Introduction: Navigating the Global Market for drive led strip with raspberry pi 5

The integration of LED strips with the Raspberry Pi 5 has unlocked new horizons in intelligent lighting solutions, making it a pivotal technology for businesses seeking innovation in automation, smart environments, and visual displays. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding how to effectively source and utilize these components is essential to maintain competitive advantage and meet growing market demands.

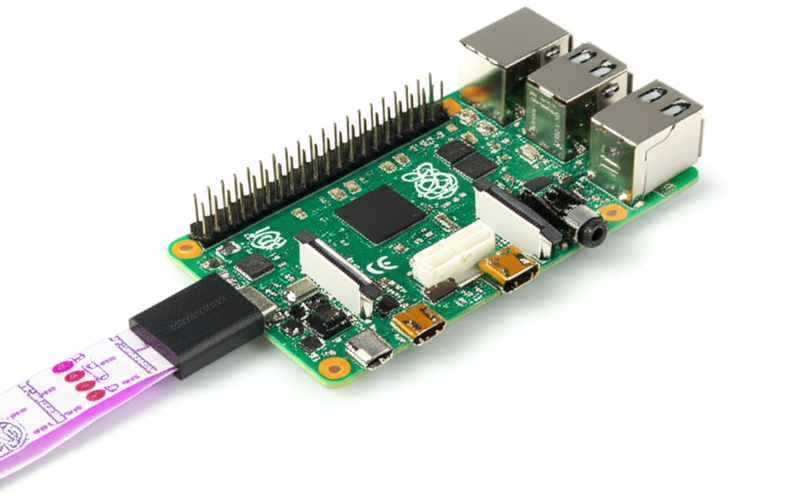

This guide delves deeply into the critical facets of driving LED strips using the Raspberry Pi 5 platform, addressing everything from the selection of LED types—such as WS2812B and APA102—to the nuances of power supply requirements and GPIO interfacing. It further explores manufacturing standards, quality control protocols, and reliable supplier identification, empowering buyers to navigate complex supply chains with confidence.

In addition to technical specifications, the guide provides comprehensive cost analyses and market insights tailored to regional considerations, including logistical challenges and import regulations relevant to diverse global markets. A dedicated FAQ section anticipates common procurement and implementation questions, offering practical solutions to streamline decision-making.

By synthesizing technical expertise with strategic sourcing intelligence, this resource equips international buyers with actionable knowledge to optimize their investments in LED strip projects powered by Raspberry Pi 5. Whether expanding smart lighting portfolios or integrating advanced visual systems, readers will gain the clarity and assurance needed to make informed, cost-effective purchasing decisions in a dynamic global marketplace.

Understanding drive led strip with raspberry pi 5 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WS2812B LED Strip | Single data line, individually addressable RGB LEDs | Retail displays, small to medium smart lighting | + Cost-effective; simple wiring – Limited for long runs |

| APA102 LED Strip | Separate clock and data lines for precise timing control | Large-scale installations, synchronized effects | + High refresh rate; scalable – Higher cost; more complex setup |

| Analog RGB LED Strip | Three separate control lines for red, green, and blue channels | Basic lighting, architectural accents | + Simpler control; lower cost – No individual LED control |

| Digital RGBW LED Strip | Adds a dedicated white LED for enhanced color accuracy | Hospitality, premium lighting solutions | + Better white tones; flexible color mixing – More expensive |

| Addressable RGB LED Strip with IC | Integrated IC chips for advanced effects and patterns | Entertainment, advertising, interactive displays | + Highly customizable; supports complex animations – Requires advanced programming and power management |

WS2812B LED Strip

WS2812B LED strips are widely used due to their affordability and simplicity, featuring a single data line controlling individually addressable LEDs. This makes them ideal for B2B buyers targeting retail environments or small smart lighting projects where cost efficiency is paramount. However, their performance can degrade over longer lengths, so businesses must consider run length limitations and power supply needs when planning installations.

APA102 LED Strip

APA102 strips stand out with separate clock and data lines, enabling faster and more reliable data transmission. This makes them suitable for large-scale commercial projects requiring smooth, synchronized lighting effects, such as event venues or architectural lighting. B2B buyers should anticipate higher upfront costs and a more complex wiring setup but gain superior performance and scalability.

Analog RGB LED Strip

Analog RGB strips use three control lines for red, green, and blue channels without individual LED addressability. They are best suited for straightforward lighting applications like accent lighting in offices or hospitality settings. For B2B buyers, these strips offer lower costs and easier integration but lack the flexibility of digital strips for dynamic effects.

Digital RGBW LED Strip

Digital RGBW strips incorporate an additional white LED, enhancing color accuracy and producing cleaner whites. This variation appeals to premium lighting markets such as hotels and high-end retail, where nuanced lighting quality is critical. Buyers should weigh the increased cost against the improved visual experience and consider compatibility with Raspberry Pi 5 control systems.

Addressable RGB LED Strip with IC

These strips integrate dedicated IC chips on each LED, enabling complex animations and interactive lighting patterns. They are favored in entertainment, advertising, and interactive installations. B2B buyers must be prepared for advanced programming requirements and robust power management strategies but benefit from unparalleled customization and visual impact.

