Introduction: Navigating the Global Market for bendable led lights

Bendable LED lights represent a transformative innovation in the lighting industry, offering unparalleled flexibility, energy efficiency, and design versatility. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—these advanced lighting solutions unlock new opportunities for commercial, architectural, and industrial applications. Their ability to conform to varied surfaces and environments makes them ideal for cutting-edge projects demanding both functionality and aesthetic appeal.

This comprehensive guide delves into every critical aspect of bendable LED lights to support well-informed sourcing decisions. You will explore the diverse types and materials used, gaining insight into the latest manufacturing processes and rigorous quality control standards that ensure product reliability and longevity. Additionally, the guide offers a detailed overview of reputable global suppliers, pricing structures, and market trends specific to your region’s unique economic and infrastructural landscape.

Key features of this guide include:

- Types and applications of bendable LED lights tailored to diverse industries

- Material composition and innovations driving durability and performance

- Manufacturing and quality assurance protocols critical for compliance and safety

- Supplier evaluation criteria to identify trustworthy partners and mitigate risks

- Cost analysis and budgeting tips aligned with international trade considerations

- Market insights focusing on demand drivers and growth opportunities in target regions

- Frequently Asked Questions addressing common buyer concerns and technical clarifications

By equipping you with this actionable intelligence, the guide empowers businesses across continents to optimize procurement strategies, enhance product quality, and capitalize on the growing global demand for flexible LED lighting solutions.

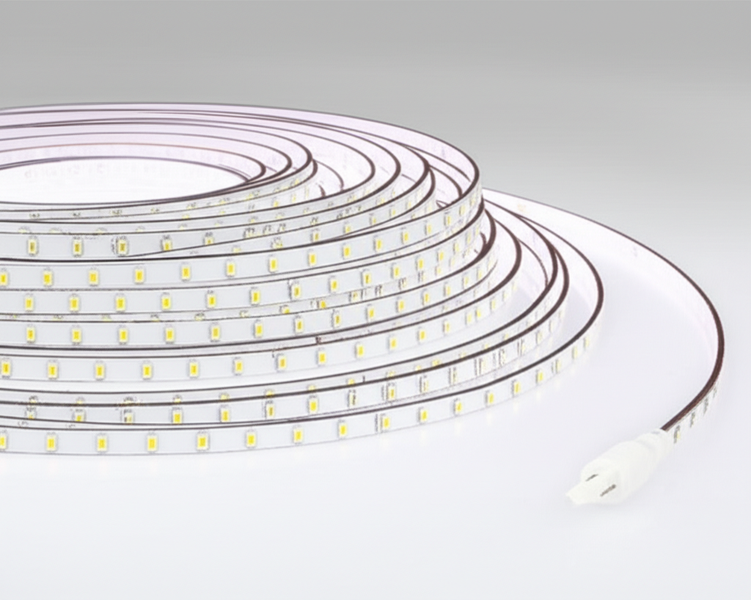

Illustrative Image (Source: Google Search)

Understanding bendable led lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible LED Strip Lights | Thin, tape-like strips with adhesive backing; highly flexible | Retail displays, architectural accents, signage | Pros: Easy installation, customizable lengths, energy-efficient; Cons: May require waterproofing for outdoor use |

| Bendable LED Neon Lights | Silicone or PVC encased LED tubes mimicking neon glow | Hospitality, outdoor signage, decorative lighting | Pros: Durable, weather-resistant, vibrant colors; Cons: Higher initial cost, less flexible than strip lights |

| LED Ribbon Lights | Narrow, flexible circuit boards with densely packed LEDs | Event lighting, stage design, commercial interiors | Pros: High brightness, versatile mounting; Cons: Heat dissipation may be a concern in tight spaces |

| Flexible COB LED Strips | Chip-on-Board technology for seamless light output | High-end retail, automotive, and display lighting | Pros: Uniform light without hotspots, slim profile; Cons: Generally more expensive, requires precise handling |

| Waterproof Bendable LEDs | Encapsulated with waterproof materials for harsh environments | Outdoor advertising, landscape lighting, marine applications | Pros: Weatherproof, durable; Cons: Slightly bulkier, potential heat build-up |

Flexible LED Strip Lights

These are the most commonly used bendable LED lights, featuring thin, adhesive-backed strips that can be cut to length. Their high flexibility makes them ideal for curved surfaces and intricate designs. For B2B buyers in retail or architectural sectors, these strips offer easy customization and cost-effective solutions. However, buyers should consider additional waterproofing for outdoor or humid environments to ensure longevity.

