Introduction: Navigating the Global Market for connectors for led lights

The global market for connectors designed specifically for LED lights is evolving rapidly, driven by increasing demand for energy-efficient lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers—particularly those operating in dynamic regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of LED connectors is essential to secure reliable, cost-effective, and high-quality components that ensure seamless installation and optimal performance.

Connectors for LED lights serve as the critical interface between power sources and LED modules, directly impacting electrical safety, durability, and lighting efficiency. Selecting the right connector involves careful consideration of types (such as wire-to-wire, strip-to-strip, or quick connectors), materials (including copper alloys and corrosion-resistant coatings), and compatibility with various LED strip specifications. Additionally, manufacturing standards and quality control protocols vary globally, making supplier vetting a vital step for buyers seeking consistency and compliance with international safety standards.

This comprehensive guide covers all these facets and more:

– Detailed breakdown of connector types and their ideal applications

– Material insights and how they affect longevity and performance

– Manufacturing processes and quality assurance best practices

– Strategies for evaluating and selecting trustworthy global suppliers

– Cost factors influencing purchasing decisions and budget optimization

– Market trends shaping demand in key regions

– Answers to frequently asked questions to clarify common buyer concerns

By leveraging this knowledge, B2B buyers from Turkey to South Africa and beyond will be empowered to make informed sourcing decisions that minimize risk, reduce costs, and enhance product reliability. Whether upgrading existing LED systems or launching new projects, this guide provides actionable insights to navigate the complexities of the LED connector supply chain with confidence and precision.

Understanding connectors for led lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solderless Quick Connectors | Tool-free installation, clip-on design, compatible with standard LED strip widths | Retail lighting, temporary event setups, prototyping | + Fast installation, no special skills needed – Limited to specific strip sizes, less durable in harsh environments |

| Wire-to-Strip Connectors | Connects LED strips to power wires, often with screw or clamp terminals | Permanent installations, architectural lighting | + Secure connection, versatile wire gauge compatibility – Requires basic electrical skills, longer installation time |

| Cross and T-Shape Connectors | Enable LED strip connections at angles or intersections (90°, T-junctions) | Complex lighting designs, commercial signage | + Allows flexible layout design – May add connection points prone to failure if not sealed properly |

| Waterproof Connectors | Sealed, IP65 or higher rated, designed for outdoor and wet environments | Outdoor lighting, landscape lighting, industrial applications | + Protects against moisture and dust – Higher cost, bulkier size may affect installation aesthetics |

| PCB Connectors (Rigid/Flexible) | Direct connection to LED PCB pads, often snap-in or soldered types | High-volume manufacturing, customized LED modules | + Reliable electrical contact, supports automated assembly – Requires precise matching to PCB design, less field serviceable |

Solderless Quick Connectors are ideal for buyers needing rapid, tool-free installation of LED strips, especially for retail displays or temporary setups common in event management across Africa and the Middle East. Their clip-on design reduces labor costs but limits compatibility to specific strip widths and may not withstand industrial or outdoor environments. B2B buyers should verify strip size compatibility and consider environmental factors before procurement.

Wire-to-Strip Connectors provide a robust connection by linking LED strips directly to power cables with screw terminals or clamps. This type suits permanent architectural or commercial lighting projects prevalent in European and South American markets. While installation requires some electrical expertise, their versatility in wire gauge and secure contact make them a reliable choice for long-term use. Buyers should assess installation capabilities and ensure compliance with local electrical standards.

Cross and T-Shape Connectors facilitate complex LED strip layouts by enabling 90-degree turns and junctions. These connectors are essential for intricate signage and commercial lighting designs, allowing for creative freedom in spatially constrained environments. However, each additional connection point introduces potential failure risks, especially if not properly sealed. B2B buyers should prioritize quality sealing and consider environmental exposure when specifying these connectors.

Waterproof Connectors come with IP65 or higher ingress protection, designed for outdoor and industrial LED lighting applications common in regions with harsh weather conditions such as South Africa or Turkey. These connectors protect against moisture, dust, and corrosion, ensuring durability and longevity. The trade-off is a higher unit cost and sometimes bulkier form factor, which may affect installation aesthetics. Buyers should weigh environmental demands against budget constraints.

PCB Connectors are specialized connectors designed for direct attachment to LED PCBs, often used in high-volume manufacturing or customized module production. They offer reliable electrical contact and compatibility with automated assembly lines, which is advantageous for large-scale industrial buyers in Europe and the Middle East. However, these connectors require precise PCB design alignment and are less suited for field modifications. Buyers should collaborate closely with manufacturers to ensure compatibility and production efficiency.

