Introduction: Navigating the Global Market for led shelves

In today’s interconnected global economy, LED shelves represent a pivotal innovation in retail, display, and commercial environments, merging cutting-edge lighting technology with functional design. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—LED shelves offer unparalleled opportunities to enhance product visibility, optimize energy consumption, and create immersive customer experiences that drive sales and brand loyalty.

This guide serves as an essential resource, delivering a comprehensive exploration of LED shelves tailored to the unique needs of global buyers. It covers a wide spectrum of critical topics, including the various types and configurations of LED shelves, materials and components used in manufacturing, and stringent quality control processes that ensure durability and performance. Buyers will also gain expert insights into identifying reputable suppliers, understanding cost structures and pricing models, and navigating the complex market dynamics shaped by regional preferences and regulatory environments.

By integrating these insights, international buyers—from emerging markets in Africa and South America to established commercial hubs in Spain and Poland—can make informed sourcing decisions that align with their operational goals and sustainability commitments. This guide not only addresses common challenges but also highlights best practices and strategic considerations to maximize return on investment. Ultimately, it empowers businesses to confidently procure LED shelf solutions that combine innovation, reliability, and cost-effectiveness, fostering long-term success in competitive global marketplaces.

Understanding led shelves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

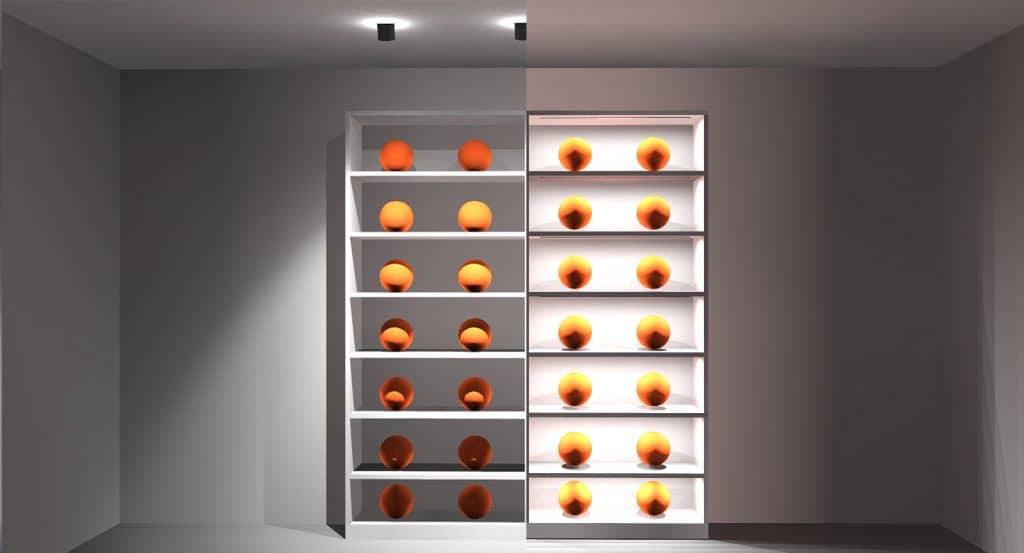

| Illuminated Display Shelves | Integrated LED lighting within shelving surfaces or edges, often customizable colors and brightness | Retail stores, showrooms, exhibitions | Pros: Enhances product visibility and appeal. Cons: Higher upfront cost and maintenance complexity. |

| Backlit LED Shelves | LED panels or strips installed behind translucent shelving material for soft, even illumination | Luxury retail, jewelry stores, galleries | Pros: Creates premium ambiance; highlights merchandise elegantly. Cons: Requires careful design integration and power management. |

| Adjustable LED Shelving Units | Shelves with modular LED lighting that can be repositioned or adjusted for various display needs | Warehouses, supermarkets, trade fairs | Pros: Flexible lighting solutions; adaptable to changing inventory. Cons: May involve complex wiring and installation. |

| Energy-efficient LED Storage Shelves | LED lighting focused on energy savings, often with motion sensors and dimming controls | Industrial storage, logistics centers | Pros: Reduces operational costs; improves visibility for safety. Cons: Less emphasis on aesthetic lighting; functional only. |

| Smart LED Shelves | Shelves integrated with IoT-enabled LED systems for remote control, color tuning, and automation | High-tech retail, smart warehouses, corporate offices | Pros: Enhances user experience and operational efficiency. Cons: Higher initial investment and requires technical support. |

Illuminated Display Shelves

These shelves incorporate LED lighting directly into their structure, often along edges or beneath transparent surfaces. They are ideal for retail and exhibition environments where product presentation drives sales. For B2B buyers in regions like Europe and the Middle East, prioritizing customizable lighting options can help tailor displays to local consumer preferences. When sourcing, consider suppliers offering durable LEDs with easy maintenance and energy efficiency certifications to optimize long-term ROI.