Bendable LED Neon Lights

Designed to replicate traditional neon lighting, these LEDs are encased in silicone or PVC tubes, offering durability and excellent weather resistance. They are favored in hospitality and outdoor signage due to their vibrant glow and robustness. B2B purchasers should weigh the higher upfront investment against their long-term durability and visual appeal, especially for premium branding projects.

LED Ribbon Lights

Featuring densely packed LEDs on a flexible circuit, LED ribbon lights provide high brightness and are widely used in event lighting and stage design. Their versatility in mounting options makes them attractive for commercial interiors. When sourcing, buyers must assess heat dissipation needs to avoid performance degradation in confined installations.

Flexible COB LED Strips

Utilizing Chip-on-Board technology, these strips produce a smooth, uniform light without visible hotspots, making them suitable for high-end retail and automotive lighting applications. Their slim profile supports sleek designs, but they come at a higher cost and require careful handling during installation. B2B buyers should prioritize quality and supplier expertise to maximize benefits.

Waterproof Bendable LEDs

Encapsulated with waterproof materials, these LEDs withstand harsh outdoor conditions, making them perfect for landscape lighting, marine environments, and outdoor advertising. While slightly bulkier, their durability justifies the trade-off. Buyers targeting outdoor applications should ensure compliance with IP ratings and consider thermal management to maintain performance.

Related Video: Bendable Aluminium Extrusions for LED Strip Lights

Key Industrial Applications of bendable led lights

| Industry/Sector | Specific Application of bendable led lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Flexible lighting for dynamic store displays and signage | Enhances visual merchandising with adaptable lighting, improving customer engagement and sales | Durability, color temperature options, ease of installation, and compliance with regional electrical standards |

| Automotive Manufacturing | Interior ambient and dashboard lighting | Provides customizable, energy-efficient, and aesthetic lighting solutions that improve user experience | Heat resistance, longevity, flexibility for complex shapes, and compatibility with automotive-grade certifications |

| Architecture & Interior Design | Contour lighting in curved architectural elements and ceilings | Enables innovative design with seamless illumination on non-linear surfaces, adding value to high-end projects | IP rating for moisture resistance, color rendering index (CRI), and flexibility to fit diverse design specifications |

| Hospitality & Events | Portable and decorative lighting for event spaces and hotels | Offers versatile, mood-enhancing lighting that can be easily adapted to different themes and layouts | Lightweight, energy efficiency, dimmability, and ease of integration with smart control systems |

| Outdoor & Landscape | Customizable pathway and facade lighting | Improves safety and aesthetics with weather-resistant, flexible lighting solutions tailored to irregular outdoor surfaces | Weatherproofing, UV resistance, power efficiency, and compliance with local outdoor lighting regulations |

Retail & Commercial Applications

In retail environments, bendable LED lights are used to create eye-catching, flexible lighting displays that conform to irregular shelving and signage shapes. This adaptability helps retailers highlight products effectively, driving customer interest and increasing sales. For international buyers in Africa, South America, the Middle East, and Europe, sourcing lights with adjustable color temperatures and robust installation options is critical to accommodate diverse store designs and local power standards.

Automotive Manufacturing

Bendable LEDs are increasingly integrated into vehicle interiors for ambient and dashboard lighting, offering manufacturers the ability to design sleek, energy-efficient, and customizable lighting elements that enhance the driving experience. Buyers must prioritize heat resistance and automotive-grade certifications to ensure performance and safety under harsh conditions, especially in regions with extreme climates such as the Middle East and parts of Africa.

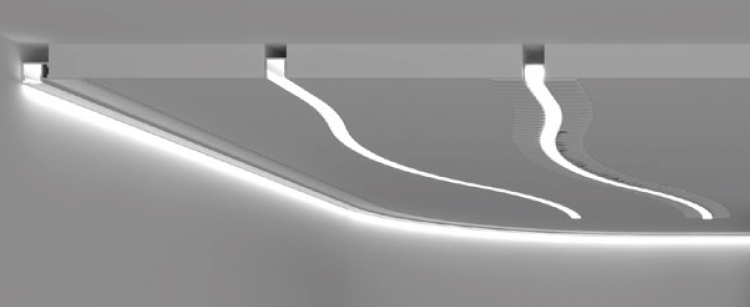

Architecture & Interior Design

Architects and interior designers use bendable LED strips to illuminate curved ceilings, walls, and other architectural features, enabling innovative lighting solutions that traditional rigid LEDs cannot achieve. This application demands high color rendering for true-to-life illumination and moisture resistance for indoor environments prone to humidity, making these features essential for buyers targeting luxury commercial and residential projects in Europe and Australia.

