Introduction: Navigating the Global Market for philips hue led light strip

In today’s rapidly evolving smart lighting industry, the Philips Hue LED light strip stands out as a benchmark of innovation, quality, and versatility. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing Philips Hue LED light strips is critical to securing competitive advantages and meeting consumer demands effectively. These smart LED strips combine advanced technology with customizable lighting solutions, appealing to a broad spectrum of commercial and residential projects.

This comprehensive guide is designed to equip procurement professionals, distributors, and wholesalers with actionable insights into every facet of the Philips Hue LED light strip ecosystem. You will explore various product types, including flexible and rigid strips, and how their material composition impacts performance and durability. We delve into the manufacturing processes and stringent quality control measures employed by Signify and its global factories, ensuring consistent reliability. The guide also analyzes the supply chain landscape, highlighting key component suppliers and assembly locations, which influence lead times and cost structures.

Moreover, this resource addresses pricing strategies, market trends, and regional considerations, providing tailored intelligence for buyers in emerging and established markets such as Vietnam and Spain. A dedicated FAQ section further clarifies common procurement challenges, helping buyers make informed, strategic sourcing decisions. By combining technical expertise with market insights, this guide empowers B2B buyers to confidently navigate the complexities of the global Philips Hue LED light strip market and optimize their purchasing outcomes.

Understanding philips hue led light strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Philips Hue Lightstrip Plus | Extensible up to 10 meters, full RGB color, dimmable | Retail displays, hospitality, office ambiance | + Flexible length, rich colors; – Higher price, requires Hue Bridge |

| Philips Hue Gradient Lightstrip | Multi-zone color gradients, seamless color transitions | Premium home automation, luxury commercial spaces | + Advanced color effects, premium appeal; – Costly, complex setup |

| Philips Hue Outdoor Lightstrip | Weather-resistant, robust IP67 rating | Outdoor signage, landscape lighting | + Durable for outdoor use; – Limited length, fewer color zones |

| Philips Hue Lightstrip Essentials | Simplified white and color ambiance, no bridge needed | Small businesses, quick installations | + Easy setup, cost-effective; – Limited integration, fewer features |

| Philips Hue Sync Box Compatible Strips | Designed for media sync with entertainment systems | Gaming arenas, media rooms, experiential marketing | + Syncs with media, immersive; – Requires Sync Box, niche use |

Philips Hue Lightstrip Plus

The Lightstrip Plus is the most versatile and widely used Philips Hue strip. It supports full RGB color with dimming capabilities and can be extended up to 10 meters, making it ideal for large-scale installations. For B2B buyers, this type suits retail environments, offices, and hospitality venues seeking customizable lighting solutions. Buyers should consider the need for a Hue Bridge for full system integration, which adds to upfront costs but enables scalable smart control and automation.

Philips Hue Gradient Lightstrip

This variation offers multi-zone color gradients that allow smooth transitions between colors along the strip, creating dynamic lighting effects. It is best suited for premium residential projects, luxury hotels, and high-end commercial spaces where ambiance and aesthetics are paramount. B2B buyers should weigh the higher price point and installation complexity against the unique value it adds to experiential environments.

Philips Hue Outdoor Lightstrip

Designed with an IP67 weather-resistant rating, the Outdoor Lightstrip is engineered for durability in harsh environments. It is ideal for outdoor signage, architectural accents, and landscape lighting in commercial properties. Buyers from regions with variable climates, such as parts of Africa and the Middle East, will find this product essential for reliable outdoor applications. The tradeoff is a shorter maximum length and fewer color zones compared to indoor models.

Philips Hue Lightstrip Essentials

This model offers a simplified smart lighting experience with white and color ambiance options but does not require a Hue Bridge, enabling quicker and more cost-effective setups. It is perfect for small businesses and quick deployment scenarios where ease of use and budget are priorities. However, integration options and advanced features are limited, which may restrict scalability for larger or more complex projects.

Philips Hue Sync Box Compatible Strips

These LED strips are optimized to work with the Philips Hue Sync Box, enabling real-time lighting effects synchronized with media content. This makes them ideal for gaming arenas, media rooms, and experiential marketing environments that demand immersive experiences. B2B buyers should account for the need to invest in the Sync Box hardware and recognize that this product targets niche entertainment-focused applications rather than general lighting.

Related Video: Philips Hue LED Strip Light Plus Unboxing and Setup

Key Industrial Applications of philips hue led light strip

| Industry/Sector | Specific Application of Philips Hue LED Light Strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Retail | Ambient and accent lighting in hotel lobbies, restaurants, and retail displays | Enhances customer experience and brand ambiance; customizable lighting scenes increase dwell time and sales | Ensure compatibility with local power standards; durability for high-traffic environments; ease of integration with existing smart systems |

| Commercial Office Spaces | Dynamic workspace lighting to improve productivity and reduce energy costs | Supports circadian rhythms and employee well-being; energy-efficient and programmable lighting reduces operational expenses | Compliance with regional energy efficiency regulations; scalability for large office installations; robust software support for multi-user control |

| Entertainment & Events | Stage and architectural lighting for concerts, exhibitions, and events | Creates immersive environments with color-changing effects; flexible installation options for temporary setups | Portability and ease of installation; high color accuracy and brightness; compatibility with DMX or other lighting control protocols |

| Smart Home & Building Automation | Integration into smart home systems for mood lighting and security | Enhances property value and user convenience; supports IoT ecosystems for remote control and automation | Interoperability with global smart home platforms (e.g., Zigbee, Apple HomeKit); warranty and after-sales support in target markets |

| Healthcare Facilities | Calming and therapeutic lighting in patient rooms and waiting areas | Improves patient comfort and recovery outcomes; customizable lighting reduces stress and anxiety | Strict adherence to safety and hygiene standards; flicker-free and low-UV emission lighting; long lifespan to minimize maintenance |

