Guide to Adapter For Led Light Strip

- Introduction: Navigating the Global Market for adapter for led light strip

- Understanding adapter for led light strip Types and Variations

- Key Industrial Applications of adapter for led light strip

- Strategic Material Selection Guide for adapter for led light strip

- In-depth Look: Manufacturing Processes and Quality Assurance for adapter for led light strip

- Comprehensive Cost and Pricing Analysis for adapter for led light strip Sourcing

- Spotlight on Potential adapter for led light strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for adapter for led light strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the adapter for led light strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of adapter for led light strip

- Strategic Sourcing Conclusion and Outlook for adapter for led light strip

Introduction: Navigating the Global Market for adapter for led light strip

The global demand for adapters for LED light strips has surged alongside the widespread adoption of LED lighting solutions in commercial, industrial, and architectural projects. For international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe—including emerging hubs like Kenya and Turkey—sourcing the right adapter is not just about compatibility but also about ensuring safety, efficiency, and long-term reliability.

Adapters serve as the critical interface between LED light strips and power sources, transforming voltage and current to meet precise electrical requirements. Selecting an adapter that matches the LED strip’s specifications, environmental conditions, and application scale directly influences installation success and maintenance costs. Poorly chosen adapters can lead to voltage drops, overheating, or premature failure, jeopardizing entire lighting systems.

This guide offers a comprehensive exploration of the adapter landscape, covering:

- Types and technical specifications tailored for various LED strip configurations (single-color, RGB, tunable white, etc.)

- Material quality and manufacturing standards that impact durability and safety certifications

- Quality control processes ensuring consistent performance across batches

- Supplier evaluation criteria to identify reliable partners aligned with regional market needs

- Cost analysis to balance budget constraints with quality and compliance

- Market trends and regional considerations for Africa, South America, the Middle East, and Europe

- Frequently asked questions addressing common concerns in procurement and installation

By leveraging this guide, B2B buyers will gain actionable insights to make informed sourcing decisions, mitigate risks, and secure adapters that optimize their LED lighting projects’ performance and longevity—empowering business growth in diverse international markets.

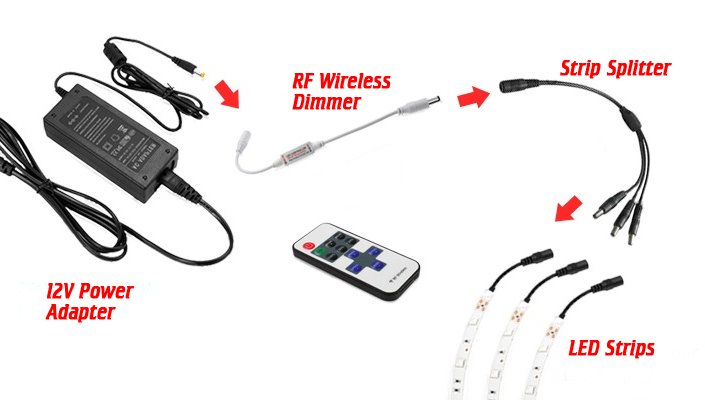

Illustrative Image (Source: Google Search)

Understanding adapter for led light strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plug-in Power Adapter | Converts AC mains to low-voltage DC; plug-and-play | Retail lighting, small to medium installations | Easy installation; limited power capacity for large projects |

| Hardwired LED Driver | Fixed installation with direct wiring to LED strip | Commercial and industrial lighting systems | High reliability and capacity; requires professional wiring |

| Dimmable LED Adapter | Supports brightness control via 0-10V, Triac, or DALI | Architectural lighting, hospitality, offices | Flexible lighting control; higher cost and complexity |

| USB-powered Adapter | Low voltage, USB interface for power supply | Portable displays, small signage, consumer electronics | Compact and versatile; limited power, not suited for long runs |

| Wireless/Bluetooth Adapter | Integrates power supply with wireless control | Smart lighting systems, IoT-enabled installations | Enables remote control; may need compatible controllers |

Plug-in Power Adapter

Plug-in power adapters are the most common and straightforward type, converting standard AC mains voltage to the low-voltage DC required by LED strips. They are ideal for small to medium-sized projects such as retail displays or decorative lighting where ease of installation is paramount. For B2B buyers, these adapters offer cost-effective solutions but are limited in power output and scalability. When sourcing for markets like Kenya or Turkey, ensure compliance with local electrical standards and voltage ratings.

Hardwired LED Driver

Hardwired LED drivers provide a more permanent and robust power solution, directly wired into the building’s electrical system. These adapters are suited for large commercial or industrial applications where high power capacity and long LED runs are required. B2B buyers should consider professional installation to meet safety and reliability standards. This type is preferred in environments demanding consistent performance, such as warehouses or office complexes in Europe or the Middle East.