Related Video: When, Why and How to Use Wired Connectors in Hobby LED Projects

Key Industrial Applications of connectors for led lights

| Industry/Sector | Specific Application of connectors for led lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural Lighting | Connecting LED strips and modules in large-scale building projects | Enables flexible, scalable lighting design with easy installation and maintenance | Durability under varied climate conditions, compatibility with LED types, certifications for safety and energy efficiency |

| Automotive Manufacturing | LED connectors for vehicle interior and exterior lighting systems | Ensures reliable, vibration-resistant connections for safety and aesthetic lighting | High resistance to temperature, moisture, and vibrations; compliance with automotive standards |

| Retail & Commercial Displays | Modular LED lighting connectors for signage and display lighting | Quick assembly and reconfiguration of lighting to enhance product visibility and customer engagement | Ease of installation, aesthetic integration, compatibility with different LED configurations |

| Industrial Automation | LED connectors for machine status indicators and workspace lighting | Improves operational efficiency and safety with clear visual signals | Robustness to industrial environments, resistance to dust and chemicals, secure locking mechanisms |

| Outdoor & Street Lighting | Waterproof connectors for LED streetlights and outdoor fixtures | Long-lasting, weather-resistant connections reduce maintenance costs and downtime | IP-rated waterproofing, UV resistance, and compliance with local electrical standards |

Architectural Lighting

In architectural projects, connectors for LED lights are crucial for linking LED strips and modules across complex building layouts. These connectors allow designers and contractors to implement flexible lighting schemes that can be easily modified or expanded. For international buyers in regions such as Europe and the Middle East, sourcing connectors that meet strict safety certifications (e.g., CE, RoHS) and perform well under diverse climate conditions is essential. Durable connectors also reduce long-term maintenance costs and ensure consistent light quality.

Automotive Manufacturing

Automotive manufacturers use specialized LED connectors to integrate lighting systems within vehicles, including headlights, interior ambient lighting, and indicator lights. These connectors must withstand extreme vibrations, temperature fluctuations, and moisture exposure. B2B buyers from South Africa and Turkey should prioritize connectors certified to automotive standards (such as ISO/TS 16949) and designed for high reliability to avoid costly recalls or warranty claims. Robust connectors enhance vehicle safety and customer satisfaction.

Retail & Commercial Displays

LED connectors enable modular and customizable lighting setups in retail environments, facilitating quick installation and easy reconfiguration of displays and signage. This adaptability helps businesses respond rapidly to marketing changes and seasonal promotions. For buyers in South America and Africa, sourcing connectors that combine aesthetic appeal with strong electrical performance is vital. Connectors should support various LED types and allow seamless integration with existing lighting infrastructure.

Industrial Automation

In industrial settings, LED connectors are used for machine status indicators, safety signals, and workspace illumination. These connectors must endure harsh conditions such as dust, chemical exposure, and mechanical stress. Businesses in industrial hubs across Europe and the Middle East should focus on acquiring connectors with secure locking features and high ingress protection ratings (IP65 or higher). Reliable connectors minimize downtime and improve worker safety by ensuring continuous operation of visual indicators.

Outdoor & Street Lighting

Outdoor LED lighting systems rely on waterproof connectors to maintain electrical integrity despite exposure to rain, dust, and sunlight. This application is particularly relevant for municipalities and infrastructure projects in Africa and South America, where weather conditions can be challenging. Buyers should prioritize IP67 or higher-rated connectors with UV resistance and compliance with local electrical codes. Investing in high-quality connectors reduces maintenance frequency and enhances public safety through dependable street lighting.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for connectors for led lights

Selecting the right material for connectors in LED lighting systems is crucial for ensuring reliability, longevity, and compliance with regional standards. International B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, must consider environmental conditions, regulatory frameworks, and cost-effectiveness when choosing connector materials.

Copper and Copper Alloys

Key Properties: Copper offers excellent electrical conductivity, thermal resistance, and good mechanical strength. It withstands moderate temperature ranges typically up to 150°C and has good corrosion resistance when properly plated (e.g., with tin or nickel).

Pros & Cons: Copper connectors provide superior electrical performance and durability, making them ideal for high-quality LED lighting applications. However, copper is relatively expensive and prone to oxidation if not adequately protected, which can impact long-term reliability.

Impact on Application: Copper connectors are preferred in environments where electrical efficiency and heat dissipation are critical, such as industrial or architectural LED installations. They perform well in dry to moderately humid conditions but require plating or coatings for harsh or corrosive environments.

Considerations for International Buyers: Buyers in Europe and the Middle East often demand compliance with ASTM B152 or DIN EN standards for copper alloys. In Africa and South America, where humidity and dust can be challenges, copper connectors with robust plating are advisable to prevent corrosion and maintain conductivity.

Polycarbonate (PC) and Other Engineering Plastics

Key Properties: Polycarbonate is a thermoplastic with excellent impact resistance, transparency, and thermal stability up to about 135°C. It offers good electrical insulation and resistance to UV radiation and chemicals.

Pros & Cons: Plastic connectors are lightweight, cost-effective, and easy to manufacture in complex shapes. However, they generally have lower mechanical strength and thermal conductivity compared to metals, limiting their use in high-current or high-temperature applications.

Impact on Application: Plastic connectors are widely used in residential and commercial LED lighting where electrical loads are moderate and aesthetic design flexibility is important. Their insulation properties make them suitable for connectors exposed to moisture or dust.

