Article Contents

Industry Insight: Cuttable Led Tape Light

In the evolving landscape of commercial and industrial lighting, flexibility, efficiency, and compliance are paramount—and cuttable LED tape lights have emerged as a transformative solution. Designed to meet the dynamic demands of modern facilities, from retail spaces and warehouses to manufacturing plants and institutional buildings, these versatile lighting strips offer seamless integration, customizable lengths, and uniform illumination across diverse applications. Their ability to be precisely trimmed and reconnected without compromising performance makes them ideal for architectural detailing, cove lighting, under-shelf installations, and task lighting in hard-to-reach areas.

Critical to their adoption in professional environments is adherence to rigorous safety and performance standards. Leading cuttable LED tape lights are ETL and CE certified, ensuring they meet North American and international requirements for electrical safety, electromagnetic compatibility, and operational reliability. These certifications provide facility managers, electrical contractors, and design professionals with the confidence that the products they install are not only energy-efficient and durable but also compliant with code and insurance requirements.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance, code-compliant lighting products tailored for commercial and industrial applications. Renowned for quality control, technical support, and a deep understanding of market needs, the company continues to set industry benchmarks in reliability and versatility—making Beauty STC a preferred partner for specifiers and contractors seeking intelligent, scalable lighting systems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance cuttable LED tape lights engineered for professional architectural, commercial, and premium residential applications. Our cuttable LED tape lights deliver exceptional efficiency, color fidelity, and environmental resilience while maintaining the critical flexibility required for seamless integration into diverse projects.

Lumens per Watt (lm/W) efficiency is a core focus in our tape light engineering. Beauty STC’s standard 24VDC cuttable LED tapes achieve a consistent system efficacy range of 80 to 110 lumens per watt, measured under standard operating conditions with a compatible constant-voltage LED driver. This high efficiency is realized through the strategic selection of mid-power 2835 or 3535 SMD LEDs paired with optimized circuit design and high-quality phosphor conversion. Actual lm/W output depends on specific binning, drive current, and thermal management during installation, but our rigorous binning process ensures minimal variation across production reels. We prioritize stable lumen maintenance, guaranteeing ≥90% of initial lumens at 25°C ambient after 50,000 hours of operation per TM-21 projections.

Color Rendering Index (CRI) performance is non-negotiable for applications demanding true color representation. All Beauty STC cuttable LED tapes marketed for high-fidelity lighting exceed CRI Ra 90, with typical values ranging from 92 to 95. Crucially, we ensure strong saturation rendering by maintaining a minimum R9 value of 50, addressing a common shortcoming in lower-tier tapes. This is achieved through multi-phosphor LED packages and stringent spectral quality control during manufacturing. Our tapes undergo spectroradiometric testing per ANSI C78.377 to verify chromaticity coordinates within a tight 3-step MacAdam ellipse (SDCM ≤ 3), ensuring visual consistency across batches and installations.

IP Rating options are engineered for real-world durability and safety compliance. Our base flexible circuit (without additional coating) carries an IP20 rating, suitable for dry, interior locations. For demanding environments, Beauty STC offers factory-applied silicone encapsulation delivering IP65 protection against dust and low-pressure water jets, ideal for cove lighting in kitchens or retail displays. For fully wet locations including outdoor landscaping or bathroom zones, our IP67-rated tapes feature a fully potted, double-layer silicone jacket resistant to submersion up to 1 meter for 30 minutes. All encapsulated tapes undergo 100% post-production IP verification testing, not just batch sampling, and maintain flexibility for installation in curved channels. It is critical to note that IP integrity requires proper end-capping and connector installation per our specifications.

Beauty STC’s quality differentiation stems from vertically integrated manufacturing and obsessive process control. We utilize automated SMT assembly with 8K+ hourly placement accuracy, ensuring precise LED alignment and solder joint integrity. Every reel undergoes 100% aging, photometric, and electrical validation – not statistical sampling – before shipment. Our silicone encapsulants are UV-stable and halogen-free, preventing yellowing and maintaining optical clarity over the product lifetime. Rigorous thermal management design minimizes lumen depreciation, while copper trace thickness (2-3 oz) exceeds industry norms for consistent current delivery even at maximum cut lengths. This commitment to quality is validated by our industry-leading 5-year warranty and compliance with IEC 60598-1, IEC 62031, and LM-80 standards. The result is cuttable tape light that performs reliably with zero dark spots, minimal color shift, and sustained efficiency in critical lighting applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which enable high-speed, accurate placement of LED components onto flexible printed circuit boards used in LED tape lights. These automated SMT lines ensure consistent soldering quality, tight tolerances, and high throughput, essential for producing reliable and uniform cuttable LED tape lights. The SMT process is closely monitored with automated optical inspection (AOI) systems to detect any placement or soldering defects in real time, ensuring a high yield rate and product reliability.

Following assembly, all LED tape light products undergo rigorous aging tests in dedicated environmental chambers. These tests simulate extended operation under various thermal and electrical conditions, typically running for 8 to 24 hours at elevated temperatures and full power. This process helps identify early failure modes, verifies thermal management performance, and ensures long-term stability before products are shipped to customers. The aging test protocols are aligned with international quality standards, supporting Beauty STC’s commitment to durability and performance.

