Introduction: Navigating the Global Market for led strip light diffuser

The global demand for LED strip light diffusers is surging as businesses worldwide seek innovative lighting solutions that blend efficiency with aesthetic appeal. For international B2B buyers—particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of LED strip light diffusers is essential to securing competitive advantages in lighting projects. These diffusers play a critical role in enhancing light quality by softening glare, improving uniformity, and protecting LED strips from dust and moisture, thereby extending product lifespan and ensuring superior performance.

This comprehensive guide is designed to empower procurement professionals and business decision-makers with actionable insights into the LED strip light diffuser market. It covers a wide spectrum of topics including the various types of diffusers—such as frosted, clear, and opal—along with the materials commonly used, like polycarbonate and acrylic. Buyers will also gain a deep understanding of manufacturing standards, quality control processes, and how to evaluate supplier credibility to mitigate risks in global sourcing.

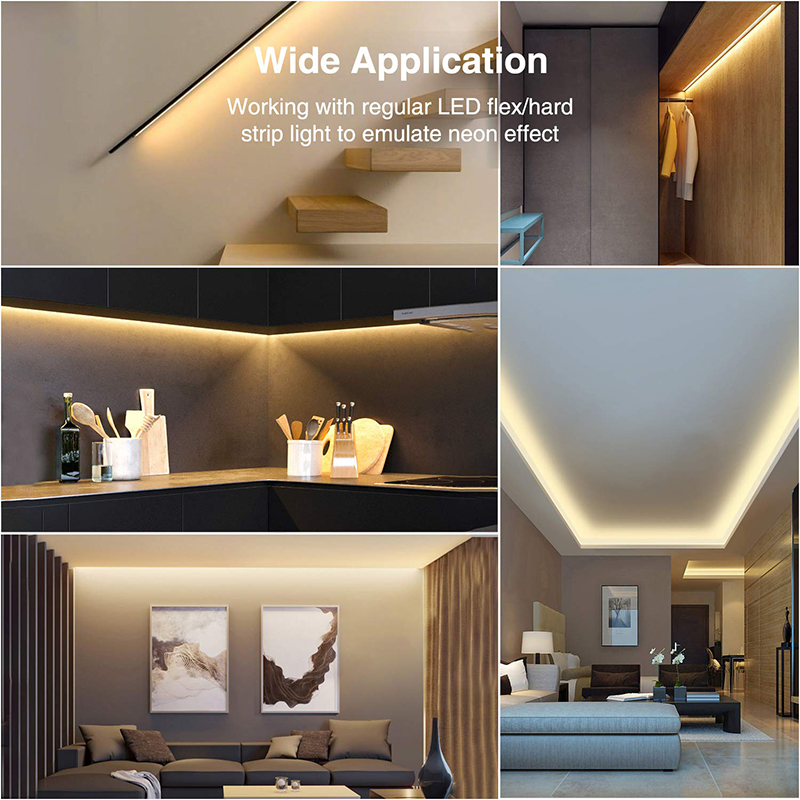

Illustrative Image (Source: Google Search)

Additionally, the guide explores cost factors, market trends, and regional considerations, providing tailored advice for buyers in countries such as Thailand and Egypt. Frequently asked questions address practical challenges in installation, customization, and integration with different LED strip types. By leveraging this knowledge, international buyers can make informed sourcing decisions that optimize cost-efficiency, product quality, and supply chain reliability, ultimately driving success in their lighting ventures.

Understanding led strip light diffuser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Diffuser | Semi-opaque cover that softens and evenly distributes light | Retail displays, office lighting, hospitality | Pros: Reduces glare, creates uniform light; Cons: Slight light intensity loss |

| Clear Diffuser | Transparent cover providing minimal light diffusion | Architectural lighting, showcase lighting | Pros: Maximizes brightness, preserves color fidelity; Cons: Can cause hotspots or glare |

| Milky Diffuser | Opaque white diffuser offering maximum diffusion | Residential, healthcare, educational facilities | Pros: Excellent glare control, smooth light output; Cons: Lower light transmission |

| Aluminum Channel with Diffuser | Combines aluminum housing with diffuser cap for heat dissipation and protection | Industrial, commercial installations, outdoor lighting | Pros: Enhances durability, improves thermal management; Cons: Higher upfront cost |

| Silicone Diffuser | Flexible, impact-resistant diffuser suitable for curved or irregular surfaces | Automotive, marine, outdoor signage | Pros: High durability, waterproof; Cons: Limited color options, higher price point |

Frosted Diffuser

Frosted diffusers are widely used for their ability to soften LED strip light output, reducing sharp glare and creating a more uniform illumination. They are ideal for environments like retail stores and hospitality venues where aesthetic appeal and comfortable lighting are critical. B2B buyers should consider the slight trade-off in light intensity against improved visual comfort. These diffusers are often cost-effective and compatible with standard LED profiles, making them a practical choice for large-scale commercial projects.