Considerations for International Buyers: In regions like South Africa and Turkey, compliance with IEC 60695 for flammability and UL94 standards is often required. Buyers should verify the plastic’s resistance to local environmental factors such as UV exposure in the Middle East or humidity in tropical African zones.

Stainless Steel

Key Properties: Stainless steel connectors offer excellent corrosion resistance, mechanical strength, and temperature tolerance up to 500°C depending on the grade. They are non-magnetic and highly durable.

Pros & Cons: Stainless steel is ideal for harsh environments, including outdoor and marine applications. However, it has lower electrical conductivity, necessitating the use of plated copper contacts inside connectors. It is also heavier and more expensive than plastic alternatives.

Impact on Application: Stainless steel connectors are favored in industrial LED lighting, outdoor installations, and regions with high salinity or pollution levels. They provide robust mechanical protection and longevity.

Considerations for International Buyers: European and Middle Eastern buyers often require compliance with EN 10088 or ASTM A240 standards. For African and South American markets, stainless steel’s corrosion resistance is a significant advantage in coastal or industrial zones, justifying the higher cost.

Brass

Key Properties: Brass, an alloy of copper and zinc, combines good electrical conductivity with excellent corrosion resistance and mechanical strength. It typically withstands temperatures up to 200°C.

Pros & Cons: Brass connectors are cost-effective and easier to machine than pure copper, providing a good balance of conductivity and durability. However, brass can tarnish over time and may require plating for enhanced corrosion resistance.

Impact on Application: Brass is commonly used in LED connectors for commercial lighting and applications where moderate electrical performance and durability are required. It performs well in indoor and some outdoor environments.

Considerations for International Buyers: Buyers in Europe and Turkey often look for brass connectors meeting DIN 17660 or ASTM B16 standards. In South America and Africa, brass connectors with protective coatings are preferred to withstand humidity and prevent tarnishing.

| Material | Typical Use Case for connectors for led lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper & Alloys | High-performance industrial and architectural LED systems | Superior electrical conductivity and heat dissipation | Higher cost and susceptibility to oxidation without plating | High |

| Polycarbonate & Plastics | Residential and commercial LED lighting with moderate electrical loads | Lightweight, excellent insulation, and UV resistance | Lower mechanical strength and thermal conductivity | Low |

| Stainless Steel | Outdoor, marine, and industrial LED lighting in harsh environments | Exceptional corrosion resistance and mechanical durability | Poor electrical conductivity, heavier, and more expensive | High |

| Brass | Commercial LED lighting requiring balanced conductivity and durability | Good conductivity with corrosion resistance and machinability | Tarnishes over time, may require plating | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for connectors for led lights

Overview of Manufacturing Processes for Connectors for LED Lights

The production of connectors for LED lights involves several critical manufacturing stages designed to ensure durability, electrical safety, and ease of installation. Understanding these stages provides international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, with insight into supplier capabilities and product reliability.

1. Material Preparation

The process begins with selecting high-quality raw materials. Typically, copper alloys or brass are chosen for conductive elements due to their excellent electrical conductivity and corrosion resistance. Insulating components are often made from flame-retardant plastics such as polycarbonate (PC) or polyvinyl chloride (PVC). Material preparation includes precision cutting, cleaning, and sometimes plating (e.g., tin or nickel plating) to enhance corrosion resistance and conductivity.

2. Forming and Stamping

Conductive parts are shaped using stamping or progressive die cutting techniques, allowing for high-volume, consistent production of metal contacts. This stage demands precision to maintain tight tolerances critical for reliable electrical connections. Plastic components are commonly produced via injection molding, which offers complex geometries and high repeatability.

3. Assembly

Assembly typically involves fitting metal contacts into the molded plastic housing. Automated or semi-automated machinery is often used to ensure precise placement and secure locking mechanisms. Some connectors include soldered joints or crimped terminals, requiring additional equipment for consistent quality.

4. Finishing and Packaging

Final finishing steps may include surface treatments such as ultrasonic cleaning or additional plating to improve durability. Connectors are then visually inspected and packaged under controlled conditions to prevent contamination or damage during transit.

Quality Assurance and Control in Connector Manufacturing

Robust quality assurance (QA) and quality control (QC) systems are essential to meet stringent international standards and satisfy the expectations of global B2B buyers.

Relevant International Standards:

– ISO 9001: The cornerstone for quality management systems, ensuring consistent product quality and continual improvement. Buyers should prioritize suppliers certified to ISO 9001, as this reflects systematic process control and documentation.

– CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements, particularly relevant for European markets.

– RoHS Compliance: Restricts hazardous substances in electronic components, critical for environmental regulations globally.

– UL Certification: Widely recognized in the Americas and parts of Europe for electrical safety compliance.

– IEC Standards: International Electrotechnical Commission standards such as IEC 60529 (IP ratings) for ingress protection are crucial for connectors exposed to environmental elements.

