Article Contents

Industry Insight: Corner Led

In the evolving landscape of commercial and industrial lighting, efficiency, durability, and design flexibility are paramount. One innovation that has gained significant traction is the corner LED lighting solution—engineered to maximize illumination in high-traffic zones, tight architectural spaces, and structural joints where traditional fixtures fall short. These specialized LED systems deliver targeted light output, reduce shadowing, and enhance visibility in warehouses, manufacturing facilities, cold storage units, and commercial buildings. With stringent safety and performance standards in mind, leading corner LED products are rigorously tested and certified to meet ETL and CE requirements, ensuring compliance with North American and international electrical and safety regulations.

At the forefront of this advancement is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its establishment in 1998. With over two decades of expertise, Beauty STC has consistently delivered high-performance, energy-efficient lighting solutions tailored for demanding commercial and industrial environments. Combining innovative engineering with a commitment to quality and regulatory compliance, the company continues to set benchmarks in reliability and illumination excellence.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance corner LED solutions primarily for architectural and commercial cove lighting applications, where precise light distribution around building or fixture corners is critical. Our corner-specific LED modules and strips are engineered to maintain consistent optical performance and thermal management at these challenging junctions, directly impacting the key specifications you require.

Regarding Lumens per Watt (lm/W), our corner LED products consistently achieve industry-leading efficacy. Standard 24VDC addressable and non-addressable corner modules within our architectural portfolio deliver 120-140 lm/W under nominal operating conditions at 25°C ambient. This high efficiency is maintained through optimized driver circuitry, low thermal resistance PCB designs specifically adapted for corner mounting constraints, and the use of premium-bin Epistar or Samsung LED chips. We rigorously validate lm/W performance at full operating temperature, not just at cold start, ensuring real-world energy savings align with specifications.

Critical to color fidelity in retail, hospitality, and high-end residential applications, all Beauty STC corner LED solutions targeting professional markets are manufactured with a minimum CRI (Ra) of 90, with typical batches exceeding Ra 93. We achieve this through stringent LED binning using high-CRI phosphor-converted blue chips and implement R9 (saturated red) values consistently above 50 to ensure vibrant, natural rendering of skin tones and materials. This commitment to spectral quality is non-negotiable in our premium product lines and is verified per ANSI C78.377 standards using calibrated spectroradiometers during final production testing.

IP Rating selection for corner applications depends entirely on the installation environment, and Beauty STC provides tailored solutions. For indoor dry locations such as ceiling coves or furniture integration, our corner modules carry IP20 certification with conformal coating for basic dust protection. For outdoor architectural corners exposed to weather, we supply IP67-rated corner profiles with seamless silicone sealing at the joint, tested to withstand 1 meter submersion for 30 minutes. In harsh environments like car parks or industrial settings where washdown occurs, IP68-rated corner solutions are available, validated for continuous submersion beyond 1 meter. All ingress protection claims are third-party certified, not self-declared.

Beauty STC’s quality assurance is embedded throughout the corner LED manufacturing process. We utilize aerospace-grade aluminum heat sinks with anodized finishes to combat thermal throttling at corners where airflow is restricted, directly supporting sustained lm/W and lumen maintenance. Every production batch undergoes 100% photometric testing, including spatial color uniformity checks critical for corner installations where multiple modules meet. Our components are sourced from ISO 14001/9001 certified suppliers, and final assemblies undergo 48-hour thermal cycling and humidity testing. This results in a standard 5-year warranty and L70 lifetimes exceeding 50,000 hours at 45°C ambient, significantly above industry averages. The precision in our corner-specific thermal and optical engineering ensures no visible color shift or lumen depreciation at the critical junction points where competitors often fail.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, well-equipped facility specializing in the design and manufacturing of LED lighting products. Strategically located in the Jiangmen High-Tech Industrial Zone, the factory benefits from excellent logistics access and a skilled local workforce, supporting both domestic and international markets.

The production floor is highly automated, featuring advanced SMT (Surface Mount Technology) lines that ensure precision and efficiency in LED component assembly. These SMT machines are capable of handling high-speed placement of small and complex LED packages, including those used in flexible and rigid strip lights. With automated optical inspection (AOI) systems integrated into the line, the factory maintains strict quality control throughout the manufacturing process, minimizing defects and ensuring consistent product performance.