Hospitality & Events

The hospitality sector benefits from bendable LEDs’ portability and flexibility, which allow for quick reconfiguration of lighting setups in event venues and hotel lobbies. These lights support mood setting through dimmability and color variation, which is vital for creating memorable guest experiences. International buyers should seek lightweight, energy-efficient products compatible with smart lighting controls to meet modern sustainability and operational efficiency standards.

Outdoor & Landscape Lighting

For outdoor applications, bendable LED lights are ideal for illuminating pathways, gardens, and building facades with tailored shapes and curves. Their weatherproof and UV-resistant properties ensure durability in harsh environments common in Africa and the Middle East. Buyers must confirm compliance with local outdoor lighting regulations and prioritize power-efficient solutions to reduce operational costs in remote or off-grid locations.

Strategic Material Selection Guide for bendable led lights

Silicone Rubber

Key Properties: Silicone rubber is highly flexible, resistant to extreme temperatures (-60°C to 230°C), and exhibits excellent UV and ozone resistance. It also provides good electrical insulation and moisture resistance, making it ideal for outdoor and harsh environment applications.

Pros & Cons: Silicone rubber offers superior durability and flexibility, enabling bendable LED lights to maintain performance under repeated bending and twisting. It is chemically inert and corrosion-resistant, which enhances longevity. However, silicone can be more expensive than other polymers and requires specialized manufacturing processes to ensure consistent thickness and adhesion.

Impact on Application: Silicone rubber is well-suited for LED lighting in outdoor signage, automotive lighting, and architectural installations, especially where exposure to sunlight, humidity, or chemicals is prevalent. Its high-temperature tolerance also supports use in industrial environments.

Considerations for B2B Buyers: Buyers in Africa, South America, the Middle East, and Europe should verify compliance with international standards such as ASTM D2000 for elastomers and IEC 60529 for ingress protection. In regions with harsh UV exposure like the Middle East or Australia, silicone’s UV resistance is a critical advantage. Cost considerations may be balanced by the material’s longevity and reduced maintenance.

Polyurethane (PU) Elastomers

Key Properties: Polyurethane offers excellent abrasion resistance, good flexibility, and moderate temperature tolerance (-40°C to 80°C). It has strong mechanical strength and good resistance to oils and solvents but is less UV stable than silicone.

Pros & Cons: PU is generally more cost-effective than silicone and easier to process in manufacturing. It provides robust protection against physical wear and tear, making it suitable for applications requiring mechanical durability. However, its lower UV resistance limits outdoor longevity without additional coatings or treatments.

Impact on Application: PU is ideal for indoor or semi-outdoor bendable LED lights, such as retail displays or industrial task lighting, where mechanical stress is a concern but prolonged UV exposure is limited.

Considerations for B2B Buyers: For buyers in regions with intense sunlight like South America or the Middle East, additional UV stabilization treatments may be necessary. Compliance with standards like DIN 53505 for polyurethane hardness and ISO 1817 for chemical resistance should be checked. PU’s cost-effectiveness makes it attractive for large-volume projects with moderate environmental demands.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a versatile polymer with good flexibility, chemical resistance, and flame retardancy. It performs well in moderate temperature ranges (-15°C to 60°C) and offers good moisture resistance.

Pros & Cons: PVC is widely available and low cost, making it a popular choice for budget-sensitive projects. However, it has lower flexibility and durability compared to silicone and PU, and can become brittle in cold climates. Environmental concerns about plasticizers and chlorine content may affect market acceptance.

Impact on Application: PVC is suitable for indoor bendable LED strips used in commercial or residential lighting where cost is a primary concern and environmental exposure is limited.

Considerations for B2B Buyers: Buyers from Europe and Australia should consider stricter environmental regulations regarding PVC use and disposal. Compliance with RoHS and REACH directives is essential. In warmer climates like Africa and the Middle East, PVC’s limited heat resistance may reduce lifespan unless properly formulated.

Thermoplastic Polyurethane (TPU)

Key Properties: TPU combines elasticity with high abrasion resistance and good chemical stability. It withstands temperatures from -40°C to 90°C and has excellent resistance to oils, greases, and weathering.

Pros & Cons: TPU offers a balance between flexibility and mechanical strength, with better UV resistance than PU but generally at a higher cost. It is easier to recycle compared to silicone and PVC, aligning with sustainability trends.

Impact on Application: TPU is ideal for high-end bendable LED lights requiring durability in moderately harsh environments, such as outdoor decorative lighting or automotive applications.

