Introduction: Navigating the Global Market for connectors for led light strips

In the rapidly evolving LED lighting industry, connectors for LED light strips serve as the critical junctions that ensure seamless power and signal transmission. For international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, sourcing the right connectors is pivotal to guarantee system reliability, ease of installation, and long-term operational efficiency. These components not only influence the performance and durability of LED installations but also affect maintenance costs and scalability—key considerations for commercial and industrial projects.

This comprehensive guide delves into the multifaceted world of LED strip light connectors, offering buyers an authoritative resource to make informed decisions. It covers an extensive range of connector types—from standard 2-pin and 4-pin variants to specialized waterproof and high-voltage models—highlighting their compatibility, materials, and manufacturing quality control standards. Additionally, the guide examines global supplier landscapes, pricing strategies, and market trends tailored to the unique demands of emerging and established regions.

With detailed insights and practical tips, this resource empowers procurement professionals and technical buyers to navigate common challenges such as voltage mismatches, connector compatibility, and supply chain complexities. Whether you are upgrading existing LED systems or launching large-scale installations, understanding these critical connection components will optimize your sourcing strategy, reduce installation risks, and enhance overall project success across international markets.

Understanding connectors for led light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2-pin Connectors | Simple two-contact design for single-color strips | Basic indoor lighting, accent lighting | + Easy to install, low cost – Limited to single color, lower flexibility |

| 4-pin Connectors | Four contacts supporting RGB color control | Dynamic displays, mood lighting, retail setups | + Enables color changing, widely compatible – Slightly higher cost, more complex wiring |

| Waterproof Connectors | Fully sealed against moisture and dust | Outdoor installations, kitchens, bathrooms | + Durable in harsh environments – Higher price, bulkier design |

| High-Voltage Connectors | Designed for 24V+ or high-current LED strips | Large-scale industrial or commercial projects | + Supports longer runs and heavy loads – More expensive, requires careful matching |

| Proprietary Connectors | Brand-specific designs with unique pin layouts | Integrated brand systems, customized solutions | + Optimized for brand performance – Limits interoperability, potential supply dependency |

2-pin Connectors

These connectors feature a straightforward two-pin design tailored for single-color LED strips operating typically at 12V or 24V. Their simplicity makes them an economical choice for straightforward indoor applications like accent lighting or signage. For B2B buyers, the key advantage lies in their ease of installation and compatibility with basic LED strips. However, they lack versatility for color-changing or complex lighting schemes, limiting their use in advanced commercial projects.

4-pin Connectors

Four-pin connectors enable RGB LED strips to receive separate signals for red, green, blue, and common ground, allowing full-color control. This makes them ideal for dynamic lighting in retail, hospitality, and entertainment venues. B2B purchasers should value their broad compatibility with standard RGB controllers and their ability to support complex lighting designs. The trade-off is a slightly more intricate wiring process and a moderate price increase compared to 2-pin connectors.

Waterproof Connectors

Built with sealed housings and rubber gaskets, waterproof connectors protect against moisture, dust, and environmental contaminants. These are essential for outdoor lighting, kitchens, bathrooms, and industrial settings where exposure is unavoidable. For international buyers in regions with humid or rainy climates—such as parts of Africa, South America, and the Middle East—waterproof connectors ensure longevity and reduce maintenance costs. Their higher upfront cost is offset by enhanced durability and compliance with safety standards.

High-Voltage Connectors

Specifically engineered for LED strips operating above 24V or requiring higher amperage, high-voltage connectors accommodate the demands of large-scale commercial or industrial installations. They support longer strip runs without significant voltage drop and maintain consistent brightness. B2B buyers engaged in infrastructure projects or expansive retail lighting should prioritize these connectors for reliability and safety. However, these connectors often necessitate precise matching with power supplies and careful planning to avoid electrical issues.

Proprietary Connectors

These connectors are unique to specific LED strip brands or systems, often featuring custom pin layouts or locking mechanisms. While they can offer optimized performance and seamless integration within a brand’s ecosystem, they pose interoperability challenges for buyers sourcing from multiple vendors. B2B customers must consider potential supply chain risks and limited flexibility when opting for proprietary connectors, especially if future scalability or cross-brand compatibility is a priority.

Related Video: How to Connect LED Strips Using Various Connectors

Key Industrial Applications of connectors for led light strips

| Industry/Sector | Specific Application of connectors for led light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Illuminated display cases and signage installations | Enhances product visibility, attracts customers, and reduces energy costs | Durable, easy-to-install connectors with good electrical ratings; compatibility with RGB and dimmable strips; waterproof options for window displays |

| Hospitality & Leisure | Ambient and accent lighting in hotels, restaurants, and event venues | Creates immersive environments, improves customer experience, and allows flexible lighting control | Connectors with robust locking mechanisms to withstand frequent maintenance; aesthetic design; compliance with local electrical standards |

| Industrial & Warehousing | High-bay and task lighting with extended LED strip runs for workstations and storage areas | Improves operational safety, energy efficiency, and reduces maintenance downtime | High-current connectors with heat resistance; long cable runs compatibility; ruggedized and waterproof connectors for harsh environments |

| Automotive & Transportation | Interior and exterior vehicle lighting, including buses, trains, and commercial trucks | Enables customizable lighting solutions, improves safety, and supports branding | Vibration-resistant, waterproof connectors; compatibility with 12V and 24V systems; compliance with vehicle industry standards |

| Architectural & Urban Development | Façade lighting and public space illumination with dynamic LED strip configurations | Enhances building aesthetics, supports smart city initiatives, and reduces energy consumption | Weatherproof, UV-resistant connectors; ability to integrate with control systems; scalability for large installations |