Philips Hue LED light strips are increasingly leveraged in hospitality and retail environments to craft inviting atmospheres that elevate customer experiences. Hotels and restaurants utilize these strips for accentuating architectural features and creating mood lighting that can be adjusted seasonally or for special events. For international buyers, especially in regions like Africa and South America, sourcing products compatible with local electrical standards and robust enough to withstand high foot traffic is critical. Integration capabilities with existing building management systems can further enhance operational efficiency.

In commercial office spaces, Philips Hue LED strips serve as dynamic lighting solutions that adapt to different work modes, promoting employee wellness by aligning with natural circadian rhythms. This application supports energy savings through programmable schedules and presence detection. B2B buyers from Europe and the Middle East should prioritize products compliant with regional energy efficiency standards and capable of scaling across large office floors, while offering centralized control for facility managers.

The entertainment and events sector benefits from Philips Hue LED strips due to their versatility in creating vibrant stage effects and immersive environments. Their color-changing and dimming features allow event organizers to tailor lighting to performances or exhibitions rapidly. For markets in Vietnam or Spain, it is essential to source strips that support common lighting control protocols like DMX and offer easy installation and portability for temporary setups.

In smart home and building automation, these LED strips integrate seamlessly with IoT platforms, enabling sophisticated mood lighting and security features. This use case enhances property appeal and user convenience. Buyers internationally must consider interoperability with popular smart ecosystems such as Zigbee or Apple HomeKit, and ensure reliable after-sales service and warranty coverage, particularly in emerging markets.

Lastly, healthcare facilities utilize Philips Hue LED light strips to create calming environments that aid patient recovery and reduce anxiety in waiting areas. The strips’ ability to produce flicker-free, low-UV light is vital for sensitive settings. International B2B buyers should verify adherence to stringent safety and hygiene standards, as well as prioritize long-lasting products to reduce maintenance disruptions in healthcare environments.

Related Video: How To Light Your Desk Setup & Workspace | Philips Hue Smart Lights Setup

Strategic Material Selection Guide for philips hue led light strip

When selecting materials for Philips Hue LED light strips, international B2B buyers must consider performance, durability, manufacturing complexity, and compliance with regional standards. The right material choice directly impacts product longevity, installation versatility, and cost-effectiveness, especially across diverse markets such as Africa, South America, the Middle East, and Europe.

1. Flexible Printed Circuit Board (FPCB) Material

Key Properties:

FPCBs are typically made from polyimide or polyester films, offering excellent flexibility, high temperature resistance (up to 260°C), and good electrical insulation. They also provide moderate resistance to moisture and chemicals.

Pros & Cons:

– Pros: Enables the LED strip to bend and conform to various surfaces, essential for architectural and decorative lighting. Lightweight and thin, it supports compact designs.

– Cons: More costly than rigid PCBs and requires precise manufacturing processes. Susceptible to damage under mechanical stress if not handled carefully.

Impact on Application:

FPCB is ideal for installations requiring curved or irregular surfaces, such as automotive interiors or complex architectural elements. Its flexibility enhances adaptability but may limit use in harsh, abrasive environments without protective coatings.

Considerations for International Buyers:

Buyers in regions with high humidity or dust (e.g., parts of Africa or the Middle East) should ensure the FPCB has adequate conformal coatings to prevent corrosion. Compliance with IEC and UL standards is common in Europe and South America, while ASTM standards may be requested in North America-influenced markets. Vietnam and Spain buyers often prioritize RoHS compliance and CE marking for environmental and safety assurance.

2. LED Chips (Semiconductor Material)

Key Properties:

LED chips are generally made from gallium nitride (GaN) or indium gallium nitride (InGaN), offering high luminous efficacy, long operational life (up to 50,000 hours), and excellent thermal stability.

Pros & Cons:

– Pros: High brightness with low power consumption, stable color output, and long lifespan.

– Cons: Sensitive to heat; requires effective thermal management. Higher-grade chips increase product cost.

Impact on Application:

The quality of LED chips directly affects light output, color accuracy, and energy efficiency. For commercial and hospitality sectors in Europe and South America, premium chips ensure superior lighting ambiance. In Africa and the Middle East, where power fluctuations are common, robust chips with thermal and electrical resilience are critical.

Considerations for International Buyers:

Buyers should verify chip certifications such as LM-80 for lumen maintenance and ensure sourcing from reputable suppliers to avoid counterfeit components. Regional preferences lean toward suppliers with ISO 9001 and ISO 14001 certifications. Vietnam and Spain markets emphasize compliance with international environmental standards (RoHS, REACH).