Backlit LED Shelves

Backlit shelves use LEDs placed behind frosted or translucent materials to produce soft, uniform illumination. This type is favored in luxury retail and galleries for creating an upscale atmosphere. B2B buyers should evaluate the quality of light diffusion and compatibility with existing interior designs. Given the technical requirements, partnering with manufacturers experienced in bespoke lighting solutions ensures seamless integration and compliance with regional electrical standards.

Adjustable LED Shelving Units

These units feature modular LED components that can be repositioned or adjusted to highlight different products or accommodate changing inventory layouts. They are popular in dynamic retail environments and trade fairs, where flexibility is paramount. Buyers should focus on ease of installation and the availability of scalable lighting modules. In emerging markets like Africa and South America, modularity reduces replacement costs and supports evolving business needs.

Energy-efficient LED Storage Shelves

Designed primarily for functional lighting in industrial and logistics settings, these shelves emphasize energy efficiency and safety. Features often include motion sensors and dimming controls to minimize power consumption. B2B purchasers should prioritize certifications such as DLC or CE and assess sensor reliability to ensure operational efficiency in warehouses or distribution centers. This type suits buyers focused on reducing overheads while maintaining workplace safety.

Smart LED Shelves

Smart LED shelves integrate IoT technology to allow remote control, scheduling, and color tuning via apps or centralized management systems. This innovation suits high-tech retail outlets and corporate environments seeking to enhance customer experience or operational control. Buyers must consider compatibility with existing IT infrastructure and the availability of after-sales support. While the upfront cost is higher, these systems offer scalable benefits through automation and data-driven lighting management.

Related Video: How to Install Ledges and Shelves at Home | Pottery Barn

Key Industrial Applications of led shelves

| Industry/Sector | Specific Application of led shelves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Supermarkets | Product Display and Merchandising | Enhances product visibility, attracts customers, and improves sales conversion rates | Uniform light distribution, energy efficiency, durability, ease of installation |

| Hospitality & Food Service | Ambient and Functional Lighting in Display Cases | Creates appealing food presentation, maintains product freshness, and elevates customer experience | Food-safe materials, adjustable color temperature, moisture resistance |

| Warehousing & Logistics | Inventory Identification and Safety Lighting | Improves inventory management accuracy and worker safety in storage areas | High durability, bright and consistent illumination, energy efficiency |

| Pharmaceuticals & Healthcare | Sterile and Controlled Environment Display | Ensures clear visibility of medical products and instruments while supporting hygiene standards | Anti-microbial coatings, easy-to-clean surfaces, compliance with health regulations |

| Electronics & High-tech Manufacturing | Component Display and Inspection Lighting | Facilitates detailed inspection and quality control of sensitive components | Flicker-free lighting, high CRI (Color Rendering Index), customizable shelf sizes |

Retail & Supermarkets

LED shelves are widely used in retail environments to illuminate products directly on display racks, significantly enhancing product visibility and attractiveness. This lighting solution helps retailers in Africa, South America, the Middle East, and Europe to differentiate their stores by creating vibrant, eye-catching displays that drive customer engagement and boost sales. Buyers should prioritize energy-efficient models with uniform light distribution and robust construction to withstand high-traffic environments, ensuring long-term operational savings and reliability.

Hospitality & Food Service

In hospitality settings, especially in bakeries, cafes, and delicatessens, LED shelves serve as ambient and functional lighting inside refrigerated and non-refrigerated display cases. They highlight the freshness and quality of food items, improving customer appeal and satisfaction. For international buyers, sourcing LED shelves with adjustable color temperatures and food-safe certifications is critical to comply with hygiene standards and maintain product integrity in varied climatic conditions prevalent in regions such as the Middle East and South America.

Warehousing & Logistics

LED shelves in warehouses provide targeted illumination for inventory racks, enhancing visibility for workers during picking and stocking operations. This application reduces errors and accidents, improving overall efficiency and safety. B2B buyers should look for LED shelves that offer high lumen output, energy efficiency, and durability to withstand industrial environments. Consideration of local power standards and ease of retrofit installation is essential for buyers in emerging markets like Africa and developing logistics hubs in Europe.

Pharmaceuticals & Healthcare

In pharmaceutical storage and healthcare facilities, LED shelves are used to illuminate medicines, instruments, and sterile products within controlled environments. These shelves must meet stringent hygiene and safety requirements, including anti-microbial surfaces and easy cleaning capabilities. Buyers from Europe and the Middle East should ensure compliance with local health regulations and certifications, while also seeking LED solutions that provide consistent, glare-free illumination critical for accurate identification and handling of sensitive items.

Electronics & High-tech Manufacturing

For electronics manufacturing and quality control, LED shelves provide precise, flicker-free lighting with high color rendering to facilitate detailed inspection of components and assemblies. This application demands customizable shelf dimensions to fit diverse product sizes and configurations. Buyers from technology hubs in Europe and South America should prioritize LED shelves with advanced features such as dimming controls and modular designs, ensuring adaptability to evolving production requirements and enhancing quality assurance processes.