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials and components undergo strict inspection, including dimensional checks, material certification verification, and surface quality assessment.

– In-Process Quality Control (IPQC): Continuous monitoring during stamping, molding, and assembly stages using statistical process control (SPC) to detect deviations early. This includes electrical continuity tests and mechanical fit assessments.

– Final Quality Control (FQC): Comprehensive testing of finished connectors, including visual inspection, mechanical durability tests (e.g., insertion/extraction force), and electrical performance tests.

Common Testing Methods:

– Electrical Testing: Measures continuity, insulation resistance, and contact resistance to ensure reliable signal and power transmission.

– Mechanical Testing: Includes pull-out force, vibration resistance, and mating cycle tests to simulate real-world usage.

– Environmental Testing: Exposure to humidity, temperature cycling, and salt spray tests validate resistance to corrosion and environmental stress.

– Flammability Testing: Verifies compliance with fire safety standards relevant for plastic components.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, particularly those operating in diverse regulatory environments such as Africa, South America, the Middle East, and Europe, ensuring supplier QC integrity is paramount. Here are actionable strategies:

1. Supplier Audits

Conduct on-site or virtual audits focusing on manufacturing capabilities, process controls, and QA/QC documentation. Audits should verify adherence to ISO 9001 and relevant industry certifications. Buyers can request audit reports or conduct independent third-party assessments.

2. Review of QC Documentation

Request detailed inspection reports, material test certificates, and batch traceability records. These documents provide transparency on material origins and production consistency.

3. Third-Party Testing and Certification

Engage accredited laboratories to perform independent testing on sample shipments, especially for electrical safety and environmental compliance. This is particularly important for markets with strict import regulations.

4. Sample Evaluation

Order pre-production samples for in-house testing or pilot projects. This allows buyers to assess connector compatibility, durability, and performance under local operating conditions.

QC and Certification Nuances for International Markets

Buyers from different regions face unique challenges related to quality standards and regulatory compliance:

- Africa and South America: Regulatory frameworks may be evolving, but importers increasingly demand compliance with international standards (ISO, CE, RoHS) to ensure safety and market acceptance. Buyers should verify supplier certifications and consider additional local testing requirements.

- Middle East: Countries often require conformity with GCC standards alongside international certifications. Environmental durability (e.g., heat and dust resistance) is critical due to harsh climates, necessitating rigorous environmental testing.

- Europe (including Turkey): Compliance with CE marking and RoHS is mandatory. Buyers should insist on comprehensive technical files and declarations of conformity. Additionally, compatibility with European electrical standards and IP ratings is essential.

Key Takeaways for B2B Buyers

- Demand transparency on manufacturing processes to ensure materials and assembly methods align with your performance and durability expectations.

- Prioritize suppliers with ISO 9001 and relevant certifications such as CE, UL, and RoHS to mitigate compliance risks.

- Implement multi-tier QC verification through audits, documentation review, and third-party testing to confirm supplier quality.

- Understand regional regulatory nuances and ensure connectors meet local market standards, especially regarding environmental resilience and electrical safety.

- Leverage sample testing to validate product suitability in your specific application and operating conditions before committing to bulk orders.

By thoroughly vetting manufacturing processes and quality assurance practices, B2B buyers can secure reliable, compliant connectors for LED lighting projects that meet global standards and local market demands.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for connectors for led lights Sourcing

Understanding the Cost Components of LED Light Connectors

When sourcing connectors for LED lights, international B2B buyers must first grasp the core cost components shaping the product price. These include:

- Materials: The primary cost driver, typically involving metals like copper or alloys for conductivity, plastics or silicone for insulation, and sometimes gold or nickel plating for corrosion resistance and better electrical contact.

- Labor: Skilled labor costs vary significantly by manufacturing location, impacting final pricing. Regions with higher wage expectations, such as Europe, may reflect increased labor costs compared to Asian or some Eastern European suppliers.

- Manufacturing Overhead: This covers factory utilities, equipment maintenance, and indirect labor, which can fluctuate depending on the production scale and efficiency.

- Tooling: Initial mold creation and setup for injection molding or stamping can be a significant upfront expense, especially for customized connectors.

- Quality Control (QC): Rigorous testing and certification processes, such as UL, CE, or RoHS compliance, add to costs but are essential for market acceptance and reliability.

- Logistics: Shipping, customs duties, and local distribution costs, which vary widely for buyers in Africa, South America, the Middle East, and Europe, must be factored into the landed cost.

- Margin: Supplier profit margins, which may be negotiable depending on order volume and relationship.

Key Pricing Influencers to Consider

Several factors influence the final price you pay for LED light connectors:

- Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock substantial price breaks. However, some suppliers set high MOQs that may challenge smaller buyers, particularly in emerging markets.

- Specifications and Customization: Tailored connectors with unique pin configurations, waterproofing, or special materials cost more due to tooling and production complexity.

- Material Quality and Certifications: Higher-grade materials and certifications (e.g., IP67 waterproof rating, UL listing) increase costs but reduce risks of failures and returns.