Dimmable LED Adapter

Dimmable adapters support advanced lighting control protocols including 0-10V, Triac, and DALI, enabling users to adjust brightness levels dynamically. These are essential for architectural lighting projects, hospitality venues, and smart office spaces that require customizable ambiance. While more expensive and complex, they add significant value for B2B buyers targeting high-end clients or projects with energy-saving mandates. Compatibility with existing control systems is a key purchasing consideration.

USB-powered Adapter

USB-powered adapters are designed for low-power LED strips, drawing power from USB ports commonly found in consumer electronics or portable setups. They are suited for small signage, exhibition booths, or temporary installations. B2B buyers should note their limited power capacity and shorter maximum strip lengths, making them unsuitable for extensive lighting projects. Their compact size and plug-and-play nature make them attractive for tech-savvy markets and smaller-scale applications.

Wireless/Bluetooth Adapter

Wireless or Bluetooth adapters integrate power delivery with remote control capabilities, facilitating smart lighting solutions and IoT integration. These adapters are gaining traction in modern smart buildings and retail environments where remote management and automation are priorities. B2B buyers should evaluate the compatibility with controllers and the range of wireless protocols supported. This type is especially relevant in markets embracing smart city initiatives and advanced lighting technologies.

Related Video: LED Lights Example: LED Strip Light DC Connector and Power Supply

Key Industrial Applications of adapter for led light strip

| Industry/Sector | Specific Application of adapter for led light strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Flexible lighting installations in display cases and signage | Enhances visual merchandising with customizable lighting, easy upgrades | Compatibility with varied LED strip models, robust connectors, voltage stability |

| Hospitality & Tourism | Ambient and accent lighting in hotels, restaurants, and resorts | Creates inviting atmospheres, improves guest experience, energy savings | Durability under humid conditions, dimmability support, safety certifications |

| Industrial & Warehousing | Task lighting and safety indicators in production lines and storage areas | Improves worker safety and productivity, reduces maintenance downtime | High ingress protection (IP) ratings, heat resistance, secure power connections |

| Architectural & Urban Development | Decorative and functional lighting in public spaces and building facades | Enhances aesthetic appeal, supports energy-efficient retrofits | Weatherproof adapters, compliance with local electrical standards, ease of installation |

| Automotive & Transportation | Interior and exterior lighting customization in vehicles and public transport | Increases visibility and safety, allows modular upgrades | Vibration-resistant adapters, compact size, compatibility with vehicle power systems |

Retail & Commercial Lighting Applications

In retail environments across Africa, South America, and Europe, adapters for LED light strips enable flexible and modular lighting setups in display cases and signage. These adapters facilitate quick installation and replacement, ensuring consistent power delivery to LED strips that highlight products effectively. Buyers should prioritize adapters that support a range of voltages and connector types to accommodate diverse LED strip models used in varied retail formats, from boutiques in Turkey to shopping malls in Kenya. Reliable adapters reduce downtime and enhance lighting quality, crucial for driving sales.

Hospitality & Tourism Sector

Hotels and restaurants demand adaptable lighting solutions that create inviting ambiances while maintaining energy efficiency. Adapters for LED light strips in these settings must withstand humid environments and support dimming controls to adjust mood lighting dynamically. For B2B buyers in the Middle East and Europe, sourcing adapters with international safety certifications and robust insulation is essential to comply with local regulations and ensure guest safety. These adapters simplify maintenance and upgrades, helping hospitality businesses reduce operational costs.

Industrial & Warehousing Use Cases

Industrial facilities and warehouses in regions like South America and Africa benefit from LED strip lighting for task illumination and safety marking. Adapters here must provide secure, stable connections capable of handling continuous operation in harsh conditions, including exposure to dust and heat. Selecting adapters with high IP ratings and heat-resistant materials is critical for reliability. B2B buyers should also consider ease of installation and compatibility with existing power supplies to minimize downtime and maintenance complexity.

Architectural & Urban Development Projects

LED light strips are increasingly used in architectural lighting for building facades and urban public spaces. Adapters for these applications must be weatherproof and comply with local electrical codes, which vary widely between Europe, the Middle East, and other markets. Buyers should seek adapters designed for outdoor use with corrosion-resistant materials and flexible mounting options. These features enable efficient energy use and aesthetic enhancements in urban lighting projects, supporting sustainable development goals.

Automotive & Transportation Lighting

In automotive and public transportation sectors, LED strip lighting customization enhances both safety and passenger experience. Adapters must be compact, vibration-resistant, and compatible with the vehicle’s power systems, often requiring support for 12V or 24V DC inputs. For international buyers in emerging markets such as Kenya or Turkey, sourcing adapters that meet automotive industry standards and provide stable connections under dynamic conditions is vital for reliability and longevity. These adapters facilitate modular lighting upgrades and repairs, reducing vehicle downtime.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for adapter for led light strip

When selecting materials for adapters used in LED light strip installations, B2B buyers must consider a range of factors including electrical safety, thermal management, environmental resistance, and compliance with international standards. The choice of material directly affects the adapter’s durability, performance, and suitability for different market conditions, especially in regions such as Africa, South America, the Middle East, and Europe where environmental and regulatory requirements vary.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a high-impact, transparent thermoplastic known for excellent electrical insulation, high heat resistance (typically up to 135°C), and good dimensional stability. It offers strong resistance to UV radiation and many chemicals, making it suitable for both indoor and outdoor LED adapter housings.