Retail & Commercial Applications

Connectors for LED light strips are pivotal in retail environments, where illuminated display cases and signage are essential to attract customer attention and highlight products. These connectors enable quick installation and maintenance of lighting systems, ensuring consistent brightness and minimizing downtime. For international buyers, especially in regions like Africa and South America where supply chain reliability varies, sourcing connectors that offer broad voltage compatibility (12V/24V) and robust build quality is crucial to withstand diverse environmental conditions and reduce replacement frequency.

Hospitality & Leisure Sector

In hotels, restaurants, and event venues, LED strip connectors facilitate ambient and accent lighting setups that create inviting atmospheres. Connectors must support flexible configurations, including dimming and color-changing capabilities, while offering secure connections to endure frequent adjustments and cleaning. Buyers in the Middle East and Europe should prioritize connectors compliant with local electrical standards and those designed to endure heat and humidity, ensuring long-lasting performance and guest satisfaction.

Industrial & Warehousing Use Cases

Industrial facilities rely on LED strip connectors for high-bay lighting and task illumination across expansive warehouse floors. These connectors must handle higher currents and longer cable runs without significant voltage drops, maintaining consistent light output critical for worker safety and operational efficiency. For buyers in emerging markets, such as parts of Africa and South America, selecting connectors with ruggedized, waterproof features and heat-resistant materials is vital to cope with harsh industrial environments and variable power quality.

Automotive & Transportation Applications

Connectors for LED strips in the automotive sector are used for interior mood lighting and exterior safety lighting on commercial vehicles like buses and trucks. These connectors must resist vibration, moisture, and temperature fluctuations, ensuring reliable operation in demanding conditions. International buyers, particularly in regions with diverse vehicle standards such as Europe and the Middle East, should seek connectors certified for automotive use and compatible with standard vehicle voltages (12V/24V) to facilitate seamless integration.

Architectural & Urban Development Projects

For façade lighting and public space illumination, connectors enable complex LED strip configurations that enhance urban aesthetics and support smart city lighting controls. These connectors require weatherproofing, UV resistance, and compatibility with dynamic control systems to allow scalable, energy-efficient installations. Buyers from Europe and the Middle East must consider connectors that meet stringent environmental and safety regulations, ensuring durability and integration with advanced lighting management technologies.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for connectors for led light strips

When selecting materials for connectors used in LED light strip installations, understanding the interplay between material properties, environmental conditions, and application demands is critical. This ensures reliability, safety, and longevity—key factors for international B2B buyers operating across diverse markets such as Africa, South America, the Middle East, and Europe.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, excellent dimensional stability, and good electrical insulation. It withstands temperatures typically up to 115°C and offers moderate resistance to UV exposure and chemicals.

Pros & Cons:

Polycarbonate connectors are lightweight, cost-effective, and easy to manufacture with injection molding, making them ideal for mass production. However, they can degrade under prolonged UV exposure and may become brittle in extremely cold environments. Their moderate heat resistance limits use in high-temperature industrial settings.

Impact on Application:

PC connectors are well-suited for indoor LED strip installations and controlled environments where exposure to harsh chemicals or extreme weather is minimal. They are popular in commercial lighting projects due to their balance of durability and cost.

Considerations for International Buyers:

Buyers in regions with intense sunlight (e.g., Middle East, parts of Africa) should verify UV-stabilized PC grades to prevent premature aging. Compliance with international standards such as ASTM D638 for tensile properties and IEC 60695 for flammability is common. European buyers often prefer PC connectors with REACH and RoHS certifications to meet environmental regulations.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile plastic with good electrical insulation, chemical resistance, and flexibility. It typically withstands temperatures up to 70°C and offers excellent resistance to moisture and many solvents.

Pros & Cons:

PVC connectors are inexpensive and provide good protection against dust and moisture, making them suitable for damp environments. However, their lower temperature tolerance and potential for plasticizer migration can limit performance in high-heat or long-term outdoor applications.

Impact on Application:

PVC connectors are widely used in budget-conscious projects and indoor installations where moderate environmental exposure is expected. They are less ideal for outdoor or industrial LED strip applications requiring higher heat resistance.

Considerations for International Buyers:

In South America and Africa, where cost sensitivity is high, PVC connectors offer an economical choice. However, buyers should ensure compliance with local fire safety standards (e.g., UL 94 HB rating) and consider PVC grades free from hazardous phthalates to meet health and environmental regulations, especially in European markets.

