Introduction: Navigating the Global Market for 2 amps vs 5 amp led strips

In the rapidly evolving global lighting industry, understanding the distinctions between 2 amp and 5 amp LED strips is crucial for international B2B buyers aiming to optimize their product offerings and supply chains. These amperage ratings directly impact power consumption, brightness, installation requirements, and overall system reliability—key factors that influence project success across diverse markets such as Africa, South America, the Middle East, and Europe. Selecting the appropriate LED strip amperage not only affects operational efficiency but also ensures compliance with regional electrical standards and cost-effectiveness.

This guide delivers a comprehensive exploration of 2 amp versus 5 amp LED strips, tailored to empower procurement professionals and technical decision-makers. It covers essential topics including the different types of LED strips, materials and construction quality, manufacturing and quality control benchmarks, and sourcing strategies from reputable global suppliers. Additionally, it provides in-depth market insights, pricing analyses, and answers to frequently asked questions that address common concerns in international trade and installation.

By leveraging this resource, buyers will gain actionable knowledge to confidently evaluate product specifications, negotiate with manufacturers, and implement LED lighting solutions that meet stringent performance and safety criteria. Whether sourcing for commercial, industrial, or architectural projects, this guide equips you with the expertise to navigate complexities in voltage and current requirements, ensuring your investments in LED technology deliver maximum value and durability across varied international markets.

Understanding 2 amps vs 5 amp led strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 2 Amp LED Strips | Low current draw (~2A), typically 12V, moderate brightness levels | Retail displays, decorative lighting, accent lighting | Pros: Lower power requirements, cost-effective; Cons: Limited length and brightness, less suitable for high-demand applications |

| High-Power 5 Amp LED Strips | Higher current draw (~5A), often 12V or 24V, higher brightness and density | Industrial lighting, architectural illumination, large-scale signage | Pros: Brighter, supports longer runs; Cons: Requires robust power supplies, higher installation complexity |

| RGB 2 Amp LED Strips | Multi-color LEDs with 2A max current, integrated color control channels | Hospitality, event staging, retail ambiance | Pros: Versatile color options, energy efficient; Cons: Limited brightness compared to higher amp variants |

| RGB 5 Amp LED Strips | High current multi-color strips with enhanced brightness and color saturation | Large venues, outdoor advertising, entertainment sectors | Pros: Superior color performance, scalability; Cons: Higher cost, specialized power and control needs |

| Warm White 2 Amp LED Strips | Warm white light output (~2700K), low current draw | Residential, hospitality, and cozy ambiance settings | Pros: Attractive warm lighting, energy efficient; Cons: Not suited for high-intensity applications |

Standard 2 Amp LED Strips

Standard 2 amp LED strips are characterized by their low power consumption and moderate brightness, making them ideal for applications where energy efficiency and cost control are priorities. These strips typically operate at 12 volts and are well-suited for decorative and accent lighting in retail environments or small-scale projects. For B2B buyers in regions like Europe or Africa, these strips offer a balance between performance and affordability, but their limited brightness and maximum run length may restrict their use in larger installations.

High-Power 5 Amp LED Strips

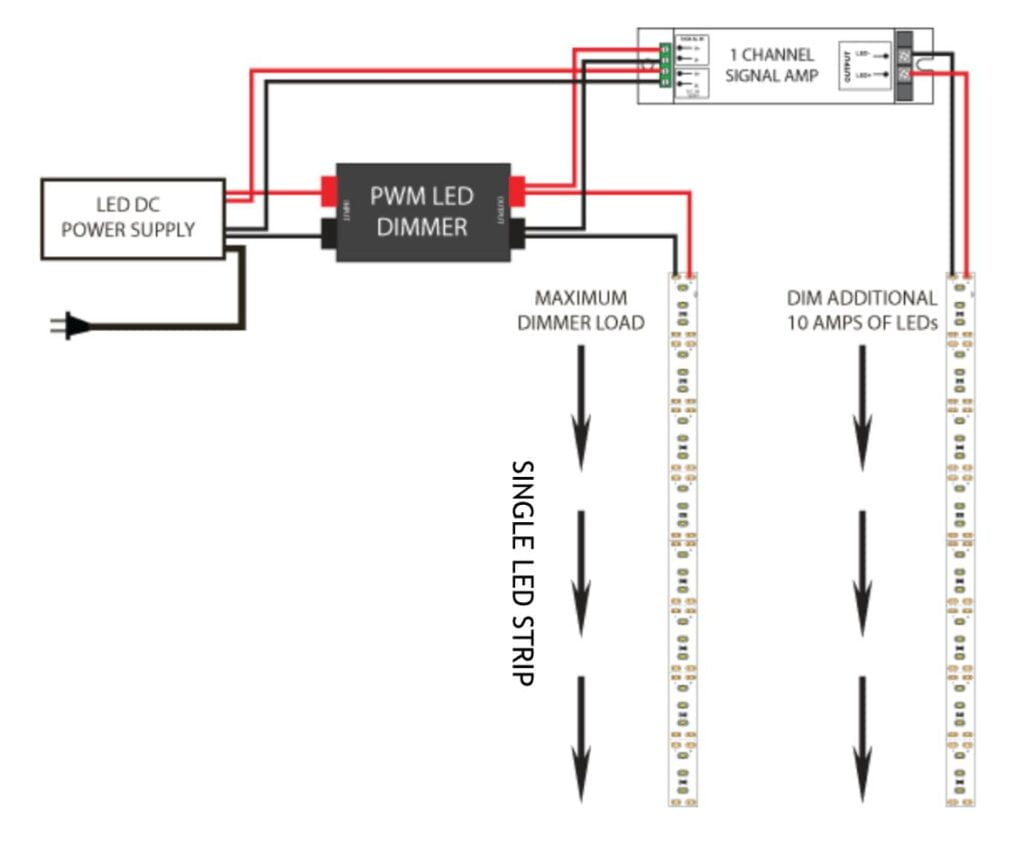

High-power 5 amp LED strips deliver significantly higher brightness and can cover longer distances without voltage drop issues, making them suitable for industrial and architectural applications. Operating often at 12V or 24V, these strips require more robust power supplies and thicker wiring, which increases installation costs and complexity. International buyers should consider local electrical standards and ensure compatibility with existing infrastructure, especially in markets with variable power quality.