Clear Diffuser

Clear diffusers allow maximum light output with minimal diffusion, preserving the brightness and color accuracy of LED strips. This type is suitable for architectural and display lighting where vivid color rendering and high brightness are priorities. However, buyers should be aware that clear diffusers can result in visible hotspots and glare, which may require additional design considerations. Bulk purchasers must evaluate the balance between brightness needs and potential visual discomfort in their target applications.

Milky Diffuser

Milky diffusers offer the highest level of light diffusion, producing soft, even illumination without visible LED points. They are favored in residential, healthcare, and educational settings where glare reduction is paramount. The main consideration for B2B buyers is the reduced luminous efficiency compared to clearer diffusers, which may necessitate higher-powered LED strips to achieve desired brightness. Their smooth light output enhances ambiance, making them attractive for premium indoor lighting projects.

Aluminum Channel with Diffuser

This type integrates an aluminum housing with a diffuser cover, providing both mechanical protection and effective heat dissipation. It is especially relevant for industrial and outdoor commercial applications where durability and thermal management directly impact LED lifespan. B2B buyers should account for the higher initial investment but benefit from reduced maintenance costs and longer service life. Customizable lengths and profiles also support large-scale installations requiring consistent lighting performance.

Silicone Diffuser

Silicone diffusers are flexible and highly resistant to impact, moisture, and UV exposure, making them ideal for curved surfaces and harsh environments such as automotive lighting, marine applications, and outdoor signage. While more expensive than plastic diffusers, their robustness translates into longer durability and reduced replacement frequency. Buyers targeting specialized markets should prioritize silicone diffusers for projects demanding weatherproof and flexible lighting solutions.

Related Video: BRILLIANT Design – Govee’s Complete LED + Diffuser System

Key Industrial Applications of led strip light diffuser

| Industry/Sector | Specific Application of led strip light diffuser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and display lighting in retail stores and shopping malls | Enhances product visibility and customer experience through uniform, glare-free lighting | Durability, ease of installation, compatibility with existing LED strips, and customization for brand aesthetics |

| Hospitality & Tourism | Mood and accent lighting in hotels, restaurants, and resorts | Creates inviting atmospheres and improves guest satisfaction with soft, evenly diffused light | Waterproof and heat-resistant diffusers for humid environments, color consistency, and scalable solutions |

| Architectural & Interior Design | Cove and under-cabinet lighting in offices and public buildings | Provides sleek, modern lighting solutions that reduce eye strain and highlight design features | High light transmission with effective diffusion, customizable shapes, and compliance with regional safety standards |

| Automotive & Transportation | Interior ambient lighting in vehicles and public transport | Improves passenger comfort and safety by reducing harsh lighting and enhancing visibility | Lightweight, vibration-resistant materials, and tailored sizes for varied vehicle models |

| Industrial & Manufacturing | Workbench and machine area lighting | Enhances worker productivity and safety by providing consistent, shadow-free illumination | Impact resistance, heat dissipation capabilities, and long lifespan under industrial conditions |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, led strip light diffusers are crucial for creating visually appealing displays that attract customers. These diffusers soften the LED light, eliminating harsh glare and shadows that can distort product appearance. For B2B buyers, selecting diffusers that are easy to install and compatible with various LED strip models is essential to maintain operational efficiency. Customizable options allow retailers to align lighting with brand identity, enhancing the overall shopping experience.

Hospitality & Tourism Industry

Hotels, restaurants, and resorts benefit significantly from led strip light diffusers by using them to create ambient and accent lighting that elevates guest experiences. Particularly in humid or outdoor settings common in regions like Thailand or Egypt, diffusers must be waterproof and heat-resistant to withstand environmental stresses. Businesses sourcing these components should prioritize products that provide consistent color rendering and can be scaled for large installations, ensuring a cohesive and inviting atmosphere.

Architectural & Interior Design

For offices and public buildings, led strip light diffusers enable designers to implement sleek cove lighting and under-cabinet illumination that enhances aesthetics while reducing eye strain. Buyers from Europe and other regions should focus on diffusers offering high light transmission with effective diffusion to achieve uniform lighting without hotspots. Additionally, compliance with local safety and fire standards is critical for large-scale architectural projects to ensure regulatory approval and occupant safety.

Automotive & Transportation Sector

In vehicle interiors and public transportation systems, led strip light diffusers are used to provide soft ambient lighting that improves passenger comfort and safety by reducing harsh contrasts. Buyers in emerging markets and developed regions alike must source diffusers made from lightweight, vibration-resistant materials tailored to diverse vehicle models. This ensures durability and consistent performance under dynamic conditions, critical for transportation industries focused on reliability.