3. Nylon (Polyamide)

Key Properties:

Nylon is a robust engineering plastic with excellent mechanical strength, abrasion resistance, and higher thermal resistance (up to 150°C). It also exhibits good chemical resistance and low moisture absorption when properly formulated.

Pros & Cons:

Nylon connectors provide superior durability and longevity, suitable for harsh environments. They are more expensive and complex to manufacture compared to PC and PVC. Moisture absorption can affect dimensional stability unless additives or coatings are applied.

Impact on Application:

Nylon is ideal for industrial LED strip installations, outdoor applications, and regions with fluctuating temperatures. Its toughness ensures connectors withstand mechanical stress and environmental challenges.

Considerations for International Buyers:

Buyers in the Middle East and Europe often favor nylon connectors for their compliance with stringent mechanical and thermal standards such as DIN EN 60695 and ISO 527. In humid climates like parts of South America, selecting moisture-resistant nylon variants is critical to maintain performance.

4. Metal (Typically Copper Alloy or Stainless Steel Contacts)

Key Properties:

Metal components in connectors, especially contact pins, are usually made from copper alloys or stainless steel, offering excellent electrical conductivity, corrosion resistance, and mechanical strength. Surface treatments like gold or tin plating enhance performance.

Pros & Cons:

Metal contacts ensure reliable electrical connections with minimal resistance and long service life. However, metal parts add cost and complexity to manufacturing and require precise plating to prevent corrosion, especially in harsh environments.

Impact on Application:

Metal contacts are indispensable for all LED strip connectors, especially in commercial and industrial settings where consistent electrical performance is critical. They are often paired with plastic housings to combine mechanical protection and electrical reliability.

Considerations for International Buyers:

For buyers in coastal or high-humidity regions (e.g., coastal Africa, South America), corrosion-resistant plating like gold or nickel is essential. Compliance with IEC 60512 for connector performance and ASTM B117 for salt spray corrosion testing is often required. European and UK buyers prioritize connectors with RoHS-compliant plating to avoid hazardous substances.

Summary Table

| Material | Typical Use Case for connectors for led light strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor commercial LED strip installations with moderate environmental exposure | High impact resistance and dimensional stability | Limited UV and temperature resistance | Medium |

| Polyvinyl Chloride (PVC) | Budget indoor LED strip projects and moisture-prone environments | Cost-effective with good moisture resistance | Lower temperature tolerance and plasticizer migration risk | Low |

| Nylon (Polyamide) | Industrial and outdoor LED strip installations requiring durability | High mechanical strength and thermal resistance | Higher cost and moisture absorption concerns | High |

| Metal (Copper Alloy/Stainless Steel Contacts) | Electrical contacts in all LED strip connectors for reliable conductivity | Excellent conductivity and corrosion resistance | Increased manufacturing complexity and cost | Medium to High |

This guide equips international B2B buyers with critical insights to select connector materials that align with their project requirements, environmental conditions, and regulatory frameworks, ensuring optimal performance and compliance across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for connectors for led light strips

Manufacturing connectors for LED light strips involves a series of precise, controlled processes designed to ensure both functional reliability and long-term durability. For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, understanding these processes and the associated quality assurance measures is crucial for selecting suppliers that meet global standards and your project’s specific requirements.

Manufacturing Processes for LED Strip Connectors

1. Material Preparation

The manufacturing journey begins with sourcing and preparing high-quality raw materials. Connectors typically use copper or copper alloys for conductive parts due to excellent electrical conductivity, paired with plastics like polycarbonate or PVC for insulation and housing. Material preparation includes:

– Purification and testing of metals to ensure conductivity and corrosion resistance.

– Plastic granule drying and compounding to maintain molding quality and mechanical strength.

– Compliance with RoHS (Restriction of Hazardous Substances) directives is often verified at this stage to meet environmental and safety regulations.

2. Forming and Stamping

Conductive metal parts undergo precision stamping and forming processes to create pins, terminals, and contact elements. Key techniques include:

– Progressive stamping for high-volume production of uniform metal contacts.

– Injection molding shapes the plastic housings and insulators around the metal parts, ensuring tight fit and electrical isolation.

– Use of automated CNC machining may be employed for proprietary or complex connector designs requiring tight tolerances.

3. Assembly

Assembly combines the conductive and insulating components into finished connectors. This stage involves:

– Automated insertion machines that place metal contacts into plastic housings with exact positioning.

– Soldering or ultrasonic welding for securing internal connections, especially in connectors designed for high current or waterproof applications.

– Integration of sealing elements (e.g., silicone gaskets) for waterproof or dustproof variants.

– Manual assembly for specialized or small-batch connectors to maintain customization flexibility.

4. Finishing and Surface Treatment

Finishing processes enhance durability and electrical performance:

– Plating of metal contacts with tin, nickel, or gold to improve corrosion resistance and conductivity.

– Surface polishing and cleaning to remove residues and ensure smooth mating surfaces.

– Application of UV-resistant coatings on plastic parts for outdoor-rated connectors.

– Final visual inspections to detect surface defects and dimensional inconsistencies.

