Introduction: Navigating the Global Market for led strip connector 2 pin

LED strip connector 2 pin components are pivotal in the rapidly expanding LED lighting industry, serving as the essential link between power sources and flexible LED strips. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of these connectors is critical to securing reliable, high-performance lighting solutions. Whether sourcing for commercial projects in the UAE, industrial installations in Colombia, or large-scale retail environments across Europe, selecting the right 2 pin connector ensures seamless electrical connectivity, safety, and longevity.

This comprehensive guide delves into every aspect of the led strip connector 2 pin market, equipping buyers with actionable insights to make well-informed procurement decisions. It covers:

- Connector types and materials: From soldered to clip and screw terminal designs, including waterproof and low-profile options tailored for various environments.

- Manufacturing standards and quality control: Key criteria for evaluating supplier reliability and product durability.

- Global supplier landscape: How to identify reputable manufacturers and distributors that meet regional compliance and logistical needs.

- Cost analysis and market trends: Understanding pricing drivers and emerging innovations influencing connector availability and performance.

- Frequently Asked Questions: Addressing common technical and sourcing challenges faced by international buyers.

By integrating engineering principles with market intelligence, this guide empowers B2B buyers to optimize their LED strip lighting installations, reduce operational risks, and enhance overall project outcomes—turning complex sourcing decisions into strategic advantages across global markets.

Understanding led strip connector 2 pin Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soldered 2 Pin Connector | Permanent connection via soldering; requires tools and skill | Industrial lighting, long-term fixed installations | Pros: Highly reliable, durable, low resistance; Cons: Time-consuming, less flexible for reconfiguration |

| Clip-on 2 Pin Connector | Tool-free clip mechanism for quick connection and disconnection | Retail displays, temporary setups, prototyping | Pros: Easy to use, fast installation; Cons: Less secure, potential contact issues over time |

| Screw Terminal 2 Pin Connector | Uses screws to clamp wires securely; no soldering needed | Commercial installations, maintenance-heavy environments | Pros: Adjustable, reusable, secure; Cons: Bulkier, slower installation than clips |