RGB 2 Amp LED Strips

RGB 2 amp LED strips provide multi-color lighting with integrated control channels at a lower current rating. They are popular in hospitality and retail sectors for creating dynamic lighting effects and ambiance. Their energy efficiency and moderate brightness make them attractive for venues prioritizing flexible lighting without high power demands. B2B buyers should evaluate controller compatibility and ensure that power supply units can handle the combined load of color channels.

RGB 5 Amp LED Strips

Offering enhanced brightness and color saturation, RGB 5 amp LED strips are designed for large-scale, high-impact installations such as outdoor advertising and entertainment venues. These strips demand specialized power supplies and controllers capable of managing higher currents and complex color mixing. Buyers should factor in increased upfront costs and ensure installation teams are skilled in handling higher voltage drops and thermal management considerations.

Warm White 2 Amp LED Strips

Warm white 2 amp LED strips emit a cozy, inviting light at approximately 2700K, ideal for residential and hospitality environments seeking a comfortable atmosphere. Their low current draw supports energy-efficient installations with simple power requirements. However, they are not designed for high-intensity lighting needs. B2B buyers focusing on ambiance and energy savings will find these strips advantageous, particularly in markets emphasizing sustainability and low operational costs.

Related Video: OLED, QLED, or Mini-LED? Which to TV Buy in 2025

Key Industrial Applications of 2 amps vs 5 amp led strips

| Industry/Sector | Specific Application of 2 amps vs 5 amp led strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in storefronts and showrooms | Enhances product visibility and customer engagement with energy efficiency | Must consider voltage stability, IP rating for indoor/outdoor use, and local electrical codes, especially in humid or dusty environments common in Africa and the Middle East |

| Automotive Manufacturing | Interior and functional lighting in vehicle assembly lines and inspection stations | Improves worker precision and safety while reducing energy costs | Requires durable strips with higher amperage (5 amp) for longer runs; sourcing must ensure compliance with automotive industry standards and reliable power supplies |

| Hospitality & Leisure | Ambient and decorative lighting in hotels, restaurants, and event spaces | Creates inviting atmospheres, flexible lighting control, and energy savings | Buyers should prioritize dimmable strips with consistent amperage ratings, compatibility with controllers, and certifications for use in European and Middle Eastern markets |

| Architectural & Urban | Façade illumination and pathway lighting in commercial and public infrastructure | Enhances aesthetic appeal and safety while minimizing maintenance | Focus on strips with higher amperage capacity (5 amp) for extended length and weather resistance; sourcing must account for climate challenges in South America and Africa |

| Electronics & Equipment | Backlighting for control panels, signage, and instrument clusters | Provides clear visibility and reliability with compact power demands | 2 amp strips are preferred for low-power, compact applications; sourcing should emphasize quality, consistency, and adherence to international safety standards |

Retail & Commercial Applications

In retail environments across Europe and emerging markets in Africa and the Middle East, 2 amp LED strips are widely used for accentuating product displays and storefronts. Their moderate amperage suits shorter runs and smaller installations, delivering vibrant lighting that attracts customers and enhances brand presentation. Buyers must ensure the strips have adequate IP ratings for indoor or semi-exposed areas and comply with local electrical regulations to avoid downtime or hazards.

Automotive Manufacturing

Automotive assembly plants in Germany, Italy, and growing industrial hubs in South America benefit from 5 amp LED strips for interior lighting of vehicles during production and inspection. The higher amperage capacity supports longer, uninterrupted runs necessary for expansive assembly lines. These strips improve worker accuracy and reduce energy consumption. Buyers should source from suppliers offering automotive-grade durability and stable power supplies compliant with strict industry standards.

Hospitality & Leisure Sector

Hotels and restaurants in the Middle East and Europe leverage both 2 amp and 5 amp LED strips to create dynamic ambient lighting that can be dimmed or color-tuned for different moods and events. While 2 amp strips fit smaller decorative features, 5 amp strips enable larger installations such as ceiling coves or bar lighting. International buyers must focus on compatibility with controllers, dimming capabilities, and certifications like CE or UL to meet regional safety and performance expectations.

Architectural & Urban Lighting

Large-scale façade and pathway lighting projects in South America and Africa require 5 amp LED strips to handle extended lengths without voltage drop, ensuring uniform illumination. These strips must be weather-resistant and capable of operating reliably in harsh climates. B2B buyers should prioritize sourcing from manufacturers with proven track records in outdoor LED solutions and verify product warranties and compliance with local environmental standards.