Related Video: F-BOMB OF PEACE: Trump uses colorful language after Israel, Iran continue to drop bombs

Strategic Material Selection Guide for led shelves

Selecting the right materials for LED shelves is a critical decision that directly impacts product performance, durability, and cost-effectiveness. For international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the properties and trade-offs of common materials is essential to align with local standards, environmental conditions, and end-use requirements.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, which helps dissipate heat generated by LEDs. It typically withstands moderate temperature ranges and resists oxidation, making it suitable for both indoor and outdoor applications.

Pros & Cons:

Aluminum offers high durability and is easy to fabricate, allowing for intricate designs and custom finishes. Its corrosion resistance reduces maintenance costs, especially in humid or coastal environments. However, aluminum can be more expensive than some plastics and requires surface treatment (anodizing or powder coating) to enhance scratch resistance and aesthetics.

Impact on Application:

Its thermal properties make aluminum ideal for LED shelves where heat dissipation is critical to prolong LED lifespan. It is well-suited for retail displays, office installations, and industrial environments where structural integrity and longevity are priorities.

International Buyer Considerations:

Buyers in regions like Europe (Spain, Poland) will appreciate aluminum’s compliance with ASTM B221 and EN 573 standards, ensuring quality and consistency. In the Middle East and Africa, corrosion resistance is a key advantage due to harsh climates. However, buyers should verify supplier adherence to international surface treatment standards to avoid premature wear.

Tempered Glass

Key Properties:

Tempered glass is strong, heat-resistant, and provides excellent light diffusion and aesthetic appeal. It can withstand thermal shocks and pressures significantly better than regular glass, typically rated to endure temperatures up to 250°C.

Pros & Cons:

Tempered glass offers a premium look with high transparency and scratch resistance. It is non-corrosive and easy to clean, making it ideal for high-end retail and exhibition shelves. The downside includes higher fragility compared to metals under impact and increased weight, which can complicate shipping and installation.

Impact on Application:

Glass LED shelves are preferred where visual clarity and product presentation are paramount. They are commonly used in luxury retail, museums, and showrooms. The material’s fragility requires careful handling, especially in logistics-heavy regions like South America and Africa.

International Buyer Considerations:

Compliance with standards such as EN 12150 (European) and ANSI Z97.1 (US) is critical for safety and quality assurance. Buyers in Europe will find tempered glass widely accepted, while those in emerging markets should assess supplier certifications to mitigate risks related to breakage and liability.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a lightweight, impact-resistant thermoplastic with good thermal stability up to around 135°C. It offers excellent transparency and UV resistance when treated, making it suitable for both indoor and outdoor LED shelves.

Pros & Cons:

PC is highly durable and shatterproof, providing superior safety compared to glass. It is easier to mold into complex shapes, allowing for innovative shelf designs. However, it is more prone to scratching and may yellow over time if not UV-stabilized, which can affect aesthetics.

Impact on Application:

Ideal for environments requiring high impact resistance and safety, such as industrial settings or public spaces. Its lighter weight reduces shipping costs and simplifies installation in regions with logistical challenges like Africa and South America.

International Buyer Considerations:

Buyers should ensure polycarbonate meets ISO 7823 or ASTM D3935 standards for mechanical and thermal properties. UV stabilization is crucial for Middle Eastern and African markets due to intense sunlight exposure. European buyers often prioritize eco-friendly, recyclable PC grades to comply with sustainability regulations.

Stainless Steel

Key Properties:

Stainless steel is highly durable, corrosion-resistant, and capable of withstanding high temperatures and mechanical stresses. Grades like 304 and 316 offer excellent resistance to oxidation and chemical exposure.

Pros & Cons:

Stainless steel provides unmatched strength and longevity, making it ideal for heavy-duty LED shelves in industrial and commercial applications. It is easy to clean and maintain but is significantly heavier and more expensive than aluminum or plastics. Manufacturing complexity and cost can be higher due to welding and finishing requirements.

Impact on Application:

Best suited for environments with stringent hygiene or corrosion requirements, such as food retail, pharmaceutical displays, or outdoor installations exposed to harsh weather. Its robustness supports heavier loads and frequent handling.

International Buyer Considerations:

Compliance with ASTM A240 and EN 10088 standards ensures material quality. Buyers in Europe and the Middle East often demand certified stainless steel for durability and safety. In Africa and South America, the higher cost may be justified by longer lifecycle and reduced replacement frequency.

| Material | Typical Use Case for led shelves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Retail displays, office shelving, industrial lighting | Excellent heat dissipation and corrosion resistance | Higher cost; requires surface treatment | Medium |

| Tempered Glass | Luxury retail, museums, showrooms | Superior aesthetics and light diffusion | Fragile and heavy, higher shipping risk | High |

| Polycarbonate | Industrial, public spaces, outdoor shelving | Impact-resistant, lightweight, easy to mold | Prone to scratching and yellowing without UV treatment | Medium |

| Stainless Steel | Food retail, pharmaceutical, outdoor heavy-duty shelving | Exceptional durability and corrosion resistance | Heavy, expensive, complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led shelves

Manufacturing Processes for LED Shelves

The production of LED shelves involves a series of meticulously coordinated stages that ensure the final product is both functional and durable. For international B2B buyers, particularly those sourcing from or supplying to regions like Africa, South America, the Middle East, and Europe, understanding these stages helps in assessing supplier capabilities and product quality.