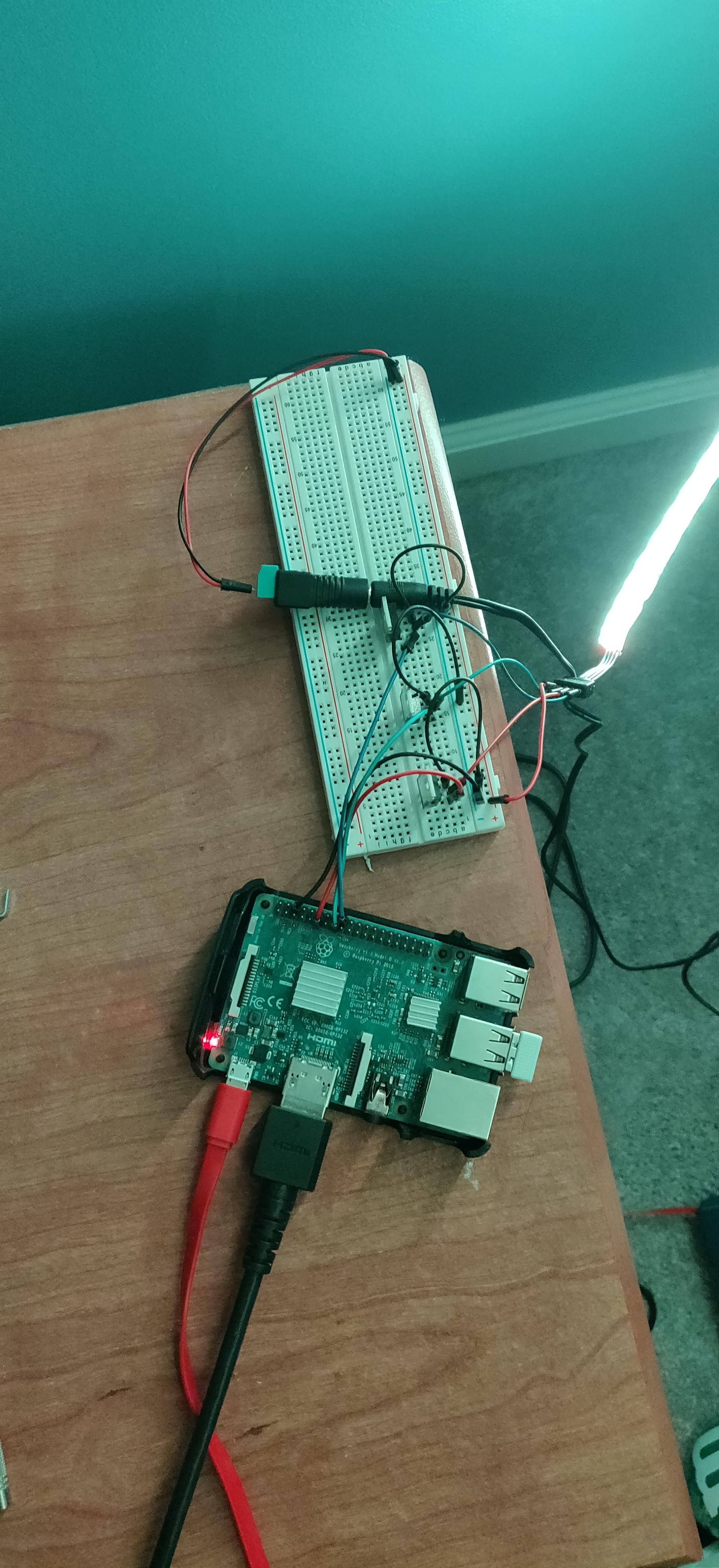

Related Video: How To Use Addressable RGB WS2812B LED Strips With a Raspberry Pi Single Board Computer

Key Industrial Applications of drive led strip with raspberry pi 5

| Industry/Sector | Specific Application of drive led strip with raspberry pi 5 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Smart Building Automation | Dynamic lighting control for energy-efficient office and commercial spaces | Reduces energy consumption, enhances occupant comfort | Compatibility with existing building management systems, power efficiency, and scalability |

| Retail & Visual Merchandising | Interactive LED displays and signage for product promotion and customer engagement | Increases foot traffic and sales conversion rates | Durability for continuous operation, ease of programming, and customization options |

| Industrial Safety & Warning Systems | Color-coded LED strips for real-time hazard alerts and machine status indicators | Improves workplace safety and operational efficiency | Reliability under harsh conditions, compliance with safety standards, and integration capability |

| Hospitality & Event Management | Ambient and mood lighting controlled via Raspberry Pi for hotels, restaurants, and events | Enhances guest experience and enables tailored ambiance | Flexibility in color patterns, remote control features, and quick installation |

| Agriculture & Controlled Environment Farming | LED grow lights with programmable spectrums for optimized plant growth | Boosts crop yields and reduces energy costs | Precision control of light spectrum, robustness in humid environments, and energy efficiency |

The Smart Building Automation sector leverages the Raspberry Pi 5 driven LED strips to implement intelligent lighting systems that adjust brightness and color temperature based on occupancy and natural light availability. This application addresses the critical need for energy savings and improved workspace comfort, which is especially valued in Europe’s energy-conscious markets like Germany and Italy. Buyers from Africa and South America should prioritize sourcing LED strips with high energy efficiency and seamless integration capabilities with existing building automation protocols.