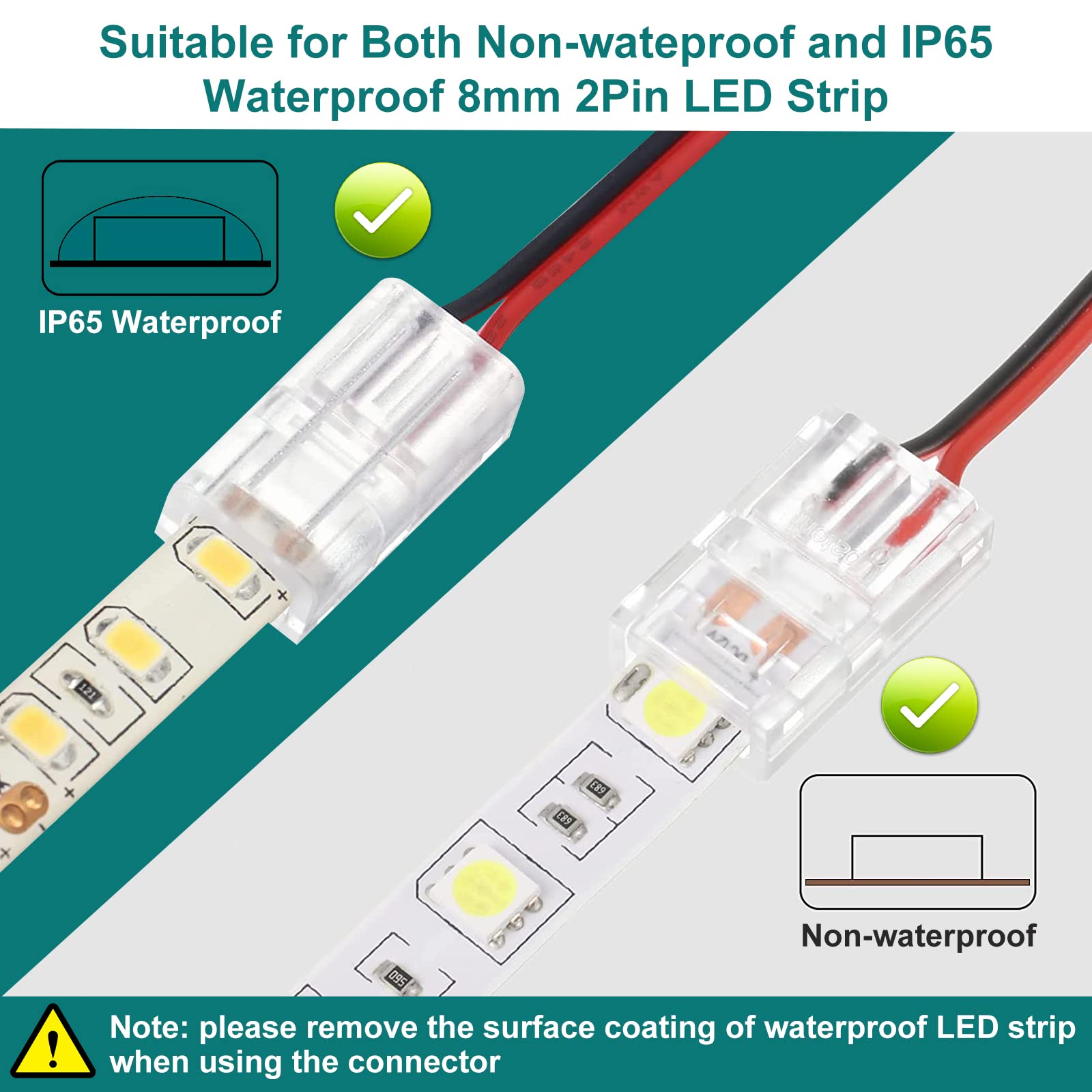

| Waterproof 2 Pin Connector | Sealed design with IP65+ rating for moisture protection | Outdoor lighting, garden installations, wet areas | Pros: Weather-resistant, durable; Cons: Higher cost, may require compatible LED strips |

| Low-Profile 2 Pin Connector | Slim design for minimal visual impact, often with flat connectors | Architectural lighting, retail, hospitality | Pros: Aesthetic appeal, easy concealment; Cons: May have lower current rating, limited robustness |

Soldered 2 Pin Connectors

Soldered connectors provide a permanent and electrically stable connection by fusing wires directly to the LED strip contacts. This type is ideal for industrial or large-scale commercial projects where reliability and longevity are paramount. B2B buyers should consider the skilled labor and time required for soldering but benefit from minimal signal loss and high durability, making it suitable for fixed installations in regions like the Middle East and Europe where long-term infrastructure is prioritized.

Clip-on 2 Pin Connectors

Clip-on connectors are designed for ease of use, allowing quick attachment without soldering or tools. This makes them perfect for temporary setups, retail displays, or prototyping in markets such as South America and Africa, where rapid deployment is often necessary. However, buyers should weigh the convenience against potential connection instability in high-vibration or long-term applications, ensuring proper quality checks for sustained performance.

Screw Terminal 2 Pin Connectors

Screw terminal connectors secure wires using screws, offering a balance between permanence and flexibility. They allow easy maintenance and wire replacement without soldering, which is advantageous in commercial and maintenance-heavy environments common in UAE and European facility projects. Buyers should note that these connectors are bulkier and may increase installation time but provide robust connections with reusable components.

Waterproof 2 Pin Connectors

Waterproof connectors feature sealed designs with IP65 or higher ratings to protect against moisture, dust, and outdoor conditions. These are essential for outdoor lighting, garden projects, and wet-area installations prevalent in African and Middle Eastern climates. While they come at a higher price point, the increased durability and protection justify the investment for buyers targeting long-lasting outdoor LED solutions.

Low-Profile 2 Pin Connectors

Low-profile connectors emphasize discreetness with slim, flat designs that blend seamlessly into architectural or retail lighting setups. This type is favored in hospitality and high-end commercial applications across Europe and South America where aesthetics are critical. Buyers must ensure that these connectors meet the required electrical specifications, as their compact size can limit current capacity and mechanical robustness.

Related Video: How to Cut, Connect & Power COB LED Strip Lighting | Solderless Connector Tutorial

Key Industrial Applications of led strip connector 2 pin

| Industry/Sector | Specific Application of led strip connector 2 pin | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Seamless illumination in display cases and shelving lighting | Enhances product visibility, drives customer engagement | Robust connectors with easy installation, low-profile design, and durability for high-traffic areas |

| Hospitality & Interior Design | Ambient and accent lighting in hotels, restaurants, and lounges | Creates mood and ambiance, flexible installation options | Waterproof or moisture-resistant connectors, aesthetic appeal, and compatibility with dimming systems |

| Automotive & Transportation | Interior cabin lighting and accent lighting in vehicles | Improves passenger experience, easy maintenance and upgrades | High vibration resistance, thermal stability, and compliance with automotive standards |

| Architectural & Outdoor Lighting | Facade, pathway, and garden lighting installations | Durable outdoor performance, energy-efficient and customizable | Weatherproof connectors with UV resistance, corrosion protection, and secure locking mechanisms |

| Manufacturing & Industrial Facilities | Task lighting and safety indicator lighting in production lines | Enhances worker safety and operational efficiency | High current capacity, secure connections for vibration-prone environments, and compliance with industrial safety standards |

Retail & Commercial Spaces

In retail environments, LED strip connector 2 pin systems are widely used to connect lighting strips in display cases and shelving units. These connectors enable quick, reliable installations that enhance product visibility and attract customers. For international B2B buyers in regions like South America and Europe, sourcing connectors that offer durability and a low-profile design is essential to maintain a clean aesthetic in busy retail spaces. Connectors must also support easy maintenance and replacement, reducing downtime in high-traffic commercial areas.