Considerations for B2B Buyers: For markets in Europe and South Africa, TPU’s recyclability and compliance with environmental standards (e.g., REACH, RoHS) enhance its appeal. Buyers in regions with variable climates benefit from TPU’s broad temperature tolerance and chemical resistance, though they should assess cost implications relative to project budgets.

| Material | Typical Use Case for bendable led lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Outdoor signage, automotive, architectural lighting | Exceptional flexibility and UV resistance | Higher cost and specialized manufacturing | High |

| Polyurethane (PU) | Indoor/semi-outdoor retail and industrial lighting | Strong abrasion resistance and cost-effective | Lower UV stability, needs UV treatment | Medium |

| Polyvinyl Chloride (PVC) | Indoor commercial/residential lighting | Low cost and flame retardant | Limited flexibility and durability, environmental concerns | Low |

| Thermoplastic Polyurethane (TPU) | Outdoor decorative and automotive lighting | Balanced flexibility and mechanical strength | Higher cost, moderate UV resistance | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for bendable led lights

Manufacturing Processes for Bendable LED Lights

The production of bendable LED lights involves a series of precise and technologically advanced stages designed to ensure flexibility, durability, and performance. For B2B buyers evaluating suppliers, understanding these stages is crucial to assess manufacturing capability and product quality.

1. Material Preparation

The process begins with selecting high-quality raw materials:

– Flexible substrates: Typically polyimide (PI) or polyethylene terephthalate (PET) films are used for flexibility and heat resistance.

– LED chips: High-efficiency SMD (Surface Mounted Device) LEDs are sourced, often requiring strict binning to ensure uniform light output and color consistency.

– Conductive materials: Copper foils and flexible printed circuit boards (FPCs) are prepared for electrical pathways.

– Encapsulation materials: Silicone or epoxy resins are chosen for their flexibility and protection against moisture and mechanical stress.

Material preparation involves stringent inspection for defects such as substrate warping, copper foil thickness uniformity, and LED chip integrity before proceeding.

2. Forming and Circuit Fabrication

This stage transforms raw materials into flexible LED strips:

– Flexible PCB fabrication: The conductive copper layer is etched or printed onto the flexible substrate. This includes creating precise circuit patterns to allow bending without breaking connections.

– Surface mounting: Automated pick-and-place machines mount LED chips and other components onto the flexible PCB.

– Soldering: Reflow soldering is used to secure components, requiring precise temperature control to avoid damaging flexible substrates.

– Bending and shaping: Some processes include pre-forming the LED strips into desired shapes or coils, ensuring consistent bending radius without compromising circuitry.

3. Assembly

Assembly integrates additional components and prepares the product for final use:

– Connection attachments: Power connectors, controllers, or dimmers are attached, often requiring custom solutions for compatibility with various lighting systems.

– Encapsulation and coating: Flexible coatings protect the LED strips from environmental factors while maintaining flexibility. This may include UV-resistant layers for outdoor applications.

– Cutting and packaging: LED strips are cut to standard or custom lengths, tested, and carefully packaged to prevent damage during transit.

4. Finishing and Customization

Finishing processes tailor the product to customer specifications:

– Color temperature tuning: Adjusting LED binning or adding phosphor layers to meet specific lighting needs.

– Waterproofing: Applying IP-rated coatings or encasements (e.g., IP65, IP67) for outdoor or harsh environment usage.

– Quality labeling and certification marks: Affixing CE, RoHS, or other compliance marks as required.

Quality Assurance and Control (QA/QC) in Bendable LED Manufacturing

For B2B buyers, particularly from diverse international regions such as Africa, South America, the Middle East, and Europe, understanding quality control frameworks and verification methods is essential to mitigate risks and ensure reliable supply.

Relevant International and Industry Standards

- ISO 9001: This global quality management system standard ensures consistent production processes and continual improvement. Suppliers certified with ISO 9001 demonstrate mature quality practices.

- CE Marking: Required for European markets, confirming compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances, critical for European and other regulated markets.

- UL/ETL Certifications: Commonly sought for electrical safety in North America but also influential for global buyers.

- IP Ratings: Defined by IEC standards, indicating waterproof and dustproof levels—important for outdoor applications.

- Other regional standards: Buyers in Australia and South Africa should verify compliance with local electrical safety and EMC (Electromagnetic Compatibility) regulations.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt. Checks include substrate integrity, LED chip binning verification, and solder paste quality.

- In-Process Quality Control (IPQC): Continuous monitoring during production stages such as PCB etching precision, solder joint quality, and bending tests to ensure no circuit breaks.

- Final Quality Control (FQC): Comprehensive testing of finished products including visual inspections, electrical performance, and packaging integrity.

Common Testing Methods

- Electrical Testing: Measuring voltage, current, and luminous flux to ensure LEDs meet specified power and brightness levels.

- Bending and Flexibility Tests: Simulating real-world use by repeatedly bending LED strips to check for circuit failure or light degradation.

- Thermal Testing: Assessing heat dissipation and stability under operating temperatures to predict lifespan.