In Retail & Visual Merchandising, businesses utilize programmable LED strips controlled by Raspberry Pi 5 to create dynamic window displays and in-store lighting that attract customers and highlight products. This technology solves the challenge of static and uninspiring retail environments, driving increased customer engagement. For international buyers, sourcing durable LED strips capable of continuous operation and easy reprogramming is essential to maximize return on investment and adapt quickly to seasonal campaigns.

Illustrative Image (Source: Google Search)

The Industrial Safety & Warning Systems industry benefits from the use of color-coded LED strips to provide instant visual alerts on factory floors or hazardous zones. Raspberry Pi 5’s ability to handle complex lighting patterns allows real-time status updates that enhance worker safety and reduce downtime. Key considerations for buyers include ensuring the LED components meet industrial-grade reliability standards and can operate effectively in extreme temperatures or dusty environments common in many African and Middle Eastern industrial settings.

In Hospitality & Event Management, programmable LED strips enable venues to create customizable ambient lighting that can be tailored to different moods or event themes. The Raspberry Pi 5’s processing power allows for smooth transitions and remote control, enhancing guest experience in hotels and restaurants. Buyers from Europe and South America should focus on sourcing LED solutions that offer flexible color control and quick installation to accommodate frequent event changes.

Finally, the Agriculture & Controlled Environment Farming sector uses Raspberry Pi 5 driven LED strips to deliver specific light spectrums that promote plant growth and optimize photosynthesis. This application addresses the demand for sustainable farming practices and higher crop yields, critical in regions like the Middle East and Africa where arable land is limited. Buyers should prioritize LED strips with precise spectral control, durability in humid or greenhouse environments, and energy efficiency to ensure cost-effective operation.

Strategic Material Selection Guide for drive led strip with raspberry pi 5

Silicone Rubber

Key Properties: Silicone rubber offers excellent thermal stability, withstanding temperatures from -60°C to 230°C, and features outstanding electrical insulation and flexibility. It is highly resistant to UV radiation, ozone, and moisture, making it ideal for outdoor and harsh environment applications.

Pros & Cons: Silicone rubber is durable, flexible, and resistant to environmental degradation, which ensures longevity in LED strip casings and wiring insulation. However, it tends to be more expensive than standard plastics and can be more complex to manufacture in precision forms. Its softness may limit mechanical protection in high-impact environments.

Impact on Application: The material’s flexibility and heat resistance make it suitable for LED strips driven by Raspberry Pi 5 in applications requiring bending or exposure to varying temperatures, such as architectural lighting or automotive installations. Its moisture resistance is advantageous in humid climates common in parts of Africa and South America.

Considerations for International B2B Buyers: Buyers in Europe (Germany, Italy) will appreciate silicone’s compliance with stringent RoHS and REACH regulations, ensuring environmental and safety standards. In the Middle East and Africa, silicone’s UV resistance is crucial due to intense sunlight exposure. However, buyers should verify certifications like ASTM D2000 for rubber materials to ensure quality and performance consistency.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic with good electrical insulation, moderate heat resistance (typically up to 105°C), and inherent flame retardant properties when formulated accordingly. It is chemically resistant to many acids and alkalis but less so to solvents.

Pros & Cons: PVC is cost-effective and easy to manufacture in various shapes and sizes, making it a popular choice for LED strip housings and cable insulation. Its rigidity can provide structural support but reduces flexibility. Over time, PVC may become brittle, especially under prolonged UV exposure.

Impact on Application: PVC suits indoor LED strip installations where cost-efficiency is a priority, such as retail displays or office lighting controlled by Raspberry Pi 5. It is less ideal for outdoor or high-temperature environments prevalent in some Middle Eastern or South American regions without additional UV stabilizers.

Considerations for International B2B Buyers: PVC products must meet international standards like DIN VDE 0472 (Germany) or ASTM D1784 (US) for electrical insulation and flame retardancy. Buyers in Africa and South America should consider local regulations on PVC use due to environmental concerns. For Europe, compliance with EU directives on hazardous substances is mandatory.

Aluminum Alloy

Key Properties: Aluminum alloys used in LED strip housings provide excellent thermal conductivity, aiding heat dissipation, and offer robust mechanical protection. They typically withstand temperatures up to 150°C and resist corrosion when anodized or coated.

Pros & Cons: Aluminum is lightweight, durable, and enhances LED strip lifespan by preventing overheating. The manufacturing process, including extrusion and anodizing, can be costlier and more complex than plastics. It is less flexible but provides superior structural integrity.

Impact on Application: Ideal for industrial or commercial LED lighting where heat management is critical, such as in manufacturing plants or outdoor installations in Europe and the Middle East. Aluminum housings improve reliability when driving LED strips with Raspberry Pi 5, especially in high-power or continuous-use scenarios.

