers from emerging markets or smaller distributors should negotiate MOQ terms to balance cost efficiency with market demand. -

RFQ (Request for Quotation)

A formal document submitted by buyers to suppliers requesting detailed pricing, delivery timelines, and specifications. An accurate RFQ with technical requirements ensures suppliers provide precise quotes, preventing misunderstandings and delays. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, duties, and risk transfer between buyer and seller. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DAP (Delivered At Place). Choosing the right Incoterm aligns logistics with buyer capabilities and cost control strategies. -

Lead Time

The period between order confirmation and product delivery. Lead times vary based on manufacturing complexity and shipping routes. B2B buyers should factor lead times into project timelines, especially when coordinating large-scale installations across continents. -

Certification and Compliance

Refers to adherence to regional safety, environmental, and quality standards such as CE (Europe), SASO (Saudi Arabia), or SABS (South Africa). Certifications provide assurance of product safety and legal market access, a crucial consideration for international buyers.

By mastering these technical properties and trade terms, international B2B buyers can make informed procurement decisions, optimize product selection for diverse markets, and negotiate effectively with global suppliers of crown molding with integrated LED lighting.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the crown molding with led light Sector

Market Overview & Key Trends

The global crown molding with LED light market is experiencing robust growth driven by evolving architectural aesthetics and increasing demand for energy-efficient, customizable lighting solutions. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are capitalizing on this trend to enhance residential, commercial, and hospitality spaces with sophisticated lighting designs. LED integration into crown molding offers a seamless blend of decorative appeal and functional illumination, aligning with modern interior design preferences across diverse markets.

Key market drivers include the rising urbanization rates and increased disposable incomes in emerging economies, which fuel investments in upscale construction and renovation projects. In regions like Saudi Arabia and South Africa, luxury real estate developments and hospitality sectors are significant consumers of LED crown molding products. European markets, including France, prioritize design innovation and quality, favoring suppliers who offer versatile, premium-grade molding combined with advanced LED technology.

From a sourcing perspective, B2B buyers are increasingly seeking suppliers that provide customizable LED solutions—such as adjustable color temperatures, dimmable options, and flexible LED strips—to accommodate different architectural profiles and client preferences. There is also a growing trend toward modular systems that simplify installation and maintenance, reducing labor costs and project timelines. Technological advancements like smart lighting integration and IoT-enabled controls are beginning to influence procurement decisions, particularly in technologically progressive European markets.

Furthermore, buyers are attentive to supply chain reliability and product certifications, demanding compliance with international safety and performance standards (e.g., CE, RoHS). The competitive landscape is marked by manufacturers in China, Europe, and Turkey offering a range of products from cost-effective to premium. Strategic partnerships with local distributors and custom design services enhance market penetration in target regions, while digital platforms and virtual showrooms facilitate remote product evaluation and order placement.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in the procurement of crown molding with LED lighting, with international buyers emphasizing the environmental impact of both materials and manufacturing processes. LED technology inherently supports energy efficiency, consuming up to 80% less power than traditional lighting, which aligns with global carbon reduction goals. However, the sustainability profile of the crown molding substrate—commonly wood, MDF, or polyurethane—also demands scrutiny.

Ethical sourcing involves selecting materials certified by recognized environmental standards such as FSC (Forest Stewardship Council) for wood or recycled-content certifications for synthetic materials. These certifications assure buyers in regions like Europe and the Middle East that products originate from responsibly managed sources, reducing deforestation and promoting biodiversity. Additionally, manufacturers adopting low-VOC (volatile organic compounds) adhesives and paints contribute to healthier indoor air quality, a growing concern in urban developments worldwide.

Buyers are increasingly prioritizing suppliers who implement circular economy principles, including the use of recyclable or biodegradable components and packaging. Transparency in the supply chain through traceability tools and third-party audits is becoming a prerequisite for large-scale contracts, especially when public or multinational clients are involved. Sustainable manufacturing practices—such as energy-efficient production lines, waste reduction programs, and water conservation—add further value to suppliers’ credentials.

Investing in green-certified crown molding with integrated LEDs not only supports environmental stewardship but also enhances brand reputation and meets regulatory demands in markets with stringent environmental policies. B2B buyers can leverage sustainability as a differentiator when specifying products for premium projects, hospitality venues, or government contracts, ensuring long-term compliance and market relevance.

Brief Evolution and Historical Context

Crown molding has a rich architectural heritage dating back to classical antiquity, where it was used to crown walls and ceilings with decorative profiles. Traditionally crafted from plaster or wood, crown molding served both aesthetic and functional roles in interior design. The integration of lighting, particularly LEDs, is a relatively recent innovation that emerged alongside advances in LED technology and energy-efficient design principles in the early 21st century.

Initially, LED lighting was used primarily for accent and task lighting, but its incorporation into crown molding transformed ambient lighting approaches by creating indirect, diffuse illumination that enhances spatial perception and mood. This evolution reflects broader shifts in interior design towards minimalist fixtures and smart lighting solutions. For B2B buyers, understanding this historical progression underscores the value of combining classic architectural elements with cutting-edge technology to meet contemporary demands for style, efficiency, and functionality.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of crown molding with led light

-

How can I effectively vet suppliers of crown molding with LED light for international B2B purchases?