3. Adhesive Backing Material

Key Properties:

Adhesive backings are commonly made from acrylic or silicone-based adhesives, designed for strong adhesion, temperature tolerance (-40°C to 150°C), and resistance to UV and moisture.

Pros & Cons:

– Pros: Facilitates easy installation on various surfaces, maintains adhesion over time in different climates. Silicone adhesives offer superior heat and chemical resistance.

– Cons: Acrylic adhesives may degrade under prolonged UV exposure; silicone adhesives are more expensive and complex to manufacture.

Impact on Application:

Adhesive quality determines installation reliability, especially in outdoor or industrial environments. In hot climates like the Middle East or tropical Africa, UV-resistant adhesives prevent peeling. For indoor use in Europe and South America, cost-effective acrylic adhesives suffice.

Considerations for International Buyers:

Buyers should assess adhesive compatibility with intended surfaces (metal, plastic, painted walls) and environmental conditions. Certifications related to chemical safety and VOC emissions are increasingly important in Europe and Vietnam. Packaging that protects adhesive integrity during shipping is crucial for long-distance imports.

4. Protective Silicone or PVC Coating

Key Properties:

Silicone and PVC coatings provide waterproofing (IP65 to IP68 ratings), chemical resistance, and mechanical protection. Silicone offers higher flexibility and thermal stability, while PVC is cost-effective but less durable in extreme conditions.

Pros & Cons:

– Pros: Extends LED strip lifespan by protecting against moisture, dust, and physical damage. Silicone coatings allow for outdoor and industrial applications.

– Cons: Silicone coatings increase production costs and complexity; PVC coatings may yellow or crack over time under UV exposure.

Impact on Application:

Essential for outdoor or wet environment installations, such as signage, landscape lighting, or industrial settings. In regions with heavy rainfall or dust storms (e.g., parts of Africa and the Middle East), silicone coatings are preferred. Indoor applications in Europe or South America may use PVC coatings to reduce cost.

Considerations for International Buyers:

Compliance with IP rating standards and chemical resistance tests is critical. European buyers often require adherence to EN standards, while ASTM and JIS standards might be relevant in South America and Asia. Buyers in Vietnam and Spain should verify that coatings meet RoHS and REACH directives to ensure environmental safety.

Summary Table

| Material | Typical Use Case for philips hue led light strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Board (FPCB) | Flexible installations requiring bending and contouring on surfaces | High flexibility and heat resistance | Higher cost and sensitive to mechanical stress | High |

| LED Chips (GaN/InGaN) | Core light source for energy-efficient, bright illumination | Long lifespan and excellent luminous efficacy | Heat sensitivity requiring thermal management | High |

| Adhesive Backing (Acrylic/Silicone) | Mounting LED strips securely on various surfaces | Strong adhesion and temperature tolerance | Acrylic less UV resistant; silicone more expensive | Medium |

| Protective Silicone/PVC Coating | Waterproofing and protection for outdoor or industrial use | Enhances durability and environmental resistance | Silicone costly; PVC less durable under UV | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for philips hue led light strip

Manufacturing Process of Philips Hue LED Light Strip

The production of Philips Hue LED light strips involves a highly controlled, multi-stage manufacturing process designed to ensure superior performance, durability, and energy efficiency. This process integrates advanced materials, precision engineering, and strict quality protocols, making the product suitable for diverse international B2B markets.

1. Material Preparation and Component Sourcing

The foundation of a high-quality Philips Hue LED strip lies in the careful selection and preparation of raw materials:

- LED Chips: Philips sources premium LED chips known for high luminous efficacy and longevity. These chips are procured from globally recognized suppliers, ensuring consistent brightness and energy efficiency.

- Printed Circuit Boards (PCBs): Flexible PCBs designed for optimal heat dissipation form the substrate of the strip. These are fabricated using high-grade materials to prevent thermal degradation and ensure mechanical flexibility.

- Adhesive Backing: Industrial-grade adhesives are chosen to guarantee robust installation across diverse surfaces and environments, from humid regions in South America to dry climates in the Middle East.

- Electronic Components: Power drivers, controllers, and connectors are sourced from certified vendors to maintain compatibility and performance with the Philips Hue ecosystem.

2. PCB Fabrication and LED Mounting

- PCB Fabrication: The process begins with the precise etching and layering of flexible PCB materials. This step is critical to provide electrical pathways and mechanical support.

- LED Chip Placement: Automated pick-and-place machines position LED chips onto the PCB with micron-level accuracy. This ensures uniform light distribution and prevents defects.

- Soldering: Reflow soldering techniques secure the chips and electronic components onto the PCB. Controlled temperature profiles during soldering prevent damage to sensitive parts.

3. Assembly and Integration

- Circuit Integration: Additional components such as resistors, capacitors, and microcontrollers are integrated to enable smart lighting features like color control and connectivity.

- Encapsulation and Sealing: The LED strips are coated with protective layers or silicone to guard against moisture, dust, and mechanical wear, enhancing durability in diverse climates.

- Connector Attachment: Specialized connectors are attached to facilitate easy installation and integration within Philips Hue systems.