Pros & Cons:

– Pros: Lightweight, cost-effective, excellent electrical insulation, and strong impact resistance. It also allows for intricate molding, enabling compact and ergonomic adapter designs.

– Cons: Susceptible to scratching and can yellow over time under prolonged UV exposure if not UV-stabilized. Moderate flammability rating requires flame retardant additives for safety compliance.

Impact on Application:

Polycarbonate adapters are ideal for environments where electrical insulation and moderate thermal resistance are required. They perform well in residential and commercial lighting setups but may require UV protection for outdoor use in intense sun regions like parts of Africa and the Middle East.

International B2B Considerations:

Polycarbonate adapters commonly meet UL 94 V-0 flammability standards and IEC 60695 for electrical safety, which are widely accepted in Europe and the Middle East. Buyers in Kenya or Turkey should verify compliance with local standards such as IEC or EN norms. Cost-effectiveness and ease of manufacturing make PC a preferred choice for large-scale production targeting emerging markets.

2. Acrylonitrile Butadiene Styrene (ABS)

Key Properties:

ABS is a thermoplastic polymer with good mechanical strength, impact resistance, and electrical insulating properties. It has a lower heat resistance than polycarbonate, typically up to 80–100°C, and moderate chemical resistance.

Pros & Cons:

– Pros: Low cost, easy to mold, good surface finish, and adequate electrical insulation for low-voltage LED adapters.

– Cons: Lower heat resistance limits use in high-temperature environments; less UV resistant, leading to degradation under prolonged sunlight exposure.

Impact on Application:

ABS adapters are suitable for indoor LED strip installations where ambient temperatures are controlled. In regions with high ambient temperatures or outdoor exposure (e.g., Middle East or parts of South America), ABS may degrade faster unless treated with UV stabilizers or protective coatings.

International B2B Considerations:

ABS is widely accepted globally, with compliance to ASTM D256 for impact resistance and UL 94 flammability ratings. However, buyers should ensure the grade used meets the thermal and fire safety requirements of their target markets. ABS is often favored for budget-sensitive projects in Africa and South America due to its affordability.

3. Aluminum Alloy

Key Properties:

Aluminum alloys used in LED adapters offer excellent thermal conductivity, corrosion resistance (especially when anodized), and mechanical strength. They typically withstand temperatures above 150°C and provide robust electromagnetic interference (EMI) shielding.

Pros & Cons:

– Pros: Superior heat dissipation helps prevent overheating of LED drivers; durable and corrosion-resistant with anodizing; premium feel and longevity.

– Cons: Higher cost and manufacturing complexity compared to plastics; heavier; potential for galvanic corrosion if improperly paired with other metals.

Impact on Application:

Aluminum adapters are highly suitable for commercial and industrial LED strip installations where heat dissipation is critical, such as in high-brightness or long-run setups. Their durability makes them ideal for harsh environments, including outdoor installations in coastal or desert regions common in the Middle East and parts of Africa.

International B2B Considerations:

Aluminum adapters must comply with standards such as DIN EN 1706 for casting alloys and ISO 9001 manufacturing quality. Buyers in Europe and Turkey often require certifications related to RoHS and REACH for environmental compliance. The higher upfront cost is offset by longer service life and reduced maintenance.

4. Nylon (Polyamide)

Key Properties:

Nylon is a strong, flexible engineering thermoplastic with good electrical insulation, chemical resistance, and a melting point around 220°C. It exhibits excellent wear resistance and dimensional stability under mechanical stress.

Pros & Cons:

– Pros: High mechanical strength, good chemical and abrasion resistance, and excellent heat resistance for a plastic. Suitable for rugged applications.

– Cons: Hygroscopic nature (absorbs moisture), which can affect dimensional stability and electrical properties; more expensive than ABS and PC.

Impact on Application:

Nylon adapters are suited for industrial LED strip applications where mechanical robustness and resistance to oils, solvents, or moisture are required. This makes them a good choice for factory or outdoor lighting in humid or chemically aggressive environments found in parts of South America and Africa.

International B2B Considerations:

Nylon materials often conform to ASTM D4066 and UL 94 standards for electrical and fire safety. Buyers should consider moisture control in packaging and storage, especially in tropical climates like Kenya or Brazil. Nylon’s durability justifies its higher cost in demanding applications.

