Introduction: Navigating the Global Market for rv awning led light strip replacement

The global demand for RV awning LED light strip replacements is experiencing significant growth, driven by the expanding recreational vehicle market and the increasing emphasis on energy-efficient, durable lighting solutions. For international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the complexities of this niche market is essential to making informed sourcing decisions that balance quality, cost, and compliance.

RV awning LED light strips are critical components that enhance the usability and aesthetic appeal of recreational vehicles, providing essential illumination for outdoor living spaces. Their replacement involves considerations around compatibility with various RV types, material durability against weather extremes, and adherence to manufacturing and quality control standards. These factors directly impact product lifespan and customer satisfaction, making supplier selection a strategic priority.

This comprehensive guide covers every aspect international buyers need to navigate the market effectively:

– Types and materials of LED strips tailored for different awning systems

– Manufacturing processes and quality assurance protocols ensuring reliability and safety

– Leading global suppliers and distribution networks with regional insights for Africa, South America, the Middle East, and Europe

– Cost analysis and pricing trends to optimize procurement budgets

– Key FAQs and troubleshooting tips to support after-sales service and client education

Armed with these insights, B2B buyers can confidently evaluate product offerings, negotiate favorable terms, and establish partnerships that deliver sustainable value and competitive advantage in their respective markets.

Understanding rv awning led light strip replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Channel LED Strip | LED strip housed within a flexible plastic channel, often rollable and trim-to-length | RV manufacturers, aftermarket suppliers, retrofit service providers | Pros: Easy installation, customizable length, durable housing Cons: Requires precise fitting, limited color options |

| Modular LED Light Kits | Pre-assembled kits with LED strips, connectors, switches, and mounting plates | RV service centers, OEMs, distributors | Pros: Plug-and-play, includes all components, simplifies replacement Cons: Higher upfront cost, less flexibility in sizing |

| Waterproof & Weatherproof LED Strips | Enhanced sealing and IP-rated strips for outdoor exposure | Exporters targeting harsh climates, aftermarket suppliers in tropical and desert regions | Pros: Superior durability, suitable for extreme weather Cons: Slightly higher cost, may require specialized connectors |

| Color-Change & RGB LED Strips | LED strips supporting multiple colors and remote control functions | Premium RV manufacturers, lifestyle-focused aftermarket sellers | Pros: Adds aesthetic value, customizable ambiance Cons: More complex wiring, higher price point |

| Hardwired LED Strip Assemblies | LED strips integrated directly into awning arms or frames with permanent wiring | OEMs for new RV builds, high-volume assembly lines | Pros: Seamless integration, robust build quality Cons: Difficult to replace individually, less modular |