Considerations for International B2B Buyers: European buyers often require compliance with EN 573 (aluminum alloy standards) and RoHS directives. In the Middle East and Africa, corrosion resistance is vital due to saline or humid environments, making anodized aluminum preferred. Supply chain considerations include sourcing from certified mills to ensure alloy consistency.

Polycarbonate (PC)

Key Properties: Polycarbonate is a transparent thermoplastic with high impact resistance, good heat resistance (up to 135°C), and excellent electrical insulation. It offers superior optical clarity, making it suitable for LED diffusers and protective covers.

Pros & Cons: Polycarbonate provides robust protection against mechanical shocks and UV exposure, maintaining clarity over time. It is more expensive than PVC but less costly than metals. However, it can be prone to scratching and may yellow under prolonged UV exposure unless UV-stabilized.

Impact on Application: Polycarbonate is well-suited for LED strip covers or lenses in smart lighting systems controlled by Raspberry Pi 5, especially in commercial or architectural applications requiring aesthetics and durability. Its optical properties enhance light diffusion, improving visual effects.

Considerations for International B2B Buyers: Compliance with ASTM D3935 (UV resistance) and ISO 7823-1 (impact resistance) is important for buyers in Europe and South America. For Middle Eastern markets, UV-stabilized grades are recommended due to intense sunlight. Polycarbonate’s recyclability aligns with sustainability trends favored in European procurement policies.

| Material | Typical Use Case for drive led strip with raspberry pi 5 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Flexible LED strip insulation and outdoor casing | Excellent thermal and UV resistance | Higher cost and softer mechanical protection | High |

| Polyvinyl Chloride (PVC) | Indoor LED strip housing and cable insulation | Cost-effective and flame retardant | Less UV resistant, can become brittle over time | Low |

| Aluminum Alloy | Heat dissipation housings for industrial and outdoor LED installations | Superior heat management and durability | Higher manufacturing complexity and cost | High |

| Polycarbonate | Protective covers and diffusers for LED strips | High impact resistance and optical clarity | Susceptible to scratching and UV yellowing | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for drive led strip with raspberry pi 5

Manufacturing Processes for Drive LED Strip with Raspberry Pi 5

The production of drive LED strips compatible with Raspberry Pi 5 involves a series of precise and controlled manufacturing stages. These stages ensure the final product meets performance, reliability, and integration requirements crucial for B2B buyers, especially those seeking scalable, high-quality solutions for diverse markets such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

- Component Sourcing: High-quality LED chips (e.g., WS2812B or APA102), resistors, capacitors, copper-clad laminates for PCB, and connectors are sourced from certified suppliers. Material traceability is critical, allowing buyers to verify component origins and certifications.

- PCB Fabrication: The printed circuit board (PCB) is manufactured using copper-clad laminates, followed by photolithography to etch precise circuit patterns. This step requires cleanroom conditions to avoid contamination that can cause defects.

- Surface Treatment: The PCB undergoes processes such as solder mask application and silkscreen printing, providing insulation and identification marks.

2. Forming and Assembly

- SMT (Surface Mount Technology) Assembly: Automated pick-and-place machines position surface-mount devices (SMDs) including LEDs, resistors, and ICs onto the PCB with micron-level accuracy. This ensures consistent electrical performance across batches.

- Soldering: Reflow soldering is employed to secure components, where the PCB is heated in controlled ovens to melt solder paste, forming robust electrical and mechanical bonds. For through-hole components, wave soldering or manual soldering may be used depending on design complexity.

- Connector Integration: Connectors for power, data input/output, and Raspberry Pi 5 GPIO interfaces are installed, ensuring compatibility and ease of integration.

3. Finishing

- Encapsulation and Coating: To protect against environmental factors such as moisture, dust, and mechanical stress, LED strips may be coated with protective layers or encased in silicone or epoxy resins. This enhances durability, especially for outdoor or industrial applications.

- Cutting and Packaging: LED strips are cut to standard or custom lengths and undergo final visual inspection before packaging. Packaging is designed to minimize electrostatic discharge (ESD) risks and physical damage during transport.

Quality Assurance (QA) and Quality Control (QC) Frameworks

Robust QA and QC systems underpin the manufacturing of drive LED strips with Raspberry Pi 5 compatibility. International B2B buyers must ensure suppliers adhere to globally recognized standards and implement comprehensive testing regimes.

Illustrative Image (Source: Google Search)

Relevant International and Industry Standards

- ISO 9001: This is the foundational quality management system (QMS) certification demonstrating that the supplier maintains consistent quality processes and continuous improvement. Buyers should request evidence of ISO 9001 certification to ensure systematic quality governance.

- CE Marking (Europe): Indicates conformity with EU safety, health, and environmental protection standards, essential for European markets.

- RoHS Compliance: Restricts hazardous substances in electronic products, critical for environmental and health safety compliance globally.

- UL Certification (if applicable): For electrical safety, particularly relevant for buyers in regions with strict safety regulations.

- API or Other Industry-Specific Standards: Depending on application sectors (e.g., automotive, industrial automation), additional certifications may be required.