Summary Table

| Material | Typical Use Case for adapter for led light strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor/outdoor LED adapters requiring good electrical insulation and moderate heat resistance | High impact resistance and electrical insulation; UV resistant with additives | Susceptible to scratching and yellowing without UV stabilizers | Medium |

| Acrylonitrile Butadiene Styrene (ABS) | Budget indoor LED adapters with moderate mechanical and electrical requirements | Low cost and easy to manufacture | Lower heat and UV resistance limit outdoor use | Low |

| Aluminum Alloy | Industrial and commercial LED adapters needing heat dissipation and durability | Excellent thermal conductivity and corrosion resistance | Higher cost and manufacturing complexity | High |

| Nylon (Polyamide) | Rugged industrial LED adapters exposed to chemicals, moisture, and mechanical stress | High mechanical strength and chemical resistance | Hygroscopic nature affects stability; higher cost | Medium |

This material selection guide equips international B2B buyers with the critical insights needed to choose the optimal adapter material for LED light strip applications. Considering local environmental conditions, regulatory compliance, and cost-performance balance will ensure long-term success in diverse markets such as Kenya,

In-depth Look: Manufacturing Processes and Quality Assurance for adapter for led light strip

Overview of Manufacturing Processes for LED Light Strip Adapters

Manufacturing an adapter for LED light strips involves several well-defined stages to ensure product reliability, efficiency, and compliance with international standards. For B2B buyers, understanding these stages helps in evaluating potential suppliers and ensuring consistent quality in large-scale procurements.

1. Material Preparation

The process begins with sourcing high-quality raw materials, primarily copper for internal wiring, high-grade plastics or thermoplastics for casings, and electronic components such as transformers, capacitors, and diodes. Material quality directly affects the adapter’s durability and electrical safety.

- Copper wire is typically coated with tin to prevent oxidation and improve solderability.

- Plastic components undergo rigorous selection for heat resistance and electrical insulation properties.

- Suppliers often require materials to meet standards like RoHS (Restriction of Hazardous Substances) and REACH for environmental compliance, crucial for export markets.

2. Forming and Component Fabrication

Key forming processes include:

- Injection Molding: Used for plastic casings, ensuring precise dimensions and robust insulation.

- Stamping and Cutting: Metal parts such as connectors and terminals are stamped and cut to shape with high precision.

- PCB Fabrication: Printed circuit boards are manufactured with surface-mount technology (SMT) or through-hole components, depending on design complexity.

Automated machinery ensures repeatability and minimizes defects, critical for large production volumes.

3. Assembly

Assembly integrates all components into a functional adapter:

- Soldering: Automated or manual soldering connects internal wiring and electronic components. Wave soldering and reflow soldering are common techniques.

- Mechanical Assembly: Casings are assembled, often snapped or screwed together, with seals applied to improve dust and moisture resistance.

- Wire Termination: Power cords and connectors are attached, ensuring secure and safe electrical contact.

Modern production lines employ automated optical inspection (AOI) during assembly to catch soldering defects early.

4. Finishing and Packaging

Final steps include:

- Surface Treatment: Plastic parts may undergo UV stabilization or flame retardant treatments.

- Labeling: Product information, certification marks, and safety instructions are printed or affixed.

- Packaging: Designed to protect adapters during transport, packaging often includes anti-static materials and moisture barriers.

Batch traceability is maintained through serial numbers or batch codes, aiding quality control and after-sales support.

Quality Assurance Frameworks and Standards

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying adherence to recognized quality standards is essential for legal compliance and operational safety.

International Quality Management Standards

- ISO 9001: This global standard governs quality management systems (QMS). Suppliers certified under ISO 9001 demonstrate consistent process control, documentation, and continuous improvement practices.

- IEC Standards: The International Electrotechnical Commission (IEC) sets electrical safety and performance standards (e.g., IEC 60598 for luminaires).

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating compliance with EU safety, health, and environmental requirements.

- UL Certification: Particularly relevant for North American markets but also recognized globally, UL marks certify electrical safety.

Industry-Specific Certifications

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment.

- REACH: European Union regulation controlling chemicals used in manufacturing.

- API and Local Standards: Some regions require adherence to additional local standards or certifications (e.g., SABS in South Africa, INMETRO in Brazil, or SASO in Saudi Arabia).

Quality Control Checkpoints and Testing Methods

Quality control (QC) in adapter manufacturing is multi-tiered to ensure product integrity at every stage.

Key QC Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected for conformity with specifications, including chemical composition, dimensions, and electrical properties.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, component placement accuracy, and functional checks.

- Final Quality Control (FQC): Comprehensive testing of finished adapters before shipment, including electrical safety, performance, and cosmetic inspections.

Common Testing Methods

- Electrical Safety Tests: Insulation resistance, dielectric withstand voltage, and leakage current tests verify user safety and compliance.

- Load and Performance Tests: Simulate operational conditions to assess voltage stability, current handling, and thermal behavior.

- Environmental Tests: Heat, humidity, and vibration testing ensure durability under various climatic conditions, critical for buyers in harsh environments like parts of Africa and the Middle East.

- Visual and Mechanical Inspections: Check for physical defects, label accuracy, and mechanical robustness.