Hospitality & Interior Design

Hotels, restaurants, and lounges leverage 2 pin LED strip connectors for ambient and accent lighting solutions that create inviting atmospheres. These connectors facilitate flexible lighting layouts and support dimming capabilities, crucial for mood-setting environments. Buyers from the Middle East and Africa should prioritize moisture-resistant and waterproof connectors due to varying climate conditions, ensuring longevity and safety. Additionally, the aesthetic integration of connectors into interior designs is a key consideration for luxury hospitality projects.

Automotive & Transportation

The automotive sector uses 2 pin LED strip connectors for interior cabin and accent lighting, where vibration resistance and thermal stability are critical. These connectors enable modular lighting configurations that improve passenger comfort and allow for easy upgrades or repairs. For B2B buyers in regions such as the UAE and Colombia, compliance with automotive standards and sourcing connectors capable of withstanding harsh operational conditions is vital to ensure reliability and safety.

Architectural & Outdoor Lighting

Outdoor architectural projects rely on weatherproof 2 pin LED strip connectors for facade illumination, pathway lighting, and garden installations. These connectors must resist UV exposure, moisture, and corrosion to maintain consistent performance over time. International buyers, especially from Africa and Europe, need to ensure that connectors come with secure locking mechanisms and appropriate IP ratings to withstand local environmental challenges, reducing maintenance costs and prolonging system lifespan.

Manufacturing & Industrial Facilities

In industrial settings, 2 pin LED strip connectors are used for task lighting and safety indicator systems along production lines. The connectors must support high current loads and maintain secure connections despite vibrations and mechanical stresses common in factories. B2B buyers in industrial hubs across South America and the Middle East should focus on sourcing connectors that comply with industrial safety standards and offer robust mechanical and electrical performance to minimize downtime and enhance operational safety.

Related Video: LED light Strip connector For Beginners

Strategic Material Selection Guide for led strip connector 2 pin

When selecting materials for 2 pin LED strip connectors, international B2B buyers must balance electrical performance, environmental resistance, cost, and compliance with regional standards. The choice of material directly influences connector durability, ease of installation, and suitability for specific applications such as indoor, outdoor, or industrial environments. Below is a detailed analysis of four common materials used in 2 pin LED strip connectors.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a robust thermoplastic known for its high impact resistance, excellent dimensional stability, and good thermal tolerance (typically up to 120°C). It also offers good electrical insulation and moderate resistance to UV radiation and chemicals.

Pros & Cons:

– Pros: Lightweight, cost-effective, easy to mold for complex connector shapes, and provides adequate mechanical strength for most indoor applications.

– Cons: Lower resistance to prolonged UV exposure and harsh chemicals compared to specialized plastics, which may cause brittleness over time if used outdoors without additional coatings.

Impact on Application:

Polycarbonate connectors are ideal for indoor lighting setups such as residential or commercial office spaces where mechanical stress is moderate and exposure to moisture or chemicals is limited. However, in outdoor or high-humidity environments (common in parts of Africa and South America), additional sealing or protective coatings may be necessary.

International Considerations:

Buyers in regions like the UAE or Colombia should verify that PC connectors meet local fire safety standards (e.g., UL94 V-0 rating) and electrical insulation requirements. Polycarbonate connectors are widely accepted under ASTM and IEC standards, making them a reliable choice for general-purpose LED installations.

2. Nylon (Polyamide)

Key Properties:

Nylon is a versatile engineering plastic with excellent mechanical strength, abrasion resistance, and good thermal stability (up to ~150°C). It also exhibits good resistance to oils, greases, and some chemicals, along with inherent flame retardant properties when appropriately formulated.

Pros & Cons:

– Pros: Durable under mechanical stress, resistant to wear and chemical exposure, and performs well in both indoor and outdoor environments.

– Cons: Absorbs moisture, which can slightly alter its mechanical properties and dimensional stability, potentially affecting connector fit over time.

Impact on Application:

Nylon 2 pin connectors are well-suited for industrial and outdoor LED strip installations where connectors may face vibration, dust, or occasional moisture exposure. This makes them attractive for infrastructure projects or commercial lighting in Middle Eastern and African markets with harsh environmental conditions.

International Considerations:

Nylon connectors often comply with DIN and IEC standards for electrical components, which is important for buyers in Europe and the Middle East. Moisture absorption should be considered in humid climates, and buyers should request moisture-resistant grades or coatings where necessary.

3. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used thermoplastic with good electrical insulation, chemical resistance, and flame retardance. It has moderate thermal resistance (typically up to 105°C) and is flexible, which aids in cable strain relief.

Pros & Cons:

– Pros: Low cost, excellent electrical insulation, and good resistance to acids and alkalis. Its flexibility reduces mechanical stress on solder joints or terminals.

– Cons: Lower temperature tolerance and mechanical strength compared to PC or Nylon; can become brittle in cold climates or degrade under prolonged UV exposure.

Impact on Application:

PVC connectors are commonly used in budget-sensitive projects or temporary installations where flexibility and cost are priorities. They are less suitable for long-term outdoor use in high-temperature or high-UV environments like the Middle East or equatorial regions of Africa without additional UV stabilizers.

International Considerations:

PVC connectors generally meet ASTM and IEC insulation standards, making them acceptable for many global markets. Buyers in South America and Africa should verify compliance with local environmental regulations concerning PVC use and disposal due to its chlorine content.