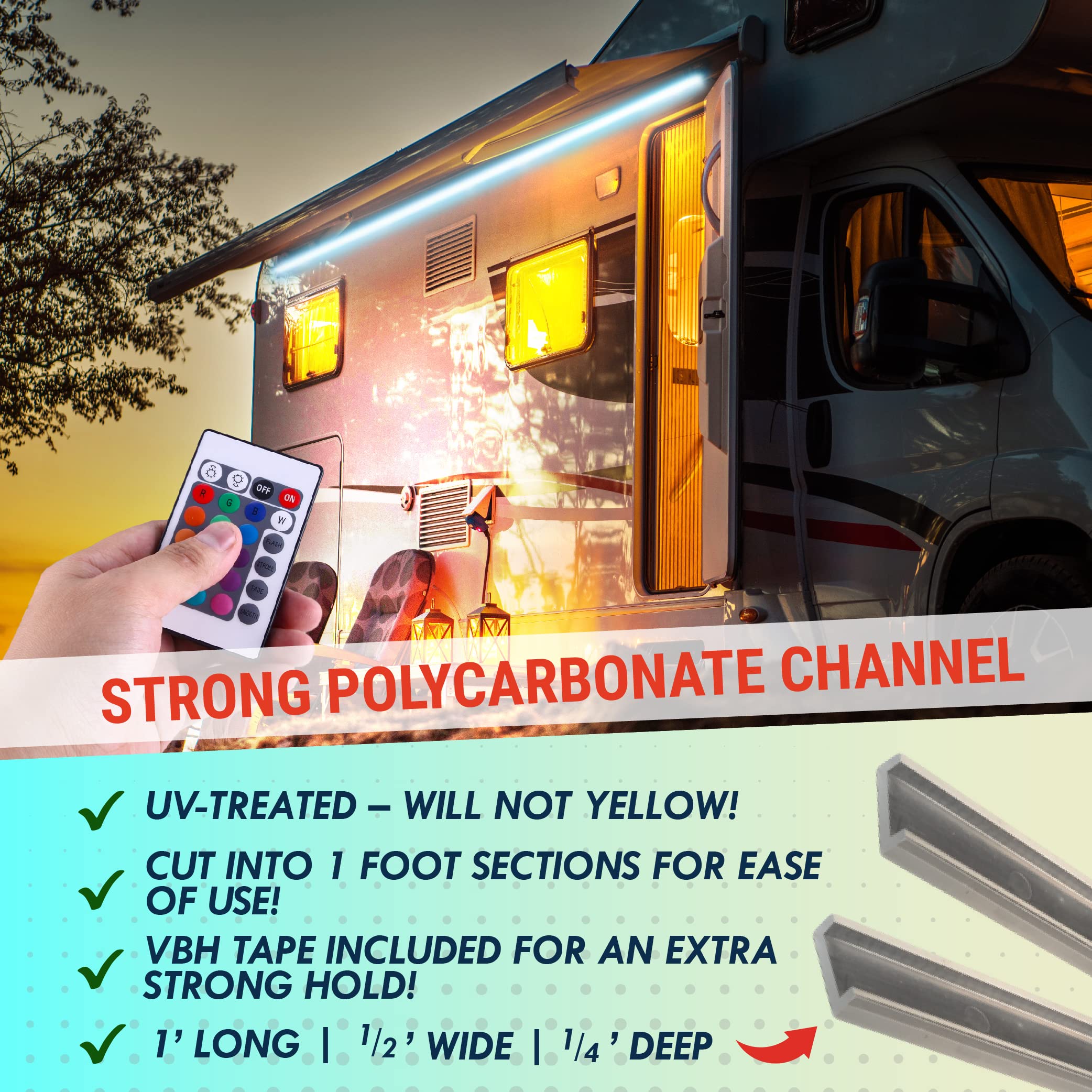

Integrated Channel LED Strip

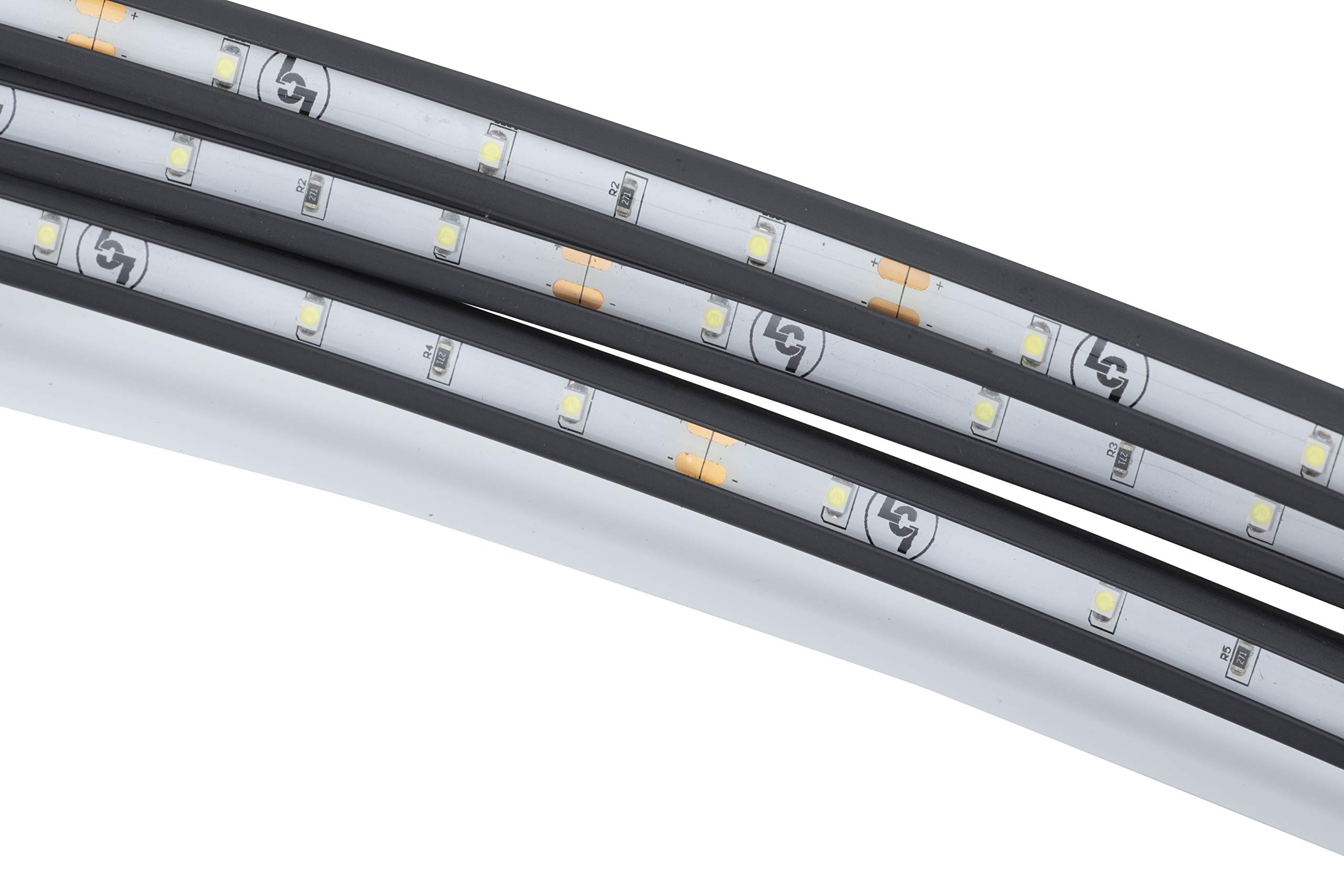

This type features an LED strip embedded within a flexible plastic channel, which can be rolled out and trimmed to the desired length. It is highly favored for retrofit projects and aftermarket replacements due to its ease of installation and adaptability. B2B buyers should consider the compatibility with existing awning dimensions and the durability of the plastic channel, especially for markets with variable weather conditions. Its moderate cost and straightforward installation make it a popular choice for distributors and service centers.