How B2B Buyers Can Verify Supplier Quality Assurance

To mitigate risks and ensure product quality, international buyers should adopt a proactive approach to supplier verification:

- Factory Audits: On-site inspections or remote audits conducted by the buyer or third-party agencies assess manufacturing processes, QC systems, and working conditions.

- Review of Quality Documentation: Request and analyze ISO 9001 certificates, test reports, inspection logs, and compliance certifications (e.g., CE, RoHS).

- Third-Party Inspections: Engage independent inspection bodies (e.g., SGS, Bureau Veritas) to conduct pre-shipment inspections (PSI) or in-process checks.

- Sample Testing: Obtain product samples for independent lab testing to verify electrical performance and safety compliance.

- Supplier Track Record: Assess supplier reputation, client references, and history of compliance with international standards.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

Understanding regional regulatory landscapes and market expectations can significantly influence purchasing decisions:

- Africa (e.g., Kenya): Regulatory frameworks may be evolving; however, buyers should prioritize suppliers with internationally recognized certifications like CE and ISO 9001 to ensure compatibility with local import regulations and safety standards.

- South America: Countries like Brazil require additional certifications (e.g., INMETRO). Buyers should verify that adapters comply with both local and international standards to avoid customs delays.

- Middle East (e.g., Turkey, GCC countries): Many countries require Gulf Conformity Mark (G-Mark) or Turkish Standards Institute (TSE) certification. Suppliers with dual certifications (CE and local marks) offer smoother market entry.

- Europe: The strictest regulatory environment, where CE marking and RoHS compliance are mandatory. Buyers should demand full documentation and product traceability to satisfy audit requirements.

Summary for B2B Buyers

- Prioritize suppliers with robust ISO 9001 QMS and recognized electrical safety certifications (CE, UL, IEC).

- Insist on detailed QC documentation, including IQC, IPQC, and FQC records, along with independent test reports.

- Use factory audits and third-party inspections to validate manufacturing processes and QC practices.

- Understand and verify compliance with local regulations and certifications relevant to your market region.

- Consider environmental testing and durability assurances for installations in extreme climates common in Africa, the Middle East, and parts of South America.

By thoroughly vetting manufacturing processes and quality assurance measures, B2B buyers can secure reliable, compliant, and high-performance adapters for LED light strips that meet the demands of their diverse markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for adapter for led light strip Sourcing

When sourcing adapters for LED light strips, understanding the intricate cost components and pricing influencers is essential for making informed procurement decisions. This analysis highlights key elements shaping the cost structure and pricing dynamics, with actionable insights tailored for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe.

Key Cost Components in Adapter Manufacturing

-

Materials

The primary cost driver is the quality and type of materials used, including plastic or metal housing, copper wiring, electronic components (transformers, capacitors, resistors), and connectors. Higher-grade components ensure durability and compliance with safety standards but increase unit costs. -

Labor

Labor costs vary significantly by manufacturing location. Countries with lower labor rates, such as parts of Asia, often offer competitive pricing. However, labor quality and process efficiency can affect production timelines and defect rates. -

Manufacturing Overhead

This includes utilities, equipment depreciation, factory rent, and indirect labor. Efficient overhead management can reduce the per-unit cost, especially in larger production runs. -

Tooling and Setup Costs

Initial tooling investments for molds and assembly jigs can be substantial. These fixed costs are amortized over production volume, making larger Minimum Order Quantities (MOQs) more cost-effective. -

Quality Control (QC)

Rigorous QC processes, including electrical safety testing and certification inspections (e.g., CE, UL, RoHS), add to costs but are vital to ensure product reliability and regulatory compliance, particularly for European and Middle Eastern markets. -

Logistics and Import Duties

Shipping, customs clearance, and local taxes impact landed cost. Buyers from regions like Africa or South America should factor in longer lead times and potentially higher freight charges. Incoterms (e.g., FOB, CIF) influence who bears these costs and risks. -

Supplier Margin

Margins vary by supplier positioning, brand reputation, and service level. Established suppliers with certifications and warranties may command higher prices but reduce risk and after-sales expenses.

Pricing Influencers and Buyer Considerations

-

Volume and MOQ

Larger order quantities typically yield significant price breaks. For buyers in Kenya, Turkey, or Brazil, consolidating orders or forming buying groups can unlock better pricing and reduce per-unit costs. -

Specifications and Customization

Custom adapters with unique voltage outputs, connector types, or cable lengths increase complexity and price. Standardized products are generally more cost-efficient. -

Material Quality and Certifications

Products compliant with international safety and environmental standards may carry premium pricing but are crucial for access to regulated markets and to avoid costly import rejections. -

Supplier Reliability and Lead Time

Suppliers offering shorter lead times and robust after-sales support may price higher but reduce total cost of ownership (TCO) by minimizing downtime and replacement expenses. -

Incoterms Impact

Terms like FOB (Free on Board) transfer shipping responsibility to the buyer early, which can be advantageous for experienced importers managing freight cost. CIF (Cost, Insurance, Freight) offers more convenience but at a higher upfront price.