Quality Assurance and Control Measures

Maintaining high-quality standards in connector manufacturing is essential to prevent failures that could compromise LED strip performance, safety, or lifespan. Buyers should expect suppliers to implement comprehensive QC systems aligned with international and industry-specific standards.

Relevant Standards:

– ISO 9001: The foundational quality management standard ensuring consistent manufacturing processes and continuous improvement.

– CE Marking: Essential for products sold in the European Economic Area, confirming compliance with safety, health, and environmental protection requirements.

– RoHS Compliance: Restricts hazardous substances in electronic components, critical for buyers in Europe and increasingly in other regions.

– UL and IEC Certifications: Validate electrical safety and performance; UL is recognized in the US and Middle East, while IEC standards have wide international acceptance.

– IP Ratings: For connectors intended for outdoor or damp environments, confirming ingress protection levels against dust and water.

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials and components are inspected for compliance with specifications before production. This includes chemical composition analysis for metals and mechanical testing for plastics.

– In-Process Quality Control (IPQC): Continuous monitoring during stamping, molding, and assembly phases. Key checks include dimensional accuracy, insertion force testing, and solder joint integrity.

– Final Quality Control (FQC): Comprehensive testing of finished connectors covering electrical, mechanical, and environmental performance.

Common Testing Methods:

– Electrical Continuity and Resistance Testing: Ensures low contact resistance and reliable conduction.

– Mechanical Durability Tests: Repeated mating cycles simulate real-world connector usage to verify longevity.

– Environmental Stress Testing: Includes thermal cycling, humidity exposure, and salt spray tests to assess corrosion resistance and stability.

– Waterproof Testing: For connectors with IP ratings, immersion or spray tests verify sealing effectiveness.

– Visual and Dimensional Inspections: Automated optical inspection systems detect defects such as cracks, burrs, or misalignments.

How B2B Buyers Can Verify Supplier Quality Assurance

1. Factory Audits and Certifications Review

Request comprehensive documentation of the supplier’s ISO 9001 certification and any relevant product-specific certifications (CE, UL, RoHS). Conduct on-site or remote factory audits focusing on process controls, equipment maintenance, and staff training. Buyers from regions with stringent import standards (Europe, UK) will particularly benefit from suppliers demonstrating robust certification portfolios.

2. Quality Control Reports and Traceability

Suppliers should provide detailed QC reports for each production batch, including material certificates, test results, and defect rate statistics. Traceability systems that track components from raw materials through final assembly help ensure accountability and facilitate problem resolution.

3. Third-Party Inspection and Testing

Engage independent inspection agencies to perform random batch inspections, sample testing, or certification renewals. This is especially valuable for buyers in Africa, South America, and the Middle East, where local regulatory frameworks may be less developed, but import regulations and customer expectations demand verified quality.

4. Sample Evaluation and Pilot Runs

Request samples or small pilot runs before full-scale orders to evaluate connector compatibility, fit, and performance in your specific LED strip configurations. This hands-on validation reduces risks associated with connector mismatches or quality variations.

QC and Certification Nuances for International Buyers

- Africa & South America: Importers should verify RoHS and CE compliance to meet increasingly enforced regional standards and facilitate easier customs clearance. Focus on suppliers who provide clear documentation and support for local certifications where applicable.

- Middle East: UL certification and adherence to IEC standards are often prerequisites for government or commercial projects. Waterproof and corrosion-resistant connectors are critical due to harsh environmental conditions.

- Europe & UK: CE marking is mandatory, and buyers should also confirm REACH compliance and adherence to WEEE directives for electronic waste. Additionally, suppliers must demonstrate compliance with the UKCA mark post-Brexit for UK-based buyers.

- Mexico and Latin America: While local standards vary, aligning with international certifications like ISO 9001, CE, and UL facilitates smoother market access and client acceptance.

Conclusion

For international B2B buyers sourcing connectors for LED light strips, a thorough understanding of manufacturing processes and quality assurance practices is essential to secure reliable, high-performance products. Prioritize suppliers who demonstrate transparent QC systems, hold relevant certifications, and support third-party verification to minimize risks. Tailoring your supplier evaluation criteria to regional regulatory and environmental conditions further ensures your LED installations achieve the desired longevity and safety standards across diverse global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for connectors for led light strips Sourcing

When sourcing connectors for LED light strips, understanding the intricate cost structure and pricing dynamics is crucial for making informed purchasing decisions. This insight helps international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, optimize procurement strategies while ensuring quality and compliance.

Key Cost Components in Connector Pricing

-

Materials:

The primary cost driver is the raw materials used, typically copper for conductive parts and various plastics for insulation and housing. Premium materials, such as gold-plated contacts for enhanced conductivity and corrosion resistance, increase costs but improve reliability, especially in humid or outdoor environments. -

Labor:

Labor costs vary significantly depending on the manufacturing location. Countries with higher wages (e.g., parts of Europe) will reflect this in their pricing, whereas manufacturing hubs in Asia or select Middle Eastern countries may offer more competitive labor rates. -

Manufacturing Overhead:

This includes factory utilities, equipment depreciation, and indirect labor. Automated production lines reduce overhead per unit but require upfront investment in tooling and machinery. -

Tooling and Setup:

Custom connectors or specialized designs incur higher tooling charges. These are often one-time costs amortized over production volumes, making MOQ (Minimum Order Quantity) an important factor in pricing. -

Quality Control (QC):

Stringent QC processes—testing for electrical continuity, durability, and environmental resistance—add to the unit cost but are essential for professional-grade connectors.