- Supplier Location and Reputation: Established suppliers with proven track records and certifications may charge premiums but offer reliability and post-sale support.

- Incoterms: Terms such as FOB, CIF, or DDP impact logistics costs and risk allocation. Buyers should understand how these terms affect total landed cost and customs responsibilities.

Actionable Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Based on Volume and Commitment: Leverage forecasted volume and repeat business potential to negotiate better pricing and MOQs, especially important for buyers in Africa and South America where capital availability can be limited.

-

Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also quality certifications, warranty, lifespan, and supplier support. A lower upfront cost may lead to higher replacement and downtime costs.

-

Request Samples and Conduct QC Checks: Before bulk purchasing, test samples for compatibility and durability to avoid costly returns or field failures.

-

Factor in Logistics and Duties: For Middle Eastern and African buyers, port charges, customs clearance, and inland transportation can significantly add to the cost. Negotiating Incoterms like DDP can simplify import processes but may raise unit costs.

-

Understand Market Pricing Nuances: European buyers, including Turkey, often face higher labor and compliance costs, so consider sourcing from Eastern Europe or Asia for price competitiveness without sacrificing quality.

-

Use Consolidated Shipping: To reduce freight costs, consolidate orders or source multiple product types from the same supplier when possible.

-

Build Long-Term Supplier Relationships: Establishing trust and communication can lead to tailored pricing, better payment terms, and priority production scheduling.

Indicative Pricing Disclaimer

Prices for LED light connectors vary widely based on specifications, order size, and sourcing region. For example, basic LED strip connectors may range from $0.10 to $0.50 per unit in bulk, while customized, waterproof connectors with certifications can cost upwards of $1.50 each. Buyers should request detailed quotations and factor in all ancillary costs to evaluate true pricing.