1. Material Preparation

The foundation of quality LED shelves lies in the careful selection and preparation of raw materials. Key materials typically include aluminum or steel for the shelf frame, high-grade PC or acrylic for light diffusers, and premium LED chips and drivers. Material preparation involves cutting metal sheets or profiles to size, surface cleaning, and pre-treatment such as anodizing or powder coating to enhance corrosion resistance—especially critical for humid or coastal markets. For buyers, ensuring suppliers source materials compliant with international standards (e.g., RoHS for hazardous substances) is essential.

2. Forming and Fabrication

This stage shapes the raw materials into the shelf components. Techniques include CNC machining for precision cutting, bending/forming of metal profiles, injection molding for plastic parts, and laser cutting for intricate designs. High-precision forming ensures components fit perfectly, which is vital for seamless assembly and consistent illumination. B2B buyers should inquire about the supplier’s equipment and technology to verify the ability to maintain tight tolerances, particularly if custom dimensions or designs are required.

3. Assembly

Assembly integrates the LED modules, wiring, drivers, and mechanical parts into the shelf structure. This process is often semi-automated to balance efficiency with quality control. Key assembly steps include mounting LED strips or modules onto heat sinks, soldering electrical connections, integrating power supplies, and attaching diffusers and outer casings. Proper thermal management design during assembly is crucial to prevent LED degradation. B2B buyers should seek suppliers with standardized assembly protocols and traceability systems to ensure consistency and ease of troubleshooting.

4. Finishing

Final finishing enhances both aesthetics and durability. Powder coating or anodizing protects metal surfaces, while UV-resistant coatings safeguard diffusers from discoloration. Some manufacturers apply anti-fingerprint or anti-glare treatments depending on application needs. Packaging is also part of finishing, where protective materials are used to prevent damage during transportation. For buyers, verifying finishing quality is critical, especially for export markets with varying climate conditions.

Quality Assurance Frameworks and Checkpoints

Robust quality assurance (QA) is indispensable in LED shelf manufacturing to guarantee product reliability, safety, and compliance with international regulations.

International and Industry Standards

- ISO 9001: A globally recognized quality management system standard that ensures consistent processes and continuous improvement. Suppliers with ISO 9001 certification demonstrate commitment to quality control and customer satisfaction.

- CE Marking: Mandatory for products sold within the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Ensures LED shelves are free from hazardous materials like lead and mercury, critical for buyers in Europe and increasingly important globally.

- UL/ETL Certification: Common in North America but also valued internationally for electrical safety assurance.

- API and Other Regional Standards: Some markets, especially in the Middle East and South America, may require compliance with regional electrical safety or environmental standards.

B2B buyers should verify that suppliers provide relevant certifications and test reports aligned with their target markets.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications. This includes checking LED chip brightness, driver functionality, and metal/alloy grades.

- In-Process Quality Control (IPQC): Monitoring during manufacturing stages, such as verifying solder joint integrity, proper assembly torque, and heat sink installation. IPQC helps detect defects early, reducing rework and waste.

- Final Quality Control (FQC): Comprehensive testing of finished LED shelves before shipment, including functional tests (lighting uniformity, brightness, color temperature), mechanical inspections (structural integrity, finishing quality), and safety checks (electrical insulation, thermal performance).

Common Testing Methods for LED Shelves

- Photometric Testing: Measures luminous flux, color rendering index (CRI), and color temperature to ensure lighting performance matches product specifications.

- Electrical Safety Testing: Includes insulation resistance, high voltage withstand, and grounding continuity to prevent electrical hazards.

- Thermal Testing: Verifies that heat dissipation mechanisms maintain LED junction temperatures within safe limits, ensuring longevity.

- Environmental Testing: Simulates conditions such as humidity, salt spray, and temperature cycling to confirm durability in various climates.

- Mechanical Testing: Assesses structural strength, vibration resistance, and impact tolerance, important for shipping and installation robustness.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers across Africa, South America, the Middle East, and Europe, verifying supplier QC systems is critical to mitigate risks and ensure product reliability.

- Factory Audits: Conduct on-site or third-party audits focusing on manufacturing capabilities, QA processes, and compliance certifications. Audits should evaluate material sourcing, equipment maintenance, employee training, and documentation controls.

- Review of Quality Documentation: Request and analyze IQC, IPQC, and FQC records, test reports, and calibration certificates to assess consistency and traceability.