Electronics & Equipment Backlighting

In control panels and signage manufacturing across Europe and emerging markets, 2 amp LED strips provide efficient backlighting with minimal power consumption. Their compact size and lower amperage requirements fit well within tight spaces and sensitive electronics. Buyers must ensure consistent quality and adherence to international safety standards to maintain product reliability and facilitate smooth integration into electronic assemblies.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for 2 amps vs 5 amp led strips

When selecting materials for 2 amp versus 5 amp LED strips, understanding the electrical load, heat dissipation, and environmental exposure is critical. The choice of substrate and conductive materials directly affects performance, durability, and compliance with international standards. Below is an in-depth analysis of four common materials used in LED strip manufacturing, highlighting their relevance to different amperage ratings and regional market considerations.

1. Flexible Copper-Clad Polyimide (FPC)

Key Properties:

FPC substrates combine a thin polyimide base with copper traces, offering excellent flexibility and a high temperature resistance typically up to 260°C. Copper provides superior electrical conductivity and efficient heat dissipation.

Pros & Cons:

– Pros: High thermal stability supports higher current loads, making it suitable for 5 amp LED strips. Its flexibility allows installation in curved or confined spaces, a significant advantage for architectural lighting projects common in Europe and the Middle East.

– Cons: Polyimide materials are more expensive than standard polyester substrates, increasing manufacturing costs. Handling requires care to avoid damage during installation.

Impact on Application:

Ideal for medium to high-power LED strips where heat management is critical. Its flexibility suits dynamic or irregular installations, such as automotive or signage applications prevalent in South American urban centers.

International B2B Considerations:

Buyers in regions like Germany and Italy often require compliance with DIN standards for thermal and electrical performance. African and Middle Eastern markets benefit from FPC’s durability in high-temperature environments. However, cost sensitivity in some African markets may limit widespread adoption.

2. Aluminum PCB (Metal Core PCB)

Key Properties:

Aluminum PCBs feature an aluminum base layer that offers superior heat dissipation, essential for LED strips operating at 5 amps or higher. They typically withstand temperatures up to 130°C and provide excellent mechanical strength.

Pros & Cons:

– Pros: Enhanced thermal conductivity reduces the risk of overheating, extending LED lifespan and reliability. Aluminum cores improve structural integrity, beneficial for outdoor or industrial applications.

– Cons: Less flexible than FPC, limiting use in curved installations. Higher weight and cost compared to standard PCBs.

Impact on Application:

Best suited for high-current LED strips (5 amps), especially in fixed installations requiring robust heat management, such as outdoor lighting in harsh climates found in the Middle East or industrial zones in South America.

International B2B Considerations:

European buyers often prioritize aluminum PCBs for compliance with RoHS and CE standards. African buyers should consider aluminum’s corrosion resistance, especially in coastal areas. The material’s rigidity may require additional design considerations for installations in tight or flexible spaces.

3. Standard Polyester (PET) Substrate with Copper Foil

Key Properties:

PET substrates are cost-effective and provide moderate flexibility. Copper foil thickness varies but generally supports lower current loads, making PET suitable for 2 amp LED strips with typical temperature ratings around 105°C.

Pros & Cons:

– Pros: Low cost and ease of manufacturing make PET ideal for large-volume, low-power LED strip production. Lightweight and flexible for simple installations.

– Cons: Limited thermal conductivity and lower temperature tolerance restrict use in high-current applications. Susceptible to warping under prolonged heat exposure.

Impact on Application:

Commonly used for decorative or accent lighting applications where current draw is low (2 amps). Suitable for indoor use in controlled environments, such as retail displays in Europe or residential lighting in South America.

International B2B Considerations:

Buyers in cost-sensitive African markets favor PET for budget projects. However, compliance with ASTM or IEC standards for electrical insulation and fire resistance should be verified. European buyers may limit PET use to low-risk environments due to stricter safety regulations.

4. Rigid FR4 PCB with Copper Traces

Key Properties:

FR4 is a glass-reinforced epoxy laminate that offers excellent mechanical strength and electrical insulation. It supports moderate to high current loads depending on copper thickness and trace design, with temperature ratings around 130°C.

Pros & Cons:

– Pros: Durable and stable, FR4 is widely used in industrial LED applications requiring reliable performance. It supports higher amperage strips (up to 5 amps) with proper design.

– Cons: Rigid nature limits flexibility, unsuitable for curved or flexible installations. Heavier and more expensive than PET substrates.

Impact on Application:

Ideal for industrial, commercial, or architectural lighting where rigid mounting is possible. Common in European markets for high-quality, long-lasting LED solutions and in Middle Eastern infrastructure projects demanding robustness.

International B2B Considerations:

FR4 meets many international standards (UL, IEC), making it attractive for buyers in regulated markets like Germany and Italy. For African and South American buyers, the higher cost is justified in applications requiring durability and compliance with local electrical codes.

| Material | Typical Use Case for 2 amps vs 5 amp led strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Copper-Clad Polyimide (FPC) | 5 amp strips in flexible, high-temp applications | High thermal resistance and flexibility | Higher cost and delicate handling | High |

| Aluminum PCB (Metal Core PCB) | 5 amp strips requiring superior heat dissipation and rigidity | Excellent heat dissipation and mechanical strength | Limited flexibility and higher weight | Medium |

| Standard Polyester (PET) Substrate | 2 amp strips for low-power, flexible indoor lighting | Low cost and lightweight | Limited thermal tolerance and durability | Low |

| Rigid FR4 PCB with Copper Traces | 5 amp strips in industrial/commercial fixed installations | Durable, stable, and compliant with international standards | Rigid, heavier, and higher cost | Medium |

This material selection guide equips international B2B buyers with a clear understanding of how substrate and conductive materials influence LED strip performance at different amperages. Considering regional standards, environmental conditions, and cost constraints ensures optimal product selection tailored to diverse markets across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 amps vs 5 amp led strips

Manufacturing Processes for 2 Amp vs 5 Amp LED Strips

The manufacturing of LED strips, whether designed for 2 amps or 5 amps, follows a structured process that ensures durability, electrical safety, and performance. Differences in current capacity directly impact material selection, copper thickness, and assembly precision.