Modular LED Light Kits

These kits come complete with LED strips, connectors, switches, and mounting hardware, enabling quick and efficient replacement or upgrades. Ideal for RV service centers and OEMs looking to streamline inventory and installation, these kits reduce labor time and technical complexity. However, buyers should weigh the higher upfront cost against the savings in installation and the convenience of a one-package solution, which is especially valuable for markets with less technical labor availability.

Waterproof & Weatherproof LED Strips

Designed to withstand harsh outdoor environments, these LED strips feature enhanced sealing and meet IP ratings for water and dust resistance. They are essential for regions with high humidity, heavy rain, or desert climates, such as parts of Africa, the Middle East, and South America. B2B buyers targeting these markets should prioritize these strips to ensure product longevity and customer satisfaction, despite the slightly increased cost and potential need for specialized connectors.

Color-Change & RGB LED Strips

Offering multi-color lighting and remote control features, these LED strips cater to premium RV models and lifestyle-focused consumers. They provide customization and ambiance, which can be a strong selling point in competitive markets. For B2B buyers, these products carry a higher price and require more sophisticated wiring and control systems. They are best suited for upscale distributors and manufacturers targeting affluent regions or niche segments.

Hardwired LED Strip Assemblies

Hardwired LED strips are integrated permanently into the awning structure, typically during RV assembly. They offer a clean, seamless look and robust durability but are less flexible for post-sale replacement. OEMs and high-volume manufacturers benefit from these assemblies by reducing assembly complexity and ensuring quality control. However, aftermarket suppliers should be cautious, as replacements may require professional installation, limiting appeal in markets with DIY tendencies.

Related Video: RV Awning Led Light Strip Replacement

Key Industrial Applications of rv awning led light strip replacement

| Industry/Sector | Specific Application of rv awning led light strip replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Recreational Vehicle (RV) Manufacturing & Servicing | Replacement of LED awning light strips in new or refurbished RVs | Enhances customer satisfaction by ensuring reliable, attractive lighting; reduces warranty claims | Compatibility with diverse RV models, durability under harsh weather, ease of installation, and compliance with regional electrical standards |

| Outdoor Hospitality & Tourism | Maintenance and upgrade of RV park and campsite awning lighting systems | Improves guest experience with better ambient lighting; lowers maintenance downtime | Long-lasting LED strips with weather resistance, energy efficiency, and availability of local technical support |

| Commercial Vehicle Customization | Installation and replacement of awning LED lights on commercial mobile units (food trucks, mobile clinics) | Increases visibility and safety; supports brand visibility and operational efficiency | Customizable lengths, robust wiring for mobile environments, and compliance with local safety regulations |

| Marine & Boat Manufacturing | Replacement of LED awning light strips on marine vessels with awnings or canopies | Provides durable lighting resistant to saltwater corrosion; enhances nighttime usability | Waterproof and corrosion-resistant materials, UV protection, and compliance with marine electrical standards |

| Event & Exhibition Services | Temporary replacement or upgrade of LED awning lights on mobile event structures and exhibition booths | Enables flexible, attractive lighting solutions that support branding and visibility | Easy installation and removal, modularity, and compatibility with various power sources |

Recreational Vehicle (RV) Manufacturing & Servicing

In the RV manufacturing and servicing sector, LED awning light strip replacement is essential for maintaining and upgrading the lighting systems on travel trailers, fifth wheels, and toy haulers. These light strips are crucial for providing functional and aesthetic outdoor lighting for RV users. For international B2B buyers, especially in regions like South Africa and Europe, sourcing LED strips that are compatible with various RV models and meet stringent regional electrical standards is critical. Durability against environmental factors such as UV exposure and moisture is also a key requirement to reduce warranty claims and enhance customer satisfaction.

Outdoor Hospitality & Tourism

RV parks and campsites rely heavily on ambient lighting to improve guest safety and experience. Replacing or upgrading LED awning light strips ensures consistent illumination around awnings, which is particularly important in regions with extended outdoor evening activities such as in the Middle East or South America. Buyers should prioritize LED strips with high energy efficiency and weather resistance to minimize maintenance and operational costs. Access to local technical support and parts availability can significantly reduce downtime in these hospitality settings.

Commercial Vehicle Customization

Mobile commercial units such as food trucks and mobile clinics utilize LED awning lights to enhance visibility and attract customers. Replacement LED strips must be robust enough to withstand frequent movement and exposure to varying weather conditions. For B2B buyers in emerging markets like Indonesia or Africa, sourcing LED strips that offer customization in length and wiring options is essential to fit diverse vehicle configurations. Compliance with local safety regulations and the ability to integrate with existing vehicle electrical systems are critical considerations.

Marine & Boat Manufacturing

Marine vessels equipped with awnings or canopies require LED awning light strips that can endure harsh marine environments, including saltwater exposure and intense sunlight. Replacement LED strips must be waterproof and corrosion-resistant to ensure longevity. Buyers from coastal regions in Europe or South America should seek suppliers offering products that comply with marine electrical safety standards and provide UV protection. This ensures operational reliability and reduces frequent replacement costs in marine applications.

Event & Exhibition Services

For companies managing mobile event structures or exhibition booths, LED awning light strip replacement offers a flexible lighting solution that enhances visual appeal and brand visibility. The ability to easily install, remove, and reconfigure LED strips is vital for temporary setups common in international trade shows or outdoor events. Buyers in diverse markets must consider modular LED lighting options compatible with various power sources to accommodate different venue requirements and ensure quick turnaround times between events.