Industrial & Manufacturing Settings

Industrial environments demand robust led strip light diffusers to deliver uniform illumination on workbenches and machinery areas, reducing shadows and eye fatigue for workers. In regions with high industrial activity, such as parts of South America and the Middle East, sourcing diffusers with excellent impact resistance and heat dissipation properties is vital. Long lifespan and maintenance-free operation are key considerations for businesses aiming to optimize productivity and safety in demanding conditions.

Strategic Material Selection Guide for led strip light diffuser

Polycarbonate (PC)

Polycarbonate is a widely used material for LED strip light diffusers due to its excellent impact resistance and high optical clarity. It performs well under a broad temperature range (-40°C to 120°C), making it suitable for diverse climates, including hot regions like the Middle East and humid tropical areas in South America. Its inherent UV resistance helps prevent yellowing, which is crucial for outdoor or semi-outdoor installations.

Pros:

– High durability and impact resistance, ideal for industrial or high-traffic environments.

– Good heat resistance ensures longevity near LED heat sources.

– Excellent light diffusion with minimal loss of brightness.

Cons:

– Higher cost compared to some plastics like acrylic.

– Can be more complex to manufacture due to molding requirements.

– Susceptible to scratching, requiring protective coatings for premium applications.

Application Impact:

Polycarbonate diffusers are favored in commercial and architectural lighting where durability and consistent light diffusion are critical. They are also compatible with waterproof LED strips used in outdoor or semi-exposed installations.

Considerations for International Buyers:

Buyers in Africa, the Middle East, and Europe should ensure compliance with ASTM D3935 (Standard Specification for Polycarbonate) or equivalent regional standards like DIN EN ISO 178 for mechanical properties. Polycarbonate sourced from reputable manufacturers typically meets RoHS and REACH standards, important for European markets. For hot climates such as Egypt or Saudi Arabia, UV stabilization is a must to extend product life.

Acrylic (PMMA)

Acrylic is another popular choice for LED strip light diffusers, known for its superior optical clarity and ease of fabrication. It has a moderate temperature resistance (up to 80°C) and is less impact-resistant than polycarbonate but offers excellent light transmission.

Pros:

– High light transmittance, enhancing brightness and color fidelity.

– Cost-effective and easier to machine or cut for custom shapes.

– Good weather resistance with proper UV treatment.

Cons:

– More brittle and prone to cracking under impact or stress.

– Lower heat resistance limits use near high-power LEDs.

– Can yellow over time if UV protection is inadequate.

Application Impact:

Acrylic diffusers are ideal for indoor applications or controlled environments such as retail displays and office lighting. They provide sharper light diffusion, suitable for decorative and accent lighting.

Considerations for International Buyers:

Compliance with ASTM D4802 (Standard Specification for Acrylic) or ISO 7823 is recommended. In regions like South America and Africa, acrylic diffusers must be selected with UV inhibitors to withstand strong sunlight exposure. European buyers should verify conformity with EU directives on plastic materials used in lighting.

Silicone

Silicone diffusers are gaining traction for their flexibility and excellent thermal stability, tolerating temperatures from -60°C up to 230°C. Their rubber-like properties make them highly resistant to environmental stress, including UV, moisture, and chemicals.

Pros:

– Outstanding thermal and weather resistance, suitable for harsh outdoor environments.

– Flexible and resistant to cracking or breaking, ideal for curved or irregular installations.

– High chemical resistance, compatible with various cleaning agents and industrial settings.

Cons:

– Generally higher cost and more complex manufacturing process.

– Lower optical clarity compared to polycarbonate and acrylic.

– May require specialized adhesives or mounting systems.

Application Impact:

Silicone diffusers are preferred in industrial, automotive, and outdoor lighting projects where durability and environmental resistance are paramount. Their flexibility supports innovative lighting designs in commercial and architectural sectors.

Considerations for International Buyers:

Buyers in regions with extreme temperature variations, such as the Middle East and Europe, will benefit from silicone’s stability. Compliance with standards like ASTM D2240 for hardness and ISO 10993 for biocompatibility (if used in public spaces) is important. Supply chain reliability and certification for chemical resistance should be verified for industrial applications.

Polyethylene Terephthalate (PET)

PET is a lightweight, cost-effective diffuser material with good chemical resistance and moderate heat tolerance (up to 120°C). It offers reasonable light diffusion and is often used in flexible LED strip applications.

Pros:

– Low cost and easy to produce in large volumes.

– Good moisture and chemical resistance, suitable for humid environments.

– Lightweight, reducing shipping and handling costs.

Cons:

– Lower impact resistance and mechanical strength compared to PC and silicone.

– Moderate thermal resistance limits use near high-power LEDs.

– Can degrade under prolonged UV exposure without additives.

Application Impact:

PET diffusers are suitable for budget-conscious projects, including residential and commercial lighting where extreme durability is not required. Their moisture resistance makes them apt for indoor applications in humid climates like parts of South America and Africa.