-

Logistics and Shipping:

Freight costs, customs duties, and import taxes depend on the shipping method (air vs. sea), Incoterms, and destination country. For example, buyers in Africa or South America may face higher logistics costs and longer lead times compared to European buyers. -

Supplier Margin:

Manufacturers and distributors build margins into pricing to cover profit and risk. Margins can be negotiated based on volume, relationship length, and payment terms.

Influencing Factors on Pricing

-

Order Volume and MOQ:

Larger orders typically secure better unit pricing due to economies of scale and lower relative tooling costs. Buyers should balance MOQ against inventory carrying costs. -

Specifications and Customization:

Standard connectors are generally less expensive than custom or proprietary designs. Waterproof or high-voltage rated connectors command premium pricing due to additional materials and testing. -

Material Quality and Certifications:

Connectors complying with certifications such as RoHS, CE, or UL generally cost more but reduce compliance risks in regulated markets like Europe. -

Supplier Location and Reliability:

Established suppliers with proven quality records may price higher but reduce risk of defects or delays, critical for complex international projects. -

Incoterms and Payment Terms:

Terms such as FOB, CIF, or DDP affect who bears shipping and customs costs. Buyers should carefully evaluate these to understand the true landed cost.

Strategic Buyer Tips for Cost Efficiency

-

Negotiate Based on Total Cost of Ownership (TCO):

Beyond unit price, factor in installation ease, warranty, failure rates, and after-sales support. Cheaper connectors may lead to higher maintenance or replacement costs. -

Leverage Volume Discounts and Long-Term Contracts:

Consolidating orders and committing to suppliers can unlock better pricing and priority production slots. -

Request Samples and Test Early:

Validating connector compatibility and quality upfront avoids costly returns or project delays, especially when sourcing internationally. -

Understand Regional Logistics Nuances:

For buyers in Africa or South America, consider local customs clearance complexities and potential delays. Partnering with suppliers offering DDP terms can simplify imports. -

Consider Currency Fluctuations:

When dealing with suppliers in different currency zones, lock pricing with forward contracts or negotiate payment in stable currencies (e.g., USD or EUR) to mitigate risk. -

Evaluate Alternative Suppliers and Materials:

Exploring multiple sources, including local manufacturers in the Middle East or Europe, can reduce shipping costs and lead times.

Pricing Disclaimer

Prices for connectors vary widely depending on specifications, volume, supplier, and market conditions. The figures discussed are indicative and should be confirmed with suppliers through direct quotations. Due diligence and ongoing market research remain vital to securing competitive and reliable sourcing arrangements.

By carefully analyzing these cost drivers and pricing influencers, international B2B buyers can optimize procurement of LED light strip connectors, balancing cost, quality, and delivery to meet their project requirements efficiently.