1. Material Preparation

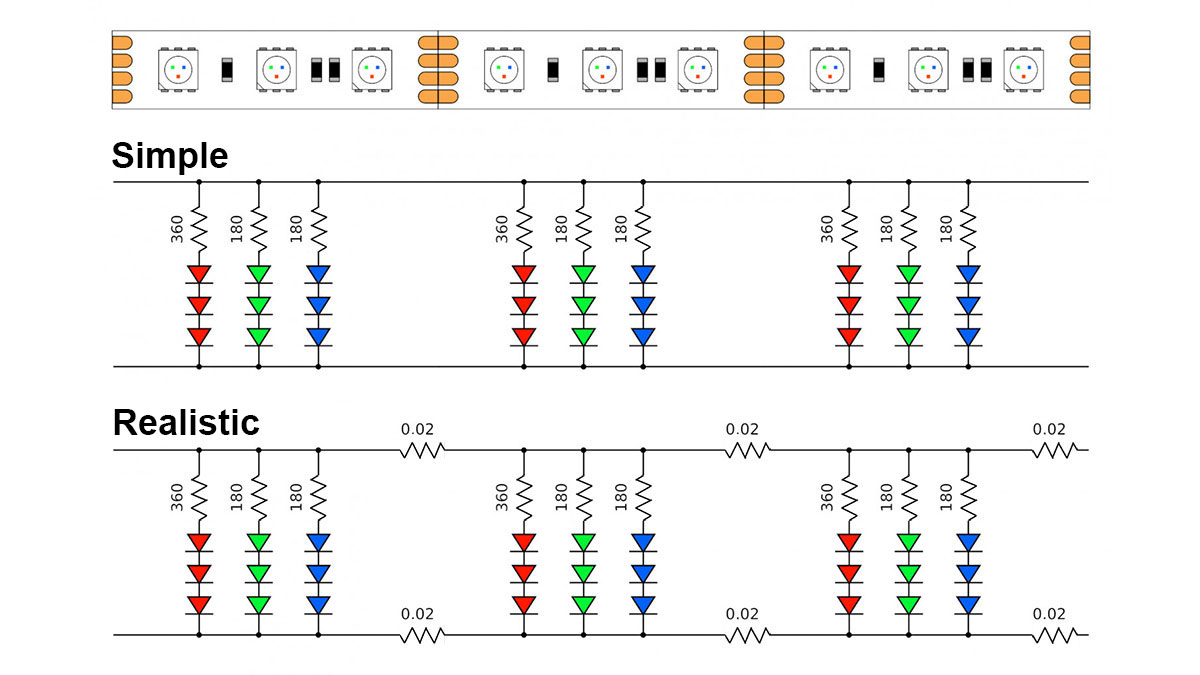

- Substrate Selection: Flexible printed circuit boards (FPCBs) form the base. For 2 amp strips, thinner copper layers (e.g., 1 oz/ft²) suffice, while 5 amp strips require thicker copper (2 oz/ft² or higher) to safely handle increased current without overheating or voltage drop.

- LED Chips & Components: High-quality LEDs (SMD types like 3528, 5050) are selected based on power ratings. Resistors and integrated circuit chips for controlling current are matched to the strip’s amperage rating.

- Adhesives and Coatings: Heat-resistant adhesives and protective coatings (silicone or epoxy) are prepared to ensure environmental resistance, essential for strips used in diverse climates.

2. Forming and PCB Fabrication

- Copper Layer Etching: Precise etching defines the circuit paths. For 5 amp strips, wider and thicker copper traces are formed to support higher current flow.

- Solder Mask and Silkscreen: Application of solder mask protects circuit traces, while silkscreen printing marks component placements and electrical information.

- Cutting and Punching: The strip is cut into reels or custom lengths, with punch holes and connectors prepared for assembly.

3. Assembly

- Component Placement: Automated pick-and-place machines position LEDs and resistors with high accuracy. For 5 amp strips, placement tolerances are tighter to prevent hotspots and ensure uniform current distribution.

- Soldering: Reflow soldering is standard, with temperature profiles carefully controlled to avoid damage to components. Higher amp strips may use thicker solder to maintain mechanical strength.

- Integration of Power Connectors: Connectors are attached to support the rated current, using materials that minimize resistance and heat generation.

4. Finishing and Packaging

- Protective Coatings: Application of waterproof or dustproof layers is common, especially for outdoor or industrial use.

- Reel Winding and Labeling: Strips are wound into reels with clear labeling of amperage, voltage, wattage, and certifications.

- Packaging: Anti-static and moisture-resistant packaging protects strips during shipping.

Quality Assurance and Control (QA/QC) Framework

International B2B buyers must insist on robust QA/QC processes that align with global standards and local regulatory requirements. This guarantees product reliability and compliance, especially in markets with stringent electrical safety norms like Europe and emerging regions like Africa and South America.

Relevant International and Industry Standards

- ISO 9001: A fundamental quality management system standard ensuring consistent manufacturing processes and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Limits hazardous materials, crucial for buyers in Europe and countries adopting similar regulations.

- UL Certification: Important for North American and some Middle Eastern markets, confirming electrical safety.

