Article Contents

Industry Insight: Crown Moulding Led Lighting

Crown moulding LED lighting has evolved far beyond its traditional residential roots to become a strategic element in commercial and industrial architectural design, where seamless integration and functional precision are paramount. In environments ranging from high-end hospitality lobbies and corporate atriums to sophisticated retail displays and institutional healthcare corridors, concealed cove lighting within crown profiles delivers critical ambient illumination without visual distraction, enhancing spatial perception while meeting stringent energy efficiency mandates. For facility managers and specifiers, the shift to LED solutions within these architectural elements is now non-negotiable, demanding not only superior optical control and thermal management for 24/7 operation but also rigorous adherence to safety certifications. ETL listing for North American building codes and CE marking for European compliance are essential baseline requirements, ensuring electrical safety, electromagnetic compatibility, and long-term reliability in demanding commercial installations where failure is not an option. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over two decades to mastering this intersection of architectural subtlety and industrial-grade performance. We engineer crown moulding LED systems specifically for the complexities of commercial and industrial projects, combining refined optical design with robust construction and uncompromising certification standards to deliver solutions that specifiers trust for both aesthetic impact and operational integrity.

Technical Specs & Certifications

Crown moulding LED lighting is designed to deliver elegant, ambient illumination along the intersection of walls and ceilings, enhancing architectural detail while providing functional light. At Beauty (STC) Manufacturing Co., Ltd., our crown moulding LED lighting solutions are engineered for high performance, durability, and aesthetic integration. Key technical specifications emphasize efficiency, color quality, and environmental protection.

Our crown moulding LED lighting systems achieve a luminous efficacy of 100 to 120 lumens per watt, ensuring energy-efficient operation without compromising brightness. This high efficiency is achieved through the use of premium-grade SMD LEDs and optimized driver technology, allowing for reduced power consumption and lower operating costs over the product’s lifetime.

Color rendering is critical in ambient and architectural lighting, which is why all our crown moulding LED products feature a Color Rendering Index (CRI) greater than 90. This ensures accurate and vibrant color representation, making spaces feel more natural and visually appealing. High CRI lighting is especially beneficial in residential, hospitality, and retail environments where visual comfort and ambiance are paramount.

In terms of environmental protection, Beauty STC offers crown moulding LED lighting with IP ratings ranging from IP20 for dry indoor environments to IP65 for semi-exposed or high-humidity areas such as bathrooms or covered porches. The IP65-rated variants provide complete dust protection and resistance to low-pressure water jets, ensuring long-term reliability even in demanding conditions. Fixtures are constructed with robust aluminum heat sinks and polycarbonate diffusers to enhance thermal management and optical clarity.

Beauty (STC) Manufacturing Co., Ltd. is committed to superior quality and precision engineering. Our LED lighting systems undergo rigorous testing for thermal performance, electrical safety, and photometric consistency. We adhere to international standards including UL, CE, and RoHS compliance, and utilize automated production processes to ensure uniformity and reliability across all units. With a focus on innovation and craftsmanship, Beauty STC delivers crown moulding LED lighting that combines technical excellence with seamless aesthetic integration.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for advanced LED lighting solutions, including specialized architectural products like crown molding LED lighting. The factory is a modern, ISO 9001-certified operation designed for high-volume precision manufacturing with stringent quality control throughout the production chain.

Our surface mount technology (SMT) production lines are anchored by multiple high-speed Fuji NXT III platforms, capable of placing components down to 0201 package size with micron-level accuracy. These machines handle the complex PCB assemblies required for crown molding LED strips, featuring multi-head configurations for rapid throughput and integrated automated optical inspection (AOI) systems that verify component placement, polarity, and solder paste quality in real-time. This ensures the dense, flexible PCBs used in low-profile crown molding applications meet exacting reliability standards before proceeding to assembly.

Rigorous aging and reliability testing forms a critical part of our quality assurance protocol. Completed crown molding LED lighting units undergo mandatory 24-hour continuous burn-in tests within temperature-controlled environmental chambers set to 45°C ambient, simulating accelerated operational stress. During this phase, we monitor lumen output stability, color consistency (using spectroradiometers), and thermal performance at multiple points along the profile. Units exhibiting any deviation beyond our tight tolerances—such as >3% lumen depreciation or thermal hotspots exceeding 85°C—are automatically flagged for root cause analysis and process refinement.