Related Video: Replacing and Installing | RV Awning LED Light Strip | Easy Install

Strategic Material Selection Guide for rv awning led light strip replacement

When selecting materials for RV awning LED light strip replacements, international B2B buyers must carefully evaluate the properties and suitability of common materials to ensure durability, performance, and compliance with regional standards. The choice of material directly impacts product longevity, ease of installation, and overall customer satisfaction, especially in diverse climatic and regulatory environments such as Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used for LED strip housings and channels due to its excellent weather resistance, moderate temperature tolerance (-15°C to 60°C), and good electrical insulation properties. It is resistant to UV degradation and corrosion, which is critical for outdoor applications like RV awnings.

Pros & Cons: PVC is cost-effective, easy to mold, and readily available globally, making it attractive for mass production. However, it can become brittle in very cold climates and may emit harmful fumes if burned, which raises environmental and safety considerations. Manufacturing complexity is low, allowing for flexible designs.

Impact on Application: PVC’s resistance to moisture and UV exposure makes it suitable for awning LED strips exposed to sun and rain. However, in extremely hot regions such as parts of the Middle East, prolonged exposure to high temperatures may accelerate material degradation unless UV stabilizers are added.

International Considerations: PVC products often comply with ASTM and DIN standards, which are recognized in Europe and parts of South America. Buyers in Africa and Indonesia should verify local environmental regulations due to concerns about PVC disposal and recycling. PVC’s widespread use and cost advantages make it a preferred choice in price-sensitive markets.

Polycarbonate (PC)

Key Properties: Polycarbonate offers superior impact resistance, high temperature tolerance (up to 135°C), and excellent optical clarity, making it ideal for protective covers on LED strips. It also exhibits strong UV resistance when treated with coatings.

Pros & Cons: PC is more durable and heat-resistant than PVC, providing longer service life under harsh conditions. However, it is more expensive and requires more precise manufacturing processes such as injection molding. It can yellow over time if not UV-stabilized.

Impact on Application: The robustness of polycarbonate makes it suitable for regions with high mechanical stress or where vandalism risk exists, such as urban areas in Europe or South Africa. Its clarity enhances light output, improving the aesthetic and functional appeal of awning lighting.

International Considerations: Polycarbonate products typically meet ISO and DIN standards, which are widely accepted in Europe and increasingly in South America. Middle Eastern buyers value PC for its heat resistance, while African markets appreciate its durability despite higher costs.

Silicone Rubber

Key Properties: Silicone rubber is prized for its exceptional flexibility, high thermal stability (-60°C to 230°C), and outstanding resistance to UV, ozone, and water ingress. It is often used as a sealing or encapsulating material for LED strips.

Pros & Cons: Silicone offers excellent protection for LED electronics against harsh weather and mechanical vibrations. It is more expensive than PVC and PC and requires specialized processing techniques. Its softness may limit structural support, necessitating combination with rigid materials.

Impact on Application: Silicone’s flexibility and weather resistance are advantageous in regions with extreme temperature fluctuations, such as desert climates in the Middle East or tropical zones in Indonesia. It ensures longevity of LED components by preventing moisture ingress.

International Considerations: Silicone materials often conform to ASTM and JIS standards, facilitating acceptance in Asia and Europe. Buyers in South America and Africa should consider supply chain availability and cost implications when opting for silicone encapsulation.

Aluminum Alloy

Key Properties: Aluminum alloys are used primarily for LED strip channels and heat sinks due to their excellent thermal conductivity, corrosion resistance (especially anodized variants), and lightweight nature. They withstand temperature extremes and mechanical impacts well.

Pros & Cons: Aluminum enhances LED lifespan by dissipating heat efficiently, reducing failure rates. It is more costly and heavier than plastic alternatives and requires more complex fabrication processes like extrusion and machining. Corrosion resistance varies with alloy and finish.

Impact on Application: Aluminum is ideal for premium RV awning LED strips where durability and heat management are priorities, particularly in hot, humid, or coastal environments like South Africa’s coastline or Mediterranean Europe. It also supports sleek, modern designs favored in European markets.

International Considerations: Aluminum products conform to global standards such as ASTM, DIN, and EN, easing cross-border trade. Middle Eastern and South American buyers benefit from aluminum’s robustness despite the higher price point, while African buyers must weigh cost against performance benefits.

| Material | Typical Use Case for rv awning led light strip replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Housing and channel for LED strips in standard outdoor conditions | Cost-effective, good weather and UV resistance | Can become brittle in cold climates, environmental concerns | Low |

| Polycarbonate (PC) | Protective covers requiring impact resistance and clarity | High impact resistance, heat tolerance, optical clarity | Higher cost, potential yellowing without UV treatment | Medium |

| Silicone Rubber | Sealing and encapsulating LED strips for moisture and vibration protection | Exceptional flexibility and thermal stability | Higher cost, limited structural support | High |

| Aluminum Alloy | Heat sinks and channels for premium, durable LED strip assemblies | Excellent heat dissipation, corrosion resistance | More expensive, heavier, complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for rv awning led light strip replacement

Overview of Manufacturing Processes for RV Awning LED Light Strip Replacement

The production of LED light strips for RV awning replacements involves a carefully coordinated sequence of manufacturing stages designed to ensure durability, weather resistance, and optimal lighting performance. For international B2B buyers, understanding these stages helps in assessing supplier capabilities and product reliability.