- IEC Standards (e.g., IEC 60598 for luminaires): Guide electrical and photometric requirements.

- Local Standards: Buyers in Africa and South America should verify compliance with regional standards such as INMETRO (Brazil) or SABS (South Africa).

QC Checkpoints During Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components, such as copper thickness and LED chip quality, to prevent defects early.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, automated optical inspection (AOI) for component placement, and electrical testing of partial circuits.

- Final Quality Control (FQC): Comprehensive testing of finished strips for electrical parameters, visual defects, and functionality before packaging.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Electrical Load Testing: Verifies current capacity (2A or 5A) under operational voltages, ensuring no overheating or voltage drop beyond specification.

- Thermal Imaging: Identifies hotspots that could indicate design flaws or assembly issues.

- Insulation and Dielectric Testing: Ensures electrical safety and resistance to leakage currents.

- Lumen and Color Consistency Testing: Measures brightness and color temperature uniformity, critical for high-end applications.

- Environmental Stress Testing: Includes humidity, salt spray, and UV exposure tests, particularly important for buyers in regions with harsh climates.

Verifying Supplier Quality: Recommendations for B2B Buyers

For international buyers, especially from Africa, South America, the Middle East, and Europe, thorough verification of a supplier’s QC capabilities is non-negotiable.

Supplier Audits and Factory Inspections

- On-site Audits: Conduct regular supplier audits focusing on process adherence, equipment calibration, and workforce training. Audits should assess compliance with ISO 9001 and any industry-specific standards.

- Third-Party Inspections: Utilize independent inspection agencies to perform random batch testing and pre-shipment inspections, providing unbiased quality verification.

- Sample Testing: Request samples tested by certified labs in your region (e.g., TÜV Rheinland in Germany) to confirm compliance with local standards.

Documentation and Reporting

- Quality Control Reports: Require detailed IQC, IPQC, and FQC reports covering materials used, test results, and defect rates.

- Certificates of Compliance: Ensure suppliers provide valid CE, RoHS, UL, or other relevant certifications.

- Traceability Records: Suppliers should maintain traceability from raw materials to finished products to facilitate recalls or audits.

QC and Certification Nuances for Regional Markets

- Europe (Italy, Germany): Emphasize CE marking, RoHS compliance, and energy efficiency standards like ERP directives. Buyers often require test reports from accredited European labs.

- Middle East: Standards vary; however, UL and IEC certifications are highly valued. Buyers should confirm compliance with local electrical codes and climate resilience.

- Africa and South America: Regulatory environments can be less uniform. Buyers should proactively request certifications recognized internationally and consider additional environmental and durability testing due to challenging operating conditions (e.g., high humidity, dust).

- Logistics and Storage: Verify that suppliers have proper storage and handling procedures to maintain LED strip quality during transit, crucial for long-distance shipments.

Key Takeaways for B2B Buyers

- Manufacturing differences between 2 amp and 5 amp LED strips primarily revolve around copper thickness, component selection, and assembly precision to safely handle higher current loads.

- Adherence to ISO 9001 and industry-specific certifications (CE, UL, RoHS) is essential to ensure quality and regulatory compliance.

- Robust QC checkpoints at IQC, IPQC, and FQC stages minimize defects and ensure product reliability.

- International buyers should leverage factory audits, third-party inspections, and comprehensive documentation to verify supplier quality, tailored to the regulatory landscape of their region.

- Understanding regional certification requirements and environmental challenges will help buyers select LED strip suppliers capable of delivering consistent, high-quality products fit for their markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for 2 amps vs 5 amp led strips Sourcing

When evaluating the cost and pricing dynamics of 2 amp versus 5 amp LED strips for international B2B procurement, it is essential to break down the key cost components and understand the primary price influencers shaping supplier quotes. This insight enables buyers from Africa, South America, the Middle East, and Europe to optimize sourcing strategies and negotiate effectively.

Key Cost Components

-

Materials: The core raw materials include LED chips, flexible PCB substrates, resistors, solder, and protective coatings. Higher amp LED strips (5 amp) generally require thicker copper traces and more robust components to handle increased current, leading to higher material costs compared to 2 amp strips.

-

Labor: Assembly complexity and labor costs can vary depending on the strip design and quality standards. More powerful LED strips may need additional manufacturing steps or testing, slightly increasing labor expenses.

-

Manufacturing Overhead: This covers factory utilities, equipment depreciation, and indirect labor. Higher amp LED strips might require more stringent process controls and quality assurance, influencing overhead allocation.

-

Tooling: Initial tooling investments, such as custom PCB dies or reel-to-reel assembly setups, can be amortized over production runs. Customized or specialized LED strips with higher amperage ratings might entail higher tooling costs.

-

Quality Control (QC): Testing for electrical safety, current handling, and reliability is more rigorous for higher amp LED strips, impacting QC costs. Certifications like CE, RoHS, or UL can add to expenses but improve marketability.

-

Logistics: Shipping costs depend on order volume, weight, packaging, and destination. For international buyers, freight charges, customs duties, and import taxes vary significantly by region, affecting landed costs.

-

Margin: Suppliers incorporate profit margins based on market demand, competition, and order size. Higher-value or customized LED strips often have higher margins.

Primary Price Influencers

-

Order Volume and Minimum Order Quantity (MOQ): Bulk orders reduce per-unit costs through economies of scale. Many suppliers require MOQs, which can differ for 2 amp versus 5 amp strips due to production complexity.