- Environmental Testing: Exposure to humidity, salt spray, or UV light to verify durability in different climates.

- Photometric Testing: Using integrating spheres and spectrometers to confirm color temperature and light uniformity.

How B2B Buyers Can Verify Supplier Quality Control

Ensuring product quality and supplier reliability extends beyond certifications. International buyers should adopt a proactive approach:

- Factory Audits: Conduct on-site or virtual audits focusing on production capacity, quality systems, and working conditions. For buyers in regions with logistical challenges, partnering with local inspection agencies is advisable.

- Review of QC Documentation: Request detailed quality control reports, including batch test results, material certificates, and compliance documentation.

- Third-Party Inspections: Engage independent inspection companies to perform random sampling and testing before shipment.

- Sample Testing: Order product samples for in-house or third-party laboratory testing to validate performance claims.

- Supplier Track Record and References: Evaluate supplier history, client feedback, and responsiveness to quality issues.

QC and Certification Nuances for International B2B Buyers

Buyers from Africa, South America, the Middle East, and Europe must consider regional market requirements and import regulations:

- Certification Recognition: Not all certifications have equal acceptance worldwide. For instance, CE is mandatory in Europe but less critical in South America; UL may be requested in Middle Eastern markets aiming for North American exports.

- Documentation Language: Ensure certificates and test reports are provided in English or the buyer’s preferred language to avoid misinterpretations.

- Customs and Compliance: Some countries require pre-import certification or local testing; buyers should verify these requirements to avoid shipment delays.

- Climate Adaptability: Products intended for tropical, desert, or cold climates must undergo additional environmental testing. Buyers should confirm suppliers’ ability to customize testing accordingly.

- After-Sales Support: Quality assurance includes warranty terms and supplier responsiveness, which are vital for regions where logistics may delay replacements.

Summary for B2B Buyers

Understanding the manufacturing and quality assurance landscape of bendable LED lights empowers international buyers to make informed sourcing decisions. Focus on:

- Supplier transparency in process details and QC practices.

- Verification of certifications relevant to target markets.

- Robust quality control checkpoints and testing methodologies.

- Utilizing audits and third-party inspections to validate supplier claims.

- Adapting requirements to regional market nuances and environmental conditions.

By prioritizing these factors, B2B buyers across Africa, South America, the Middle East, and Europe can secure high-quality bendable LED lighting solutions that meet performance expectations and regulatory standards.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for bendable led lights Sourcing

Understanding Cost Components in Bendable LED Lights

When sourcing bendable LED lights, international B2B buyers should recognize the multifaceted cost structure behind the product pricing. Key cost components include:

- Materials: The quality and type of LED chips, flexible substrates, adhesives, and protective coatings significantly influence costs. Premium materials, such as high-grade copper for flexible circuits or advanced phosphor coatings, elevate pricing but improve durability and light quality.

- Labor: Skilled labor is essential for precise assembly, soldering, and quality checks. Labor costs vary widely by manufacturing location, with countries in Asia often offering lower rates compared to Europe or the Middle East.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with automation can reduce these overhead costs.

- Tooling and Setup: Initial tooling for custom designs or new product lines can be a substantial upfront investment, often amortized over large production runs.

- Quality Control (QC): Rigorous testing protocols, including photometric testing and durability checks, add to costs but are critical for consistent product performance and certification compliance.

- Logistics and Shipping: International freight, customs duties, and insurance can add significant costs, especially for buyers in regions with complex import regulations like Africa and South America.

- Supplier Margin: The supplier’s profit margin varies with market competition, product exclusivity, and order volume.

Key Price Influencers to Consider

Several dynamic factors influence the final pricing of bendable LED lights:

- Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically secure lower unit prices due to economies of scale. Buyers should negotiate MOQs suited to their demand to avoid overstocking or high per-unit costs.

- Product Specifications and Customization: Customized lengths, color temperatures, and control options (e.g., dimmable, RGB) increase complexity and cost. Standard product lines generally offer better pricing.

- Material Quality and Certifications: LEDs with certifications like CE, RoHS, UL, or DLC command higher prices but provide assurance of safety and energy efficiency, which is vital for compliance in Europe and Australia.

- Supplier Location and Reputation: Established suppliers with proven quality and reliable delivery may price higher but reduce risks related to defects and delays.

- Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect who bears shipping and customs costs. Buyers should clarify these terms upfront to understand total landed costs.

Practical Tips for International Buyers

-

Negotiate Based on Total Cost of Ownership (TCO): Instead of focusing solely on the unit price, evaluate energy savings, product lifespan, warranty, and after-sales support. High-quality bendable LED lights may have higher upfront costs but offer superior ROI through lower maintenance and energy bills.