- Third-Party Inspections: Employ independent inspection agencies to perform random sampling and testing before shipment, providing unbiased verification of quality. This is particularly recommended for new suppliers or high-volume orders.

- Sample Testing: Obtain product samples for in-house or third-party laboratory testing to verify performance and compliance with buyer-specific standards.

- Certification Verification: Confirm the authenticity and validity of supplier certifications (ISO, CE, RoHS) through official registries or certification bodies.

QC and Certification Nuances for International Buyers

- Regional Compliance Variations: Buyers in Europe (e.g., Spain, Poland) should prioritize CE marking and RoHS compliance, while Middle Eastern buyers may require additional electrical safety approvals. African and South American markets may have evolving standards, so proactive engagement with suppliers about certifications is advised.

- Climate Adaptation: Quality assurance should consider regional environmental conditions—suppliers must demonstrate testing for humidity, dust, and temperature extremes relevant to the buyer’s location.

- Language and Documentation: Ensure all QC documentation and certifications are available in a language understandable to the buyer’s team or local authorities to avoid customs or regulatory issues.

- Long-Term Support: Evaluate supplier commitment to after-sales service, warranty terms, and spare parts availability, which are integral components of quality assurance for B2B partnerships.

- Sustainability Credentials: Increasingly, buyers are demanding compliance with environmental and social governance (ESG) standards, which can be part of supplier audits and certifications.

Summary for B2B Buyers

Understanding the manufacturing processes and quality assurance protocols for LED shelves equips international buyers with the tools to select reliable suppliers and ensure product performance. Prioritize suppliers that demonstrate transparent, standardized manufacturing stages, hold internationally recognized certifications, and maintain rigorous QC checkpoints. Employ a combination of audits, documentation reviews, and third-party inspections tailored to your regional compliance requirements to safeguard your investment and build lasting supplier relationships.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led shelves Sourcing

Understanding the cost and pricing framework for sourcing LED shelves is crucial for international B2B buyers aiming to optimize procurement budgets while ensuring product quality and performance. The pricing of LED shelves integrates multiple cost components and is influenced by several market and transactional factors. Insight into these elements empowers buyers from Africa, South America, the Middle East, and Europe to negotiate better deals and forecast total ownership costs accurately.

Key Cost Components in LED Shelves Pricing

-

Materials

LED shelves typically combine aluminum or steel frames with integrated LED modules and diffusers made from acrylic or polycarbonate. Material costs fluctuate based on metal prices, LED chip quality, and diffuser transparency. Premium components—such as high-grade LEDs with superior lumen output or corrosion-resistant frames—command higher prices but offer longer lifespans and better efficiency. -

Labor and Manufacturing Overhead

Labor costs vary significantly by manufacturing location. Asian suppliers often provide competitive labor rates, which can reduce unit costs but might affect lead times or quality control rigor. Overhead includes factory utilities, equipment depreciation, and administrative expenses, impacting the final price especially for smaller batch orders.

Illustrative Image (Source: Google Search)

-

Tooling and Setup Costs

Custom LED shelves or those with unique dimensions and features require specialized tooling and molds. These upfront investments are amortized over the order volume, making low Minimum Order Quantities (MOQs) relatively more expensive per unit. Buyers should assess whether standard models can meet their needs to avoid excessive tooling charges. -

Quality Control (QC) and Certification

Rigorous QC processes and compliance certifications (e.g., CE, RoHS, UL) add to production costs but are critical for safety and regulatory adherence, especially in European and Middle Eastern markets. Certified products reduce risks of import delays or rejections and support brand reputation. -

Logistics and Shipping

Freight costs depend on shipment size, weight, distance, and chosen Incoterms (e.g., FOB, CIF). International buyers must factor in customs duties, taxes, and inland transportation. Consolidated shipments and choosing ports with efficient customs procedures can reduce total logistics expenses. -

Supplier Margin

Supplier margins vary with market conditions, order volume, and supplier reputation. Established manufacturers may price higher but offer stability and after-sales support, whereas emerging suppliers might offer aggressive pricing with potential trade-offs.

Influential Pricing Factors to Consider

-

Order Volume and MOQ

Larger volumes typically unlock volume discounts and reduce per-unit costs. Buyers from smaller markets or with limited budgets should negotiate flexible MOQs or consider group purchasing to leverage economies of scale. -

Product Specifications and Customization

Custom features such as adjustable color temperature, smart controls, or specific shelf dimensions increase complexity and price. Standardized models offer cost savings but may limit differentiation. -

Material Quality and Certifications

Higher-quality LEDs with better color rendering, durability, and energy efficiency elevate costs but lower total cost of ownership through reduced replacements and energy savings. -

Supplier Selection and Reliability

Suppliers with strong track records, transparent communication, and robust warranty policies can justify premium pricing by mitigating risks of defects or delays. -

Incoterms and Payment Terms

Understanding Incoterms is vital to accurately compare quotes. For example, CIF pricing includes freight and insurance, whereas FOB places shipping responsibility on the buyer. Payment terms like Letters of Credit or escrow services can impact cash flow and negotiating power.