1. Material Preparation

The process begins with sourcing high-quality raw materials such as flexible printed circuit boards (FPCBs), LED chips (commonly SMD LEDs), silicone or PVC encapsulants for waterproofing, and aluminum or plastic channels for mounting. Material preparation includes:

Illustrative Image (Source: Google Search)

- Inspection and testing of incoming components to verify electrical and mechanical specifications.

- Cutting and cleaning of substrates to size.

- Preparing adhesives and sealants that comply with outdoor use standards.

2. Forming and Assembly

Forming involves shaping the LED strip and its housing to fit the specific awning profiles:

- Surface Mount Technology (SMT): Automated machines place LED chips and resistors onto the FPCB with precision.

- Soldering: Reflow soldering ensures strong electrical connections.

- Encapsulation: The LED strip is coated or encased with a UV-resistant, waterproof silicone or epoxy to protect against environmental factors.

- Channel Assembly: The flexible LED strip is inserted into extruded aluminum or plastic channels that provide structural support and facilitate installation on the awning.

3. Finishing Processes

Finishing enhances durability and aesthetics:

- Application of protective coatings to resist corrosion and UV damage.

- Cutting strips to standard lengths or customized sizes based on client specifications.

- Fitting connectors, wiring harnesses, and mounting hardware.

- Packaging designed to prevent damage during transport.

Quality Assurance Frameworks and Standards

Robust quality assurance (QA) is critical due to the demanding outdoor environment in which these LED strips operate. Buyers should prioritize suppliers adhering to internationally recognized standards and best practices.

Relevant International Standards

- ISO 9001: Specifies requirements for a quality management system, ensuring consistent product quality and continual improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, increasingly demanded worldwide.

- IP Ratings (Ingress Protection): Defines protection levels against dust and water ingress; typically, awning LED strips require IP65 or higher.

- UL Certification: Ensures electrical safety compliance, especially important for wiring and LED components.

Industry-Specific Standards

- IEC Standards: Such as IEC 60598 for luminaires, which may be relevant for LED light strips.

- ASTM and SAE Standards: For material durability and environmental resistance.

- REACH Regulation (Europe): Controls chemical substances and ensures environmental safety.

Key Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, segmented into:

- Incoming Quality Control (IQC): Verification of raw materials and components, including LED chip lumens, substrate integrity, and waterproofing materials.

- In-Process Quality Control (IPQC): Continuous monitoring during SMT placement, soldering quality checks, and encapsulation uniformity to detect defects early.

-

Final Quality Control (FQC): Comprehensive testing of finished products, including:

-

Visual inspection for physical damage or defects.

- Electrical testing for continuity, voltage, and current draw.

- Waterproof testing (e.g., immersion or spray tests).

- Thermal performance and heat dissipation evaluation.

- Functional testing of lighting uniformity and color temperature.

Testing Methods Commonly Employed

- Automated Optical Inspection (AOI): Detects soldering defects and component misplacement.

- Electrical Load Testing: Ensures LEDs operate within specified electrical parameters.

- Environmental Stress Testing: Accelerated aging under UV light, humidity, and temperature cycling to simulate real-world conditions.

- Mechanical Stress Testing: Flexibility and vibration tests to confirm strip durability during installation and operation.

- Photometric Testing: Measures light output and color consistency.

How B2B Buyers Can Verify Supplier Quality Assurance

To mitigate risks and ensure product reliability, international buyers should adopt a proactive approach to supplier evaluation:

- Factory Audits: Conduct on-site or virtual audits focusing on production processes, QC protocols, and compliance with certifications like ISO 9001 and CE.

- Request Documentation: Review quality manuals, test reports, and certifications. Confirm traceability of materials and components.

- Third-Party Inspections: Engage independent inspection agencies to perform pre-shipment inspections or random batch testing.

- Sample Testing: Obtain and test product samples under local environmental conditions to verify claims.

- Supplier Capability Assessment: Evaluate supplier experience with export markets, especially for compliance with regional regulations in Africa, South America, the Middle East, and Europe.

QC and Certification Nuances for International Markets

Understanding regional requirements and market-specific nuances is vital for buyers from diverse geographies:

- Africa & Middle East: Emphasize durability under extreme heat, dust, and sand exposure. Certifications like CE and RoHS are increasingly recognized, but local standards and customs clearance may require additional documentation.

- South America: Import regulations often demand strict compliance with electrical safety standards, and customs can be stringent about certification authenticity.

- Europe: The CE mark is mandatory, with tight restrictions on hazardous substances and environmental impact. Buyers should ensure suppliers hold valid EU declarations of conformity.

- Indonesia & Southeast Asia: While standards vary, buyers should insist on IP65+ ratings due to tropical climate conditions and verify suppliers’ compliance with international standards to facilitate import and reduce liability.

Conclusion

For B2B buyers seeking RV awning LED light strip replacements, a thorough understanding of manufacturing processes and quality assurance practices is essential. Prioritizing suppliers with transparent, well-documented QC systems and relevant international certifications safeguards investment and ensures product longevity in diverse and challenging environments worldwide. Leveraging factory audits, third-party inspections, and sample testing can significantly reduce risks and foster successful international partnerships.

Related Video: How To Replace Your RV Awning Lights With OEM Lippert LED Light Strip

Comprehensive Cost and Pricing Analysis for rv awning led light strip replacement Sourcing

When sourcing RV awning LED light strip replacements, understanding the detailed cost structure and pricing drivers is essential for international B2B buyers seeking optimal value and reliability.

