Article Contents

Industry Insight: Crown Molding With Led Light

The integration of LED technology into architectural elements like crown molding has evolved beyond residential aesthetics to become a strategic tool in commercial and industrial lighting design. In high-traffic lobbies, upscale retail environments, precision manufacturing facilities, and healthcare settings, crown molding with integrated LED lighting serves critical functional purposes: enhancing spatial perception, improving wayfinding, reducing shadow-related safety hazards, and reinforcing brand identity through sophisticated ambient illumination. Unlike decorative residential applications, commercial and industrial deployments demand rigorous adherence to safety and performance standards. Compliance with ETL (Electrical Testing Laboratories) certification for North American markets and CE marking for Europe is non-negotiable, ensuring these systems meet stringent electrical safety, electromagnetic compatibility, and operational durability requirements essential for professional environments. At Beauty STC Manufacturing Co., Ltd., established in 1998, we have dedicated over 25 years to engineering precisely this intersection of architectural integration and industrial-grade reliability. Our expertise lies in developing certified, high-performance LED crown molding solutions designed from the ground up for the demanding thermal management, longevity, and safety expectations of commercial and industrial projects worldwide. We understand that in these settings, lighting is not merely decorative—it is a fundamental component of operational efficiency and occupant well-being.

Technical Specs & Certifications

Crown molding with integrated LED lighting from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high-performance, elegant illumination for architectural and residential applications. These LED-embedded crown moldings are designed with precision to combine aesthetic appeal with advanced lighting technology, ensuring consistent, high-quality light output and durability.

Each system utilizes high-efficiency LED chips that achieve a luminous efficacy of 90 to 110 lumens per watt, depending on the configuration and color temperature. This efficiency ensures optimal energy consumption while maintaining bright, uniform illumination along ceilings and wall junctions. The LED modules are thermally managed through aluminum heat-dissipating substrates integrated within the molding profile, enhancing longevity and consistent lumen maintenance over time.

A key feature of Beauty STC’s crown molding LED systems is the high Color Rendering Index (CRI), consistently exceeding 90, with select models reaching CRI 95. This ensures accurate and vibrant color representation, making them ideal for high-end residential, hospitality, and retail environments where light quality is critical. The LEDs are available in multiple color temperatures—typically 2700K, 3000K, and 4000K—to suit various design schemes and ambiance requirements.

In terms of environmental protection, Beauty STC offers crown molding LED solutions with IP ratings ranging from IP20 for dry indoor environments to IP65 for semi-outdoor or high-humidity areas such as bathrooms or covered patios. The IP65-rated versions feature fully sealed LED strips and protective diffusers that prevent dust ingress and resist water jets, ensuring reliable performance in demanding conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout production, using only premium-grade components including high-transmission polycarbonate diffusers and stable constant-current LED drivers. Their manufacturing process adheres to international standards, with products undergoing extensive thermal, electrical, and optical testing. This commitment to quality ensures long operational life—typically rated at L70 >50,000 hours—as well as consistent color uniformity and minimal lumen depreciation over time.

With a focus on seamless integration, durability, and superior light quality, Beauty STC’s crown molding LED systems offer a reliable and elegant lighting solution trusted by designers and contractors worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in the Jiangmen National High-Tech Industrial Development Zone, Guangdong Province, China. This strategically positioned factory leverages Jiangmen’s strong industrial ecosystem and logistical advantages within the Pearl River Delta. The facility spans over 30,000 square meters and is purpose-built for modern LED lighting production, featuring clean rooms for SMT assembly, dedicated aging and testing labs, comprehensive R&D spaces, and flexible production lines for various fixture types including integrated architectural solutions.

Our SMT production lines are central to manufacturing high-reliability LED lighting products. We operate multiple state-of-the-art Yamaha YS Series high-speed placement machines, configured with numerous heads to handle diverse component sizes from ultra-miniature 0201 passives to larger power LEDs and ICs. These machines feature advanced vision systems for precise component placement and are integrated with automated solder paste printers and reflow ovens. The lines are designed for flexibility, supporting both high-volume production runs and smaller batch sizes required for custom OEM projects. Daily maintenance schedules and rigorous calibration protocols ensure consistent placement accuracy and throughput exceeding 1 million components per hour across the facility, forming the foundation for robust circuit board assembly.

Aging and reliability testing are critical non-negotiable processes at our Jiangmen factory, strictly enforced for all products including crown molding. We maintain a dedicated environmental testing laboratory housing numerous large-scale aging chambers. Finished LED modules and integrated fixtures undergo mandatory burn-in testing, typically operating at elevated temperatures (85°C) and humidity (85% RH) for a minimum of 72 hours, significantly exceeding standard industry practice. During this period, we continuously monitor key parameters such as lumen output, chromaticity shift, forward voltage, and thermal performance using integrated spectroradiometers and data loggers. Any unit exhibiting deviation beyond stringent internal thresholds is automatically flagged for failure analysis. This comprehensive aging regime, combined with statistical process control data, allows us to identify and eliminate infant mortality failures and validate long-term reliability before shipment.