-

Specifications and Customization: Custom lengths, color temperatures, brightness levels, or special coatings increase costs. Higher amp strips may have fewer off-the-shelf options, leading to premium pricing.

-

Material Quality and Certifications: Premium LED chips or compliance with international standards (e.g., CE for Europe, SASO for the Middle East) raise product and sourcing costs but reduce risks.

-

Supplier Location and Capabilities: Domestic suppliers in Europe or the Middle East may charge more due to labor and overhead but offer faster lead times. Asian manufacturers typically provide competitive pricing but require careful vetting.

-

Incoterms: Delivery terms (FOB, CIF, DDP) affect who bears shipping, insurance, and customs risks. Buyers should factor these into total cost calculations.

Actionable Buyer Tips for International B2B Sourcing

-

Negotiate on Volume and Lead Times: Leverage larger order quantities or flexible delivery schedules to obtain better unit prices, especially for 5 amp LED strips with higher production costs.

-

Focus on Total Cost of Ownership (TCO): Consider energy efficiency, durability, and warranty support. Higher amp LED strips may have a higher upfront cost but deliver better performance for demanding applications.

-

Request Detailed Cost Breakdowns: Ask suppliers for transparent pricing on materials, labor, and logistics to identify potential savings.

-

Assess Supplier Certifications and Quality: Prioritize suppliers with internationally recognized certifications to avoid costly compliance issues, especially in regulated markets like Europe.

-

Optimize Logistics and Incoterms: Choose Incoterms that align with your import capabilities and cost structure. For example, DDP terms reduce customs risk but may increase supplier pricing.

-

Understand Regional Market Nuances: Be aware of local import duties, taxes, and electrical standards in your region to avoid unexpected costs and ensure product compatibility.

-

Plan for Currency Fluctuations: For buyers in Africa or South America, currency volatility can affect landed costs; locking in pricing or using hedging strategies may be beneficial.

Disclaimer on Pricing

Prices for 2 amp and 5 amp LED strips vary widely based on supplier, order size, customization, and market conditions. The figures referenced here are indicative and should be validated through direct supplier quotations and market research. Buyers are encouraged to conduct thorough due diligence to achieve optimal cost-efficiency and supply reliability.

By integrating these cost insights and strategic considerations, international B2B buyers can make informed decisions when sourcing 2 amp versus 5 amp LED strips, balancing upfront expenses with long-term value and operational requirements.

Spotlight on Potential 2 amps vs 5 amp led strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘2 amps vs 5 amp led strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 2 amps vs 5 amp led strips

Understanding the technical properties and trade terminology related to 2 amp and 5 amp LED strips is crucial for international B2B buyers seeking to make informed procurement decisions. These insights help ensure product quality, compatibility, and compliance with regional standards across Africa, South America, the Middle East, and Europe.

Critical Technical Properties of 2 Amp vs 5 Amp LED Strips

-

Current Rating (Amperage)

– Defines the maximum current the LED strip can safely carry without overheating or damage. A 2 amp strip supports lower power output and shorter lengths, ideal for compact or low-brightness applications. A 5 amp strip supports higher power, enabling longer runs or brighter lighting.

– B2B Importance: Selecting the right amperage ensures operational safety and reduces risks of failure or fire hazards, aligning with electrical regulations in target markets. -

Voltage Specification

– Most common LED strips operate at 12V or 24V DC. The amperage rating is closely tied to voltage, as power (watts) = voltage × current. For example, a 2 amp, 12V strip consumes 24 watts; a 5 amp strip consumes 60 watts.

– B2B Importance: Buyers must match voltage and current to their power supply capabilities to avoid inefficiencies and ensure stable performance.

-

Copper Thickness (Copper Weight)

– Measured in ounces per square foot, copper thickness in the LED strip’s PCB affects current capacity and heat dissipation. Thicker copper (e.g., 2 oz) supports higher amperage strips better than thinner copper (e.g., 1 oz).

– B2B Importance: Higher copper weight means improved durability and reliability, critical for industrial or commercial installations. -

LED Density and Chip Type

– LED density (LEDs per meter) and chip quality determine brightness and uniformity. Higher amperage strips often use more LEDs or higher-power chips to leverage increased current capacity.

– B2B Importance: Ensures lighting meets client specifications for brightness and energy efficiency, which is vital in competitive markets like Europe and the Middle East. -

Tolerance and Quality Control

– Refers to the allowable deviation in electrical specs like current draw and voltage drop. Tight tolerance (±5% or less) ensures consistent performance across batches.

– B2B Importance: Critical for large-scale projects where consistency affects installation time and maintenance costs. -

Thermal Management

– Effective heat dissipation mechanisms, such as aluminum backing or integrated heat sinks, extend LED lifespan, especially for higher amperage strips.

– B2B Importance: Buyers targeting hot climates or demanding applications (e.g., outdoor lighting in Africa or South America) must prioritize thermal design to reduce failures.

Common Trade Terminology in LED Strip Procurement

-

OEM (Original Equipment Manufacturer)

– Refers to manufacturers producing LED strips that other companies brand and sell. OEMs can customize specifications to buyer requirements.

– B2B Insight: Partnering with reputable OEMs allows buyers to source tailor-made LED strips with assured quality and compliance for different regional markets. -

MOQ (Minimum Order Quantity)

– The smallest order size a supplier will accept, often dictated by manufacturing costs and inventory considerations.

– B2B Insight: Understanding MOQ helps buyers balance inventory investment with project scale, especially critical for small to medium enterprises in emerging markets. -

RFQ (Request for Quotation)

– A formal document buyers send to suppliers to obtain pricing, lead times, and terms for specific LED strip configurations.