4. Finishing and Packaging

- Visual Inspection: Automated optical inspection (AOI) systems detect surface defects or misalignments.

- Cutting and Sizing: Strips are cut to standard or custom lengths based on market requirements.

- Packaging: Each strip is packaged with anti-static materials and protective layers to prevent damage during shipping. Packaging is designed to comply with international shipping regulations, which is especially important for global B2B buyers.

Quality Assurance Framework and Standards

Philips Hue LED light strips are subject to rigorous quality assurance (QA) protocols aligned with international standards and industry-specific certifications. These processes are critical for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, who must ensure compliance with local regulations and market expectations.

Key International and Industry Standards

- ISO 9001: Philips adheres to this globally recognized quality management system standard, ensuring consistent manufacturing processes and continuous improvement.

- CE Marking: Compliance with European Union safety, health, and environmental requirements, essential for buyers in Europe and countries recognizing CE certification.

- RoHS (Restriction of Hazardous Substances): Ensures the product is free from hazardous materials like lead and mercury, critical for environmental compliance worldwide.

- UL and ETL Listings: Relevant for markets like the Middle East and parts of Africa, these certifications verify electrical safety and performance.

- Energy Star and IEC Standards: Validate energy efficiency and electromagnetic compatibility, important for sustainable procurement policies.

Quality Control Checkpoints in Manufacturing

Quality control (QC) in Philips Hue LED strip production is multi-layered, with checkpoints embedded throughout the manufacturing cycle:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to verify specifications and certifications. This prevents substandard inputs from entering the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB fabrication, LED placement, soldering, and assembly stages. This includes visual inspections, automated optical inspections, and functional tests to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips before packaging. This involves electrical performance tests, visual quality checks, adhesion tests, and environmental stress tests.

Common Testing Methods for Philips Hue LED Strips

- Electrical Testing: Verification of voltage, current, and power consumption to ensure energy efficiency and safety.

- Light Output and Color Consistency Testing: Use of spectrometers to measure brightness, color temperature, and uniformity, ensuring the smart lighting experience meets Philips standards.

- Thermal Testing: Assessment of heat dissipation under continuous operation to prevent premature failure.

- Environmental Stress Testing: Exposure to humidity, temperature cycles, and vibration to simulate real-world conditions, assuring durability in diverse climates.

- Adhesion and Flexibility Tests: Confirming that strips maintain adhesion and mechanical integrity on various surfaces.

How B2B Buyers Can Verify Supplier Quality Control

For international B2B buyers, especially in emerging markets such as Vietnam or established ones like Spain, due diligence on supplier QC is vital:

- Factory Audits: Conduct or commission on-site audits to review manufacturing processes, quality systems, and worker training. Third-party audits by firms like SGS or TÜV provide impartial verification.

- Review of Quality Documentation: Request detailed QC reports, certificates of compliance (CE, RoHS, UL), and test data for batch samples.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment.

- Sample Testing: Obtain product samples for in-house or local laboratory testing to verify performance claims.

- Supplier Certifications: Confirm that suppliers maintain ISO 9001 certification and relevant product certifications applicable to your market.

QC and Certification Nuances for International Markets

- Africa and South America: Markets may require additional certification for electrical safety and environmental compliance. Buyers should verify that Philips Hue strips meet local regulatory requirements, such as INMETRO in Brazil or SABS in South Africa.

- Middle East: Compliance with Gulf Cooperation Council (GCC) standards and SASO certification is often mandatory. Suppliers must demonstrate adherence to these regional requirements.

- Europe: CE marking and RoHS compliance are non-negotiable. Buyers should also consider energy efficiency certifications, as environmental standards are increasingly stringent.

- Vietnam and Southeast Asia: While local regulations may be evolving, buyers often demand international certifications like CE and UL for imported lighting products to assure quality and safety.

Key Takeaways for B2B Buyers

- Demand transparency: Engage suppliers who provide comprehensive quality documentation and are open to audits.

- Understand local regulations: Align procurement decisions with the certification requirements of your target market.

- Prioritize durability and efficiency: Philips Hue LED light strips undergo rigorous material selection and testing to ensure performance across diverse environmental conditions.

- Leverage third-party inspections: Independent verification reduces risks and strengthens supplier relationships.

- Consider supply chain reliability: Philips’ global manufacturing footprint supports consistent quality and timely delivery, vital for international buyers managing complex logistics.

By understanding the detailed manufacturing and quality assurance processes behind Philips Hue LED light strips, B2B buyers can make informed decisions that align with their operational needs, regulatory frameworks, and customer expectations across global markets.

Comprehensive Cost and Pricing Analysis for philips hue led light strip Sourcing

Sourcing Philips Hue LED light strips involves a nuanced understanding of the cost structure and pricing dynamics that impact international B2B transactions. For buyers from diverse regions such as Africa, South America, the Middle East, and Europe, mastering these elements is key to optimizing procurement and ensuring competitive margins.

Key Cost Components

- Materials: The primary cost driver includes high-quality LED chips, PCBs (printed circuit boards), adhesives, and durable plastics. Premium LED chips enhance performance but come at a higher price, directly influencing product longevity and energy efficiency.