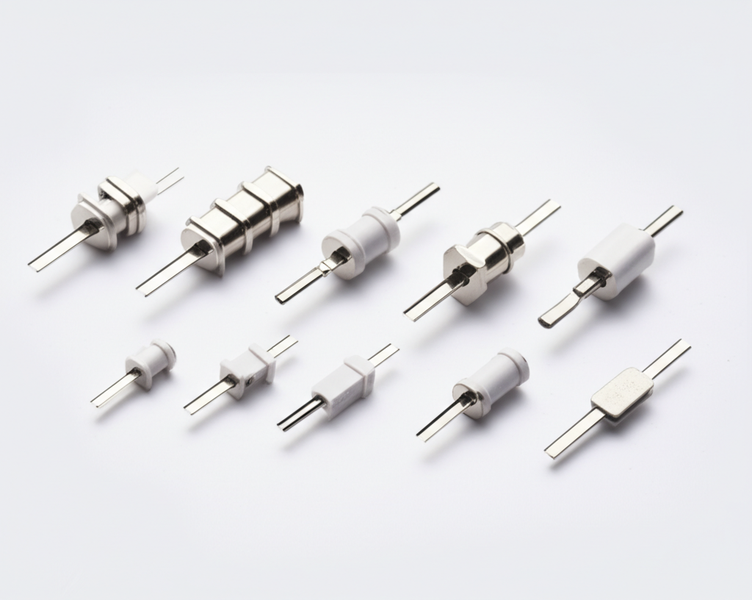

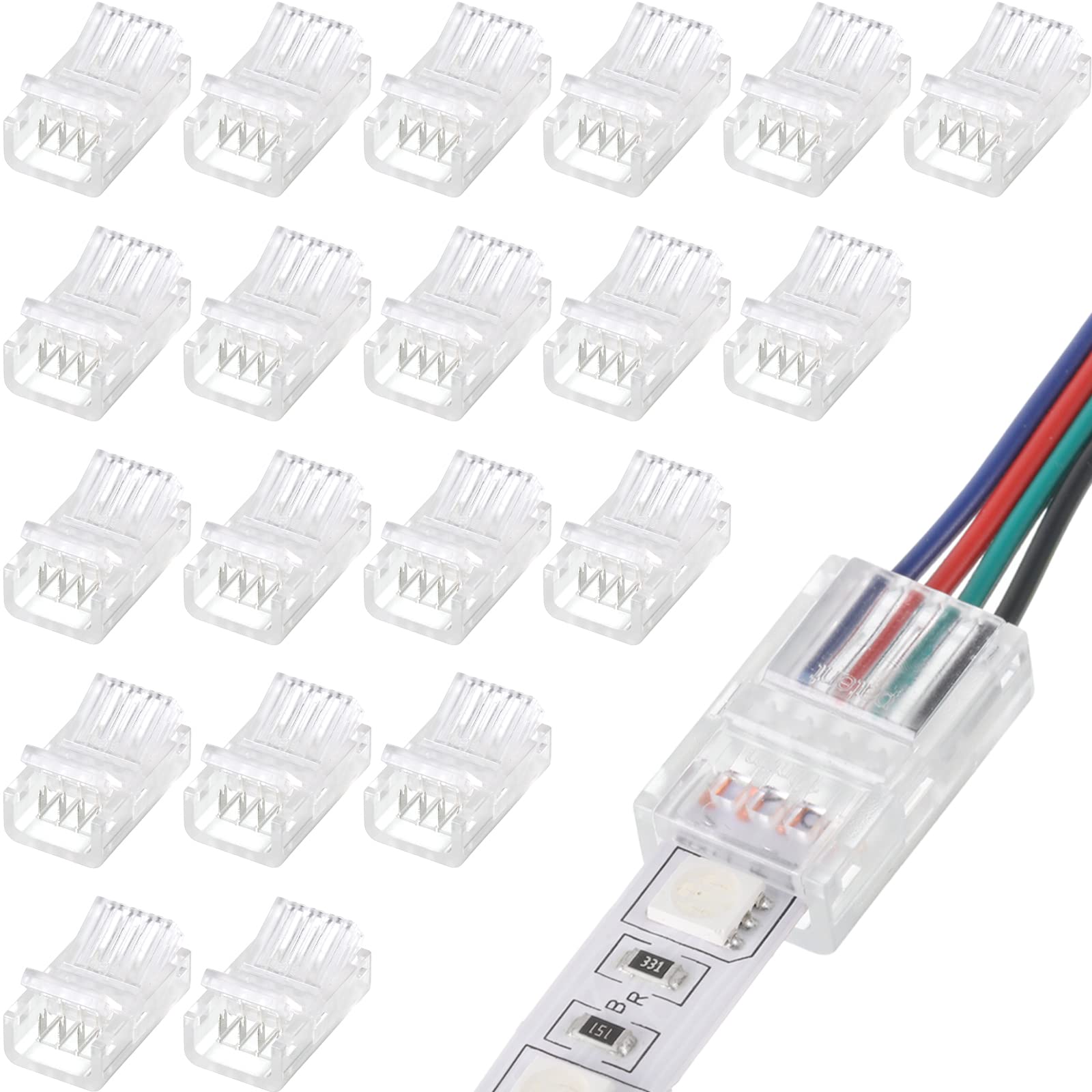

Illustrative Image (Source: Google Search)

By carefully analyzing these cost components and pricing influencers, international B2B buyers can optimize sourcing strategies, ensuring competitive pricing while maintaining quality and supply reliability in diverse markets across Africa, South America, the Middle East, and Europe.

Spotlight on Potential connectors for led lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘connectors for led lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for connectors for led lights

Key Technical Properties of Connectors for LED Lights

When sourcing connectors for LED lighting projects, understanding the critical technical specifications ensures compatibility, reliability, and long-term performance. Below are essential properties every international B2B buyer should evaluate:

-

Material Grade and Conductivity

Connectors are typically made from copper alloys with surface plating such as tin, nickel, or gold. High-grade conductive materials ensure minimal electrical resistance and efficient current flow, which is vital for maintaining LED brightness and longevity. For buyers, insisting on certified material grades prevents failures caused by corrosion or poor conductivity, especially in humid or industrial environments common in regions like South Africa or Turkey. -

Voltage and Current Rating

Each connector is rated for a maximum voltage and current capacity, often expressed in volts (V) and amperes (A). Selecting connectors with appropriate ratings avoids overheating and electrical hazards. For large-scale installations, ensuring connectors meet or exceed the project’s power demands reduces downtime and maintenance costs. -

Tolerance and Fit Precision

Tolerance refers to the allowable deviation in connector dimensions and electrical contact quality. Tight tolerances guarantee a secure, vibration-resistant connection, crucial in transportation or outdoor lighting applications prevalent in Middle Eastern markets. Buyers should request tolerance specifications to ensure connectors fit perfectly with LED strips or wiring harnesses. -

Ingress Protection (IP) Rating

The IP rating defines the connector’s resistance to dust and water ingress. For outdoor or industrial LED lighting, connectors with IP65 or higher ratings are recommended to prevent damage and maintain electrical safety. This property is critical for buyers in regions with harsh climates, such as parts of Africa and the Middle East. -

Thermal Stability

Connectors must withstand operating temperatures generated by LED systems without deforming or losing connectivity. Thermal ratings indicate the maximum temperature the connector can tolerate. Understanding thermal limits helps buyers avoid product failures in high-temperature installations or enclosed environments. -

Compatibility with LED Types and Profiles

Different LED strips and modules may require specific connector types (e.g., 2-pin, 4-pin, quick connectors, or solderless connectors). Buyers should verify compatibility with their LED lighting profiles and installation methods to streamline assembly and reduce technical issues during deployment.