4. Brass (with Nickel or Tin Plating)

Key Properties:

Brass is a metal alloy known for excellent electrical conductivity, corrosion resistance (especially when plated), and mechanical durability. Nickel or tin plating enhances corrosion resistance and solderability.

Pros & Cons:

– Pros: Superior electrical performance, excellent mechanical strength, and long service life even in harsh environments. Plated brass connectors resist oxidation and maintain low contact resistance.

– Cons: Higher material and manufacturing costs, increased weight, and more complex production processes compared to plastics.

Impact on Application:

Brass connectors are preferred in high-reliability or industrial LED lighting applications where stable electrical contact and durability are critical. This includes commercial buildings, outdoor installations, and industrial facilities common in Europe and the Middle East.

International Considerations:

Brass connectors with proper plating conform to international standards such as ASTM B16 for brass and IEC 60512 for connector performance. Buyers in regions with high humidity or saline environments (e.g., coastal areas in Africa or the UAE) benefit from the corrosion resistance of plated brass connectors.

Summary Table

| Material | Typical Use Case for led strip connector 2 pin | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor residential and commercial lighting | Lightweight, cost-effective, good impact resistance | Moderate UV and chemical resistance limits outdoor use | Low |

| Nylon (Polyamide) | Industrial and outdoor installations | High mechanical strength and chemical resistance | Moisture absorption affects dimensional stability | Medium |

| Polyvinyl Chloride (PVC) | Budget-sensitive or flexible wiring applications | Excellent electrical insulation and flexibility | Lower temperature tolerance and UV resistance | Low |

| Brass (Nickel/Tin Plated) | High-reliability industrial and outdoor connectors | Superior conductivity and corrosion resistance | Higher cost and manufacturing complexity | High |

This material selection guide empowers international B2B buyers to make informed decisions based on application demands, environmental conditions, and regional compliance requirements, ensuring optimal performance and longevity of their 2 pin LED strip connectors.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip connector 2 pin

Manufacturing Processes for LED Strip Connector 2 Pin

The production of 2 pin LED strip connectors involves a series of well-defined stages designed to ensure precision, durability, and electrical safety. Understanding these stages helps B2B buyers evaluate supplier capabilities and product quality, especially for complex international projects.

1. Material Preparation

Raw materials for connectors typically include copper or copper alloy for conductive parts, and high-grade plastics such as polycarbonate or nylon for insulation and housing. Material selection emphasizes electrical conductivity, mechanical strength, and heat resistance. Suppliers often source materials compliant with RoHS (Restriction of Hazardous Substances) directives to meet environmental and safety regulations in Europe and other regions.

2. Forming and Stamping

The conductive metal components are formed using precision stamping or metal forming machines. This process shapes pins and contact terminals with tight tolerances to ensure reliable electrical contact. Advanced tooling and CNC machines are often employed to maintain repeatability and reduce material waste. For connectors destined for outdoor or harsh environments (common in Middle East and Africa), additional plating (e.g., tin or gold) may be applied to enhance corrosion resistance.

3. Assembly

Assembly combines the metal terminals with insulating housings. This can be automated or manual depending on production scale. Automated assembly lines employ robotic arms and vision systems to insert and align components accurately, increasing throughput and consistency. Manual assembly is sometimes used for custom or low-volume orders. Soldering or ultrasonic welding may be used to secure wires to terminals, ensuring strong mechanical and electrical connections.

4. Finishing

Finishing includes surface treatments such as plating, coating, or polishing to improve conductivity and protect against oxidation. Connectors may also undergo sealing or encapsulation processes to achieve IP ratings (e.g., IP65, IP67) for waterproof or dustproof applications. Final packaging is designed to prevent damage during shipping and to facilitate ease of use in installation.

Quality Assurance and Control in Production

A rigorous quality assurance (QA) system is critical for LED strip connector suppliers to meet the expectations of international B2B buyers, especially those operating in demanding markets like UAE, Colombia, or South Africa. Quality control (QC) spans multiple stages and integrates international standards and testing protocols.

International and Industry Standards

– ISO 9001: The foundational quality management standard, ensuring consistent process control and continuous improvement. Buyers should prioritize suppliers with ISO 9001 certification as it demonstrates a structured approach to quality.

– CE Marking: Essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

– RoHS Compliance: Crucial for environmental safety, restricting hazardous substances in electronic components.

– UL and CSA Certifications: Particularly relevant for North American markets but increasingly requested globally to verify electrical safety.

– IP Ratings (Ingress Protection): Important for connectors used outdoors or in moist environments, certifying resistance to dust and water penetration.

Key Quality Control Checkpoints

1. Incoming Quality Control (IQC)

Materials are inspected upon receipt to verify chemical composition, mechanical properties, and conformity to specifications. For metals, this may involve spectrometry and hardness tests. For plastics, dimensional verification and flame retardancy tests are common.

2. In-Process Quality Control (IPQC)

During manufacturing, checkpoints ensure that stamping dimensions, assembly alignment, soldering quality, and plating thickness remain within tolerance. Inline visual inspections, automated optical inspection (AOI), and functional electrical tests (continuity and insulation resistance) are standard practices.