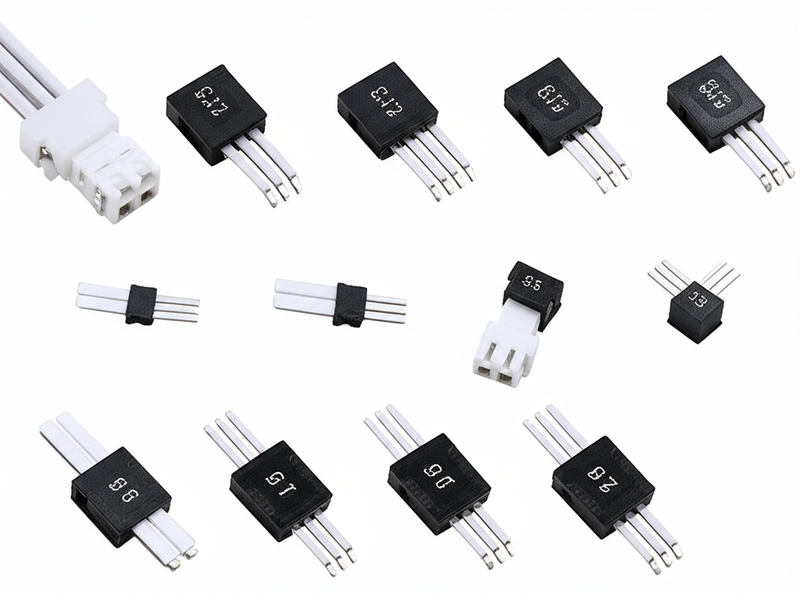

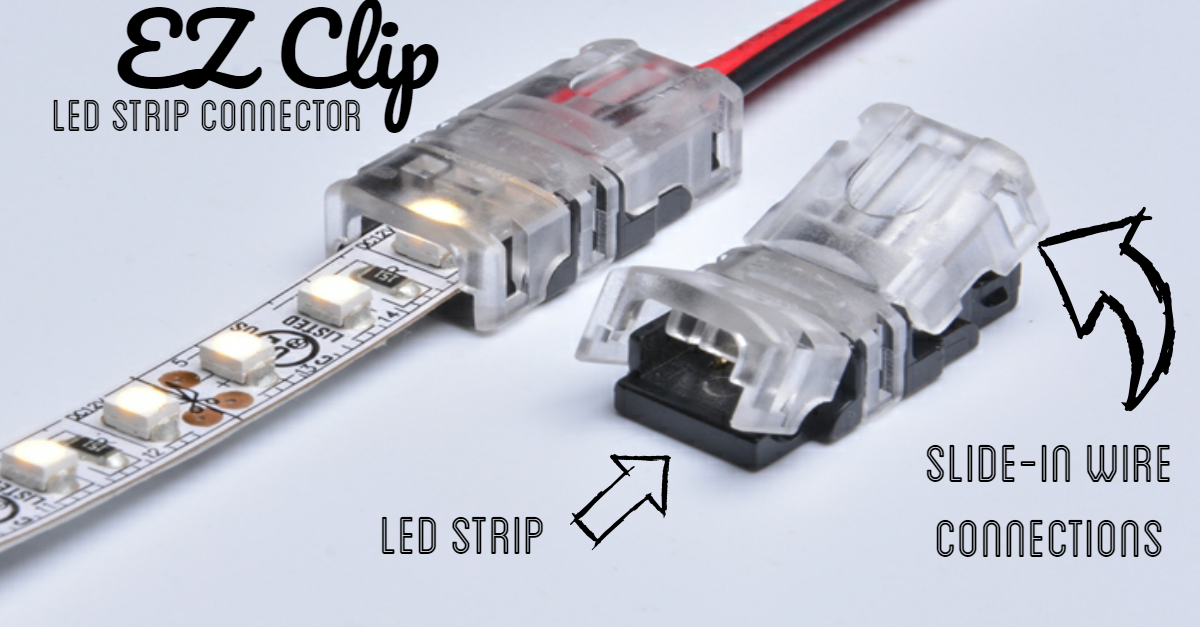

Illustrative Image (Source: Google Search)

Spotlight on Potential connectors for led light strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘connectors for led light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for connectors for led light strips

Critical Technical Properties of LED Light Strip Connectors

1. Material Grade and Conductivity

High-quality connectors use copper or copper alloys with gold or tin plating for contacts. This ensures excellent electrical conductivity and corrosion resistance, which is vital for maintaining consistent current flow and preventing voltage drops. For B2B buyers, selecting connectors with superior material grades reduces maintenance costs and enhances system reliability, especially in humid or outdoor environments common in Africa, the Middle East, and parts of South America.

2. Voltage and Current Ratings

Connectors are rated for specific voltages (commonly 12V or 24V) and maximum current loads. Using connectors rated below your LED strip’s requirements risks overheating and failure. B2B professionals must verify these ratings to ensure compatibility with their LED lighting systems, avoiding costly downtime and warranty claims.

3. Ingress Protection (IP) Rating

The IP rating indicates a connector’s resistance to dust and water ingress, such as IP65 or IP67. For installations in kitchens, outdoor signage, or humid environments, waterproof connectors safeguard against environmental damage. International buyers should prioritize IP-rated connectors tailored to their application’s climate and regulatory standards.

4. Mechanical Tolerance and Fit Precision

Connector tolerance refers to the allowable deviation in dimensions and pin alignment. Precise tolerances ensure secure connections without wobble or loose contacts, critical for preventing flickering or intermittent failures. Buyers should request connectors with tight mechanical tolerances to guarantee installation consistency across large-scale projects.

5. Temperature Range and Thermal Stability

Connectors must operate reliably across expected temperature ranges, typically -20°C to +60°C or higher for industrial applications. Thermal stability prevents deformation or contact degradation under heat stress, which is crucial in high-ambient-temperature regions like parts of the Middle East and Africa.

6. Connector Type and Pin Configuration

Common configurations include 2-pin for single-color LED strips and 4-pin for RGB strips. Matching the connector type to the LED strip’s pin count and layout is essential to ensure seamless integration. Misalignment here can lead to installation delays or component damage.

Key Trade Terminology for International LED Strip Connector Procurement

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce connectors either under their own brand or for other brands. B2B buyers often deal with OEMs when sourcing custom connectors or requiring consistent quality for large orders. Understanding OEM relationships helps in negotiating pricing, lead times, and quality assurance.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of connector units a supplier will sell per order. For international buyers, especially SMEs or regional distributors in Europe and South America, negotiating MOQ is critical to balancing inventory costs against project demands. Some suppliers may offer flexible MOQs for long-term partnerships.

RFQ (Request for Quotation)

An RFQ is a formal document sent by buyers to suppliers to obtain pricing, delivery times, and terms for specific connector types and quantities. Well-prepared RFQs streamline supplier evaluation, enabling buyers to compare offers efficiently and ensure compliance with technical specifications.

Incoterms (International Commercial Terms)

Incoterms define responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). For cross-border LED connector purchases, understanding Incoterms helps avoid unexpected costs and logistical delays, which is especially important for buyers in Africa and South America dealing with complex import regulations.