Regarding OEM capability for crown molding LED lighting, our Jiangmen factory provides comprehensive turnkey solutions from concept to shipment. We support full customization of extruded aluminum profiles, flexible PCB layouts, optical lenses, and driver integration tailored to specific architectural requirements. Our engineering team collaborates directly with clients during the design phase to optimize thermal management, light distribution, and mechanical fit for unique crown molding applications. We maintain dedicated production cells for low-volume prototyping and high-volume runs, with the capacity to handle orders from 500 meters to over 50,000 meters monthly while adhering to strict IP protection agreements. This includes custom labeling, packaging configurations, and compliance testing for global markets including UL, CE, and TÜV standards.

Application Scenarios

Crown moulding LED lighting is a decorative and functional lighting solution that enhances architectural details by illuminating the junction between walls and ceilings. This type of lighting is commonly used in high-end interior spaces where aesthetics and ambiance are crucial. It is particularly effective in hotels, malls, and offices, each benefiting from its visual appeal and subtle illumination.

In hotels, crown moulding LED lighting is often installed in lobbies, ballrooms, executive suites, and hallways. It creates a luxurious and inviting atmosphere, emphasizing architectural details and contributing to a refined guest experience. The soft, indirect glow enhances the perceived height of ceilings and adds depth to the space, making areas feel more spacious and elegant.

Malls utilize crown moulding LED lighting in common areas, food courts, high-end retail zones, and entrances. It helps define zones within large open spaces and adds a layer of sophistication. The lighting can be customized with color temperature and dimming options to match branding or create dynamic visual interest, especially during evening hours or promotional events.

In office environments, crown moulding LED lighting is typically found in executive offices, boardrooms, reception areas, and conference rooms. It provides ambient lighting that reduces glare and eye strain while contributing to a professional and modern aesthetic. The indirect illumination helps maintain a comfortable work environment without the harshness of direct overhead lighting.

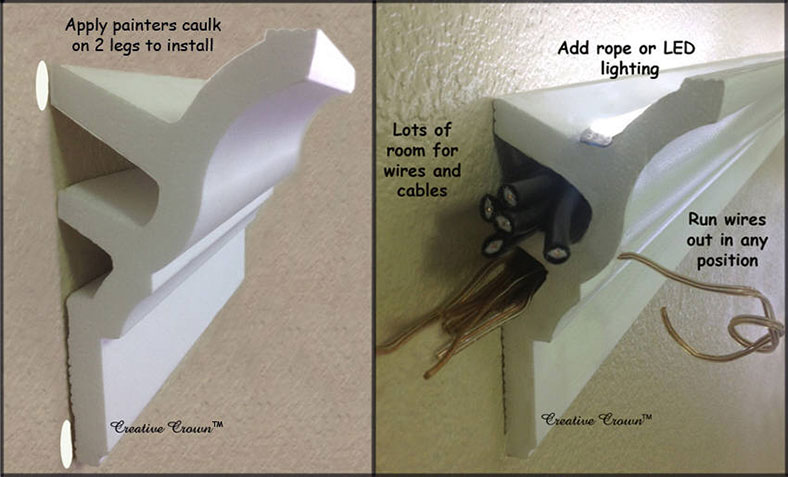

For installation, it is important to plan the layout during the early stages of construction or renovation. The LED strips should be mounted on the inner edge of the crown moulding, facing upward toward the ceiling to achieve optimal light reflection. Use high-quality, flexible LED strips with a high color rendering index (CRI) of at least 90 to ensure accurate color representation and a pleasing light quality. Choose a color temperature that matches the space’s function—warmer tones (2700K–3000K) for hospitality settings, cooler tones (3500K–4000K) for offices.

Ensure the power supply and drivers are properly sized and located in accessible areas for maintenance. Consider using dimmable drivers to allow flexibility in light levels. Conceal wiring within the moulding or wall cavity to maintain a clean appearance. Finally, test the lighting before sealing any access points to verify uniform illumination and avoid hotspots or dark gaps. Proper installation ensures both aesthetic success and long-term reliability.

Why Choose Beauty STC Lighting

Transform architectural details with precision-engineered crown moulding LED lighting solutions designed to elevate residential and commercial spaces. Beauty (STC) Manufacturing Co., Ltd. specializes in seamless integration of high-quality, energy-efficient LED systems into complex crown moulding profiles, ensuring optimal light distribution, zero visible hardware, and effortless installation for contractors and designers. Our proprietary optical technology eliminates glare while accentuating ceiling lines with museum-grade consistency, backed by rigorous thermal management for 50,000+ hour lifespans. Partner with Beauty STC to access custom profile compatibility, dimming-certified drivers, and dedicated engineering support that turns lighting challenges into signature design elements. Elevate your projects with lighting that performs as beautifully as it looks—contact our technical partnership team at [email protected] to discuss specifications, samples, and volume collaboration opportunities.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.