Cost Components Breakdown

-

Materials: The primary cost driver includes LED chips, flexible PCB substrates, protective channel rails (often extruded plastic), wiring, connectors, and adhesives. High-quality LEDs with better luminosity and energy efficiency command higher prices, as do durable, weather-resistant materials suitable for outdoor use.

-

Labor: Assembly involves precise placement of LEDs, soldering, wiring, and sealing within protective channels. Labor costs vary significantly by manufacturing location; for instance, Southeast Asian or Eastern European factories may offer cost advantages compared to Western Europe or North America.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Overhead rates fluctuate with factory scale and automation levels, affecting per-unit cost.

-

Tooling: Initial investment in molds for plastic channels, PCB assembly jigs, and cutting tools can be substantial. For buyers ordering custom lengths or designs, tooling costs may be amortized over MOQ volumes.

-

Quality Control (QC): Critical for ensuring LED longevity and waterproofing. QC processes include electrical testing, waterproof sealing verification, and durability assessments, adding to the overall cost but reducing returns and warranty claims.

-

Logistics: Shipping costs depend on volume, weight, and delivery terms. LED light strips are lightweight but fragile, requiring careful packaging. International freight costs vary significantly by origin and destination, with air freight preferred for urgent orders but sea freight being more economical for bulk shipments.

-

Margin: Supplier margins typically reflect their market positioning, brand reputation, and after-sales support. Established brands or certified suppliers may charge premiums justified by reliability and warranty coverage.

Key Pricing Influencers

-

Volume and Minimum Order Quantities (MOQ): Larger orders reduce per-unit costs due to economies of scale. Buyers from Africa, South America, the Middle East, and Europe should negotiate MOQ aligned with their demand to optimize pricing without excessive inventory.

-

Specifications and Customization: Customized LED color temperatures, lengths, connectors, or integrated switches increase costs. Standardized products are more cost-effective but may not fit all RV models.

-

Material Quality and Certifications: Products compliant with international standards (e.g., CE, RoHS, IP65/IP67 waterproof ratings) command higher prices but ensure safety and durability, which is crucial in harsh climates found in many emerging markets.

-

Supplier Location and Capacity: Proximity to shipping hubs and factory production capacity influence lead times and pricing. Suppliers in Asia often offer competitive prices but may require longer lead times and more stringent quality audits.

-

Incoterms: The choice of Incoterms (FOB, CIF, DDP, etc.) affects total landed cost. Buyers unfamiliar with import duties, taxes, and customs clearance in their countries should consider DDP terms to avoid unexpected expenses.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, lead times, packaging, and after-sales service. Volume discounts and flexible MOQ can improve cost efficiency.

-

Assess Total Cost of Ownership (TCO): Include warranty terms, product lifespan, ease of installation, and replacement frequency. Lower upfront costs may lead to higher long-term expenses if product quality is compromised.

-

Leverage Regional Trade Agreements: Buyers in Africa, South America, or the Middle East should explore suppliers from trade partner countries to reduce tariffs and simplify logistics.

-

Request Samples and Certifications: Validate quality and compliance before large orders. This is particularly important for LED strips exposed to outdoor elements, where failure rates impact reputation and operational costs.

-

Consider Currency Fluctuations and Payment Methods: Use hedging strategies or negotiate contracts in stable currencies to mitigate exchange rate risks.

-

Local Support and Spare Parts Availability: Ensure suppliers can provide technical support and spare components locally or regionally to minimize downtime and shipping costs.

Indicative Pricing Disclaimer

Prices for RV awning LED light strip replacements vary widely based on specifications, volume, and supplier. Indicative price ranges might start from approximately $10–$25 per linear foot for standard LED strips with channel rails, excluding shipping and taxes. Buyers should request detailed quotations tailored to their specific requirements and sourcing conditions.

By carefully analyzing these cost factors and pricing influencers, international B2B buyers can strategically source high-quality RV awning LED light strip replacements that balance cost, performance, and reliability across diverse markets.

Spotlight on Potential rv awning led light strip replacement Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘rv awning led light strip replacement’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rv awning led light strip replacement

Critical Technical Properties for RV Awning LED Light Strip Replacement

-

Material Grade and Durability

The LED light strip housing is typically made from UV-resistant polycarbonate or flexible PVC to withstand prolonged sun exposure and harsh weather conditions. For B2B buyers, sourcing high-grade materials ensures longevity and reduces warranty claims, especially in regions with intense sunlight like parts of Africa and the Middle East. -

Waterproof Rating (IP Rating)

An Ingress Protection (IP) rating, commonly IP65 or higher, indicates the light strip’s resistance to dust and water. This is crucial for awnings exposed to rain or dust storms. Buyers must verify the IP rating to guarantee product reliability in diverse climates found across Europe and South America. -

Voltage Compatibility and Power Consumption

Most RV awning LED strips operate on 12V DC systems, compatible with standard RV electrical setups. Power efficiency (measured in watts per meter) affects energy consumption and battery life. International buyers should confirm voltage standards and power specs to ensure compatibility with local RV electrical systems and avoid costly modifications. -

Length and Customizability

LED strips come in standard lengths (e.g., 15 or 21 feet) but should be easily cuttable or extendable to fit various awning sizes. Flexibility in length customization reduces inventory complexity and allows suppliers to serve diverse market needs, from compact trailers in Europe to larger motorhomes in South America. -

Light Output and Color Temperature

Measured in lumens and Kelvin (K), these specs define brightness and light hue. Typical awning LED strips emit warm white light (2700K–3500K) for ambiance or cool white (4000K–6000K) for visibility. Buyers should align light output with end-user preferences and safety requirements, balancing illumination and power consumption. -

Connector Type and Installation Ease

Common connectors include butt connectors, bell caps, or plug-and-play systems. Ease of installation affects labor costs and after-sales service complexity. Products designed for simple wire splicing or quick-snap connectors are preferred in markets with limited technical support infrastructure.