QC Checkpoints

- Incoming Quality Control (IQC): Raw materials and components undergo rigorous inspection for specifications, such as LED brightness, PCB integrity, and connector dimensions. Use of automated optical inspection (AOI) machines and component analyzers is common.

- In-Process Quality Control (IPQC): During assembly, continuous monitoring ensures solder joint quality, component placement accuracy, and functional testing at intermediate stages to catch defects early.

- Final Quality Control (FQC): Completed LED strips undergo comprehensive tests including visual inspection, electrical tests (voltage, current, signal integrity), and functional tests (color accuracy, brightness, response time).

Common Testing Methods

- Optical Testing: Measures LED luminance, color spectrum, and uniformity to guarantee visual performance matches specifications.

- Electrical Testing: Includes continuity, insulation resistance, and power consumption tests to ensure safe and efficient operation.

- Environmental Stress Testing: Thermal cycling, humidity exposure, and vibration tests simulate operational conditions to verify durability.

- Functional Testing with Raspberry Pi 5: End-to-end testing where the LED strip is connected to a Raspberry Pi 5 to validate real-world performance, including software control responsiveness and synchronization.

How B2B Buyers Can Verify Supplier QC

For buyers across Africa, South America, the Middle East, and Europe, verifying supplier quality assurance systems is vital to mitigate risks and ensure product consistency.

Supplier Audits

- Onsite Factory Audits: Conducted by buyer representatives or third-party inspection agencies to assess manufacturing capabilities, process controls, and compliance with standards. Audits should cover raw material handling, assembly lines, and QC labs.

- Remote Audits: Useful for initial screening or when travel is restricted, leveraging video inspections and document reviews.

Documentation and Reporting

- Quality Certificates: Obtain copies of ISO 9001, CE, RoHS, and other relevant certificates.

- Test Reports: Request detailed IQC, IPQC, and FQC reports with batch-specific data for transparency.

- Process Flowcharts and Control Plans: Understand the supplier’s process steps and key control points to evaluate their quality system robustness.

Third-Party Inspection Services

Engaging independent inspection firms for pre-shipment inspections (PSI) or during production can provide unbiased verification of product quality. Inspectors assess dimensions, functionality, and packaging compliance, delivering detailed reports to buyers.

QC and Certification Nuances for International Buyers

Regional Compliance Considerations

- Africa and South America: Regulatory frameworks may vary; buyers should ensure products meet local electrical safety standards and import regulations. CE and RoHS certifications are often accepted, but local certifications may be necessary.

- Middle East: Some countries require GCC (Gulf Cooperation Council) conformity marks; buyers should verify if additional documentation or testing is required.

- Europe (Germany, Italy): Strict enforcement of CE and RoHS directives applies. Buyers should also consider REACH compliance for chemical safety and ensure suppliers provide Declaration of Conformity (DoC).

Logistics and After-Sales Support

- Ensure suppliers provide clear warranty terms, replacement policies, and technical support, which are critical for remote markets.

- Verify packaging meets international shipping standards to avoid damage or contamination during transit.

Summary: Actionable Insights for B2B Buyers

- Demand transparency on manufacturing processes and insist on supplier adherence to ISO 9001 and relevant regional certifications.

- Insist on comprehensive QC documentation including IQC, IPQC, and FQC reports, and consider engaging third-party inspectors for added assurance.

- Evaluate supplier’s testing capabilities, especially functional testing with Raspberry Pi 5, to ensure compatibility and performance.

- Understand regional certification requirements to avoid customs delays and ensure market acceptance.

- Plan for robust after-sales support and logistics to maintain supply chain continuity and product reliability.

By focusing on these detailed manufacturing and quality assurance aspects, international B2B buyers can make informed procurement decisions, reduce risks, and secure high-performance drive LED strips tailored for Raspberry Pi 5 applications across diverse global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for drive led strip with raspberry pi 5 Sourcing

Understanding the Cost Structure for Driving LED Strips with Raspberry Pi 5

When sourcing solutions to drive LED strips with Raspberry Pi 5, B2B buyers must analyze the full cost structure beyond the initial unit price. The primary cost components include:

- Materials: This covers the Raspberry Pi 5 board, LED strips (commonly WS2812B or APA102), power supplies, logic level converters, and necessary wiring. Material costs fluctuate based on LED strip quality, length, and specifications such as color accuracy or brightness.

- Labor: Assembly and testing labor costs vary by manufacturing location and complexity of integration, especially if customized programming or hardware modifications are required.

- Manufacturing Overhead: Includes factory utilities, machinery depreciation, and indirect labor, which are typically allocated based on production volume.

- Tooling and Setup: Initial tooling for PCB assembly, soldering fixtures, or custom casings can add upfront costs, impacting pricing especially for small orders.

- Quality Control (QC): Rigorous testing of LED functionality, Raspberry Pi configurations, and power supply stability is essential to ensure reliability, adding to cost but reducing failure rates.

- Logistics and Import Fees: Freight, customs duties, and insurance vary significantly depending on origin (often China or Southeast Asia) and destination countries in Africa, South America, the Middle East, or Europe.