Lead Time

Lead time is the period between placing an order and receiving the goods. Reliable lead times are essential for project scheduling and cash flow management. Buyers should verify supplier lead times, factoring in customs clearance and shipping, to avoid installation setbacks.

Compatibility

This term refers to the connector’s ability to physically and electrically interface with specific LED strip models or brands. Ensuring compatibility avoids costly returns and rework, a common challenge in international procurement where multiple brands and standards coexist.

By understanding these critical technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can make informed decisions that optimize cost, quality, and reliability in their LED strip lighting projects. This knowledge also facilitates smoother communication with suppliers and helps mitigate risks associated with international sourcing.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the connectors for led light strips Sector

Market Overview & Key Trends

The global market for connectors used in LED light strips is witnessing dynamic growth driven by the widespread adoption of LED lighting in commercial, industrial, and residential sectors. Increasing energy efficiency regulations and rising demand for smart lighting solutions are key drivers influencing the market. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, the focus is on sourcing connectors that support reliable, scalable, and customizable LED installations.

Key market dynamics include:

-

Diverse Connector Types: The market offers a variety of connectors—ranging from simple 2-pin connectors for single-color strips to complex 4-pin or proprietary connectors for RGB and smart LED strips. Buyers must navigate compatibility across different LED strip voltages (12V, 24V) and configurations (series vs. parallel wiring).

-

Rising Demand for Waterproof and High-Voltage Connectors: Due to increased outdoor and industrial lighting applications, demand for waterproof connectors and those capable of handling higher voltages is growing. This trend is particularly relevant in Middle Eastern and African markets where environmental resilience is critical.

-

Supply Chain Localization and Customization: Buyers in emerging markets like Mexico and South America are increasingly seeking suppliers who offer tailored connector solutions that align with regional electrical standards and installation practices. This reduces dependency on imports and improves lead times.

-

Technological Integration: Integration with smart lighting systems demands connectors that support control wiring for dimming, color changing, and IoT connectivity. B2B buyers prioritize suppliers who provide connectors compatible with these advanced features.

-

Quality and Certification: European buyers, especially in the UK and EU, emphasize compliance with CE, RoHS, and UL certifications to ensure safety and reliability. African and Middle Eastern buyers also increasingly require certifications to meet rising regulatory standards.

For B2B buyers, understanding these trends helps in selecting suppliers who not only provide compatible and reliable connectors but also support evolving market requirements, including customization, certification, and advanced functionality.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor in the procurement of connectors for LED light strips, influencing purchasing decisions globally. The environmental impact of connector manufacturing—primarily linked to raw material extraction, energy consumption, and end-of-life disposal—necessitates a responsible sourcing approach.

Key sustainability considerations include:

-

Material Selection: Connectors made from recyclable and non-toxic materials such as lead-free solder and halogen-free plastics reduce environmental harm. B2B buyers should seek suppliers offering products compliant with RoHS and REACH regulations, which restrict hazardous substances.

-

Energy-Efficient Manufacturing: Suppliers adopting energy-saving manufacturing processes and using renewable energy sources contribute to reducing the carbon footprint. Buyers can request sustainability reports or certifications like ISO 14001 to verify environmental management practices.

-

Ethical Supply Chains: Transparency in sourcing raw materials—especially metals like copper and tin—is essential to avoid conflict minerals and labor abuses. Ethical audits and certifications (e.g., Responsible Minerals Initiative) assure buyers of fair labor practices and conflict-free sourcing.

-

Product Longevity and Reusability: High-quality connectors designed for durability minimize replacement frequency, reducing waste. Modular designs that facilitate easy maintenance and upgradeability support circular economy principles.

-

Packaging and Logistics: Eco-friendly packaging and optimized logistics reduce waste and emissions during shipping. B2B buyers should encourage suppliers to minimize plastic use and adopt recyclable or biodegradable packaging materials.

For B2B buyers in regions such as Europe, where sustainability regulations are stringent, and in emerging markets, where environmental concerns are rising, partnering with suppliers committed to green practices enhances brand reputation and compliance readiness.

Evolution of Connectors for LED Light Strips

Connectors for LED light strips have evolved significantly alongside advances in LED technology and lighting applications. Initially, LED strip lighting relied on simple soldered wire connections, which limited installation flexibility and increased labor costs. The development of standardized connectors—starting with basic 2-pin designs for single-color strips—simplified assembly and enabled modular configurations.

As LED technology advanced to include RGB and addressable LEDs, connector designs became more complex, incorporating multiple pins (e.g., 4-pin) to handle color channels and control signals. Waterproof and high-voltage connectors emerged to meet outdoor and industrial application demands, expanding the use cases of LED strips globally.

In recent years, the rise of smart lighting systems has driven innovation toward connectors that support integrated control wiring for dimming, color management, and IoT connectivity. This evolution reflects the market’s shift from basic illumination to sophisticated, interactive lighting solutions, requiring B2B buyers to stay informed about compatibility and technological trends to ensure future-proof sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of connectors for led light strips

- How can I effectively vet suppliers of connectors for LED light strips to ensure quality and reliability?