Key Trade Terminology for RV Awning LED Light Strip Replacement

-

OEM (Original Equipment Manufacturer)

Refers to parts produced by the original maker of the RV or its components. OEM light strips guarantee fit and performance but may carry a premium price. B2B buyers must weigh OEM authenticity against aftermarket alternatives for cost efficiency. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. Understanding MOQ is critical for budgeting and inventory planning, especially for buyers in emerging markets with limited warehouse space or fluctuating demand. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers to obtain pricing, lead times, and terms. Crafting clear RFQs with technical specs reduces negotiation cycles and speeds up procurement. -

Incoterms (International Commercial Terms)

Standardized trade terms defining delivery responsibilities, costs, and risks between buyers and sellers (e.g., FOB, CIF, DDP). Familiarity with Incoterms helps international buyers from Africa, South America, and Europe manage logistics efficiently and avoid unexpected expenses. -

Lead Time

The time from order placement to product shipment. Short lead times are advantageous for supply chain agility, important for markets with seasonal demand fluctuations. -

RoHS Compliance (Restriction of Hazardous Substances)

Indicates the product meets environmental standards restricting harmful materials like lead or mercury. RoHS certification is often mandatory in European markets and increasingly expected worldwide, affecting import eligibility and brand reputation.

By understanding these technical properties and trade terms, international B2B buyers can make informed sourcing decisions that optimize product quality, cost efficiency, and supply chain reliability for RV awning LED light strip replacements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rv awning led light strip replacement Sector

Market Overview & Key Trends

The global market for RV awning LED light strip replacements is experiencing steady growth driven by increasing RV ownership and outdoor recreational activities worldwide. For international B2B buyers, particularly from emerging regions such as Africa, South America, the Middle East, and mature markets in Europe and Indonesia, key dynamics revolve around durability, energy efficiency, and ease of installation. These regions see rising demand for aftermarket RV accessories due to expanding middle-class consumer bases and growing tourism sectors.

Technological advancements in LED lighting, including improvements in brightness, power consumption, and waterproofing, are reshaping sourcing priorities. Buyers are increasingly focused on modular LED strips that can be easily cut to size or linked, accommodating various awning lengths and RV models. This modularity is critical for markets with diverse RV types and sizes, such as travel trailers and fifth wheels, common in Europe and South America.

Supply chain agility is another pivotal trend. Due to the fragmented nature of global RV manufacturing, B2B buyers value suppliers who offer customizable products with flexible MOQ (Minimum Order Quantity) and quick turnaround times. This flexibility supports inventory management in regions where storage and import costs are high, such as parts of Africa and the Middle East.

Moreover, digital sourcing platforms and virtual product demonstrations are becoming essential tools, helping buyers from distant markets assess product compatibility and quality without the need for costly travel. Partnerships with local distributors and aftersales support networks are also increasingly important to ensure smooth installation and maintenance.

Sustainability & Ethical Sourcing in B2B

Environmental sustainability is gaining traction within the RV awning LED light strip replacement sector, reflecting broader global commitments to reducing carbon footprints and waste. For B2B buyers, particularly those operating in Europe and increasingly in Africa and South America, eco-conscious procurement is no longer optional but a competitive differentiator.

Key considerations include sourcing LED strips manufactured with low-energy consumption chips, recyclable materials, and durable components that minimize replacement frequency. Suppliers offering certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and compliance with ISO 14001 environmental management standards provide assurance of responsible manufacturing processes.

Ethical supply chains are equally critical. Buyers are advised to verify that suppliers adhere to fair labor practices and avoid conflict minerals, which is particularly relevant when sourcing from regions with complex geopolitical landscapes. Transparency in sourcing and production helps mitigate reputational risks and aligns with increasing regulatory scrutiny in European and Middle Eastern markets.

Additionally, the adoption of biodegradable or recyclable packaging, and the use of non-toxic sealants and adhesives during installation, contribute to a greener product lifecycle. Buyers can further promote sustainability by partnering with suppliers who invest in solar-compatible LED light strips, enabling RV owners to leverage renewable energy sources—a growing trend in regions with abundant sunlight, such as the Middle East and parts of Africa.

Brief Evolution & Historical Context

The evolution of RV awning LED light strips reflects broader trends in lighting technology and outdoor living preferences. Initially, RV awnings utilized incandescent or fluorescent lighting, which were less energy-efficient and more prone to damage. The transition to LED technology over the past two decades has revolutionized the sector by offering longer lifespan, lower power consumption, and enhanced durability under outdoor conditions.

Early LED awning lights were often rigid and limited in length, constraining their application across diverse RV models. Over time, manufacturers introduced flexible LED strip lights housed in protective channels, allowing for easy customization and replacement—an essential feature for the aftermarket parts market.