3. Final Quality Control (FQC)

Before shipment, finished connectors undergo comprehensive testing:

– Electrical Testing: Verifying continuity, contact resistance, and dielectric strength to prevent failures in the field.

– Mechanical Testing: Including pull tests on terminals and housing integrity under stress.

– Environmental Testing: Exposure to humidity, temperature cycling, and salt spray for corrosion resistance.

– Visual Inspection: Checking for defects such as burrs, cracks, or incomplete assembly.

Common Testing Methods for LED Strip Connectors

- Contact Resistance Measurement: Ensures low resistance paths to maintain LED brightness and prevent voltage drop.

- Pull Force Test: Confirms the mechanical strength of wire-to-connector bonds, critical for installations in vibration-prone environments.

- Thermal Cycling: Tests the connector’s ability to withstand temperature fluctuations without degradation.

- Waterproofing Tests: For connectors with IP ratings, immersion or spray tests simulate real-world exposure to moisture.

- X-Ray Inspection: Used in high-end manufacturing to detect internal defects or improper solder joints without damaging the product.

How B2B Buyers Can Verify Supplier Quality Control

For buyers from Africa, South America, the Middle East, and Europe, verifying supplier QC systems is essential to mitigate risk and ensure product reliability:

- Factory Audits: Conduct onsite or third-party audits to review manufacturing processes, equipment condition, and employee training. Audits should assess compliance with ISO 9001 and other relevant certifications.

- Quality Reports and Certificates: Request detailed QC reports, including batch test results, material certificates, and compliance declarations (e.g., RoHS, CE).

- Third-Party Inspection Services: Engage independent inspection agencies to perform random sampling and testing before shipment. This is especially valuable for large orders or when dealing with new suppliers.

- Sample Testing: Obtain product samples for in-house testing to verify electrical and mechanical performance under local environmental conditions.

- Supplier Quality Agreements: Establish clear agreements outlining QC expectations, testing frequencies, and defect handling procedures.

QC and Certification Nuances for International Buyers

- Regional Compliance Variations: Buyers in the UAE or European markets must prioritize CE marking and RoHS compliance, while South American buyers (e.g., Colombia) might also require certification aligned with local electrical safety standards such as INMETRO in Brazil or RETIE in Colombia.

- Environmental Conditions: Middle East and African buyers should emphasize testing for high temperature and humidity resistance due to challenging climates. Waterproof and dustproof connectors with appropriate IP ratings are often mandatory.

- Logistics and Traceability: International buyers benefit from suppliers who provide batch traceability and serialized documentation, facilitating warranty claims and regulatory audits.

- After-Sales Support: Quality assurance extends beyond manufacturing; suppliers offering robust technical support, replacement policies, and clear communication channels enhance buyer confidence and reduce operational risks.

By closely examining the manufacturing processes and quality assurance protocols of 2 pin LED strip connectors, international B2B buyers can make informed decisions, ensuring product longevity, safety, and compliance across diverse markets. Partnering with suppliers that demonstrate rigorous QC and certification adherence ultimately protects investments and strengthens supply chain resilience.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip connector 2 pin Sourcing

Cost Components in LED Strip Connector 2 Pin Sourcing

When sourcing 2 pin LED strip connectors, understanding the breakdown of cost components is crucial for effective procurement and budgeting. The primary cost drivers include:

- Materials: The base metals (usually copper or brass), plastics (such as PVC or nylon), and plating (e.g., tin, nickel) define raw material costs. Premium materials, like gold plating for corrosion resistance or high-grade polymers for durability, increase costs but enhance connector longevity.

- Labor: Assembly labor varies by region and complexity. Automated soldering or injection molding reduces labor costs, while manual assembly or quality checks add to labor expenses.

- Manufacturing Overhead: This includes facility utilities, equipment depreciation, and indirect labor supporting production.

- Tooling: Initial investment in molds, dies, and stamping tools for connector bodies and pins impacts unit cost, especially in low-volume orders.

- Quality Control (QC): Testing for electrical continuity, mechanical durability, and compliance with safety standards adds incremental costs but mitigates risks of defects.

- Logistics: Freight, customs duties, and packaging tailored for international shipping affect landed cost, particularly for buyers in Africa, South America, the Middle East, and Europe.

- Margin: Supplier profit margins vary based on market positioning, competition, and order volume.

Key Price Influencers for LED Strip Connector 2 Pin

Several factors influence the final price offered by suppliers:

- Order Volume & MOQ: Larger orders significantly reduce per-unit cost due to economies of scale and amortized tooling expenses. MOQ requirements differ by manufacturer and can be negotiated.

- Specifications & Customization: Connectors with special features—such as waterproof ratings (IP65/IP67), flexible cable lengths, or branded certifications—command higher prices.

- Material Quality: Higher-grade metals and flame-retardant plastics increase cost but improve reliability and compliance with international standards.

- Certifications & Compliance: RoHS, CE, UL, or other certifications required for certain markets add testing and documentation costs.