– B2B Insight: Crafting detailed RFQs with technical specs reduces ambiguity, accelerates supplier evaluation, and ensures competitive pricing. -

Incoterms (International Commercial Terms)

– Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance (e.g., FOB, CIF, DDP).

– B2B Insight: Selecting appropriate Incoterms mitigates logistical risks and clarifies cost allocation, crucial for cross-border shipments to Africa, South America, and Europe. -

Voltage Drop

– The reduction in voltage along the length of the LED strip due to resistance, affecting brightness and lifespan.

– B2B Insight: Higher amperage strips require careful voltage drop management with proper wiring and power supply placement to maintain uniform lighting. -

Color Rendering Index (CRI)

– A measure of how accurately the LED strip renders colors compared to natural light. Higher CRI (>80) is preferred for retail and hospitality sectors.

– B2B Insight: Buyers should specify CRI based on end-use to meet quality expectations in discerning markets like Germany and Italy.

By mastering these technical properties and trade terms, international buyers can better navigate supplier discussions, ensure product suitability, and optimize procurement strategies for 2 amp and 5 amp LED strips tailored to diverse global market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 2 amps vs 5 amp led strips Sector

Market Overview & Key Trends

The global LED strip market, particularly the niche segment comparing 2 amp versus 5 amp LED strips, is driven by increasing demand for energy-efficient lighting solutions across commercial, industrial, and architectural applications. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding regional power infrastructure and regulatory environments is critical. In regions such as Europe (notably Germany and Italy), stringent energy efficiency standards and certifications are shaping procurement decisions, favoring LED strips with optimal power consumption profiles and longevity.

Emerging trends include a growing preference for higher amperage LED strips (e.g., 5 amp) in projects requiring brighter illumination or longer runs, as these strips often support higher LED density and improved color rendering. Conversely, 2 amp LED strips remain popular for smaller-scale or low-profile installations where power efficiency and ease of integration are prioritized. B2B buyers must consider the trade-offs between amperage, brightness, and power supply requirements. For example, 5 amp strips necessitate heavier gauge wiring and more robust power supplies, impacting installation complexity and cost.

Sourcing trends reveal a surge in demand for customizable LED strips, enabling buyers to specify amperage ratings aligned with project requirements. Suppliers in Asia, particularly China, continue to dominate production, but buyers from Africa and South America are increasingly seeking local or regional partnerships to reduce lead times and logistics costs. Additionally, the rise of smart LED strips compatible with IoT controllers presents new opportunities, especially in technologically progressive markets like Europe and the Middle East.

Understanding market dynamics also involves recognizing the balance between upfront costs and total cost of ownership. While 5 amp LED strips may have higher initial investment due to power supply and wiring needs, their enhanced performance and durability can yield long-term savings. B2B buyers should conduct thorough technical evaluations and collaborate closely with suppliers to optimize product selection for specific applications and regulatory compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone for B2B buyers in the LED strip sector. The environmental impact of LED production, usage, and disposal is under increasing scrutiny, particularly in Europe and the Middle East where regulatory frameworks emphasize circular economy principles. Buyers are prioritizing LED strips manufactured with eco-friendly materials such as lead-free solder, halogen-free substrates, and recyclable components to minimize hazardous waste.

Ethical sourcing extends beyond environmental concerns to encompass labor practices and supply chain transparency. International buyers from Africa and South America often face challenges with traceability in complex global supply chains. Partnering with suppliers who demonstrate compliance with international labor standards and provide verifiable documentation, such as SA8000 or ISO 45001 certifications, is critical for maintaining corporate social responsibility (CSR) standards.

Green certifications, including RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), and Energy Star, are increasingly demanded by B2B buyers to ensure compliance and market acceptance. For 2 amp and 5 amp LED strips, these certifications verify that products meet environmental safety and energy efficiency criteria, reducing risks related to regulatory penalties and reputational damage.

Moreover, buyers should assess the carbon footprint associated with sourcing decisions, considering factors like manufacturing location, transportation emissions, and product lifecycle. Engaging suppliers with sustainability initiatives—such as renewable energy use in manufacturing or take-back recycling programs—can enhance the buyer’s sustainability profile and align with growing consumer and regulatory expectations in their respective markets.

Evolution and Historical Context

LED strip technology has evolved significantly since its inception in the early 2000s. Initially, LED strips operated at lower amperages with limited brightness and color options, primarily serving accent lighting roles. The development of higher amperage options, such as 5 amp strips, allowed for increased LED density and enhanced luminous output, expanding their use into mainstream commercial and industrial lighting.

Advancements in power management, including improved power supplies and copper thickness in strips, have enabled safer and more efficient high-amperage LED strips. This evolution has been driven by demand for flexible, customizable lighting solutions that can integrate into smart building systems and meet energy-saving targets.

For B2B buyers, understanding this progression is vital for making informed sourcing decisions, as newer LED strip generations offer superior performance, longer lifespans, and better compatibility with modern control technologies—key factors in optimizing project outcomes across diverse international markets.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of 2 amps vs 5 amp led strips

-

How can I effectively vet suppliers of 2 amp vs 5 amp LED strips for international trade?

When sourcing LED strips internationally, especially from regions like Africa, South America, the Middle East, or Europe, thoroughly evaluate supplier credibility. Request detailed company profiles, certifications (e.g., CE, RoHS), and factory audit reports. Verify their production capacity aligns with your order volume and inquire about their experience exporting to your region. Cross-check references or client testimonials and use third-party inspection services to assess product quality before shipment. This due diligence minimizes risks and ensures you partner with a reliable supplier capable of meeting your technical and delivery requirements. -

What customization options are typically available for 2 amp and 5 amp LED strips, and how do I request them?