Considerations for International Buyers:

Buyers should ensure PET meets ASTM D6278 or ISO 527 standards for mechanical properties. For markets like Egypt or Thailand, UV-stabilized PET variants are preferable to avoid premature degradation. PET’s recyclability aligns well with European environmental regulations, a key consideration for sustainable procurement.

Summary Table

| Material | Typical Use Case for led strip light diffuser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Outdoor and industrial LED strip lighting requiring durability | High impact and heat resistance | Higher cost and prone to scratching | High |

| Acrylic | Indoor decorative and retail lighting | Excellent optical clarity and low cost | Brittle and lower heat resistance | Medium |

| Silicone | Harsh environment and flexible lighting installations | Superior thermal stability and flexibility | Lower clarity and higher cost | High |

| PET | Budget-friendly indoor applications in humid conditions | Low cost and good chemical resistance | Moderate heat resistance and UV sensitivity | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light diffuser

Manufacturing Processes for LED Strip Light Diffusers

The production of LED strip light diffusers involves a series of carefully controlled stages designed to ensure the product delivers optimal light diffusion, durability, and aesthetic appeal. Understanding these stages helps B2B buyers evaluate suppliers and ensure alignment with project specifications.

1. Material Preparation

The primary materials used in LED strip light diffusers are high-grade plastics such as polycarbonate (PC) or acrylic (PMMA). These materials are chosen for their excellent light transmission, UV resistance, and mechanical strength. Material preparation includes:

- Raw Material Inspection: Suppliers verify the quality and consistency of plastic pellets or sheets, ensuring they meet specifications for clarity, color, and thermal properties.

- Additive Mixing: To enhance properties like UV resistance, anti-yellowing, or flame retardancy, additives are mixed into the raw plastic before molding.

2. Forming and Shaping

The diffuser’s shape and surface texture are critical to light diffusion performance. The main forming techniques include:

- Extrusion: The most common method for producing continuous diffuser profiles. Plastic pellets are melted and forced through a shaped die to create long diffuser strips. This method allows customization of cross-sectional shapes (e.g., flat, curved, frosted).

- Injection Molding: Used for more complex or shorter diffuser components, injection molding offers precise control over dimensions and surface finish.

- Thermoforming: For diffuser covers requiring specific bends or curves, thermoforming heats plastic sheets and molds them over forms.

Surface treatments such as frosted finishes or micro-structured patterns are often applied during or post-forming to optimize light scattering.

3. Assembly

Assembly integrates the diffuser with other components, such as LED strips and aluminum channels:

- Cutting to Length: Diffusers are cut to precise lengths matching the LED strip sizes or installation requirements.

- Fitting and Sealing: Diffusers are fitted into aluminum profiles or channels, often with rubber gaskets or adhesives to ensure dust and moisture resistance.

- Customization: Some manufacturers offer branding, color tinting, or anti-glare coatings during assembly.

4. Finishing and Packaging

Finishing includes quality checks for surface defects, clarity, and dimensional accuracy. Protective films may be applied to prevent scratches during transport. Packaging is designed to minimize damage and may include custom branding or batch identification for traceability.

Quality Assurance Frameworks and Testing for LED Strip Light Diffusers

Quality assurance (QA) in diffuser manufacturing is essential to guarantee product reliability, safety, and compliance with international standards. B2B buyers should seek suppliers with robust QA systems aligned to both general and industry-specific standards.

Key International Standards and Certifications

- ISO 9001: This is the foundational quality management system (QMS) standard that ensures consistent production processes, supplier management, and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical equipment, crucial for LED lighting components.

- UL Certification: Particularly relevant for North American markets, UL tests product safety and performance.

- IP Ratings: Indicate ingress protection against dust and water, important for diffusers used in outdoor or wet environments.

- REACH: Ensures chemical safety compliance, especially relevant for European buyers.

While API certifications are more common in industrial sectors unrelated to LED diffusers, some buyers may require additional environmental or safety certifications based on local regulations.

Quality Control Checkpoints

Manufacturers typically implement multiple QC stages throughout the production cycle:

- Incoming Quality Control (IQC): Raw materials and components, such as plastic resins and additives, are inspected for conformity before entering production.

- In-Process Quality Control (IPQC): Ongoing inspections during extrusion, molding, and assembly check dimensions, surface finish, and mechanical properties to catch deviations early.

- Final Quality Control (FQC): Finished diffusers undergo comprehensive testing including optical clarity, dimensional accuracy, and physical durability before packaging.

Common Testing Methods

- Light Diffusion and Transmission Testing: Ensures the diffuser scatters light uniformly without significant loss of brightness. Spectrophotometers or integrating spheres may be used.

- UV and Weathering Tests: Accelerated aging tests simulate sunlight exposure to verify resistance to yellowing or brittleness.

- Mechanical Strength and Impact Tests: Confirm the diffuser can withstand handling and installation stresses.