Common Industry and Trade Terminology for LED Connectors

Navigating international trade requires familiarity with key terms that frequently appear in negotiations and contracts. Here are several important terms with clear explanations:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce connectors that are branded and sold by another company. For B2B buyers, OEM partnerships can offer customized connectors tailored to specific LED lighting designs, enabling differentiation in competitive markets such as Europe or South America. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. Understanding MOQ helps buyers plan procurement budgets and inventory. For buyers in emerging markets, negotiating MOQs can be critical to balancing initial investment with supply chain flexibility. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific connector models or quantities. RFQs are a standard step in international purchasing, enabling buyers to compare offers and select the best value while ensuring technical compliance. -

Incoterms (International Commercial Terms)

A set of standardized trade terms (e.g., FOB, CIF, DDP) that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Knowing Incoterms is essential for B2B buyers to accurately calculate landed costs and manage logistics across borders, especially when importing connectors into Africa or the Middle East. -

Lead Time

The time interval between placing an order and receiving the product. Lead times impact project schedules and inventory management. Buyers should clarify lead times upfront to avoid delays in large lighting projects or seasonal demand spikes. -

Connector Type (e.g., Quick Connect, Solderless, Cross Connector)

Describes the mechanical and electrical design of the connector. Quick connectors enable tool-free installation, speeding up assembly, which is advantageous for large-scale commercial lighting projects. Understanding connector types helps buyers specify products that match installation expertise and project requirements.

By focusing on these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that optimize performance, cost-efficiency, and supply chain reliability for LED lighting connector procurement.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the connectors for led lights Sector

Market Overview & Key Trends

The global market for connectors used in LED lighting is experiencing robust growth driven by widespread adoption of LED technologies across residential, commercial, and industrial sectors. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe (including Turkey and South Africa), understanding the evolving market dynamics is crucial for strategic sourcing and competitive advantage.

Key Market Drivers:

– Rising LED Penetration: Increasing demand for energy-efficient lighting solutions globally fuels the need for reliable connectors that ensure optimal electrical performance and safety.

– Urbanization and Infrastructure Development: Rapid urban growth and infrastructure projects in emerging markets, especially in Africa and South America, create significant opportunities for bulk procurement of LED connectors.

– Technological Innovation: Advances such as quick-connect and waterproof connectors enhance installation speed and durability, meeting the requirements of harsh environments common in Middle Eastern and African markets.

– Customization and Modular Designs: Buyers are increasingly seeking connectors compatible with diverse LED strip types and configurations, enabling flexible lighting designs and easier maintenance.

Sourcing Trends:

– Shift Towards Integrated Supply Chains: Many B2B buyers prefer suppliers who offer end-to-end solutions — from connectors to aluminum profiles and LED drivers — to simplify procurement and ensure compatibility.

– Preference for Certified and Standardized Components: Compliance with international certifications (e.g., UL, CE) is critical, particularly for buyers in Europe and the Middle East, to meet regulatory requirements and guarantee product safety.

– Local vs. Global Sourcing Balance: While global manufacturers from Asia remain dominant, regional distributors and manufacturers in Europe and the Middle East are gaining ground by providing faster delivery and localized support.

– Digital Procurement Platforms: Increasing use of online catalogs, instant quoting tools, and streamlined logistics enhances transparency and reduces lead times, benefiting buyers in geographically dispersed markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of LED connectors, reflecting broader corporate responsibility and regulatory trends worldwide. For B2B buyers, sourcing connectors that align with environmental and ethical standards can enhance brand reputation and compliance.

Environmental Impact:

– Connectors often contain metals and plastics that, if not responsibly sourced, contribute to pollution and resource depletion.

– Sustainable sourcing prioritizes materials with lower carbon footprints, such as recycled plastics and lead-free metals.

– Energy-efficient manufacturing processes and minimal packaging waste also play a vital role in reducing environmental impact.

Ethical Supply Chains:

– Ensuring transparency and traceability within the supply chain helps avoid unethical labor practices and conflict minerals.

– Buyers increasingly demand certifications such as RoHS (Restriction of Hazardous Substances) and REACH compliance to confirm the absence of harmful chemicals.

– Partnering with suppliers committed to fair labor practices and environmental stewardship mitigates risks and aligns with global sustainability goals.

Green Certifications and Materials:

– Look for connectors certified under recognized eco-labels or manufactured with biodegradable or recyclable components.

– Use of halogen-free materials and adherence to eco-design principles supports circular economy initiatives.

– Suppliers offering product lifecycle analyses and end-of-life recycling programs provide added value for sustainability-conscious buyers.

Brief Evolution and Industry Context

The evolution of connectors for LED lighting reflects the broader transformation of lighting technology from incandescent to solid-state solutions. Early LED connectors were simple, often requiring manual soldering and lacking standardization. As LED strip lighting gained popularity, particularly in architectural and decorative applications, the need for versatile, easy-to-install connectors became apparent.

Modern connectors now emphasize plug-and-play designs, compatibility with various LED types (single-color, RGB, addressable LEDs), and environmental protection features such as IP65/IP67 ratings for outdoor use. This evolution supports faster installation, reduced labor costs, and enhanced reliability — factors that resonate strongly with international B2B buyers managing complex projects across diverse climatic conditions.