- Labor: Manufacturing labor costs vary significantly by country and factory sophistication. Assembly, testing, and quality control require skilled labor, often reflected in the final pricing.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Overhead costs fluctuate based on the scale of production and automation level.

- Tooling and Setup: Initial tooling for PCB fabrication and LED chip mounting can be substantial, especially for custom specifications or smaller production runs.

- Quality Control (QC): Rigorous testing for durability, luminous efficacy, and compliance with international certifications (CE, RoHS, UL) adds to the cost but safeguards product reliability.

- Logistics: Shipping from manufacturing hubs (commonly China, Hungary, or Germany) to target markets involves freight, customs duties, insurance, and handling fees, which vary by Incoterms and destination.

- Margin: Suppliers incorporate profit margins that reflect product exclusivity, brand reputation (Philips Hue as a premium brand), and service levels.

Price Influencers

- Order Volume & Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts, reducing unit costs. However, buyers with smaller needs may face higher per-unit pricing or tooling fees.

- Specifications & Customization: Custom lengths, colors, or integration features increase complexity and cost. Standardized SKUs are generally more cost-effective.

- Material Quality & Certifications: Compliance with international safety and environmental standards can increase costs but is crucial for market acceptance, especially in Europe and regulated Middle Eastern markets.

- Supplier Factors: Factory location, production capacity, and supplier reputation impact pricing. Established suppliers with proven quality control often command premium prices.

- Incoterms: Terms such as FOB, CIF, or DDP affect who bears freight and customs costs, influencing the total landed cost.

Actionable Buyer Tips for International B2B Procurement

- Negotiate Based on Total Cost of Ownership (TCO): Look beyond unit price to include shipping, customs, duties, and potential warranty or after-sales service costs.

- Leverage Volume Flexibility: Consolidate orders or collaborate with other buyers in your region to meet MOQ thresholds for better pricing.

- Prioritize Certified Quality: Insist on products with relevant certifications to avoid costly regulatory delays or rejections in your market.

- Clarify Incoterms Early: Ensure clarity on shipping terms to prevent unexpected logistical expenses, especially for importers in Africa and South America where customs processes may be complex.

- Assess Supplier Reliability: Choose suppliers with transparent QC processes and good communication to minimize risks related to defective products or delays.

- Consider Local Assembly or Value-Add: For markets like Vietnam or Spain, explore local assembly options to reduce import tariffs or customize offerings cost-effectively.

- Currency and Payment Terms: Negotiate payment terms that minimize foreign exchange risks and support cash flow, which is particularly relevant for buyers in emerging markets.

Pricing Nuances by Region

- Africa & South America: Import duties and variable logistics infrastructure can significantly add to landed costs. Opt for suppliers offering DDP terms or local partnerships to streamline delivery.

- Middle East: Compliance with Gulf standards and preference for fast delivery necessitate reliable logistics and certified products.

- Europe (e.g., Spain): Stringent regulations and consumer expectations make certification and warranty terms critical, often justifying higher upfront costs.

Disclaimer on Pricing

Prices for Philips Hue LED light strips are indicative and subject to change based on global supply chain fluctuations, raw material availability, and geopolitical factors. Buyers should conduct up-to-date market research and request detailed quotations from multiple suppliers before committing.

By understanding these cost drivers and pricing influences, international B2B buyers can strategically source Philips Hue LED light strips that balance quality, cost, and compliance — ensuring successful market entry and sustainable profitability.

Spotlight on Potential philips hue led light strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘philips hue led light strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for philips hue led light strip

Critical Technical Properties of Philips Hue LED Light Strip

1. LED Chip Quality and Type

The LED chips are the core of the light strip, determining brightness, color accuracy, and lifespan. Philips Hue uses premium-grade chips that provide consistent luminous efficacy and vibrant color rendering (often measured by CRI – Color Rendering Index). For B2B buyers, sourcing strips with high-quality LED chips ensures durability and customer satisfaction, reducing returns and warranty claims.

2. PCB Material and Design

The printed circuit board (PCB) is typically made from high-quality, heat-dissipating materials such as flexible polyimide or rigid fiberglass. Efficient heat management prevents early LED degradation and maintains performance over time. For international buyers, understanding PCB quality helps evaluate product longevity, especially in warmer climates like Africa and the Middle East.

3. Power Supply and Voltage Compatibility

Philips Hue LED strips operate on low voltage DC power (commonly 24V). Power supply quality affects energy efficiency and safety compliance. Buyers should confirm voltage compatibility with local standards and infrastructure to avoid costly modifications or regulatory issues during import and installation.

4. Adhesive Backing and Environmental Resistance

The adhesive backing must be industrial-grade to ensure secure installation on various surfaces without peeling. Additionally, resistance to humidity, dust, and temperature fluctuations is critical, particularly for regions with extreme climates. This property supports installation versatility and reduces maintenance costs in commercial projects.

5. Control Interface and Connectivity Protocols

Philips Hue LED strips integrate with Zigbee or Bluetooth protocols for smart control. Compatibility with existing smart home or building management systems is vital for seamless integration. For B2B buyers, understanding these protocols enables tailored solutions for automation and remote management, enhancing value propositions for end clients.