- Dimensional Accuracy Checks: Precision measuring tools verify compliance with design specifications.

- Flammability Tests: Evaluate resistance to ignition, important for safety compliance.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s QA capabilities is crucial to mitigate risks related to product failure, delays, or regulatory non-compliance.

1. Supplier Audits

- On-site Audits: Conduct factory visits or hire third-party auditors to review manufacturing processes, equipment, and quality management systems.

- Remote Audits: Virtual inspections via video calls and digital document reviews can be effective when travel is restricted.

- Audit Focus Areas: Process controls, worker training, equipment calibration, traceability, and corrective action records.

2. Review of Documentation and Certifications

Request up-to-date copies of:

– ISO 9001 certificates

– CE and RoHS declarations of conformity

– Test reports from accredited labs

– Material safety data sheets (MSDS) for raw materials

– Production process flowcharts and QC protocols

3. Product Sampling and Testing

- Sample Orders: Obtain product samples for independent laboratory testing to verify optical and mechanical properties.

- Third-Party Inspection: Employ inspection agencies to perform pre-shipment inspections verifying quantity, quality, and packaging standards.

4. Quality Reporting and Traceability

- Batch Traceability: Ensure suppliers use batch numbers or serial codes to track production lots.

- Quality Reports: Regular quality control reports help monitor ongoing production consistency.

- Non-Conformance Handling: Understand the supplier’s process for addressing defects or deviations.

QC and Certification Nuances for Diverse International Markets

International B2B buyers should be aware of regional regulatory and market nuances affecting LED strip light diffuser sourcing:

- Africa: Markets like Egypt increasingly demand CE compliance and RoHS due to import regulations. Local standards may also require additional testing for durability in high-temperature, dusty environments.

- South America: Brazil and Argentina have specific electrical and safety certification requirements. Importers often prefer suppliers with UL or IEC certifications.

- Middle East: Countries such as UAE and Saudi Arabia emphasize compliance with GCC standards and often require certification from internationally recognized bodies. High UV resistance and IP ratings are critical due to harsh climates.

- Europe: The EU enforces strict CE marking, RoHS, and REACH compliance. Buyers also prioritize environmental sustainability certifications and supplier transparency.

- Southeast Asia (e.g., Thailand): Buyers seek suppliers with ISO 9001 and adherence to IEC standards. There is growing demand for customization and rapid lead times.

Summary for B2B Buyers

- Evaluate manufacturing processes: Prioritize suppliers with advanced extrusion and molding capabilities and strict in-process controls.

- Demand comprehensive QA: Verify adherence to ISO 9001 and relevant regional certifications such as CE, RoHS, and UL.

- Implement multi-level inspections: Insist on IQC, IPQC, and FQC checkpoints supported by robust testing.

- Verify through audits and testing: Use third-party inspections, supplier audits, and independent lab tests to validate quality claims.

- Adapt to regional requirements: Understand local standards and climatic conditions to select diffusers suited for target markets.

By thoroughly understanding manufacturing and quality assurance practices, international B2B buyers can confidently source LED strip light diffusers that meet performance expectations and regulatory demands, supporting successful project outcomes across diverse global markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip light diffuser Sourcing

Understanding the cost and pricing dynamics of LED strip light diffusers is essential for international B2B buyers aiming to optimize procurement decisions and manage budgets effectively. This analysis breaks down key cost components, pricing influencers, and practical buyer strategies tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Light Diffuser Manufacturing

-

Materials: The diffuser’s primary materials include polycarbonate (PC), acrylic (PMMA), or silicone, each with distinct cost profiles. High-grade, UV-resistant plastics command premium prices but enhance durability, especially for outdoor or industrial applications.

-

Labor: Labor costs vary significantly by manufacturing location. Factories in Asia typically offer lower labor expenses compared to Europe or the Middle East, impacting the final product price. Automation levels also influence labor intensity and cost.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and administrative expenses. Efficient production lines and economies of scale help reduce overhead per unit.

-

Tooling: Initial mold creation for extrusion or injection molding is a substantial upfront investment. Custom diffuser profiles or specialized finishes increase tooling costs, which are amortized over production volumes.

-

Quality Control (QC): Rigorous QC processes ensure diffuser light diffusion properties meet specifications and comply with certifications (e.g., RoHS, CE). QC adds to unit cost but reduces returns and warranty claims.

-

Logistics and Shipping: Freight costs depend on shipment size, weight, and destination. Buyers from Africa, South America, and the Middle East should consider port infrastructure and customs clearance expenses, which can substantially affect landed costs.

-

Supplier Margin: Supplier pricing includes a margin reflecting their business model, risk, and market positioning. Direct factory sourcing often reduces intermediary margins.

Primary Price Influencers

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes drastically reduce per-unit costs due to economies of scale. MOQ thresholds vary by supplier; negotiating flexible MOQs can help smaller buyers manage cash flow.