- Supplier Location & Capacity: Regional suppliers may offer competitive pricing due to lower labor costs or proximity to raw materials, but may have longer lead times or less stringent QC.

- Incoterms & Shipping Terms: Prices vary depending on whether the contract is FOB, CIF, DDP, etc. Buyers must account for additional import duties and local taxes under different terms.

Strategic Buyer Tips for International B2B Procurement

For buyers from Africa, South America, the Middle East, and Europe, several strategies can optimize cost-efficiency and procurement success:

- Negotiate Volume Discounts and Flexible MOQs: Consolidate orders across projects or with partners to meet supplier minimums and unlock better pricing tiers.

- Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also shipping costs, customs clearance, warranty terms, and potential downtime due to connector failures.

- Request Samples and Verify Quality: Investing in samples helps validate material quality and compatibility with existing LED strips, reducing costly returns.

- Leverage Local and Regional Suppliers: Where possible, sourcing closer to the end market reduces logistics complexity, lead times, and risks associated with customs delays.

- Clarify Incoterms Early: Ensure clarity on who bears freight, insurance, and import duties to avoid unexpected charges.

- Plan for Certification Needs: Align supplier capabilities with market-specific compliance requirements to prevent regulatory hurdles.

- Consider Long-Term Supplier Relationships: Building partnerships can lead to better pricing, priority production slots, and collaborative product development.

Pricing Nuances for Specific Regions

- Africa & South America: Import tariffs and customs can significantly inflate landed costs. Buyers should factor in local taxes and consider bonded warehouses or free trade zones to optimize cash flow.

- Middle East (e.g., UAE): Competitive port infrastructure and free zones often facilitate smoother logistics. However, stringent quality and certification standards necessitate careful supplier vetting.

- Europe: Compliance with RoHS and CE standards is mandatory, increasing upfront costs but reducing liability. Buyers benefit from robust logistics networks but must navigate VAT and customs regulations carefully.

Indicative Pricing Disclaimer

Pricing for 2 pin LED strip connectors varies widely based on volume, specifications, and supplier. Typical FOB unit prices range from $0.05 to $0.30 per connector at moderate volumes. Custom features and certifications can push prices higher. All prices should be treated as indicative; buyers are encouraged to request formal quotations tailored to their specific requirements and sourcing conditions.

By thoroughly understanding these cost drivers and pricing influencers, international B2B buyers can negotiate more effectively, optimize procurement strategies, and ensure sustainable supply chains for LED strip connector 2 pin sourcing.

Illustrative Image (Source: Google Search)

Spotlight on Potential led strip connector 2 pin Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip connector 2 pin’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip connector 2 pin

Critical Technical Properties of 2 Pin LED Strip Connectors

When sourcing 2 pin LED strip connectors for B2B applications, understanding their essential technical properties ensures compatibility, durability, and safety across diverse markets such as Africa, South America, the Middle East, and Europe.

-

Material Grade and Finish

Connectors are commonly made from high-quality copper alloys or brass with nickel or tin plating. These materials provide excellent electrical conductivity and corrosion resistance, crucial for long-term reliability, especially in humid or outdoor environments like the UAE or coastal regions in Colombia. For buyers, specifying material grade helps prevent premature failure and reduces maintenance costs. -

Current and Voltage Rating

Typically, 2 pin connectors support low-voltage DC systems (12V or 24V), with current ratings ranging from 2A to 10A depending on design. Selecting connectors with appropriate current and voltage ratings is critical to avoid overheating, voltage drops, or fire hazards. B2B buyers should align connector specifications with their LED strip power requirements to ensure safety compliance and system stability. -

Wire Gauge Compatibility

Connectors are designed to accommodate specific wire gauges (e.g., 18-22 AWG). Correct wire gauge matching ensures minimal resistance and secure mechanical connection. For longer wire runs common in commercial installations, using connectors compatible with thicker wires prevents voltage drop and ensures consistent brightness, a key consideration in professional lighting projects. -

Tolerance and Fit Precision

The mechanical tolerance of connector pins and housing affects connection stability and ease of installation. Tight tolerances reduce the risk of loose contacts, which can cause flickering or intermittent failures. For bulk buyers, verifying manufacturing tolerances ensures uniform product quality and reduces installation troubleshooting. -

Ingress Protection (IP) Rating

Many 2 pin connectors come with IP65 or higher ratings, indicating resistance to dust and water ingress. This is vital for outdoor or industrial applications where moisture exposure is common. Buyers targeting markets with harsh environmental conditions should prioritize connectors with certified IP ratings to enhance system longevity. -

Operating Temperature Range

Connectors must withstand operating temperatures typically from -20°C up to +60°C or higher. This property ensures performance stability in diverse climates, from the cold winters of Europe to the hot deserts of the Middle East. Understanding temperature limits helps buyers select connectors that maintain integrity without degradation.

Key Trade Terminology for LED Strip Connector 2 Pin Procurement

Navigating international B2B procurement requires fluency in common trade terms to streamline communication, negotiation, and logistics.