When sourcing internationally, start by verifying the supplier’s certifications such as ISO 9001 for quality management and RoHS for environmental compliance. Request product samples to test compatibility and durability under your operating conditions. Check customer references and online reviews, focusing on their experience with similar B2B projects. For buyers in Africa, South America, the Middle East, and Europe, prioritize suppliers with proven export experience and clear communication in your preferred language to minimize misunderstandings and delays.

-

Is customization of LED strip connectors commonly available, and what should I consider when requesting custom solutions?

Many manufacturers offer customization in terms of connector type, pin configuration, and waterproofing to suit specific project requirements. When requesting custom connectors, clearly provide detailed technical specifications, drawings, and expected environmental conditions. Confirm minimum order quantities (MOQs) and lead times for custom orders, as these typically exceed standard products. Also, ensure that the supplier can provide compliance certifications for customized parts, which is critical for regulatory approval in different markets. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders of LED strip connectors?

MOQs can range widely, from a few hundred pieces for standard connectors to several thousand for specialized or customized types. Lead times generally span 3 to 8 weeks, depending on customization and production capacity. Payment terms often include 30% upfront deposit with the balance paid before shipment or via letter of credit for larger orders. Negotiate terms that balance risk and cash flow, and consider suppliers offering flexible payment options or trade assurance to protect your investment. -

Which quality assurance measures and certifications should I require from LED connector suppliers?

Demand proof of compliance with international standards such as CE marking (for Europe), UL certification (for North America), and RoHS directives restricting hazardous substances. Quality assurance should include documented production inspections, electrical safety testing, and durability assessments under expected operating conditions. Ask for batch-specific test reports and be wary of suppliers unwilling to provide traceability documentation, as these are key to minimizing product failures and warranty claims. -

How do I manage logistics and customs challenges when importing LED strip connectors from overseas suppliers?

Work with freight forwarders experienced in handling electronic components and ensure all paperwork—commercial invoices, packing lists, certificates of origin—is accurate and complete to prevent customs delays. Consider consolidated shipments to reduce costs and ask suppliers about Incoterms (e.g., FOB, CIF) to clarify responsibility for shipping and insurance. For buyers in regions with complex import regulations, partnering with local customs brokers can expedite clearance and reduce unexpected fees. -

What are the best practices for handling disputes or quality issues with international LED connector suppliers?

Establish clear contractual terms covering product specifications, delivery schedules, and dispute resolution mechanisms before placing orders. Insist on pre-shipment inspections or third-party quality audits to catch issues early. If defects arise, document them thoroughly with photos and test reports, and communicate promptly with the supplier. Utilize arbitration clauses or international trade mediation bodies as stipulated in contracts to resolve conflicts efficiently, minimizing disruptions to your supply chain. -

Are there specific connector types or features that international buyers should prioritize for durability and compatibility?

Buyers should prioritize connectors with robust materials (e.g., high-quality copper contacts, corrosion-resistant plating) and IP-rated waterproofing for outdoor or humid environments. Compatibility with your LED strip’s voltage and pin layout is critical to avoid electrical failures. For large-scale or industrial applications, connectors rated for higher current loads and temperature tolerance enhance reliability. Always verify connector compatibility with existing systems or controllers used in your target markets. -

How can I ensure smooth communication and coordination with LED connector suppliers across different time zones and cultures?

Establish regular communication schedules that accommodate both parties’ working hours, using video calls or messaging platforms to maintain clarity. Employ bilingual staff or professional translators if language barriers exist. Clearly document all technical requirements, changes, and approvals in writing to avoid misunderstandings. Demonstrating cultural awareness and patience fosters trust and long-term partnerships, which are invaluable in international B2B trade.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for connectors for led light strips

Ensuring optimal performance and reliability in LED light strip installations hinges on selecting the right connectors tailored to your specific project needs. For international B2B buyers across Africa, South America, the Middle East, and Europe, strategic sourcing means prioritizing compatibility, quality, and compliance with regional electrical standards. Choosing connectors that match voltage requirements, support desired wiring configurations, and withstand environmental conditions is essential to minimize downtime and maintenance costs.

Key takeaways for buyers include:

- Prioritize connectors with verified compatibility to avoid costly mismatches or system failures.

- Opt for robust, industry-standard connectors that facilitate ease of installation and future scalability.

- Consider environmental factors such as moisture or temperature to select appropriate waterproof or high-temperature rated connectors.

- Leverage parallel wiring approaches to ensure consistent brightness and simplify troubleshooting in commercial-scale projects.

Looking ahead, the demand for smart, energy-efficient lighting solutions will continue to grow globally, emphasizing the need for connectors that integrate seamlessly with advanced controls and IoT systems. Buyers should engage with trusted suppliers who offer technical support, customization options, and compliance certifications to future-proof their investments.

Take action now: Evaluate your sourcing strategies to secure high-quality connectors that enhance system longevity and performance. Collaborate with experienced manufacturers and distributors who understand your regional market dynamics and can support your evolving LED lighting projects with innovative, reliable connection solutions.