Beauty STC possesses extensive OEM capability specifically for crown molding with integrated LED lighting, a core product category we manufacture at scale in Jiangmen. We offer full turnkey solutions starting from client specifications or collaborative design. Our expertise covers the complete integration process: extruding custom PVC or aluminum profiles to precise architectural dimensions, embedding high-density flexible LED strips or rigid PCB modules with various CCT options (2700K-6500K) and CRI values (80+ or 90+), integrating low-voltage drivers within the profile cavity, and implementing robust sealing for desired IP ratings (commonly IP20, IP54, or IP65). We excel at customizing length, color temperature tuning, dimming protocols (including 0-10V, DALI, TRIAC), connector types, and packaging to meet specific client requirements and target market regulations, particularly for North American and European projects. Our Jiangmen facility handles all aspects from prototype development through to volume production and final quality assurance for these integrated architectural lighting solutions.

Application Scenarios

Crown molding with LED lighting is a sophisticated design solution that combines architectural detail with ambient illumination. It is increasingly popular in commercial and hospitality environments where aesthetics and atmosphere play a crucial role in user experience.

In hotels, crown molding with integrated LED lighting is commonly used in lobbies, ballrooms, guest corridors, and high-end guest rooms. The soft, indirect glow enhances the sense of luxury and warmth, highlighting architectural features without creating glare. In ballrooms and event spaces, LED-lit crown molding can be programmed to change color or intensity, supporting different themes or moods for various functions.

Shopping malls utilize this feature in high-traffic areas such as main entrances, food courts, and premium retail zones. The lighting adds visual interest to ceilings and draws the eye upward, creating a more spacious and inviting environment. It also helps guide customer movement by subtly accentuating key areas or transitions between zones.

In office environments, crown molding with LED lighting is typically applied in executive suites, boardrooms, reception areas, and conference rooms. It contributes to a professional and modern aesthetic while providing indirect ambient lighting that reduces eye strain and supports a comfortable working atmosphere. In open-plan offices, it can be used to define zones or highlight architectural elements without disrupting workflow.

When installing crown molding with LED lighting, several best practices should be followed to ensure optimal performance and appearance. First, select high-quality LED strips with consistent color temperature and high CRI (Color Rendering Index) to ensure accurate and pleasing light output. Warm white (2700K–3000K) is often preferred in hospitality settings, while neutral white (3500K–4000K) works well in offices.

Ensure the crown molding profile includes a built-in recess or cove designed to hide the LED strip from direct view, allowing light to reflect off the ceiling for a seamless, floating effect. This indirect lighting technique minimizes glare and creates a soft, diffused glow.

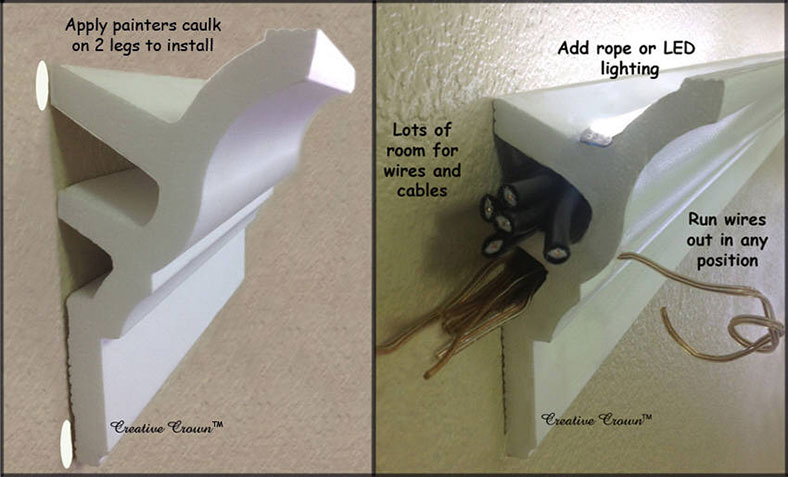

Proper mounting is essential. The molding must be securely attached to the wall and ceiling using appropriate fasteners and adhesives, especially in commercial spaces where durability is critical. For longer runs, plan for adequate power supply and consider using LED drivers with dimming capabilities to integrate with building lighting controls.

Electrical connections should comply with local codes, and low-voltage LED systems are recommended for safety and ease of installation. In high-traffic or public areas, ensure all wiring is concealed and protected, and use junction boxes where necessary.

Finally, consider maintenance access. Design the installation so that LED strips can be easily accessed or replaced without removing large sections of molding. Using modular LED systems or connectors can simplify future repairs or upgrades.

When implemented thoughtfully, crown molding with LED lighting enhances both the visual appeal and functionality of commercial interiors across hotels, malls, and offices.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co. Ltd I understand the critical importance of flawless integration and performance in architectural lighting solutions. Our engineered crown molding systems with integrated LED technology represent the pinnacle of precision design thermal management and optical quality specifically developed for demanding high-end residential and commercial installations. We solve common industry pain points such as inconsistent color rendering inadequate heat dissipation in thin profiles and complex installation processes through our proprietary driver integration and modular mounting system ensuring seamless long-term performance. Partnering with Beauty STC means gaining access to not just superior products but also dedicated engineering support from concept to completion including custom profile development photometric validation and on-site technical consultation to guarantee your project specifications are exceeded. Elevate your projects with lighting that enhances architectural integrity while delivering exceptional energy efficiency and reliability built to the highest industry standards. Contact our Lighting Solutions Manager directly at [email protected] to discuss how our integrated LED crown molding systems can become a cornerstone of your next premium installation. Let us engineer the light that defines your vision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.