6. Compliance Certifications

Key certifications such as CE, RoHS, and UL guarantee that the product meets international safety, environmental, and quality standards. For buyers in Europe, South America, and the Middle East, verified compliance simplifies customs clearance and reassures clients regarding product reliability and safety.

Essential Trade Terminology for Philips Hue LED Light Strip Procurement

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products or components that are purchased by another company and retailed under that purchasing company’s brand. For Philips Hue LED strips, OEM status may indicate authentic, high-quality products versus generic or counterfeit alternatives. B2B buyers benefit from engaging with OEMs to ensure product authenticity and warranty support.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Understanding MOQ helps buyers manage inventory and cash flow, especially for startups or distributors targeting smaller markets in Africa or South America. Negotiating MOQ is often key to optimizing purchase costs without overstocking.

RFQ (Request for Quotation)

A formal process where buyers invite suppliers to submit price proposals based on specified product details and quantities. RFQs are essential for comparing offers from multiple Philips Hue LED strip suppliers and securing the best terms. Clear, detailed RFQs reduce misunderstandings and expedite procurement cycles.

Incoterms (International Commercial Terms)

Standardized trade terms defined by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Common Incoterms include FOB (Free on Board) and DDP (Delivered Duty Paid). For international buyers, choosing the right Incoterm impacts total landed cost and risk management.

Lead Time

The period between order placement and product delivery. Understanding lead times is crucial for project planning and inventory management. Philips Hue LED strips may have variable lead times depending on customization and shipping routes, especially relevant for buyers in remote regions.

Batch Number / Lot Number

A unique identifier assigned to a production batch. This helps in tracking product quality, managing recalls, and ensuring traceability. B2B buyers should request batch information to maintain quality control and warranty claims, particularly when sourcing large volumes.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, streamline supply chain processes, and ensure that Philips Hue LED light strips meet their operational and market requirements effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the philips hue led light strip Sector

Market Overview & Key Trends

The Philips Hue LED light strip sector is positioned at the intersection of smart home innovation and energy-efficient lighting, driven by increasing global demand for connected, customizable lighting solutions. For international B2B buyers in Africa, South America, the Middle East, and Europe—including markets like Vietnam and Spain—several key market dynamics and sourcing trends are shaping the landscape.

Global Drivers:

Urbanization and digitization are major catalysts, with rising consumer interest in smart homes and IoT integration fueling demand for Philips Hue products. Additionally, the commercial sector’s adoption of dynamic lighting systems for retail, hospitality, and office environments is expanding opportunities. Markets in emerging regions are rapidly upgrading infrastructure, creating demand for scalable, energy-efficient lighting solutions.

Sourcing Trends:

Philips Hue LED light strips rely on a complex supply chain, sourcing components such as high-quality LED chips, flexible PCBs, and controllers from specialized global suppliers. Manufacturing hubs in China, Europe (notably Germany and Hungary), and the U.S. enable Philips to optimize production costs and logistics. For B2B buyers, understanding this diversified sourcing approach is crucial for negotiating lead times, pricing, and quality assurance. Increasingly, buyers are favoring suppliers who demonstrate agility in supply chain management and can provide reliable certification compliance (e.g., CE, RoHS).

Technology & Integration:

Compatibility with voice assistants and home automation platforms remains a decisive factor. Philips Hue’s continual software upgrades and open APIs enhance integration capabilities, a strong selling point for B2B customers aiming to offer holistic smart lighting ecosystems.

Regional Considerations:

– Africa & Middle East: Infrastructure development and rising middle-class populations are driving growth, but buyers must navigate import regulations and ensure product adaptability to local voltage and climate conditions.

– South America: Economic volatility requires flexible procurement strategies, with local partnerships often needed to optimize distribution and after-sales support.

– Europe & Vietnam: These markets prioritize innovation and sustainability, with demand for premium quality and certified eco-friendly products. Vietnam’s growing manufacturing sector also presents opportunities for localized assembly or component sourcing.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a critical factor in B2B procurement decisions for Philips Hue LED light strips. Environmental impact considerations span product design, material sourcing, manufacturing, and end-of-life disposal.

Environmental Impact:

LED technology inherently offers significant energy savings compared to traditional lighting, reducing carbon footprints for end-users. Philips Hue products emphasize long lifespan and low power consumption, which aligns with corporate sustainability goals. However, the sourcing of raw materials—particularly rare earth elements and plastics—necessitates scrutiny to minimize ecological damage.

Ethical Supply Chains:

B2B buyers increasingly demand transparency in supply chains to avoid risks associated with labor abuses, conflict minerals, and environmental violations. Philips’ commitment to ethical sourcing includes partnering with suppliers adhering to international labor standards and environmental regulations. For buyers, verifying supplier certifications and conducting audits can mitigate reputational and operational risks.

Green Certifications & Materials:

Philips Hue LED strips often carry certifications such as RoHS (Restriction of Hazardous Substances) and CE marking, ensuring compliance with European environmental and safety standards. Additionally, buyers should look for products incorporating recycled plastics or biodegradable packaging to further reduce environmental impact. Sustainable packaging and minimized waste during manufacturing are growing expectations in global B2B contracts.