Practical Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Beyond Price

Engage suppliers on payment terms, lead times, warranty, and after-sales service. These factors impact total cost and operational continuity. -

Calculate Total Cost of Ownership (TCO)

Consider energy consumption, maintenance, lifespan, and warranty coverage, not just upfront price. For instance, investing slightly more in high-efficiency LED shelves can yield significant electricity savings in the long run. -

Leverage Regional Trade Agreements

Buyers in Europe or the Middle East should explore sourcing from countries with favorable trade agreements to reduce tariffs and expedite customs clearance. -

Demand Transparent Cost Breakdown

Request detailed quotations breaking down costs by materials, labor, logistics, and margins. This transparency aids negotiation and comparison. -

Adapt to Currency Fluctuations

For buyers in volatile currency markets (e.g., South America, Africa), consider contract clauses or hedging options to manage exchange rate risks.

Disclaimer on Pricing

Prices for LED shelves vary widely depending on specifications, order size, supplier location, and global material costs. The figures discussed here are indicative and should be validated through direct supplier engagement and market research tailored to specific sourcing scenarios.

This comprehensive understanding of cost components and pricing influencers equips international B2B buyers to make informed decisions, negotiate effectively, and optimize the procurement of LED shelves in diverse markets.

Spotlight on Potential led shelves Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led shelves’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led shelves

Critical Technical Properties of LED Shelves

When sourcing LED shelves, understanding key technical specifications is crucial to ensure product quality, compatibility, and long-term value. Below are essential properties that international B2B buyers should evaluate:

-

Material Grade and Finish

LED shelves typically use aluminum or steel alloys for durability and heat dissipation. High-grade materials (e.g., anodized aluminum) enhance corrosion resistance and structural integrity, especially important in humid or industrial environments found in Africa, South America, and the Middle East. The finish affects aesthetics and maintenance requirements, impacting buyer decisions in retail and hospitality sectors. -

LED Chip Type and Lumens Output

The quality of LED chips (commonly SMD or COB) directly influences brightness and energy efficiency. Lumens measure the light output; higher lumens mean brighter shelves. Buyers should balance lumens against power consumption to optimize energy costs and lighting effectiveness for product displays or workspace illumination. -

Color Temperature (Kelvin Scale)

Color temperature determines the light’s warmth or coolness, ranging from warm white (~2700K) to cool white (~6500K). This affects ambiance and product presentation, essential for retail and exhibition buyers in Europe and the Middle East, who often require tunable options to adapt to different environments and customer preferences. -

Power Supply and Voltage Compatibility

LED shelves must be compatible with local power standards, typically 110-240V AC. For international buyers, verifying power supply compatibility avoids costly retrofit or operational failures. Efficient power drivers with dimming and surge protection enhance shelf longevity and safety. -

IP Rating (Ingress Protection)

The IP rating indicates resistance to dust and moisture, critical for buyers deploying LED shelves in warehouses, outdoor settings, or humid climates. For example, an IP65 rating ensures protection against dust ingress and water jets, extending shelf lifespan and reducing maintenance. -

Dimensional Tolerances and Mounting Options

Precision in shelf dimensions and mounting hardware ensures seamless integration into existing retail or industrial infrastructure. Tight tolerances reduce installation errors and downtime. Adjustable or modular mounting solutions provide flexibility, a valuable feature for diverse markets such as Europe and South America.

Common Trade Terminology for LED Shelf Procurement

Navigating international LED shelf sourcing requires familiarity with industry jargon to streamline communication and negotiation. Here are key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED shelves that other companies brand and sell. Engaging with OEMs allows buyers to customize product specifications and secure competitive pricing, especially for bulk orders. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and cash flow, balancing cost efficiency with storage and demand considerations, particularly relevant for emerging markets. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific LED shelf configurations. Well-prepared RFQs enable buyers to compare offers objectively and negotiate better deals. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify cost allocation and risk, essential for cross-border transactions involving Africa, South America, and Europe. -

Lead Time

The period between order confirmation and product delivery. Accurate lead time estimates are vital for project scheduling and supply chain coordination, minimizing downtime in retail or industrial applications. -

DLC and ETL Certifications

These certifications indicate compliance with safety, energy efficiency, and quality standards. DLC (DesignLights Consortium) and ETL (Electrical Testing Laboratories) marks are often prerequisites for buyers seeking to meet regional regulations or qualify for utility rebates.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and ensure the successful deployment of LED shelves tailored to their specific market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led shelves Sector

Market Overview & Key Trends

The global LED shelves market is experiencing robust growth driven by increasing demand for energy-efficient, versatile, and aesthetically appealing lighting solutions across retail, hospitality, office, and industrial sectors. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including mature markets like Spain and Poland—understanding regional market dynamics and sourcing trends is critical to securing competitive advantage and operational efficiency.