To vet suppliers, begin by verifying their business licenses and certifications relevant to LED lighting and building materials, such as CE, RoHS, or UL marks. Request product samples to assess quality firsthand and review detailed technical specifications. Check references and past client testimonials, especially from your region, to confirm reliability in delivery and after-sales service. Utilize third-party inspection services for factory audits and quality checks. Confirm their experience exporting to your target markets (Africa, South America, Middle East, Europe) to ensure compliance with local standards and regulations. -

What customization options are typically available for crown molding with integrated LED lighting?

Most manufacturers offer customization in molding profiles, materials (PVC, wood, MDF), LED color temperature (warm, neutral, cool), brightness (lumens), and LED strip length or density. You can also specify dimmable features, smart controls, and power supply compatibility. For international buyers, custom packaging and labeling may be available for branding purposes. Early communication of your design preferences and technical requirements is critical to ensure the supplier can accommodate your needs, as some customization may affect lead times and pricing. -

What should I expect regarding minimum order quantities (MOQs), lead times, and payment terms?

MOQs vary widely but typically start at 100-500 meters per style or color for LED crown molding. Lead times range from 3 to 8 weeks depending on customization complexity and order size. Payment terms commonly include 30% upfront deposit and 70% balance before shipment or against documents. International buyers should confirm if suppliers accept Letters of Credit (LC) or escrow services for secure transactions. Negotiating flexible payment terms is often possible with established suppliers or larger orders. -

Which quality assurance processes and certifications should I require from suppliers?

Demand evidence of consistent quality control, including in-process inspections and final product testing for LED brightness, color consistency, and electrical safety. Certifications to look for include CE (Europe), RoHS (restriction of hazardous substances), UL (safety), and ISO 9001 (quality management). For markets like Saudi Arabia, conformity with SASO standards may be necessary. Request test reports or certificates from accredited labs and ensure the supplier has traceability protocols for components and finished goods. -

How do I navigate logistics and shipping challenges for crown molding with LED light when importing internationally?

Ensure your supplier provides accurate volumetric and weight data to calculate shipping costs. Crown molding with LED lighting is fragile; request protective packaging and consider insurance for transit damage. Choose Incoterms carefully (e.g., FOB, CIF) to clarify responsibility for freight and customs clearance. Work with freight forwarders familiar with your destination country’s import regulations to avoid delays. Plan for customs duties, VAT, and compliance documentation such as certificates of origin and technical data sheets. -

What are best practices for managing after-sales support and warranty claims internationally?

Verify the supplier’s warranty terms, typically 1-3 years for LED components and molding materials. Clarify processes for reporting defects, including photographic evidence and timelines. Confirm if the supplier offers replacement parts or onsite technical support. Establish clear communication channels and multilingual support if necessary. For long-term partnerships, negotiate service level agreements (SLAs) that include response times and remedies for defective products to minimize downtime and maintain client satisfaction. -

How can I resolve disputes or quality issues with overseas suppliers effectively?

First, document all communications, contracts, and quality inspections thoroughly. Engage in direct negotiation to seek amicable solutions such as product replacement, refunds, or discounts. If unresolved, use mediation or arbitration clauses specified in your contract, preferably under internationally recognized frameworks like ICC or UNCITRAL. Employ third-party inspection agencies to provide impartial reports. Building a relationship based on trust and clear contractual terms upfront reduces the likelihood of disputes. -

Are there specific considerations for sourcing crown molding with LED light for markets like Africa, South America, the Middle East, and Europe?

Yes, regional factors influence product specifications and compliance. For example, Europe requires strict adherence to CE and RoHS standards, while the Middle East may require SASO certification and robust heat tolerance due to climate. Africa and South America often have variable power supply voltages; verify LED voltage compatibility and consider ruggedized designs for harsh environments. Also, factor in regional aesthetic preferences and installation practices. Partnering with suppliers experienced in your target markets facilitates smoother import processes and market acceptance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for crown molding with led light

Crown molding with integrated LED lighting represents a sophisticated blend of aesthetics and functionality, offering B2B buyers an opportunity to elevate interior environments across hospitality, residential, and commercial projects. Strategic sourcing in this sector demands careful evaluation of product quality, LED specifications (lumens, color temperature, lifespan), and supplier reliability to ensure seamless integration and long-term performance. For buyers in Africa, South America, the Middle East, and Europe, understanding regional preferences—such as warmer lighting tones favored in residential applications or durable, energy-efficient solutions for commercial spaces—is essential.

Key sourcing considerations include:

- Customization capabilities to match diverse architectural styles and lighting needs.

- Energy efficiency and compliance with local regulations and sustainability goals.

- Supplier partnerships that offer technical support, flexible MOQ (minimum order quantities), and reliable logistics.

Looking ahead, the market for LED crown molding will continue to grow as demand for smart, energy-saving, and visually striking lighting solutions intensifies globally. International buyers should proactively engage with manufacturers who innovate in LED technology and offer scalable solutions adaptable to varied climates and design trends.

Take action now by leveraging comprehensive supplier audits and pilot projects to secure cutting-edge LED crown molding products that meet your exacting standards—turning spaces into luminous showcases that captivate and inspire.