Strategic Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership

Evaluate price alongside warranty terms, certification status, and supplier responsiveness. Cheaper units with poor reliability often lead to higher operational costs. -

Leverage Volume Discounts and Payment Terms

Negotiate MOQs and payment terms (e.g., net 30, letter of credit) to improve cash flow while securing favorable pricing. -

Consider Local Regulations and Certification Requirements

Ensure adapters meet the electrical standards of target markets (e.g., CE marking for Europe, SABS for South Africa) to avoid costly non-compliance penalties. -

Account for Logistics Complexity

For buyers in regions with less developed port infrastructure, factor in potential delays and additional freight surcharges. Partnering with suppliers experienced in these markets can mitigate risks. -

Request Samples and Conduct Factory Audits

Prioritize suppliers who allow sample testing and factory visits or third-party inspections to verify quality before committing to large orders.

Indicative Pricing Disclaimer

Prices for LED light strip adapters vary widely based on specifications, order volume, and supplier location. As a rough guide, standard adapters with basic specifications might range from $1 to $5 per unit at scale. Custom or certified products can cost significantly more. Buyers should request detailed quotations and factor in all associated costs for an accurate budget.

By thoroughly analyzing these cost drivers and pricing influencers, international B2B buyers can optimize sourcing strategies, balancing cost-efficiency with product quality and compliance, ultimately ensuring successful LED lighting projects across diverse global markets.

Spotlight on Potential adapter for led light strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘adapter for led light strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for adapter for led light strip

Critical Technical Properties of Adapters for LED Light Strips

When sourcing adapters for LED light strips, understanding the key technical properties ensures compatibility, safety, and long-term performance. Here are the most important specifications international B2B buyers should consider:

-

Input and Output Voltage Compatibility

Adapters convert AC mains power (commonly 100-240V) to the low-voltage DC required by LED strips, typically 12V or 24V. Ensuring the adapter’s output voltage matches the LED strip’s rating is critical to avoid damage or suboptimal brightness. For buyers in regions with fluctuating voltage supplies (e.g., parts of Africa or South America), adapters with wide input voltage tolerance are preferred. -

Current and Power Rating (Amperage and Wattage)

The adapter must supply sufficient current (measured in amps) to power the total length of LED strip connected. Undersized adapters cause dimming, flickering, or failure. Calculate power needs by multiplying the LED strip’s wattage per meter by total length, then select an adapter with at least 20% higher wattage capacity for reliability and future expansion. -

Material Grade and Build Quality

High-quality adapters use flame-retardant plastic or metal enclosures with reliable internal components to ensure heat dissipation and longevity. This is especially vital in commercial or industrial installations common in the Middle East or Europe, where strict safety standards apply. Look for certifications such as CE, RoHS, or UL that indicate compliance. -

Tolerance and Regulation Accuracy

Voltage and current tolerance specify how much the output can deviate from nominal values. Tight tolerance (±5% or better) ensures consistent LED performance and prevents premature LED degradation. For sensitive applications like retail displays or architectural lighting, stable output is a must. -

Connector Type and Polarity

Adapters come with various connectors (barrel plugs, screw terminals, quick connectors). Confirming connector compatibility with LED strips reduces installation time and avoids costly modifications. Polarity protection (reverse polarity safeguard) is another valuable feature that protects LEDs from wiring errors. -

Operating Temperature Range

The adapter’s ability to function reliably within a specified temperature range is critical for installations in hot climates (e.g., Middle East, parts of Africa). Adapters rated for wider temperature ranges reduce the risk of failure and maintain performance over time.

Key Industry and Trade Terminology for B2B Buyers

Familiarity with common trade terms and industry jargon empowers buyers to navigate supplier communications, contracts, and negotiations confidently:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce adapters that other companies brand and sell under their own name. OEM partnerships often enable buyers to customize features or packaging and benefit from lower costs at scale. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. Understanding MOQ helps buyers plan inventory and negotiate better pricing. In markets like Turkey or Kenya, suppliers may offer flexible MOQs to attract smaller businesses. -

RFQ (Request for Quotation)

A formal document or inquiry sent to suppliers requesting detailed pricing, lead times, and terms for specific adapter models or volumes. Preparing clear RFQs accelerates supplier responses and ensures comparable offers. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Choosing the right Incoterm clarifies cost allocation and risk during transport. -

Lead Time

The period between placing an order and receiving the goods. For LED adapter sourcing, shorter lead times are advantageous for projects with tight schedules, but may increase costs. Buyers should balance urgency against budget. -

CE and RoHS Certification

CE marks compliance with EU safety and environmental standards, while RoHS certifies restriction of hazardous substances. These certifications are often mandatory for selling in European markets and signal product quality to buyers worldwide.

By prioritizing these technical properties and mastering relevant trade terminology, international B2B buyers can make informed procurement decisions, ensuring reliable LED light strip installations that meet regional requirements and business goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the adapter for led light strip Sector

Market Overview & Key Trends

The global market for adapters used in LED light strip systems is experiencing robust growth, driven by increasing adoption of LED lighting solutions in commercial, industrial, and residential projects. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Kenya and Turkey—are fueling demand due to urbanization, infrastructure development, and energy efficiency mandates.