This evolution has enabled international B2B buyers to source versatile, cost-effective lighting solutions that meet the growing expectations of end-users for convenience, brightness, and sustainability. Understanding this history helps buyers appreciate the technological maturity of current offerings and informs decisions about product specifications and supplier partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of rv awning led light strip replacement

-

How can I effectively vet suppliers of RV awning LED light strip replacements for international trade?

Begin by assessing supplier certifications such as ISO 9001 for quality management and compliance with international electrical safety standards (e.g., CE, RoHS). Request detailed product specifications and samples to verify quality and compatibility. Conduct background checks on the supplier’s export history, client references, and financial stability. Utilize trade platforms and B2B marketplaces with verified suppliers. For regions like Africa and South America, prioritize suppliers familiar with local import regulations and capable of providing after-sales support. -

What customization options are typically available for RV awning LED light strips, and how can they benefit my business?

Suppliers often offer customization in length, LED color temperature, waterproof ratings, and connector types to suit different RV models and regional preferences. Custom branding and packaging may also be available for bulk orders. Tailoring products to local market demands enhances customer satisfaction and competitive advantage. When negotiating, clarify minimum order quantities (MOQs) for customized items and lead times to ensure alignment with your supply chain schedules. -

What are the common minimum order quantities (MOQs) and lead times for these LED light strips in international B2B transactions?

MOQs vary widely, typically ranging from 100 to 500 units depending on supplier capacity and customization level. Lead times can range from 3 to 8 weeks, influenced by production complexity, customization, and shipping method. For buyers in regions like the Middle East or Europe, factor in potential customs clearance delays. Establish clear communication with suppliers about production schedules and confirm flexible MOQs where possible to minimize inventory risks. -

Which payment terms are advisable when sourcing RV awning LED light strip replacements internationally?

Common payment terms include a 30% deposit upfront and 70% balance before shipment or upon delivery. Letters of credit (LC) and escrow services provide additional security for large transactions. For new suppliers, consider smaller initial orders with secure payment methods to mitigate risks. Always verify supplier banking details independently to avoid fraud. Negotiating payment terms that balance cash flow needs and supplier trustworthiness is critical for sustainable partnerships. -

What quality assurance measures and certifications should I expect from reputable suppliers?

Reputable suppliers should provide product testing reports confirming LED brightness, durability, waterproof ratings (IP65 or higher), and electrical safety compliance. Certifications like CE (Europe), FCC (USA), and RoHS (restriction of hazardous substances) demonstrate adherence to international standards. Request factory audit reports and inquire about production process controls. For buyers in Africa or South America, ensuring conformity with local electrical standards and certification requirements can prevent import rejections. -

How can I optimize logistics and shipping for RV awning LED light strip replacements to Africa, South America, the Middle East, or Europe?

Choose suppliers with experience shipping to your region, preferably offering FOB or CIF terms to clarify responsibility. Consolidate shipments to reduce costs and request packaging optimized for long transit to prevent damage. Air freight offers speed but at higher cost; sea freight is cost-effective for bulk orders but requires longer lead times. Collaborate with freight forwarders familiar with regional customs to streamline clearance. Track shipments actively and prepare for import duties and taxes to avoid surprises. -

What strategies can help resolve disputes related to product quality or delivery delays in international B2B purchases?

Incorporate clear terms in contracts covering product specifications, inspection rights, delivery schedules, and penalties for non-compliance. Use third-party inspection services before shipment to verify quality and quantity. Maintain transparent communication and document all correspondences. If disputes arise, leverage mediation or arbitration clauses in contracts to avoid costly litigation. Building long-term relationships with trusted suppliers through regular audits and feedback reduces the risk of future conflicts. -

Are there specific considerations for sourcing RV awning LED light strips in emerging markets such as Indonesia or South Africa?

Emerging markets may face challenges including fluctuating currency rates, variable import regulations, and infrastructure limitations affecting shipping and delivery times. Partner with suppliers who understand these dynamics and can provide flexible terms or local warehousing options. Prioritize products with robust durability to withstand diverse climates. Establish strong local partnerships for after-sales support and ensure compliance with regional standards to facilitate smoother market entry and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rv awning led light strip replacement

Strategic Sourcing Insights and Future Perspectives for RV Awning LED Light Strip Replacement

For international B2B buyers across Africa, South America, the Middle East, and Europe, sourcing RV awning LED light strips demands a strategic approach centered on quality, compatibility, and supply chain resilience. Key takeaways highlight the importance of partnering with manufacturers who provide modular, easily installable LED strips designed for varied awning lengths and environmental conditions. Prioritizing suppliers offering customizable lengths, robust sealing solutions, and reliable connectors can significantly reduce installation time and maintenance costs, enhancing end-user satisfaction.

Illustrative Image (Source: Google Search)

Strategic sourcing also involves vetting suppliers for proven product durability in diverse climates and ensuring compliance with regional electrical standards. Leveraging local distributors with technical expertise can facilitate after-sales support and streamline inventory management. Moreover, embracing suppliers that provide transparent product specifications and installation guidance empowers buyers to make informed procurement decisions aligned with their market needs.

Looking ahead, the growing global RV market and increasing demand for energy-efficient, durable lighting solutions signal a promising outlook. Buyers are encouraged to explore innovative LED technologies and establish long-term partnerships that foster product innovation and supply stability. By adopting a proactive sourcing strategy, international buyers can secure competitive advantages and meet evolving consumer expectations in their regions.