-

Leverage Volume and Long-Term Partnerships: Buyers from Africa, South America, the Middle East, and Europe can benefit from consolidating orders or committing to long-term contracts to negotiate better pricing and priority production.

-

Factor in Logistics and Import Duties Early: Shipping from Asia to remote markets can add 10–30% to product costs. Explore freight consolidation, local warehouses, or partnerships with freight forwarders experienced in your region to optimize logistics expenses.

-

Verify Certification and Compliance: For markets with strict regulations (EU’s CE marking, Australia’s RCM), insist on documentation before purchase to avoid costly rejections or delays at customs.

-

Understand Pricing Nuances by Region: In some African and South American markets, fluctuating currency rates and import tariffs can unpredictably affect landed costs. Consider hedging options or negotiating fixed-price contracts in stable currencies.

-

Request Detailed Cost Breakdowns: Transparent suppliers often provide itemized quotes showing material, labor, tooling, and shipping costs. This visibility aids in targeted negotiations and identifying cost-saving opportunities.

Disclaimer on Pricing

The prices for bendable LED lights vary significantly depending on product specifications, order volume, supplier location, and prevailing market conditions. The insights provided are indicative and should be validated with direct supplier quotes and due diligence. Buyers are encouraged to factor in all ancillary costs beyond the product price to ensure accurate budgeting and sourcing success.

Illustrative Image (Source: Google Search)

By thoroughly analyzing the cost components and price influencers, and applying strategic negotiation and logistics planning, international B2B buyers can optimize their sourcing of bendable LED lights for both cost-efficiency and quality assurance.

Spotlight on Potential bendable led lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bendable led lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bendable led lights

Key Technical Properties of Bendable LED Lights

Understanding the critical technical properties of bendable LED lights is essential for international B2B buyers to ensure product quality, compatibility, and cost-effectiveness. Below are the most important specifications to consider:

-

Material Grade and Flexibility

Bendable LED strips are typically made from flexible printed circuit boards (FPC) that allow bending without damaging the circuitry. The quality of the FPC material determines durability and resistance to repeated flexing. High-grade materials ensure longer lifespan and reliability, which is crucial for installations in curved or irregular surfaces common in architectural or automotive lighting. -

LED Chip Type and Luminous Efficiency

The LED chips used (e.g., SMD 2835, 5050) influence brightness and energy consumption. Luminous efficiency, measured in lumens per watt (lm/W), indicates how effectively the LED converts power into light. Buyers should prioritize LEDs with high luminous efficiency for energy savings and better illumination, especially relevant for commercial projects seeking sustainable solutions. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the light’s hue, ranging from warm white (~2700K) to daylight (~6500K). CRI indicates how accurately the light renders colors compared to natural sunlight, with values above 80 considered good for retail and hospitality environments. Selecting the right combination affects ambiance and product presentation, impacting customer satisfaction. -

Ingress Protection (IP) Rating

IP ratings classify the protection level against dust and water. Bendable LEDs used outdoors or in humid environments require a minimum of IP65 (dust-tight and water-resistant). Understanding IP ratings helps buyers ensure the product’s suitability for specific climates, especially important for regions with high humidity or dust exposure. -

Voltage and Power Consumption

Common bendable LED strips operate on 12V or 24V DC, affecting installation complexity and safety standards. Power consumption per meter (watts/m) impacts energy costs and power supply requirements. Buyers should verify voltage compatibility with their existing electrical systems and calculate total wattage to specify adequate power drivers. -

Tolerance and Dimensional Accuracy

Tolerance refers to allowable deviations in length, width, and electrical characteristics. Tight tolerances ensure consistent performance and simplify integration into complex lighting systems. For OEM buyers or large-scale projects, specifying tolerance levels reduces risks of incompatibility or malfunction during assembly.

Essential Trade Terminology for B2B Buyers

Navigating the international LED lighting market requires familiarity with common industry and trade terms. Here are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products or components used in another company’s final product. For bendable LED lights, OEM manufacturers often customize product specifications, packaging, and branding according to buyer requirements. This is vital for businesses seeking private-label solutions or tailored technical features. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers balance inventory costs and supplier relationships. Suppliers often set MOQs based on production efficiency and material costs, so negotiating MOQs is important for buyers from emerging markets or small-to-medium enterprises. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting price and delivery terms for specified products. It is a critical step in the procurement process, enabling buyers to compare offers and clarify technical details. Well-prepared RFQs accelerate supplier responsiveness and improve negotiation leverage. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting the right Incoterm affects total landed cost and risk allocation, especially important when importing to Africa, South America, the Middle East, or Europe. -

Lead Time

Lead time is the period between placing an order and receiving the goods. It varies based on production complexity, customization, and shipping method. Accurate lead time estimates are crucial for project planning and supply chain management, reducing risks of delays and stockouts. -

Certification and Compliance

Certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) indicate compliance with safety, environmental, and quality standards. Buyers should verify certifications to ensure legal importation and customer trust in target markets.