-

OEM (Original Equipment Manufacturer)

Refers to a manufacturer who produces components or products that are branded and sold by another company. For LED strip connectors, OEM partnerships allow buyers to obtain customized connectors with specific technical or branding requirements, enhancing product differentiation. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and budget effectively, especially when importing to regions with varying demand scales like Africa or South America. -

RFQ (Request for Quotation)

A formal document sent to suppliers asking for pricing, delivery, and terms for specified products. RFQs are essential for comparing multiple vendors and securing competitive pricing on LED strip connectors, particularly when evaluating quality certifications and lead times. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers regarding shipping, insurance, and customs clearance. Common terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) clarify who bears risk and costs at each stage, critical for cross-border transactions. -

Lead Time

The period between placing an order and receiving the goods. For LED strip connectors, shorter lead times can accelerate project timelines but might come at a premium. Buyers should negotiate lead times aligned with their project schedules and consider buffer times for customs clearance. -

Certification Standards

Refers to compliance with international or regional quality and safety standards, such as CE (Europe), RoHS (Restriction of Hazardous Substances), or UL (Underwriters Laboratories). Verifying certifications ensures connectors meet legal requirements and performance benchmarks, reducing the risk of import restrictions or product recalls.

By prioritizing these technical properties and mastering trade terminology, international B2B buyers can make informed purchasing decisions, optimize supply chain efficiency, and ensure high-quality LED strip lighting installations across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip connector 2 pin Sector

Market Overview & Key Trends

The global market for LED strip connector 2 pin products is experiencing robust growth fueled by the expanding adoption of LED lighting solutions across commercial, industrial, and residential sectors. Key drivers include increasing urbanization, smart city initiatives, and demand for energy-efficient lighting systems, particularly in regions such as Africa, South America, the Middle East, and Europe. Countries like the UAE and Colombia are investing heavily in infrastructure modernization and sustainable building projects, creating substantial opportunities for B2B buyers sourcing reliable LED connectors.

From a sourcing perspective, buyers are gravitating towards modular, easy-to-install connectors that reduce labor costs and installation time. The 2 pin connector’s simplicity aligns well with this trend, offering quick connections without the need for soldering, which is especially attractive in markets with growing DIY and small-scale commercial installations. Additionally, there is a marked preference for connectors that support waterproofing and dust resistance, addressing diverse environmental conditions across these regions—from humid tropical climates in South America to arid desert environments in the Middle East.

Technology advancements in connector design are also shaping procurement strategies. Innovations such as low-profile connectors, enhanced thermal performance, and compatibility with higher gauge wires enable longer LED strip runs without voltage drop, critical for large-scale commercial projects. Moreover, the shift towards smart lighting systems demands connectors that integrate smoothly with control modules, dimmers, and RGB LED strips, pushing suppliers to offer more versatile, interoperable products.

B2B buyers from emerging markets often prioritize cost-effectiveness combined with quality assurance, seeking suppliers who provide certification compliance (e.g., CE, RoHS) and offer scalable production capabilities. Strategic sourcing now involves partnering with manufacturers that can adapt quickly to custom specifications and deliver consistent quality to meet fluctuating demand cycles.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of LED strip connector 2 pin components. As global supply chains face increasing scrutiny, B2B buyers—especially in Europe and the Middle East—are emphasizing environmentally responsible sourcing practices. This includes selecting connectors made from recyclable and non-toxic materials such as flame-retardant plastics and lead-free metals, which reduce environmental impact and improve end-of-life recyclability.

Ethical supply chains are critical, with buyers demanding transparency in sourcing raw materials to avoid conflict minerals and ensure fair labor practices. Certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) are increasingly requested to validate supplier compliance. Buyers in Africa and South America, regions often challenged by regulatory enforcement, are leveraging these certifications to mitigate reputational risks and align with international standards.

Energy efficiency is another sustainability consideration. Connectors that support optimal current management and reduce power loss contribute indirectly to lowering the carbon footprint of LED lighting systems. Moreover, sourcing connectors with robust thermal management properties enhances product longevity, reducing waste and the frequency of replacements.

For buyers focused on green building certifications like LEED or BREEAM, selecting LED strip connectors that comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations is essential. These standards ensure products are free from harmful substances and support broader corporate sustainability goals.

Illustrative Image (Source: Google Search)

Brief Evolution & Historical Context

The 2 pin LED strip connector originated as a straightforward solution to simplify the electrical connections in flexible LED strip installations. Early connectors required soldering, which limited flexibility and increased installation time. Over time, manufacturers introduced clip and screw terminal connectors to accommodate faster assembly and easier maintenance, crucial for both permanent and temporary lighting setups.

As LED technology advanced, so did the connector designs, evolving to support higher currents, better waterproofing, and integration with smart lighting controls. This evolution reflects the broader trend of LED lighting becoming more modular, scalable, and user-friendly, enabling widespread adoption in global markets with diverse environmental and regulatory demands.