Actionable Insight:

International buyers should prioritize suppliers who offer full lifecycle transparency, from component sourcing to end-of-life recycling programs. Partnering with manufacturers invested in circular economy principles can deliver long-term cost savings and align with corporate social responsibility (CSR) mandates.

Evolution and Historical Context

The Philips Hue LED light strip sector has evolved significantly since the launch of the Philips Hue ecosystem in 2012. Initially focused on smart bulbs, Philips expanded into LED strips to capture demand for flexible, ambient lighting solutions that can be integrated into diverse settings—residential, commercial, and hospitality.

Early iterations prioritized basic color-changing capabilities, but advancements in wireless connectivity, app control, and interoperability with voice assistants have transformed these strips into sophisticated devices. This evolution reflects broader trends in smart lighting: increasing user control, energy efficiency, and seamless integration with smart home platforms.

For B2B buyers, understanding this history underscores Philips Hue’s commitment to innovation and reliability, reinforcing its position as a premium brand with mature supply chains and proven technology. This legacy supports confidence in product quality and the availability of ongoing software and hardware support critical for long-term business deployments.

Frequently Asked Questions (FAQs) for B2B Buyers of philips hue led light strip

- How can I effectively vet suppliers of Philips Hue LED light strips for international B2B purchase?

To ensure reliability, verify that suppliers are authorized Philips Hue distributors or certified partners within the Signify network. Request documentation of product authenticity, including certificates of origin and compliance (e.g., CE, RoHS). Conduct factory audits or virtual inspections focusing on manufacturing standards, quality control procedures, and supply chain transparency. Review customer references and past export experience, especially in your region (Africa, South America, Middle East, Europe). Using platforms with escrow or payment protection and insisting on clear contracts with defined responsibilities mitigates risks of counterfeit or substandard products.

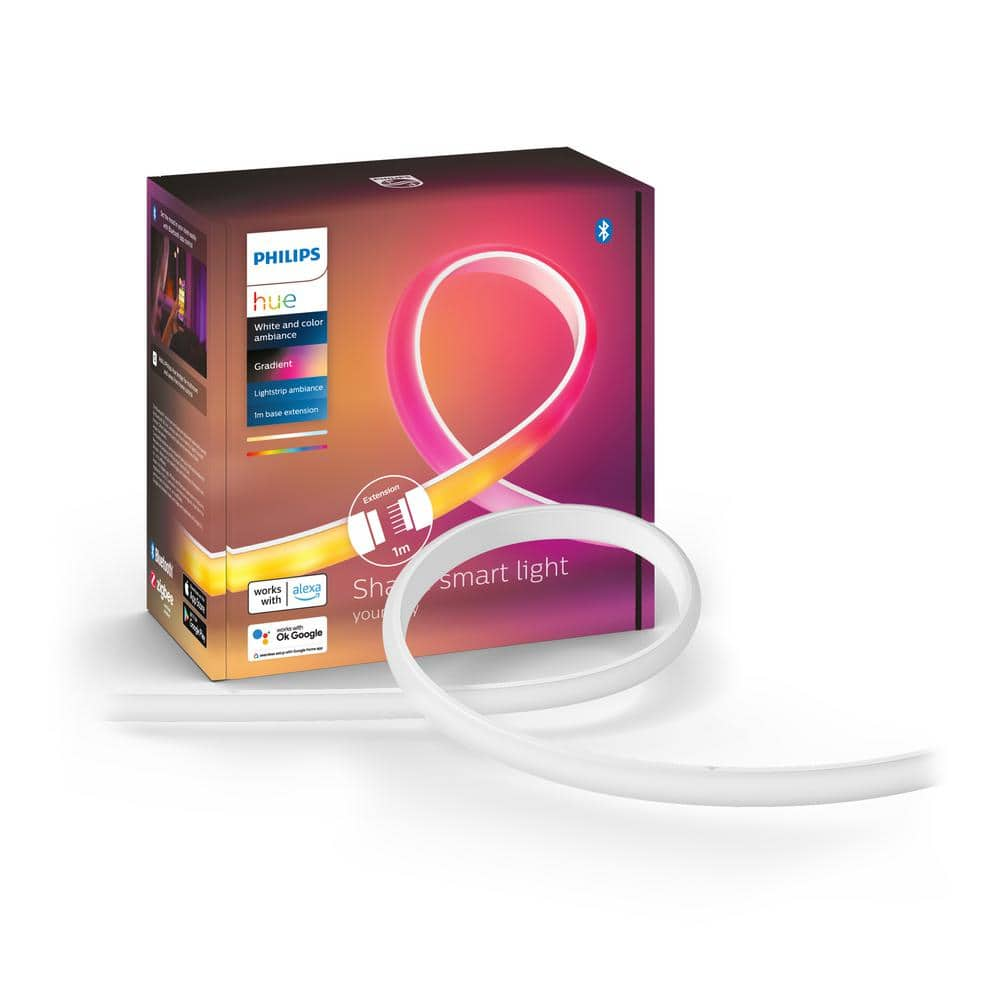

Illustrative Image (Source: Google Search)

-

Is customization of Philips Hue LED light strips possible for bulk international orders?