- Supplier Margin: Vendors include their profit margin, which can be negotiable depending on order size and relationship.

Key Pricing Influencers in the B2B Marketplace

Several factors heavily influence the final price when sourcing drive LED strip solutions with Raspberry Pi 5:

- Order Volume and Minimum Order Quantity (MOQ): Larger volumes dramatically reduce per-unit costs due to economies of scale. Buyers from emerging markets should consider consolidating orders or group purchasing to meet MOQs.

- Customization and Specifications: Custom firmware, specific LED strip lengths, or integration with additional sensors raise costs. Standardized products are more cost-effective but may not meet all project needs.

- Material Quality and Certifications: LED strips with certifications like RoHS, CE, or UL command higher prices but are often required for compliance in Europe and some Middle Eastern markets.

- Supplier Reliability and Location: Established suppliers with proven track records may price higher but reduce risk. Proximity to manufacturing hubs affects shipping costs and lead times.

- Incoterms: Delivery terms such as FOB, CIF, or DDP impact responsibility for shipping costs, customs clearance, and insurance, influencing total landed cost.

Practical Buyer Tips for Cost-Efficient Sourcing

For international B2B buyers, especially in Africa, South America, the Middle East, and Europe, understanding pricing nuances is critical to maximizing value:

- Negotiate Beyond Unit Price: Discuss payment terms, volume discounts, and after-sales support. Suppliers may offer better pricing for multi-year contracts or bundled purchases of Raspberry Pi kits and LED strips.

- Consider Total Cost of Ownership (TCO): Factor in installation, maintenance, power consumption, and potential warranty claims. For example, investing in higher-quality LED strips may reduce replacement costs and downtime.

- Leverage Local Compliance Requirements: For European buyers in Germany or Italy, insist on compliance certificates upfront to avoid costly delays or rejections at customs.

- Optimize Logistics: Explore consolidated shipping or regional distribution centers to reduce freight expenses and customs complexities, especially for buyers in Africa and South America where infrastructure may vary.

- Assess Supplier Capabilities: Evaluate if the supplier offers technical support or customization services, which can reduce integration costs and accelerate time-to-market.

- Use Transparent Incoterms: Choose terms that align with your import capabilities and risk appetite. DDP (Delivered Duty Paid) can simplify procurement for less experienced importers but may be costlier.

Indicative Pricing Overview and Market Dynamics

While exact pricing varies widely, a typical Raspberry Pi 5 board costs approximately $60–$80 per unit at scale, whereas LED strips vary from $5 to $20 per meter depending on type and quality. Additional components such as power supplies and logic level converters add $10–$30 per setup. Bulk orders often achieve 10–20% discounts. Buyers should always request detailed quotations including all ancillary costs to avoid surprises.

Disclaimer: Prices and cost components mentioned are indicative and subject to change based on market fluctuations, supplier negotiations, and regional factors. Buyers are encouraged to conduct direct supplier consultations and request tailored quotes for precise budgeting.

Spotlight on Potential drive led strip with raspberry pi 5 Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘drive led strip with raspberry pi 5’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for drive led strip with raspberry pi 5

Critical Technical Properties for Driving LED Strips with Raspberry Pi 5

1. Voltage and Current Ratings

LED strips typically operate at 5V DC, matching the Raspberry Pi 5’s power requirements. Understanding the current draw per meter or per LED is essential to avoid overloading power supplies and ensure stable operation. For B2B buyers, specifying voltage tolerance (±5% is common) and maximum current helps in designing reliable power systems and avoiding premature failures.

2. LED Type and Communication Protocol

Common LED strips compatible with Raspberry Pi 5 include WS2812B (single data line) and APA102 (separate clock and data lines). The choice affects control complexity, refresh rates, and scalability. Buyers should specify LED types clearly to ensure software compatibility and meet project requirements for lighting effects and synchronization.

3. Material Quality and Durability

High-quality LED strips use premium PCB materials (e.g., flexible polyimide or fiberglass) and reliable soldering processes to withstand bending and environmental stress. For international projects, especially in harsh climates (e.g., high humidity in parts of Africa or the Middle East), IP-rated waterproofing (e.g., IP65 or IP67) is critical for long-term reliability.

4. LED Density and Brightness (LEDs per Meter)

LED density, such as 30, 60, or 144 LEDs per meter, determines the resolution and brightness of the lighting effect. Higher density strips provide smoother gradients but require more power and data bandwidth. Buyers must balance desired visual quality with power consumption and cost considerations for efficient project planning.

5. Data Signal Voltage Level and Logic Compatibility

The Raspberry Pi GPIO operates at 3.3V logic, while many LED strips expect 5V data signals. This mismatch necessitates a logic level converter to ensure signal integrity and prevent damage. Clarifying this requirement in procurement avoids integration issues and costly redesigns.

6. Operating Temperature Range

LED strips and associated drivers must operate reliably across the intended temperature range, typically -20°C to +60°C. This is especially relevant for outdoor or industrial applications across diverse geographies, ensuring consistent performance and longevity.