For buyers in emerging markets, this progression means access to more sophisticated products that are easier to source and integrate, enabling the expansion of LED lighting applications in commercial, industrial, and public infrastructure sectors.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of connectors for led lights

-

How can I effectively vet suppliers of LED light connectors for international B2B sourcing?

To ensure reliability, start by verifying the supplier’s business credentials and certifications such as ISO, CE, or RoHS compliance relevant to LED connectors. Request samples to evaluate quality firsthand. Check references or reviews from other international buyers, especially those in similar regions like Africa or Europe. Confirm the supplier’s experience with export processes and their ability to handle customs documentation. Engaging suppliers with transparent communication and established trade histories reduces risks in cross-border transactions. -

Is customization of LED connectors possible, and what should I consider when requesting it?

Many manufacturers offer customization options including connector types, wire length, and waterproofing features. When requesting customization, provide detailed technical specifications and intended application environments. Clarify minimum order quantities (MOQs) and additional costs upfront. For international buyers, ensure that customized connectors meet local standards and certifications. Early engagement with suppliers about design feasibility and lead times helps avoid production delays and ensures the product fits your market needs. -

What are typical minimum order quantities (MOQs) and lead times for LED connector orders from overseas suppliers?

MOQs vary widely depending on the complexity of the connector and supplier scale; they often range from a few hundred to several thousand units. Lead times typically span 3 to 8 weeks, factoring in production and shipping. For buyers in regions like South America or the Middle East, plan for additional transit time and customs clearance. Negotiate MOQs if your project size is smaller, and consider consolidating orders with other buyers or products to meet thresholds cost-effectively. -

Which payment terms are common in international B2B transactions for LED connectors, and how can buyers protect themselves?

Suppliers typically request 30% upfront deposit with balance paid before or after shipment via methods like wire transfer, letter of credit (L/C), or PayPal for smaller amounts. Letters of credit provide higher security for buyers by ensuring payment only upon fulfillment of contract terms. Always request proforma invoices and confirm payment details directly with suppliers. Using escrow services or trade finance options can also reduce risks, especially when dealing with new or distant suppliers. -

What quality assurance measures and certifications should I expect from LED connector suppliers?

High-quality LED connectors should come with certifications such as CE (European conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), or equivalent local standards. Request detailed test reports on electrical safety, durability, and waterproof ratings if applicable. Insist on factory audits or third-party inspections before shipment to verify production consistency. These measures are critical for compliance and acceptance in regulated markets across Europe, the Middle East, and beyond. -

How do I manage logistics and shipping challenges when importing LED connectors from Asia or Europe?

Choose suppliers experienced with international shipping who can provide clear Incoterms (e.g., FOB, CIF). Consolidate shipments to reduce freight costs and use reliable freight forwarders familiar with your region’s customs procedures. Track shipments closely and prepare all necessary import documentation, including certificates of origin and compliance. For Africa and South America, plan for potential delays due to customs inspections or port congestion by building buffer time into your supply chain.

Illustrative Image (Source: Google Search)

-

What steps should I take if there is a dispute or quality issue with my LED connector order?

First, document the issue with photos and detailed descriptions. Contact the supplier immediately to discuss resolutions, referencing your contract terms and quality agreements. Utilize trade platforms or chambers of commerce in the supplier’s country for mediation if necessary. Maintain open communication and seek amicable solutions such as replacement shipments or refunds. For larger contracts, having a clear dispute resolution clause in your purchase agreement specifying jurisdiction and arbitration methods is essential. -

Are there regional considerations for buying LED connectors in markets like Turkey, South Africa, or Brazil?

Yes, regional factors such as local electrical standards, climate conditions (humidity, temperature), and import regulations affect connector choice and supplier selection. For example, waterproof connectors are critical in tropical African climates. Understanding local certification requirements and customs duties helps avoid compliance issues. Partnering with suppliers who have experience exporting to your specific region ensures smoother transactions and products tailored to local market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for connectors for led lights

Strategic sourcing of connectors for LED lights is a critical component in optimizing supply chain efficiency and product quality. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the nuances of connector types, compatibility standards, and supplier reliability can significantly impact project success and cost management. Prioritizing suppliers who offer comprehensive product ranges, customization options, and robust technical support ensures adaptability to diverse application needs and evolving market demands.

Key takeaways for buyers include:

- Evaluate connector compatibility with existing LED systems to minimize integration issues.

- Consider supplier certifications and compliance with international standards to guarantee safety and performance.

- Leverage volume purchasing and long-term partnerships to negotiate better terms and ensure supply continuity.

- Stay informed on technological advancements such as quick-connect and waterproof connectors to future-proof installations.

Looking ahead, the LED lighting industry continues to innovate, driving demand for smarter, more durable connectors that support energy-efficient solutions. Buyers are encouraged to engage proactively with manufacturers and distributors who demonstrate agility and a commitment to sustainable practices. By adopting a strategic sourcing mindset, businesses across emerging and established markets can unlock competitive advantages and foster growth in the dynamic LED lighting sector.