A critical part of the quality assurance process at the Jiangmen facility is the comprehensive aging test procedure. After assembly, all LED products undergo extended burn-in tests under controlled thermal and electrical conditions. These aging tests typically run for 24 to 72 hours, depending on the product type and customer requirements, to identify early failure modes and verify long-term reliability. Environmental chambers are also used to simulate real-world operating conditions, further validating product durability.

Beauty STC has strong OEM capabilities, particularly for specialized LED products such as corner LED strips. These are custom-designed solutions for applications requiring seamless lighting transitions around edges and corners, commonly used in signage, display cases, and architectural lighting. The company supports full OEM services including custom PCB design, tailored lumen output, specific color temperatures, unique diffuser profiles, and branded packaging. Clients can provide technical specifications or application requirements, and the engineering team in Jiangmen will develop a solution optimized for performance, cost, and manufacturability.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible customization to deliver high-quality, reliable LED lighting solutions for global partners, with a particular strength in niche applications like corner LED configurations.

Application Scenarios

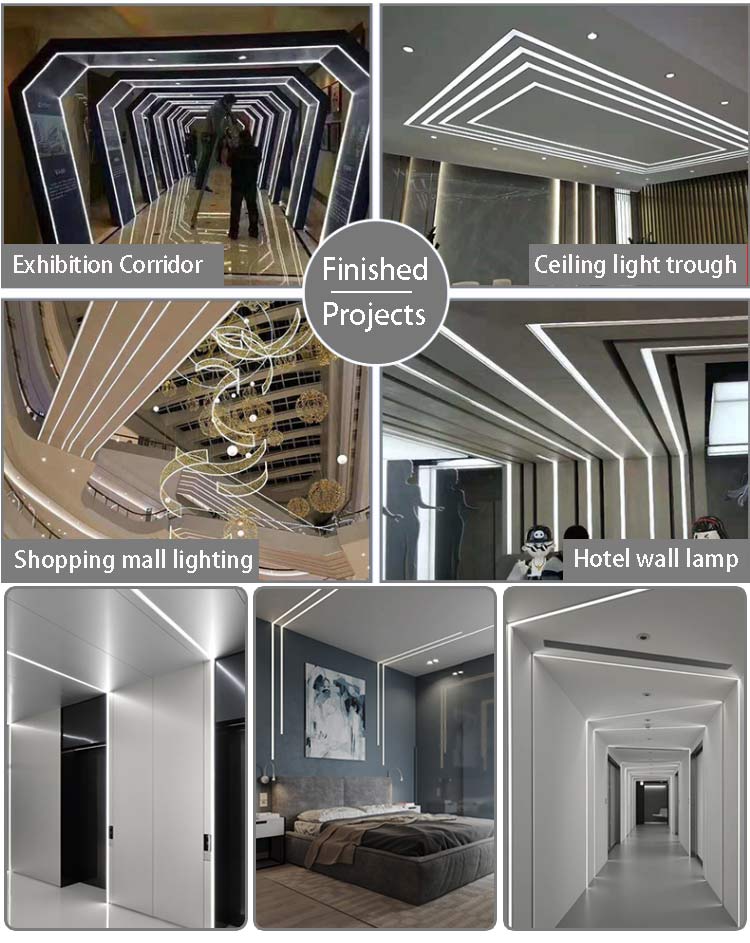

Corner LED lighting, typically referring to linear LED strips or channels installed within architectural coves or recesses at wall-ceiling junctions, serves distinct functional and aesthetic purposes across hotels, malls, and offices. Its primary role is indirect ambient or accent illumination, creating depth, enhancing spatial perception, and contributing to a refined atmosphere without direct glare.

In hotels, corner LED cove lighting is essential in lobbies to establish a welcoming, high-end ambiance by softly illuminating architectural features and guiding guest movement. Guest room corridors benefit from low-level cove lighting for safe nighttime navigation while preserving a serene environment. Within guest rooms, it provides subtle, glare-free ambient light above headboards or within ceiling coves, supporting relaxation and reducing harsh shadows. Executive lounges and spa areas utilize tunable white corner LEDs to dynamically shift color temperature, enhancing mood and perceived luxury.