Key Trade and Industry Terminology for B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to companies that manufacture products or components sold by another company under its brand. For B2B buyers, partnering with OEMs can offer customization options and cost advantages, especially when sourcing LED strips tailored for Raspberry Pi integration.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is vital for budgeting and inventory management. Buyers from emerging markets or smaller enterprises should negotiate MOQ terms to align with market demand and cash flow constraints.

RFQ (Request for Quotation)

A formal process where buyers ask suppliers to provide pricing and terms for specific products. An RFQ should clearly detail technical specs (LED type, length, power requirements) and delivery expectations. Effective RFQs help buyers compare offers and secure the best value globally.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Clarity on Incoterms ensures smooth logistics and cost transparency, critical for international buyers in Africa, South America, the Middle East, and Europe.

Lead Time

The duration from order placement to delivery. Understanding lead times helps B2B buyers plan production schedules and manage supply chains effectively. Long lead times can impact project deadlines, so buyers should confirm this with suppliers upfront.

Bill of Materials (BOM)

A detailed list of all components and materials required to build a product. For LED strip projects with Raspberry Pi 5, a BOM includes LED strips, power supplies, connectors, and control boards. A precise BOM aids in cost estimation, procurement accuracy, and streamlining assembly.

By mastering these technical properties and trade terms, international B2B buyers can make informed procurement decisions, optimize supply chains, and ensure successful integration of LED strips with Raspberry Pi 5 in their projects. This knowledge is especially valuable across diverse markets with varying environmental conditions and regulatory requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drive led strip with raspberry pi 5 Sector

Market Overview & Key Trends

The global market for driving LED strips with Raspberry Pi 5 is rapidly expanding, fueled by increasing demand for customizable lighting solutions across industries such as retail, hospitality, smart buildings, and entertainment. The Raspberry Pi 5’s enhanced processing power and GPIO capabilities enable more sophisticated LED control, making it a preferred choice for B2B buyers seeking advanced, programmable lighting systems. International buyers from Africa, South America, the Middle East, and Europe—especially tech-forward regions like Germany and Italy—are leveraging these solutions to enhance automation, energy efficiency, and user experience in their projects.

Key market drivers include the rise of IoT integration and smart home/office automation, which are pushing LED strip solutions beyond simple decorative lighting to functional, sensor-driven systems. For instance, motion sensors, sound triggers, and environmental monitoring are increasingly incorporated, expanding the use cases for LED strips controlled by Raspberry Pi 5. Additionally, the trend towards modular, scalable lighting systems supports diverse project sizes, from small installations in African tech hubs to large-scale commercial deployments in European cities.

Sourcing trends reveal a growing preference for suppliers who offer complete kits—including Raspberry Pi 5 boards, compatible LED strips (WS2812B, APA102), power supplies, and accessories—streamlining procurement for B2B buyers. Buyers in emerging markets are particularly focused on reliable supply chains and local or regional distributors to reduce lead times and import complexities. The adoption of open-source software and Python libraries further empowers buyers to customize lighting effects without heavy dependence on proprietary systems, enhancing flexibility and reducing total cost of ownership.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for B2B buyers in the drive LED strip with Raspberry Pi 5 sector. LED technology is inherently energy-efficient compared to traditional lighting, but the environmental impact of manufacturing and disposing of electronic components remains a concern. Buyers across Africa, South America, the Middle East, and Europe increasingly prioritize suppliers that adhere to environmentally responsible manufacturing practices, such as minimizing hazardous substances and reducing carbon emissions during production.

Ethical sourcing in this sector involves ensuring that components—particularly LED strips and electronic boards—are procured from manufacturers who comply with labor standards and avoid conflict minerals. Certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management standards are valuable indicators of responsible suppliers.

Moreover, the use of recyclable materials in LED strip substrates and Raspberry Pi enclosures aligns with circular economy principles, appealing to European buyers who face stringent regulatory environments. B2B buyers should also evaluate suppliers’ end-of-life management programs, including options for component recycling or refurbishment, which can reduce waste and lower the environmental footprint of their projects.

Brief Evolution and Industry Context

The integration of LED strips with microcontrollers like Raspberry Pi has evolved significantly over the past decade. Initially, LED strips were controlled by simple microcontrollers with limited programming capability. The introduction of the Raspberry Pi series brought a leap forward, offering powerful computing in a compact form factor with robust GPIO support and network connectivity.

With the release of the Raspberry Pi 5, improvements in processing speed, expanded GPIO functionality, and enhanced software libraries have enabled more complex lighting effects, real-time sensor integration, and remote control capabilities. This evolution has transformed LED strips from basic lighting elements into dynamic components of smart environments. For international B2B buyers, understanding this progression is key to selecting solutions that offer scalability, integration potential, and long-term innovation capacity.

Related Video: Raspberry Pi LED Matrix Display

Frequently Asked Questions (FAQs) for B2B Buyers of drive led strip with raspberry pi 5

-

How can I effectively vet suppliers of drive LED strips with Raspberry Pi 5 for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications relevant to electronics and export compliance. Request references and case studies of previous international shipments, especially to regions like Africa, South America, the Middle East, and Europe. Evaluate their quality assurance processes, product testing standards, and after-sales support capabilities. Engage in direct communication to assess responsiveness and technical knowledge. Utilizing third-party inspection services or requesting sample orders can further ensure the supplier’s reliability and product quality before committing to bulk purchases. -

What customization options are typically available when sourcing drive LED strips with Raspberry Pi 5 in bulk?