Key Market Drivers:

- Energy Efficiency Mandates: Governments worldwide are imposing stricter energy consumption regulations, boosting adoption of LED shelves that reduce power usage and operational costs.

- Retail & Display Innovation: Retailers and brands increasingly rely on LED shelves to enhance product visibility and customer engagement, especially in luxury and tech sectors.

- Technological Advancements: Integration of smart controls, tunable color temperatures, and sensor-driven automation are reshaping product offerings, enabling buyers to procure highly customizable LED shelf solutions.

- Urbanization & Infrastructure Growth: Emerging markets in Africa and South America are witnessing rapid urbanization, creating demand for modern commercial spaces equipped with advanced lighting systems.

Sourcing Trends for B2B Buyers:

- Customization & Modularity: Buyers prioritize suppliers offering modular LED shelf systems that allow easy installation and scalability, accommodating diverse space layouts.

- Supplier Reliability & Quality Control: Given the technical complexity, thorough vetting of manufacturers’ quality assurance processes—including certifications like ISO 9001 and compliance with regional safety standards—is essential.

- Cost-Performance Balance: While initial investment varies, buyers seek suppliers that deliver long-term value through durability, energy savings, and minimal maintenance.

- Regional Sourcing Hubs: Europe’s LED manufacturing hubs in Germany, Poland, and Spain provide high-quality products with shorter lead times, whereas Asian markets, especially China, dominate in cost-competitive solutions. Strategic sourcing from multiple regions enables risk mitigation and price optimization.

Market Dynamics:

- Fluctuating raw material costs, particularly for semiconductors and aluminum, impact pricing and availability.

- Supply chain disruptions encourage buyers to diversify supplier bases and consider nearshoring options.

- Increasing digitalization in procurement processes facilitates data-driven supplier selection and contract management.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the procurement of LED shelves, reflecting growing corporate responsibility commitments and compliance with international environmental standards. For B2B buyers, especially in regions with stringent environmental regulations like the European Union, aligning sourcing strategies with sustainability goals is increasingly non-negotiable.

Environmental Impact Considerations:

- Energy Consumption: LED shelves inherently offer significant energy savings compared to traditional lighting. Buyers should quantify lifecycle energy use to maximize ROI and environmental benefits.

- Material Selection: Preference for shelves using recycled or recyclable materials such as aluminum and sustainable plastics reduces ecological footprint.

- Manufacturing Footprint: Assessing suppliers’ environmental management practices—including waste reduction, water usage, and emissions control—ensures alignment with buyers’ sustainability policies.

Ethical Supply Chain Importance:

- Transparency and traceability in sourcing components mitigate risks related to labor abuses and conflict minerals.

- Certification schemes such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and Energy Star provide assurance on chemical safety and energy efficiency.

- Increasingly, buyers demand suppliers adhere to ISO 14001 environmental management standards and demonstrate corporate social responsibility (CSR) commitments.

Green Certifications & Standards:

- LED shelves with DLC (DesignLights Consortium) certification assure superior energy performance and eligibility for utility rebates, particularly relevant for buyers in North America and Europe.

- Suppliers offering products compliant with WEEE (Waste Electrical and Electronic Equipment Directive) support responsible end-of-life management.

- Adoption of Cradle to Cradle certified materials signals a circular economy approach, appealing to buyers targeting sustainable procurement.

Incorporating sustainability criteria into supplier evaluation not only fulfills regulatory and reputational requirements but also drives cost savings through energy efficiency and reduced waste.

Brief Evolution and Historical Context

The evolution of LED shelves is intertwined with advances in LED technology and retail display innovation. Initially, shelving lighting was limited to incandescent or fluorescent sources, which were inefficient, bulky, and had shorter lifespans. The introduction of LED lighting in the early 2000s revolutionized the sector by offering compact, energy-efficient, and long-lasting illumination.

Over the past two decades, LED shelves have transitioned from simple under-shelf lighting to sophisticated, integrated systems featuring adjustable color temperatures, dimming capabilities, and smart controls. This progression has enabled retailers and commercial spaces to create dynamic, visually engaging displays that adapt to varying lighting needs and consumer behaviors.

For B2B buyers, understanding this technological trajectory is vital to appreciate the performance improvements, cost implications, and sourcing complexities associated with modern LED shelf solutions. It also highlights the importance of partnering with forward-looking manufacturers capable of delivering cutting-edge, sustainable products that meet evolving market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led shelves

-

How can I effectively vet LED shelf suppliers from different regions like Africa, South America, the Middle East, and Europe?

To ensure reliability, start by verifying supplier credentials such as business licenses, ISO certifications, and industry-specific accreditations. Request product samples to assess quality and confirm compliance with international standards. Utilize third-party inspection services or factory audits to validate manufacturing capabilities. Additionally, review client testimonials and case studies to gauge reputation. For buyers in diverse regions, consider suppliers with experience exporting to similar markets to ensure familiarity with local regulations and logistics challenges. -

What customization options are typically available for LED shelves, and how can I negotiate these for my specific market needs?