-

Specifications and Customization: Custom colors, diffuser shapes, or coatings tailored to specific lighting designs increase costs. Standard profiles and finishes are more cost-effective.

-

Material Quality and Certifications: Certified materials that meet international standards carry premium prices but facilitate smoother import processes and enhance product reliability.

-

Supplier Capabilities and Reputation: Established suppliers with proven quality records may price higher but offer lower risks and better after-sales support.

-

Incoterms and Payment Terms: Understanding delivery terms (e.g., FOB, CIF, DDP) is crucial for accurate cost calculation. Buyers should factor in customs duties, taxes, and local handling fees when evaluating supplier quotes.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and after-sales service. Volume discounts are common, but flexibility in delivery schedules or packaging can add value.

-

Calculate Total Cost of Ownership (TCO): Consider not just the unit price but also shipping, customs clearance, installation, and warranty servicing costs. Higher upfront costs for certified, durable diffusers may reduce long-term expenses.

-

Leverage Local Market Knowledge: Buyers from regions like Africa, South America, the Middle East, and Europe should assess regional logistics hubs and trade agreements that could lower tariffs or expedite shipments.

-

Request Samples and Small Trial Orders: Validate diffuser quality and compatibility with LED strips before committing to bulk purchases. This reduces the risk of costly returns or project delays.

-

Monitor Currency Fluctuations and Inflation: Exchange rate volatility can impact landed costs. Locking favorable payment terms or using forward contracts with suppliers can mitigate risks.

-

Understand Pricing Nuances: Prices may vary depending on global raw material trends (e.g., plastic resin costs), energy prices, and geopolitical factors affecting supply chains.

Disclaimer on Pricing

Prices for LED strip light diffusers can vary widely based on design complexity, order size, supplier location, and global market conditions. The cost insights provided here are indicative and should be validated through direct supplier quotations and market research tailored to specific buyer requirements.

By carefully analyzing these cost factors and strategically managing supplier relationships, international buyers can secure competitive pricing while ensuring quality and supply reliability for their LED strip light diffuser projects.

Spotlight on Potential led strip light diffuser Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light diffuser’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light diffuser

Critical Technical Properties of LED Strip Light Diffusers

-

Material Grade and Composition

High-quality diffusers are commonly made from polycarbonate (PC) or acrylic (PMMA). Polycarbonate offers excellent impact resistance and heat tolerance, crucial for durability in diverse climates, including hot Middle Eastern regions or humid African environments. Acrylic provides superior light diffusion and UV resistance, ideal for outdoor or decorative uses. Choosing the right material impacts longevity, safety, and optical performance, which are essential for maintaining client satisfaction and reducing warranty claims. -

Light Transmission and Diffusion Rate

This property defines how much light passes through the diffuser and how evenly it spreads. Typical transmission rates range from 70% to 90%, with diffusion designed to soften glare and eliminate hotspots from individual LEDs. For B2B buyers, understanding diffusion rates ensures the final lighting effect meets project requirements—whether for retail ambiance in Europe or industrial task lighting in South America—balancing brightness with visual comfort. -

Tolerance and Dimensional Accuracy

Precise dimensions and tight manufacturing tolerances (often ±0.1 mm) are vital for seamless integration with LED profiles and strip lights. Poor tolerance can lead to installation challenges, gaps, or light leakage. Reliable suppliers provide consistent tolerances, reducing installation time and costs, especially important for large-scale orders or custom architectural projects requiring uniformity. -

UV and Heat Resistance

Diffusers exposed to sunlight or high temperatures must resist yellowing and warping. UV-stabilized materials and heat-resistant coatings extend product lifespan, particularly in outdoor or high-heat applications such as solar street lighting in Egypt or factory lighting in Brazil. This resistance minimizes maintenance and replacement frequency, ensuring better return on investment. -

Fire Retardancy and Safety Ratings

Compliance with fire safety standards (such as UL94 V-0 or equivalent) is critical for commercial projects. Fire-retardant diffusers reduce risks in public spaces and meet regulatory requirements, which vary across regions. B2B buyers should verify certifications to ensure compliance and safeguard end users. -

Surface Finish and Texture

Diffuser surfaces may be smooth, frosted, or micro-textured to influence light scattering and aesthetics. Micro-textured finishes can enhance uniformity and reduce glare, preferred in luxury retail or hospitality sectors. Understanding finish options allows buyers to select diffusers that align with both functional and design goals.