Many suppliers offer customization such as LED strip length, LED type (e.g., WS2812B or APA102), power supply specifications, and connector types to suit regional standards. Software customization, including pre-installed control scripts or compatibility with specific Raspberry Pi GPIO pins, is often available. Packaging and branding can also be tailored for B2B resellers. Clarify your exact requirements upfront and inquire about minimum order quantities (MOQs) tied to customizations, as this influences lead times and cost efficiency. -

What are common MOQ and lead time expectations for international orders of drive LED strips with Raspberry Pi 5?

MOQs can vary widely, typically ranging from 50 to 500 units depending on customization and supplier scale. Standard lead times for production and shipping usually range from 3 to 8 weeks but can extend during peak seasons or for highly customized orders. For buyers in Africa, South America, or the Middle East, consider additional transit time and customs clearance delays. Negotiate flexible MOQs where possible and confirm lead times in writing to align supply chain planning with your market demand.

-

Which payment methods are most secure and commonly accepted in international B2B transactions for these products?

Suppliers often accept letters of credit (L/C), telegraphic transfers (T/T), PayPal for smaller orders, and increasingly, escrow services to protect both parties. Letters of credit provide strong payment security but may involve higher banking fees and processing times. T/T payments are common but require trust, so initial transactions may require partial upfront payments. Always clarify payment terms, such as deposits and final payments, and consider using trade finance instruments or third-party payment platforms to mitigate risks in cross-border transactions. -

What quality assurance certifications should I look for when buying drive LED strips integrated with Raspberry Pi 5?

Look for CE certification for European compliance, RoHS to ensure hazardous substances are limited, and FCC certification if the product involves radio frequency emissions. ISO 9001 certification indicates robust quality management systems. Additionally, inquire if the supplier conducts in-house testing for LED color accuracy, power stability, and software compatibility with Raspberry Pi 5. Certifications and testing reports should be documented and provided to facilitate smooth customs clearance and reassure your customers of product reliability. -

How can I optimize logistics and shipping for large orders of drive LED strips with Raspberry Pi 5 to regions like Africa or South America?

Partner with freight forwarders experienced in electronics shipments to your target regions. Consolidate shipments where possible to reduce costs and choose reliable carriers with proven customs clearance expertise. Consider shipping terms such as FOB (Free On Board) or CIF (Cost, Insurance, Freight) depending on your import capabilities. Ensure proper packaging to prevent damage during transit, and understand import regulations and tariffs in destination countries to avoid delays. Tracking systems and clear documentation will help maintain supply chain transparency. -

What strategies should I use to resolve disputes related to product quality or delivery delays in international B2B purchases?

Establish clear contractual terms detailing product specifications, delivery timelines, and penalties for non-compliance. Maintain thorough documentation of all communications and shipment records. In case of disputes, initiate direct negotiation with the supplier to seek amicable solutions such as replacements, refunds, or discounts. If unresolved, leverage third-party mediation or arbitration clauses included in contracts. Building long-term relationships with suppliers who demonstrate transparency and responsiveness can also minimize future disputes. -

Are there any region-specific considerations for B2B buyers in Europe, the Middle East, Africa, or South America when sourcing these products?

Yes, each region has unique regulatory, logistical, and market factors. European buyers must ensure strict compliance with CE and RoHS directives and prioritize suppliers familiar with GDPR in data handling if software integration is involved. Middle Eastern buyers should consider customs duties and local certification requirements. African markets often require flexible MOQs and robust after-sales support due to infrastructure challenges. South American buyers need to navigate complex import tariffs and longer shipping times. Understanding these nuances aids in selecting the right supplier and optimizing the supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drive led strip with raspberry pi 5

In navigating the procurement of drive LED strips compatible with Raspberry Pi 5, international B2B buyers must prioritize strategic sourcing to unlock both innovation and cost-efficiency. Key considerations include selecting reputable suppliers offering high-quality LED strips such as WS2812B or APA102, ensuring compatibility with the Raspberry Pi 5’s GPIO interface, and verifying robust power supply solutions tailored for extended LED runs. For buyers across Africa, South America, the Middle East, and Europe, understanding regional logistics, import regulations, and supplier reliability is equally crucial to mitigate supply chain risks and optimize lead times.

Investing in suppliers with proven technical support and customization capabilities can significantly enhance project success and scalability. Moreover, leveraging partnerships that provide comprehensive kits and expansion modules facilitates smoother integration and faster time-to-market. By adopting a holistic procurement approach—balancing cost, quality, and innovation—businesses can future-proof their IoT, smart lighting, or display projects powered by Raspberry Pi 5-driven LED strips.

Looking ahead, as demand for dynamic, programmable LED solutions grows globally, B2B buyers are encouraged to engage proactively with emerging suppliers and technology innovators. Strategic collaboration and continuous market intelligence will be vital in capturing new opportunities and driving competitive advantage in this evolving landscape.