Key market drivers include:

- Energy Efficiency and Cost Savings: LED lighting significantly reduces power consumption, prompting buyers to seek compatible, reliable adapters that ensure optimal LED performance and longevity.

- Technological Advancements: The evolution of smart lighting systems integrating IoT and dimmable controls is pushing demand for sophisticated adapters capable of handling variable voltages, PWM dimming, and RGB/RGBW configurations.

- Customization & Compatibility: Diverse LED strip specifications across regions necessitate adapters with multi-voltage support (commonly 12V and 24V DC), standardized connectors, and enhanced safety features to accommodate different wiring practices and power requirements.

- Supply Chain Localization: Buyers increasingly prefer suppliers who can provide localized inventory or regional warehousing to minimize lead times and logistics costs, critical for markets with fluctuating import regulations and infrastructure constraints.

Sourcing Trends:

- Parallel Power Distribution Preference: Commercial projects favor adapters supporting parallel wiring to mitigate voltage drop and maintain uniform brightness over extended LED strip runs.

- Modular & Scalable Solutions: B2B buyers seek adapters that integrate easily with controllers, amplifiers, and dimmers, enabling scalable lighting designs for complex layouts.

- Quality & Certification Focus: Certifications such as CE, RoHS, and UL are becoming baseline requirements, especially for buyers in Europe and the Middle East, reflecting a heightened emphasis on product safety and regulatory compliance.

For buyers in emerging markets, establishing relationships with manufacturers or distributors who understand local power standards, environmental conditions (e.g., high ambient temperatures), and installation expertise is essential for successful deployment.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly shaping procurement strategies for adapters in the LED light strip sector. B2B buyers recognize the environmental impact of electronic components and are prioritizing suppliers committed to reducing carbon footprints and promoting circular economy principles.

Environmental Impact Considerations:

- Material Selection: Use of lead-free solder, halogen-free plastics, and recyclable materials in adapter manufacturing reduces toxic waste and facilitates safer end-of-life recycling.

- Energy Efficiency: Adapters with high conversion efficiency minimize energy loss during AC to DC power transformation, aligning with global energy-saving targets and reducing operational costs.

- Waste Reduction: Modular designs that allow easy replacement of faulty parts rather than entire units help decrease electronic waste volumes.

Ethical Supply Chain Importance:

- Buyers are increasingly scrutinizing supplier transparency regarding labor practices, sourcing of raw materials, and adherence to international standards such as ISO 14001 (environmental management) and SA8000 (social accountability).

- Collaborating with manufacturers who maintain conflict-free sourcing policies and promote fair labor conditions supports corporate social responsibility goals and mitigates reputational risks.

Green Certifications to Look For:

- RoHS (Restriction of Hazardous Substances): Ensures adapters are free from hazardous materials like lead, mercury, and cadmium.

- Energy Star or Equivalent Efficiency Labels: Certify energy-efficient performance.

- UL Sustainability Certifications: Indicate compliance with environmental and safety standards.

- ISO 14001 Certification: Demonstrates commitment to environmental management systems.

For international buyers, especially from Europe and the Middle East where regulatory frameworks are stringent, prioritizing sustainable and ethically sourced adapters is not only a compliance requirement but also a competitive differentiator.

Evolution and Historical Context

The adapter for LED light strips has evolved significantly alongside the rapid advancement of LED technology. Initially, adapters were simple power supplies converting AC mains voltage to a fixed low-voltage DC output, mainly designed for basic single-color LED strips.

Illustrative Image (Source: Google Search)

With the proliferation of diverse LED strip types—such as RGB, tunable white, and addressable LEDs—adapters have transformed into intelligent power modules incorporating features like:

- Dimming compatibility: Supporting PWM, 0-10V, Triac, and DALI dimming protocols.

- Multi-voltage support: Catering to both 12V and 24V systems prevalent in different markets.

- Enhanced safety: Incorporating over-voltage, over-current, and short-circuit protection to comply with international electrical standards.

This evolution reflects the increasing complexity and customization demands of modern lighting projects, emphasizing the critical role of adapters in ensuring system reliability and performance. For B2B buyers, understanding this progression aids in selecting adapters that align with current and future lighting technologies.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of adapter for led light strip

-

How can I effectively vet suppliers of adapters for LED light strips to ensure quality and reliability?

When vetting suppliers, prioritize those with verifiable certifications such as CE, RoHS, and UL, which demonstrate compliance with international safety and environmental standards. Request samples to assess build quality and compatibility with your LED strips. Review their production capacity, lead times, and after-sales support. Checking references or customer testimonials, especially from buyers in similar regions (Africa, South America, Middle East, Europe), helps verify reliability. Additionally, confirm the supplier’s experience with export logistics and international trade compliance to avoid shipment delays. -

Is customization of LED light strip adapters possible, and what should I consider when requesting it?