Philips Hue products have standardized designs to maintain compatibility and system integrity; however, some customization options may be available through authorized B2B channels. Customizations could include packaging, labeling for local markets, or integration with specific smart home ecosystems. Discuss customization needs early with suppliers, as minimum order quantities (MOQs) and lead times may increase. Ensure compliance with Philips Hue’s brand guidelines and certification standards to avoid warranty or regulatory issues. For large-scale projects, leveraging authorized Philips Hue commercial solutions may offer tailored options. -

What are typical minimum order quantities (MOQs), lead times, and payment terms when sourcing Philips Hue LED light strips internationally?

MOQs vary by supplier but commonly start around hundreds to low thousands of units due to Philips Hue’s premium brand positioning. Lead times typically range from 4 to 8 weeks depending on stock availability, customization, and shipping routes. Payment terms for international buyers often involve a 30% advance deposit with the balance paid before shipment or via letter of credit for larger transactions. Negotiate payment terms carefully, considering currency risks and international banking fees. Use trade finance solutions like export credit insurance to protect transactions across regions. -

What quality assurance measures and certifications should I expect with Philips Hue LED light strips?

Philips Hue LED strips undergo rigorous quality assurance aligned with Signify’s global standards. Expect compliance with international certifications such as CE (Europe), RoHS (hazardous substances), FCC (USA), and possibly UL or ETL for electrical safety. Quality control includes performance testing, durability, and firmware validation to ensure seamless smart home integration. Request certificates and test reports from suppliers and verify them with recognized bodies if possible. This diligence ensures product safety, regulatory compliance, and reduces risks of recalls or customs delays. -

How should I plan logistics and shipping for Philips Hue LED light strips to regions like Africa, South America, the Middle East, or Europe?

Plan for multi-modal logistics combining sea freight for cost efficiency and air freight for urgent deliveries. Choose suppliers with experience exporting to your region to navigate customs regulations, tariffs, and import duties effectively. Ensure packaging meets international transit standards to prevent damage. Work with freight forwarders familiar with smart lighting products’ handling requirements. Consider Incoterms carefully—DAP or DDP can minimize your customs clearance burdens. Early coordination with local customs brokers expedites clearance and avoids costly delays. -

What are best practices for resolving disputes related to Philips Hue LED light strip international orders?

Disputes commonly arise from delays, product defects, or shipment discrepancies. Mitigate risks by drafting clear contracts specifying product specifications, delivery timelines, inspection rights, and warranty terms. Include arbitration clauses referencing neutral venues or international trade bodies (e.g., ICC). Maintain thorough documentation of communications, inspections, and payments. Engage third-party inspection services pre-shipment to verify compliance. If disputes occur, seek amicable resolutions through negotiation or mediation before escalating to legal action, which can be costly and time-consuming across jurisdictions.

Illustrative Image (Source: Google Search)

-

Are there regional considerations when importing Philips Hue LED light strips into Africa, South America, the Middle East, or Europe?

Yes, regional factors such as local electrical standards (voltage, plugs), import regulations, and certification requirements vary. For example, Europe mandates CE marking, while some Middle Eastern countries may require SASO certification. Africa and South America may have specific customs duties or import quotas impacting cost and timing. Additionally, consider language localization for manuals and packaging. Partnering with local distributors knowledgeable about these nuances can streamline market entry and ensure regulatory compliance, minimizing delays and facilitating smoother B2B transactions. -

How can I ensure Philips Hue LED light strips remain compatible and up-to-date with evolving smart home technologies?

Philips Hue products rely on ongoing software support and firmware updates managed by Signify. Confirm that your supplier provides genuine, upgradable products with access to the official Philips Hue ecosystem. For bulk B2B deployments, consider service agreements that include firmware update support and technical assistance. Stay informed of Philips Hue’s product lifecycle policies and ecosystem changes to avoid obsolescence. Integrating these lights into broader smart building solutions may require coordination with certified system integrators to maintain compatibility and maximize ROI over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for philips hue led light strip

Philips Hue LED light strips represent a pinnacle of smart lighting innovation, combining advanced LED chip technology, precision PCB fabrication, and robust software integration. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing is essential to capitalize on quality, reliability, and cost-efficiency. Understanding Philips’ global manufacturing footprint and their commitment to high standards enables buyers to navigate complex supply chains and secure authentic, compliant products.

Key takeaways for sourcing Philips Hue LED light strips include prioritizing suppliers with verified certifications (e.g., CE, RoHS), assessing component quality—especially LED chips and PCBs—and factoring in logistics capabilities to minimize lead times and costs. Additionally, engaging with manufacturers who emphasize rigorous quality control ensures consistency in product performance, a critical factor in competitive B2B markets.

Looking ahead, the smart lighting sector will continue evolving with increased demand for customization, sustainability, and integration with IoT ecosystems. Buyers from emerging and mature markets alike should leverage strategic partnerships and adopt agile sourcing strategies to stay ahead. By doing so, businesses can unlock growth opportunities, enhance brand reputation, and meet the dynamic needs of end consumers worldwide. Now is the time to act decisively—invest in sourcing excellence to illuminate your business’s future with Philips Hue LED light strips.