Malls deploy corner LED systems strategically in high-traffic zones like main entrances and central atriums to create visual interest and vertical dimension, drawing attention upward. Retail storefronts integrate it within ceiling coves to highlight brand identity and merchandise displays without competing with spotlighting. Escalator landings and food court perimeters use uniform cove lighting to define transitional spaces and improve wayfinding, while consistent application throughout corridors ensures a cohesive, upscale shopping experience.

Offices implement corner LED cove lighting primarily in executive boardrooms and reception areas to convey professionalism through layered, shadow-free illumination that supports video conferencing. Open-plan workspaces use it to soften ceiling planes and reduce visual fatigue, though it must be supplemented with task lighting. Meeting rooms benefit from dimmable cove systems that adjust to presentation modes, while stairwells and lobbies employ it for safety-oriented ambient light that maintains architectural clarity without distraction.

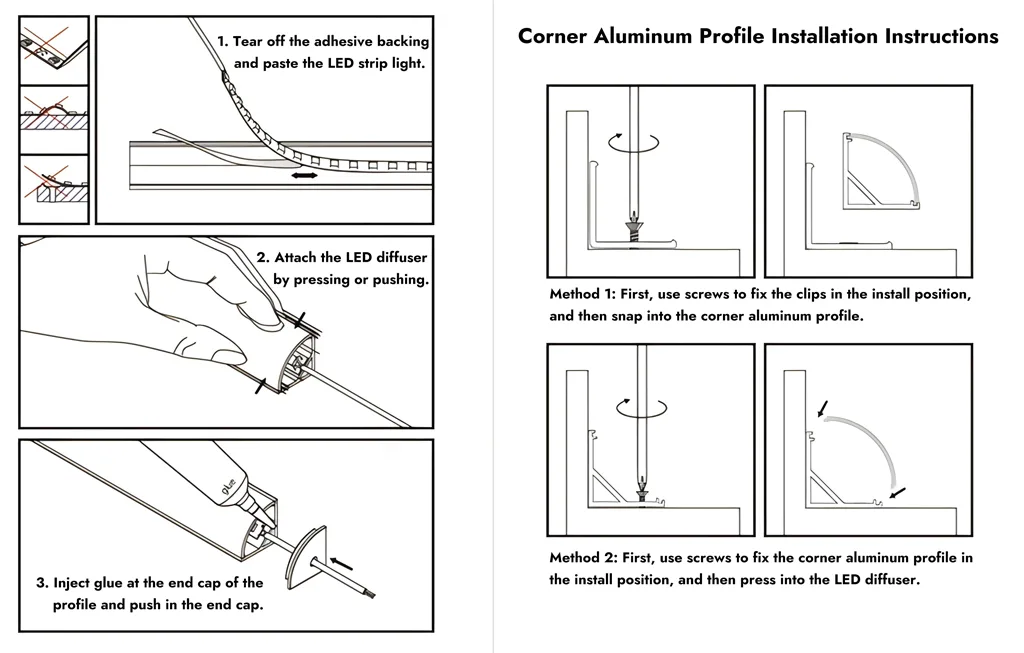

Installation requires meticulous attention to detail for optimal performance. Always verify the LED strip’s maximum continuous run length to prevent voltage drop, especially in long mall corridors; use parallel wiring or additional power feeds beyond 10-15 meters. Thermal management is critical—ensure adequate airflow within the cove channel and never exceed the manufacturer’s specified wattage per meter to avoid premature lumen depreciation. Select diffusers carefully; frosted or prismatic acrylic diffusers are superior to cheap polycarbonate for eliminating hotspots and ensuring uniform glow. Position the LED strip 15-30 cm back from the cove edge to allow light to fully bounce off the ceiling, creating a seamless wash. Conduct on-site mockups to confirm light distribution and color consistency before full rollout, as wall texture and ceiling height significantly impact results. Finally, integrate with building management systems using 0-10V or DALI controls in offices and hotels to enable scene-setting and energy savings, ensuring all drivers and controllers are compatible. Neglecting these steps risks uneven illumination, visible strip patterns, or thermal failure, undermining the intended aesthetic and functional benefits.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality corner LED solutions from Beauty STC. As a trusted manufacturer, we specialize in durable, energy-efficient LED products designed for seamless integration and superior performance. Partner with Beauty STC to access customized solutions, reliable supply chains, and expert technical support. For collaboration opportunities and product inquiries, contact our team at [email protected]. Let’s illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.