Today’s 2 pin connectors represent a mature technology that balances simplicity with performance, making them a staple component for international B2B buyers seeking reliable, cost-effective, and sustainable lighting solutions.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of led strip connector 2 pin

1. How can I effectively vet international suppliers of 2 pin LED strip connectors?

When sourcing 2 pin LED strip connectors globally, prioritize suppliers with verifiable certifications such as ISO 9001 for quality management and compliance with RoHS and CE standards. Request product samples and technical datasheets to verify specifications. Check for references or case studies involving clients in your region (Africa, South America, Middle East, Europe) to ensure the supplier understands local market requirements. Additionally, confirm their production capacity and lead times to assess reliability. Using third-party inspection services or audits can further mitigate risks in supplier selection.

2. What customization options are typically available for 2 pin LED strip connectors?

Many manufacturers offer customization tailored to B2B needs, including cable length, wire gauge, connector housing material (e.g., waterproof IP65/IP67 ratings), and terminal types (soldered, clip, or screw). Custom branding and packaging can also be arranged to enhance your product offering. For international buyers, it’s crucial to communicate your technical requirements clearly upfront and verify the supplier’s ability to meet those specs through prototypes or samples before committing to large orders.

3. What are common minimum order quantities (MOQs) and lead times for these connectors?

MOQs vary widely depending on supplier scale and customization level, typically ranging from 500 to 5,000 units. Standard off-the-shelf connectors usually have lower MOQs, while custom designs may require higher minimums. Lead times average between 3 to 6 weeks, influenced by production complexity and current demand. Buyers from regions like the UAE or Colombia should factor in additional shipping time and customs clearance. Negotiating MOQs or splitting orders with multiple suppliers can help manage inventory and cash flow.

4. What payment terms are customary in international B2B transactions for LED strip connectors?

Common international payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and increasingly, secure escrow services. Typical terms are 30% upfront deposit with balance paid upon shipment or after inspection. For new suppliers, consider smaller initial orders or using trade platforms that offer payment protection. Clear contract terms regarding payment schedules, penalties, and dispute resolution should be established to protect your interests, especially when dealing with suppliers across Africa, South America, or the Middle East.

5. How do I ensure quality assurance and compliance with international standards?

Request quality certificates such as CE, RoHS, and UL marks, which demonstrate compliance with European and international safety and environmental standards. Verify that connectors undergo electrical testing (e.g., voltage, current rating) and mechanical durability tests. Insist on factory quality control reports and consider independent third-party testing before shipment. For buyers in regulated markets, aligning with suppliers who maintain traceability and batch testing is critical to avoid product recalls or customs issues.

6. What logistics considerations should I be aware of when importing 2 pin connectors?

Plan for lead times that include manufacturing, inland transport, customs clearance, and last-mile delivery. Choose suppliers experienced with export documentation such as commercial invoices, packing lists, and certificates of origin to avoid delays. Consider freight options (air, sea, express courier) based on cost and urgency. For buyers in Africa, South America, and the Middle East, evaluate local import duties and taxes, and work with freight forwarders familiar with regional regulations to streamline logistics and reduce unexpected costs.

7. How can I resolve disputes or quality issues with overseas suppliers effectively?

Establish clear contractual terms covering product specifications, delivery schedules, inspection rights, and penalties for non-compliance. Maintain open communication channels and document all transactions. If quality issues arise, request photographic evidence and samples for assessment. Utilize third-party inspection agencies to provide impartial reports. For persistent disputes, international arbitration clauses or recourse through trade platforms can offer structured resolution. Building long-term relationships and choosing reputable suppliers reduces the likelihood of conflicts.

8. Are there specific considerations for sourcing 2 pin connectors for harsh environments?

Yes, for applications in outdoor or high-moisture areas common in many African and Middle Eastern markets, prioritize connectors with IP65 or higher waterproof ratings and corrosion-resistant materials. Verify thermal performance specifications to ensure connectors can handle local temperature extremes without degradation. Confirm supplier testing includes exposure to humidity, UV, and salt spray when relevant. Tailoring connector choice to environmental conditions improves system longevity and reduces maintenance costs, delivering greater value to your end customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip connector 2 pin

Effective sourcing of 2 pin LED strip connectors is pivotal for international B2B buyers aiming to optimize lighting installations across diverse markets such as Africa, South America, the Middle East, and Europe. Prioritizing connectors that combine reliability, compatibility with electrical specifications, and environmental resilience ensures superior system performance and longevity. Understanding the nuances of connector types—whether soldered, clip, or screw terminal—and their suitability for specific applications empowers buyers to reduce installation complexity and maintenance costs.

Strategic sourcing also means partnering with suppliers who offer quality assurance, scalability, and customization options to meet regional demands and regulatory standards. For buyers in regions like the UAE or Colombia, where climate and infrastructure vary widely, selecting connectors with appropriate IP ratings and thermal management capabilities is essential to withstand local conditions.

Looking ahead, the evolving LED lighting landscape calls for proactive engagement with manufacturers innovating in connector design and power management. Buyers should leverage data-driven insights and engineering expertise to anticipate future trends such as smart lighting integration and energy efficiency improvements. By adopting a forward-thinking procurement strategy, businesses can secure competitive advantages, enhance operational reliability, and foster sustainable growth in the global LED lighting market.