LED shelves often offer customization in size, lighting color temperature, brightness levels, power consumption, and control systems (e.g., dimmable, Bluetooth-enabled). Buyers should clearly communicate their technical requirements and intended application to suppliers early in the negotiation process. Request prototypes or design samples to validate specifications. Negotiating customization is easier when ordering larger volumes, so aligning customization needs with MOQ can lead to cost-effective solutions. Always confirm lead times and additional costs associated with bespoke features before finalizing orders. -

What are common Minimum Order Quantities (MOQs) and lead times for international B2B orders of LED shelves?

MOQs vary widely depending on manufacturer scale and customization level, typically ranging from 50 to 500 units. Lead times can span 4 to 12 weeks, influenced by order complexity, customization, and shipping method. Buyers from regions like Europe or the Middle East should account for additional time due to customs clearance and potential delays. It’s advisable to discuss MOQs and lead times upfront and explore suppliers offering flexible batch sizes or staged deliveries to better match cash flow and inventory management. -

Which payment terms are standard in international LED shelf transactions, and how can buyers minimize financial risk?

Common payment terms include 30% upfront deposit with balance paid upon shipment or via Letter of Credit (L/C) to safeguard funds. For new suppliers, using L/C or escrow services can reduce risk. Established buyers may negotiate net 30-60 day terms post-delivery. Always confirm accepted currencies and consider currency fluctuation risks when dealing with suppliers from different regions. Using trade credit insurance or working with reputable trade finance institutions can further mitigate payment-related risks. -

What quality assurance processes and certifications should I require to ensure LED shelves meet international standards?

Request suppliers to provide certifications such as CE (Europe), RoHS (hazardous substances compliance), UL (safety in North America), or IEC standards relevant to your market. Quality assurance should include in-line inspections, functional testing, and final product audits. Ask for detailed QA reports and warranty terms. For critical applications, consider third-party lab testing or factory audits. Ensuring compliance with local electrical and safety regulations in your target market is crucial to avoid import rejections or liability issues. -

How do I manage logistics and shipping challenges when importing LED shelves internationally?

Choose suppliers experienced in international shipping and familiar with Incoterms (e.g., FOB, CIF) to clarify responsibility for freight and customs duties. Opt for consolidated shipments to reduce costs when ordering from multiple suppliers. For buyers in Africa or South America, factor in longer transit times and potential customs delays. Engage freight forwarders who provide end-to-end tracking and customs brokerage services. Proper packaging to prevent damage and compliance with import regulations should be verified before shipment. -

What are effective dispute resolution strategies if product quality or delivery timelines are not met?

Establish clear contractual terms covering quality standards, delivery schedules, and penalties for non-compliance. Use written purchase agreements specifying remedies such as replacement, refunds, or discounts. Maintain open communication channels and document all correspondence. For cross-border disputes, consider arbitration through recognized international bodies (e.g., ICC) to avoid lengthy court processes. Engaging local legal counsel familiar with supplier jurisdiction can also help. Building strong supplier relationships reduces risks but always prepare contingency plans. -

How can I leverage LED shelf technology trends to gain a competitive edge in my regional market?

Stay informed about innovations such as smart controls (Bluetooth, Wi-Fi), energy-efficient drivers, and customizable RGB lighting that cater to retail or hospitality sectors. Buyers should seek suppliers offering scalable solutions that integrate with existing store management systems. Tailoring LED shelf features to local consumer preferences and regulations enhances market appeal. Collaborate with suppliers for pilot projects to test new technologies before large-scale adoption. Leveraging these trends can improve customer engagement and operational efficiency across diverse international markets.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led shelves

Effective sourcing of LED shelves demands a strategic approach that balances quality, cost-efficiency, and supplier reliability. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding the nuances of product specifications—such as LED types, energy consumption, and material durability—is crucial. Prioritizing suppliers who demonstrate strong manufacturing controls and offer customizable solutions will enable businesses to tailor LED shelves to diverse market requirements and application needs.

Key takeaways include:

- Aligning product features with end-use environments to maximize operational benefits and customer satisfaction.

- Evaluating total cost of ownership, including installation, maintenance, and energy savings, rather than focusing solely on upfront price.

- Leveraging supplier partnerships for innovation, compliance with regional standards, and scalability.

Looking ahead, the LED shelves market will continue to evolve with advancements in smart lighting controls and sustainable materials. Buyers should actively engage with manufacturers that invest in R&D and provide flexible order volumes to accommodate growing or fluctuating demands. Embracing strategic sourcing now positions businesses to capitalize on emerging trends, improve competitive advantage, and support sustainable growth in their respective regions.

International buyers are encouraged to conduct thorough market research and foster long-term supplier relationships that align with their strategic goals, ensuring their LED shelf investments deliver lasting value.