Beauty STC has robust OEM (Original Equipment Manufacturer) capabilities, particularly for customizable cuttable LED tape lights. The company can tailor specifications such as color temperature, CRI (Color Rendering Index), lumen output, IP rating, tape length, and packaging to meet specific client requirements. With flexible production lines, in-house PCB design support, and material sourcing control, the factory efficiently handles small to large-scale OEM orders. Clients can also benefit from private labeling, custom printing on tape reels, and technical collaboration during product development.

Overall, Beauty STC’s Jiangmen factory combines advanced automation, stringent quality assurance, and strong customization capabilities to deliver high-performance, cuttable LED tape lights for global markets.

Application Scenarios

Cuttable LED tape light offers exceptional flexibility for commercial lighting applications due to its ability to be shortened at precise intervals, typically every 50mm or 100mm, matching the circuit design. In hotels, it excels for creating layered ambient lighting in guest room headboards, under vanity cabinets, and within custom millwork in lobbies to highlight architectural features without visible fixtures. It is ideal for concealing within cove lighting in ballrooms and conference centers to provide soft, glare-free illumination that enhances the perceived space and supports adaptable event atmospheres. The precise cutting capability ensures seamless integration into curved reception desks or bespoke furniture where standard fixtures cannot fit, maintaining a clean, high-end aesthetic crucial for premium hospitality environments.

Within malls and retail environments, cuttable tape is indispensable for dynamic product display lighting. It allows installers to tailor lengths exactly to the dimensions of display cases, shelving gondolas, and signage, ensuring uniform illumination without dark spots or excess material. This precision is critical for highlighting merchandise in high-end boutiques or jewelry counters where even illumination affects perceived product value. It is also effectively used in soffit lighting along walkways to guide customers subtly, within column wraps for visual interest, and in service corridors where custom lengths fit between structural elements, providing functional lighting while adhering to strict fire and safety codes for concealed installations. The ability to cut minimizes waste during large-scale deployments across diverse architectural elements.

For office settings, cuttable LED tape provides solutions for both functional and aesthetic needs. It is commonly installed under desk overhangs to create comfortable, indirect task lighting that reduces eye strain without glare on computer screens, with lengths cut precisely to match individual workstation dimensions. In collaborative spaces, it illuminates whiteboards or feature walls to enhance focus areas, while within suspended ceiling coves it delivers uniform ambient light that improves spatial perception in open-plan layouts. The tape is also valuable for under-cabinet lighting in break rooms and reception areas, where exact sizing prevents unsightly overlaps or gaps. Its low-profile nature supports modern, minimalist office designs where visible fixtures would disrupt the clean aesthetic.

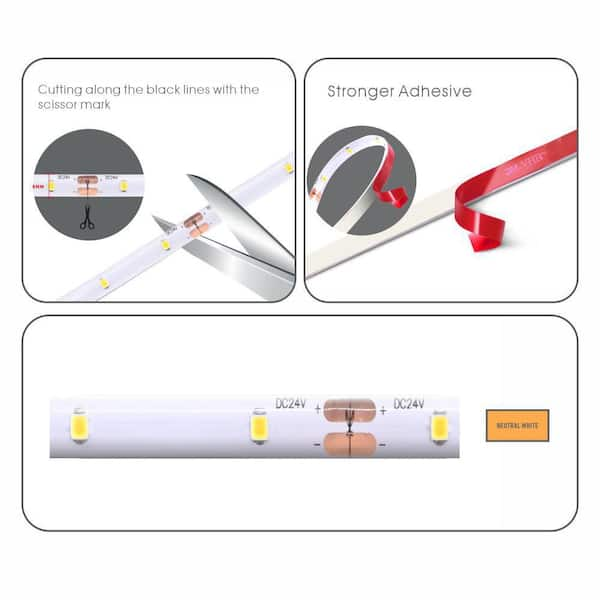

Installation requires strict adherence to electrical and thermal management principles. Always cut only at the designated marks, usually indicated by a scissor symbol and copper solder pads, to avoid open circuits; cutting elsewhere will render sections inoperable. For runs exceeding 5 meters on 12V systems or 10 meters on 24V systems, inject power at multiple points to prevent significant voltage drop causing dimming at the tape’s end. Mount the tape exclusively within extruded aluminum channels designed for thermal dissipation; direct mounting on flammable surfaces like wood without a channel violates fire codes and drastically shortens LED lifespan due to overheating. Ensure the channel has a diffuser to eliminate pixelation and provide even light distribution. Use only IP-rated tape and connectors matching the environment—IP65 minimum for indoor damp areas like hotel bathrooms, IP67 for outdoor-facing mall entrances. Before final sealing, test the entire run for consistent brightness and secure all solderless connectors with a crimping tool to prevent intermittent failures, especially in high-vibration areas like above mall escalators. Finally, maintain accessibility to the tape’s power end for future maintenance in concealed locations like above ceiling tiles in offices.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s innovative cuttable LED tape light—flexible, energy-efficient, and designed for seamless integration into any application. Whether you’re working on architectural accents, cabinetry, or commercial displays, our high-performance LED tape offers precise cut points for a perfect fit every time.

Partner with Beauty STC, a trusted leader in LED lighting solutions, and gain access to premium quality, custom configurations, and dedicated support. Our team is ready to help you bring your vision to life.

Contact us today at [email protected] to discuss your project and discover how our cuttable LED tape light can elevate your designs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.