Many suppliers offer customization options including voltage specifications, connector types, cable lengths, and branding. When requesting customization, clearly specify your technical requirements and intended application environment (e.g., voltage standards in your country, IP rating for moisture resistance). Understand the supplier’s minimum order quantity (MOQ) for custom products and any associated tooling or setup fees. Allow extra lead time for custom orders and verify if samples can be provided before full production to minimize risks. -

What are typical MOQ and lead times for ordering LED light strip adapters from international suppliers, especially for buyers in emerging markets?

MOQ varies widely depending on supplier scale and customization level but typically ranges from 500 to 5,000 units. Lead times can range from 3 to 8 weeks, factoring in production, quality checks, and international shipping. Buyers in emerging markets should negotiate MOQs aligned with their market demand to avoid excess inventory. Establish clear timelines upfront and consider buffer periods for customs clearance and potential logistical delays. Frequent communication with the supplier throughout production helps manage expectations and avoid surprises. -

Which payment terms are most common and advisable when sourcing adapters for LED light strips internationally?

Common payment terms include 30% deposit upfront and 70% balance before shipment or upon delivery. Letters of credit (LC) are preferred for larger orders as they protect both buyer and supplier. For trusted suppliers, buyers may negotiate net 30 or net 60 payment terms. Always ensure payment methods are secure and traceable, such as bank transfers or escrow services. Avoid full upfront payments unless the supplier is well-established and references are confirmed. Clear payment terms reduce risk and foster strong supplier relationships. -

What quality assurance (QA) measures and certifications should I demand for LED light strip adapters?

Demand adapters that comply with international standards such as CE (Europe), UL (North America), RoHS (environmental), and IEC certifications. QA measures should include 100% electrical testing, insulation resistance tests, and durability checks under operating temperatures. Request documented test reports and factory inspection records. For critical applications, consider third-party laboratory testing or factory audits. Consistent QA minimizes returns and warranty claims, crucial for maintaining reputation in international B2B markets. -

How can I optimize logistics and shipping for bulk orders of LED light strip adapters to Africa, South America, the Middle East, or Europe?

Work with suppliers experienced in international shipping who can provide DDP (Delivered Duty Paid) or FOB (Free On Board) terms depending on your logistics capabilities. Choose reliable freight forwarders familiar with your destination’s customs processes to avoid delays. Consolidate shipments when possible to reduce costs. Understand import duties and taxes specific to each region to factor into total landed cost. For urgent orders, air freight is faster but more expensive; sea freight is cost-effective for large volumes but requires longer lead times. -

What steps should I take to resolve disputes or quality issues with international suppliers of LED light strip adapters?

First, maintain clear, documented communication detailing the issue with photos or videos. Refer to contract terms covering warranty, returns, and dispute resolution. Use mediation or arbitration clauses if available to avoid lengthy legal processes. Engage third-party inspection services to verify claims objectively. Building a relationship based on trust and transparency often facilitates amicable resolutions. For recurring problems, consider diversifying suppliers or requesting stricter quality controls before shipment. -

Are there regional considerations for sourcing LED light strip adapters for markets in Kenya, Turkey, or similar countries?

Yes, local voltage standards, plug types, and certification acceptance vary by region. For example, Kenya typically uses 240V/50Hz with British-style plugs, while Turkey uses European plug types and 230V/50Hz. Ensure adapters meet local electrical regulations and are compatible with regional LED strip specifications (12V or 24V DC). Understanding import regulations and preferred documentation for customs clearance in each country expedites delivery. Partnering with suppliers who have experience exporting to these regions reduces compliance risks and enhances supply chain efficiency.

Strategic Sourcing Conclusion and Outlook for adapter for led light strip

Ensuring the right adapter for LED light strip is sourced strategically is pivotal for B2B buyers aiming to deliver reliable, efficient lighting solutions across diverse markets such as Africa, South America, the Middle East, and Europe. Key considerations include compatibility with voltage standards (12V vs. 24V), adherence to safety certifications, and the capacity to support the expected power load without compromising system longevity or performance. Selecting adapters that facilitate parallel wiring and reduce voltage drop enhances installation quality, minimizes maintenance challenges, and supports scalable commercial projects.

Strategic sourcing also involves partnering with suppliers who understand regional infrastructure nuances—such as fluctuating power conditions in emerging markets—and who can provide tailored technical support and flexible logistics. Buyers in countries like Kenya and Turkey benefit from sourcing solutions that balance cost-efficiency with compliance to international standards, ensuring seamless integration into local and export-oriented projects.

Looking ahead, the demand for adaptable, energy-efficient LED lighting continues to grow globally. B2B buyers are encouraged to invest in long-term supplier relationships, prioritize innovative adapter technologies, and leverage expert guidance on wiring and power management. By doing so, they position themselves to capitalize on expanding opportunities in dynamic markets while maintaining high-quality, safe, and sustainable lighting installations.