Common Trade Terminology in LED Strip Light Diffuser Procurement

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce diffusers that other brands sell under their own label. For B2B buyers, OEM partnerships allow customization, private labeling, and cost-effective procurement, helping companies differentiate their product offerings in local markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. MOQs vary widely; understanding them helps buyers plan inventory and budget, especially for small businesses or regional distributors in Africa or South America who may have storage constraints. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific diffuser specifications. Crafting a detailed RFQ ensures clear communication, enabling buyers to compare offers accurately and negotiate better deals. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities and costs between buyers and sellers during shipping. Knowing Incoterms helps buyers manage logistics, customs clearance, and total landed costs, critical for international shipments to regions like the Middle East or Europe. -

Lead Time

The period from order confirmation to product delivery. Shorter lead times improve project scheduling and reduce stockholding costs. Buyers should assess suppliers’ lead times to align with project deadlines and avoid costly delays. -

Custom Extrusion

A manufacturing process where diffuser profiles are tailor-made to specific dimensions or shapes. This term is important for buyers with unique architectural or branding requirements, enabling them to secure bespoke solutions rather than standard off-the-shelf products.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge to select LED strip light diffusers that meet performance standards and optimize procurement processes. This insight is vital for sourcing reliable, cost-effective lighting components that satisfy diverse market demands across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light diffuser Sector

Market Overview & Key Trends

The global LED strip light diffuser market is experiencing robust growth, driven by increasing demand for energy-efficient and customizable lighting solutions across commercial, residential, and industrial sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are capitalizing on this trend, leveraging LED diffusers to enhance lighting quality by softening and evenly distributing light emitted from LED strips. Countries like Egypt and Thailand are witnessing growing infrastructure and commercial projects, further propelling demand for advanced lighting components like diffusers.

Key market drivers include the shift toward sustainable lighting, urbanization, and growing adoption of smart lighting systems. Technological advancements, such as diffusers with improved optical clarity, UV resistance, and modular designs compatible with various LED strip profiles, are becoming standard expectations. Moreover, customization is a significant sourcing trend; B2B buyers are increasingly requesting tailored diffuser shapes, materials, and finishes to meet specific project requirements, including architectural aesthetics and functional performance.

From a sourcing perspective, buyers are focusing on suppliers who offer flexible minimum order quantities (MOQs), reliable quality control certifications, and efficient logistics to emerging markets. The rise of digital B2B platforms and direct manufacturer relationships has streamlined procurement, allowing buyers in Africa and South America to access a broader range of diffuser types, including silicone, polycarbonate, and acrylic options. Additionally, integration with LED aluminum profiles is gaining traction, enabling seamless installation and enhanced heat dissipation.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement strategy for LED strip light diffusers, as buyers worldwide prioritize reducing environmental impact and adhering to green building standards. The production of diffusers traditionally involves plastics and polymers, which can contribute to pollution if not responsibly sourced or recycled. Leading manufacturers now emphasize the use of recyclable materials, low-VOC (volatile organic compounds) substances, and bio-based plastics to minimize the ecological footprint.

Ethical sourcing is equally critical, with B2B buyers demanding transparency across the supply chain to ensure compliance with labor standards and environmental regulations. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), and ISO 14001 (Environmental Management Systems) serve as important indicators of supplier commitment to sustainability. For buyers in Europe and the Middle East, these certifications often align with local regulatory requirements and corporate social responsibility (CSR) mandates.

Furthermore, green procurement policies encourage partnerships with suppliers who invest in energy-efficient manufacturing processes and circular economy initiatives, such as take-back programs for end-of-life diffusers. These sustainable practices not only reduce carbon emissions but also enhance brand reputation and appeal to environmentally conscious end-users, which is increasingly important in competitive B2B markets.

Brief Evolution and Industry Context

The evolution of LED strip light diffusers parallels the rapid advancement of LED lighting technology over the past two decades. Initially, diffusers were simple acrylic or polycarbonate covers designed primarily for protection. However, as LED strips became more widespread, the need for diffusers that could improve light uniformity, reduce glare, and support longer LED lifespans became apparent.

Innovation in materials and extrusion techniques has transformed diffusers into critical components of LED lighting systems, offering enhanced optical performance and compatibility with diverse LED strip formats. This evolution reflects a broader industry shift from mere illumination to integrated lighting solutions emphasizing design flexibility, energy efficiency, and sustainability—key factors that B2B buyers must consider when sourcing today.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light diffuser

-

How can I verify the credibility of LED strip light diffuser suppliers when sourcing internationally?

To ensure supplier credibility, start by requesting company certifications such as ISO, CE, or RoHS, which indicate compliance with international quality and safety standards. Check for trade licenses and verify them through official government or trade portals. Review customer feedback on independent platforms and ask for references from previous B2B clients, particularly those in your region. Conduct virtual factory tours or request detailed product and manufacturing documentation. Partnering with suppliers who have experience exporting to Africa, South America, the Middle East, and Europe can also reduce risks related to compliance and product quality. -

What customization options are typically available for LED strip light diffusers in bulk orders?