Most manufacturers offer customization including length, color temperature, brightness, voltage, and waterproofing. For 2 amp vs 5 amp LED strips, specify your exact power requirements to ensure compatibility with your application. Request custom PCB thickness and copper width for enhanced durability or voltage drops, especially for long runs. Clearly communicate your desired certifications, packaging, and labeling preferences. Early engagement with suppliers on technical drawings and samples ensures the final product meets your market’s regulatory and functional needs, particularly important for diverse international standards. -

What are the typical minimum order quantities (MOQs) and lead times for 2 amp vs 5 amp LED strips?

MOQs vary widely depending on manufacturer scale and customization level but generally start around 500 to 1,000 meters per order. Lead times average 3 to 6 weeks, influenced by order complexity, customization, and supplier backlog. For B2B buyers in Africa, South America, the Middle East, and Europe, factor in additional shipping and customs clearance time. Negotiate MOQs when possible to align with your inventory strategy, and confirm lead times upfront to avoid project delays. Building a strong supplier relationship can also help secure priority production slots during peak demand. -

Which quality assurance measures and certifications should I require for LED strips to ensure compliance and reliability?

Request suppliers provide internationally recognized certifications such as CE (European conformity), RoHS (restriction of hazardous substances), UL or ETL (safety standards), and ISO 9001 (quality management). These ensure compliance with regional regulations and product safety. Additionally, insist on in-house quality control reports, including electrical testing (amperage, voltage, wattage), longevity tests, and visual inspections. For markets with strict import regulations like the EU, certifications are mandatory. Third-party testing or factory audits add an extra layer of assurance to minimize returns and warranty claims. -

How should I plan logistics and shipping for 2 amp vs 5 amp LED strips to ensure timely delivery and cost efficiency?

Coordinate with suppliers early to choose optimal shipping methods (air, sea, or express courier) based on order size, urgency, and destination infrastructure. LED strips are lightweight but sensitive to moisture and static; ensure proper packaging and labeling. For bulk orders, sea freight is cost-effective but slower; for urgent projects, air freight is preferred despite higher cost. Understand customs duties, import taxes, and local compliance requirements in your target markets. Collaborate with experienced freight forwarders familiar with your regions (Africa, South America, Middle East, Europe) to streamline customs clearance and reduce delays. -

What payment terms are standard for international B2B transactions involving LED strips, and how can I mitigate financial risks?

Common payment terms include 30% advance deposit with balance before shipment or upon delivery. Letters of credit (LC) offer enhanced security for both parties. For new suppliers, consider escrow services or smaller trial orders to build trust. Always confirm payment methods accepted (T/T, PayPal, LC) and beware of upfront full payments without verified supplier credentials. Use contracts detailing product specs, delivery schedules, and penalties for non-compliance. Engage legal counsel experienced in international trade law to draft or review agreements, reducing risk exposure in cross-border transactions. -

How can I handle disputes or quality issues with LED strip suppliers across different regions?

Establish clear communication channels and document all agreements to facilitate dispute resolution. Include arbitration or mediation clauses specifying neutral venues and governing laws in contracts. For quality issues, request photographic evidence and arrange third-party inspections. Many suppliers offer warranties—confirm terms before purchase. Engage local trade chambers or export promotion agencies for support if disputes escalate. Building relationships based on transparency and prompt issue resolution encourages suppliers to cooperate, essential for long-term partnerships in diverse international markets. -

Are there significant differences in electrical standards or installation requirements for 2 amp vs 5 amp LED strips across regions like Europe and the Middle East?

Yes, electrical codes and installation standards vary by region. Europe typically mandates CE compliance and adherence to IEC standards with strict voltage and current regulations. The Middle East may follow IEC or local standards, with additional environmental considerations like heat and dust. Higher amperage LED strips (5 amp) require thicker wiring and proper circuit protection to avoid voltage drops and overheating, especially in longer runs. Consult local electrical codes and work with certified installers to ensure safe and compliant installations, preventing warranty voidance and safety hazards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 2 amps vs 5 amp led strips

Strategic sourcing of LED strips, particularly when weighing 2 amp versus 5 amp options, is a critical decision that directly impacts project efficiency, cost management, and long-term operational reliability. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the electrical demands, installation complexities, and power supply requirements ensures optimized procurement tailored to diverse infrastructure environments.

Key takeaways include:

– Power capacity alignment: Selecting LED strips with appropriate amperage reduces risks related to voltage drop and overheating, enhancing safety and longevity.

– Cost-efficiency through scalability: 2 amp strips may suit smaller, low-intensity applications, while 5 amp strips support high-brightness, extensive installations—allowing buyers to strategically match product specs with project scale.

– Compliance and standards awareness: Navigating regional electrical codes and wiring standards is essential to avoid costly retrofits and ensure seamless integration.

By embracing a strategic sourcing approach that balances technical specifications, supplier reliability, and regional regulations, international buyers can secure competitive advantages and foster sustainable partnerships.

Looking ahead, as LED technology evolves and demand for energy-efficient lighting intensifies globally, proactive sourcing aligned with innovation will empower businesses to lead in their markets. Buyers are encouraged to leverage detailed supplier evaluations and engage in collaborative planning to harness the full potential of both 2 amp and 5 amp LED strip solutions.

Illustrative Image (Source: Google Search)