By focusing on these technical properties and mastering relevant trade terminology, international B2B buyers can make informed decisions, optimize procurement strategies, and build strong partnerships with reliable bendable LED light suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bendable led lights Sector

Market Overview & Key Trends

The global bendable LED lights market is experiencing robust growth driven by increasing demand for flexible, energy-efficient lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, this sector presents compelling opportunities aligned with urbanization, smart city initiatives, and infrastructure modernization.

Key market drivers include:

- Energy efficiency and cost savings: Bendable LEDs offer superior energy efficiency and longer lifespans compared to traditional lighting, making them attractive for large-scale commercial projects and government infrastructure.

- Design versatility: Their flexible form factor enables innovative applications in architectural lighting, signage, automotive, and wearable tech, opening new business niches.

- Technological advancements: Integration with IoT-enabled controls and Bluetooth connectivity enhances functionality, appealing to buyers seeking smart lighting solutions.

- Regional infrastructure development: Emerging markets in Africa and South America are investing in modern lighting for public spaces and commercial buildings, while Europe and the Middle East emphasize smart, sustainable urban lighting.

Sourcing trends for bendable LED lights reflect growing preferences for OEM partnerships offering customization, rapid prototyping, and compliance with international standards. Buyers increasingly prioritize suppliers capable of delivering:

- Flexible manufacturing volumes to match project scales.

- Certifications such as CE, RoHS, and DLC for quality assurance.

- Advanced features like tunable color temperature and dimmability.

Supply chain resilience is a critical consideration amid global logistics challenges, with many buyers diversifying sourcing across Asia, Europe, and emerging local manufacturers to mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability is rapidly becoming a decisive factor in bendable LED lights procurement. International buyers are emphasizing environmental responsibility throughout the product lifecycle—from raw material extraction to manufacturing, usage, and end-of-life disposal.

Environmental impacts to consider include:

- Material selection: Preference for non-toxic, recyclable components such as lead-free solder and halogen-free plastics reduces hazardous waste.

- Energy consumption: LEDs inherently consume less power, but buyers increasingly demand products verified by energy efficiency certifications (e.g., ENERGY STAR, DLC).

- Manufacturing footprint: Suppliers employing green manufacturing practices, including waste minimization, water recycling, and renewable energy use, are favored.

Ethical sourcing extends beyond environmental concerns to social responsibility. Buyers are requiring transparency in supply chains to avoid conflict minerals and ensure fair labor practices. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) provide assurance on these fronts.

For B2B buyers targeting Europe and Australia, compliance with stringent regional regulations on hazardous substances (RoHS) and waste (WEEE) is mandatory. In Africa and South America, sustainable procurement is also linked to long-term cost savings and alignment with international development goals.

Evolution and Industry Context

The bendable LED light sector has evolved significantly over the past decade. Initially emerging as niche products for decorative and signage uses, advances in flexible substrate technology and miniaturized LED chips have expanded their application scope. Today, bendable LEDs are integral to smart lighting systems, offering enhanced adaptability and integration with digital controls.

This evolution reflects broader industry trends prioritizing energy efficiency, design innovation, and user-centric functionality. For B2B buyers, understanding this trajectory helps anticipate future product capabilities and sourcing opportunities, ensuring investments align with cutting-edge technologies and market demands.

This comprehensive insight into market dynamics, sourcing trends, and sustainability considerations equips international B2B buyers with actionable knowledge to strategically navigate the bendable LED lights sector across diverse global markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bendable led lights

-

How do I effectively vet suppliers of bendable LED lights for international B2B purchases?

To vet suppliers, begin by verifying their certifications such as ISO, CE, RoHS, and any region-specific approvals relevant to Africa, South America, the Middle East, or Europe. Request product samples to assess quality and durability, especially for flexible LED strips. Review their manufacturing capabilities, lead times, and after-sales support. Checking references or customer testimonials and conducting factory audits (virtual or onsite) can further validate reliability. Prioritize suppliers who demonstrate transparency in production processes and compliance with international standards to mitigate risks in cross-border transactions. -

What customization options are typically available for bendable LED lights in bulk orders?