Many manufacturers offer customization including diffuser length, shape (round, square, U-channel), material (PC, PMMA), and light transmission levels (clear, frosted, milky). Color customization for branding or specific lighting effects is often available. Additionally, packaging can be tailored to your brand requirements. When negotiating, specify your technical needs such as UV resistance or heat tolerance, especially for outdoor or industrial applications. Custom orders may require minimum quantities and slightly longer lead times, so clarify these details upfront to align with your project timelines. -

What are common minimum order quantities (MOQs) and lead times for LED strip light diffusers?

MOQs vary widely depending on supplier capacity and customization level but typically range from 500 to 5,000 units per SKU. Standard stock items may have lower MOQs, while custom products usually require higher minimums. Lead times generally span 3 to 8 weeks, factoring in tooling, production, and quality inspections. For international shipments to regions like Africa or South America, add extra time for logistics and customs clearance. Planning orders well in advance and maintaining communication with your supplier can help manage expectations and avoid project delays. -

Which payment methods are safest and most common for international B2B purchases of LED strip light diffusers?

Common payment options include Telegraphic Transfer (T/T), Letter of Credit (L/C), and Escrow services. T/T is widely used due to its simplicity but carries higher risk if the supplier is unverified. L/C offers stronger protection by involving banks in the transaction and is preferred for larger orders. Escrow services act as intermediaries, releasing funds only after satisfactory delivery. For new suppliers, requesting an initial smaller order with partial payment upfront can reduce risk. Always confirm payment terms in your contract and avoid full prepayment without guarantees. -

What quality assurance processes and certifications should I expect from LED strip light diffuser suppliers?

Reliable suppliers implement rigorous QA processes including raw material inspection, in-process monitoring, and final product testing for light diffusion uniformity, durability, and UV resistance. Key certifications to request include ISO 9001 for quality management, CE for European market compliance, RoHS for hazardous substances, and UL or ETL for safety standards. Certifications relevant to your target market ensure compliance with local regulations and reduce the risk of import issues. Request third-party lab test reports when possible, and consider factory audits to verify QA capabilities firsthand. -

How can I optimize logistics and shipping for bulk LED strip light diffuser orders to regions like the Middle East or Europe?

Choose suppliers familiar with international shipping protocols and experienced in exporting to your region. Consolidating orders can reduce freight costs and simplify customs clearance. Use freight forwarders who specialize in electronics or lighting products to navigate complex regulations. Opt for sea freight for cost efficiency on large orders, but air freight may be preferable for urgent shipments. Ensure all documentation (commercial invoices, packing lists, certificates of origin) is accurate and compliant with destination country requirements. Planning for potential customs delays and selecting Incoterms that clarify responsibilities will streamline delivery. -

What should I do if I encounter product quality issues or disputes with my LED strip light diffuser supplier?

First, communicate clearly and promptly with the supplier, providing detailed evidence such as photos, videos, and inspection reports. Refer to your purchase contract and warranty terms to support your claims. Many suppliers offer replacements or refunds for defective goods within warranty periods. If direct negotiation stalls, consider mediation through trade platforms or chambers of commerce in the supplier’s country. For larger disputes, arbitration under international trade rules or legal action might be necessary. Maintaining thorough documentation and choosing suppliers with transparent dispute resolution policies helps mitigate risks. -

Are there specific considerations for sourcing LED strip light diffusers for African or South American markets?

Yes, regional factors such as climate, electrical standards, and import regulations should guide your sourcing decisions. For hot, humid climates common in Africa and South America, prioritize diffusers with UV protection and high heat resistance to prevent yellowing or deformation. Verify voltage compatibility (e.g., 110V vs. 220V) and certifications recognized locally to avoid customs issues. Additionally, consider suppliers who offer after-sales support and spare parts availability within your region. Understanding local market preferences and ensuring compliance with environmental regulations will enhance product acceptance and reduce logistical challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light diffuser

Strategic sourcing of LED strip light diffusers is critical for businesses aiming to optimize lighting quality, efficiency, and cost-effectiveness in diverse markets. By prioritizing suppliers who offer customizable options, reliable product quality, and scalable solutions, international buyers can ensure consistent performance tailored to specific applications—whether commercial, residential, or industrial. This is especially valuable for buyers in Africa, South America, the Middle East, and Europe, where varying environmental conditions and regulatory standards demand adaptable diffuser solutions.

Illustrative Image (Source: Google Search)

Key considerations include evaluating supplier capabilities for custom manufacturing, verifying compliance with regional certifications, and negotiating favorable bulk pricing and shipping terms. Leveraging these factors enhances supply chain resilience and supports long-term project success while enabling businesses to meet evolving customer expectations for energy-efficient, visually appealing lighting.

Looking ahead, the LED strip light diffuser market is poised for innovation, with advancements in materials and integration with smart lighting controls. International buyers are encouraged to engage proactively with trusted manufacturers and distributors to access cutting-edge products that drive differentiation and sustainability. Strategic partnerships and informed sourcing decisions will empower businesses to capitalize on emerging opportunities in the global LED lighting landscape.