Most manufacturers offer customization in terms of LED color temperature, length, width, brightness (lumens), waterproof rating (IP levels), and flexible substrate materials. B2B buyers can often request specific cut lengths, soldering points, and connector types tailored to their project needs. Advanced options include dimmable drivers, smart controls (e.g., Bluetooth, Wi-Fi), and branding on packaging. It’s essential to clarify customization capabilities upfront, including minimum order quantities (MOQs) for bespoke designs, to ensure the supplier can meet your technical specifications and volume requirements. -

What are typical MOQs and lead times for bendable LED light orders from international suppliers?

MOQ varies widely depending on the supplier and customization level but generally ranges from 500 to 5,000 meters per order for bendable LED strips. Lead times typically span 3 to 8 weeks, factoring in manufacturing, quality checks, and shipping. For buyers in regions like Africa or South America, additional time should be allowed for customs clearance and inland logistics. Establish clear communication on MOQs and lead times early in the negotiation to align expectations and plan inventory accordingly, especially when sourcing from Asia or Europe.

-

Which payment terms and methods are safest and most common in international B2B LED lighting transactions?

Common payment methods include letters of credit (LC), telegraphic transfers (T/T), and escrow services. For new supplier relationships, a 30% deposit upfront with the balance paid after inspection or before shipment is standard. Letters of credit provide security for both parties but may incur additional banking fees. Buyers should negotiate terms that balance risk and cash flow, such as partial payments tied to production milestones. Using reputable payment platforms and confirming supplier bank details via independent channels helps prevent fraud. -

What quality assurance and certifications should I insist on for bendable LED lights?

Ensure the products carry internationally recognized certifications such as CE (Europe), UL or ETL (North America), RoHS for hazardous substances, and IEC standards for electrical safety. For Middle East and African markets, additional compliance with regional standards like SASO (Saudi Arabia) or SABS (South Africa) may be required. Request factory inspection reports and third-party lab test results verifying parameters like luminous efficacy, waterproof rating, and lifespan. Robust QA protocols reduce the risk of defective products and support warranty claims. -

How can I optimize logistics and shipping for bulk orders of bendable LED lights internationally?

Choose suppliers experienced with international freight forwarders who can handle customs documentation, duties, and taxes efficiently. Shipping options include sea freight for cost efficiency (longer lead time) and air freight for urgent orders (higher cost). Consolidate shipments to reduce per-unit freight costs and verify Incoterms (e.g., FOB, CIF) to understand responsibility and risk transfer points. For buyers in remote or landlocked regions, coordinate with local logistics providers to ensure smooth last-mile delivery and avoid unexpected delays or charges. -

What steps should I take to resolve disputes or quality issues with bendable LED light suppliers?

Start with clear communication, providing documented evidence such as photos, inspection reports, and purchase agreements. Negotiate amicably to seek remedies like replacement, repair, or partial refund. Include dispute resolution clauses in contracts specifying arbitration venues or legal jurisdiction favorable to your location. Engage third-party inspection agencies to provide impartial assessments when disagreements arise. Maintaining detailed records throughout the transaction helps protect your interests and facilitates smoother conflict resolution. -

Are there any region-specific considerations when sourcing bendable LED lights for Africa, South America, the Middle East, and Europe?

Yes, regional variations affect product specifications, certifications, and logistics. For example, voltage standards differ—Europe uses 220-240V while some African and South American countries may use 110-127V or 220V. Climate conditions require appropriate IP ratings for moisture and dust resistance, especially in humid or desert environments. Customs regulations and import duties vary widely; understanding these beforehand avoids delays. Additionally, local preferences for color temperature or lighting design should guide product selection. Collaborate with suppliers familiar with your target market’s regulations and consumer expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bendable led lights

Strategic sourcing of bendable LED lights offers international B2B buyers a unique opportunity to leverage flexibility, energy efficiency, and design innovation in their lighting solutions. Key takeaways include the importance of selecting suppliers with proven manufacturing expertise, certifications, and customization capabilities to meet diverse market needs across Africa, South America, the Middle East, and Europe. Prioritizing partners who provide scalable production, quality assurance, and after-sales support ensures long-term value and competitive advantage.

Value-driven sourcing strategies should emphasize:

– Supplier reliability and compliance with international standards to minimize risks.

– Customization and innovation, enabling tailored products for specific applications and environments.

– Cost-effectiveness, balancing upfront investment with lifecycle savings through energy efficiency.

– Sustainability credentials, increasingly critical in global procurement decisions.

Looking ahead, the bendable LED lighting market is poised for growth fueled by rising demand for adaptable, smart lighting systems. Buyers are encouraged to adopt a proactive sourcing approach, engaging with manufacturers who invest in R&D and sustainable practices. By doing so, businesses can not only optimize their supply chains but also position themselves at the forefront of lighting technology advancements, driving enhanced operational performance and market differentiation in their regions.