Article Contents

Industry Insight: Controlador De Luces Led

The strategic implementation of LED lighting control systems has evolved from a luxury to an operational imperative within commercial and industrial facilities globally. As building operators face relentless pressure to reduce energy consumption, minimize maintenance costs, and enhance occupant productivity through dynamic lighting environments, the humble LED controller emerges as the critical intelligence layer transforming static illumination into a responsive, data-driven asset. In environments ranging from expansive warehouses and manufacturing floors to sophisticated retail spaces and healthcare facilities, the reliability, precision, and compatibility of the controlador de luces led directly dictate system performance, longevity, and the realization of promised energy savings. Crucially, adherence to stringent safety and performance standards is non-negotiable; controllers bearing recognized certifications such as ETL for the North American market and CE marking for Europe are fundamental requirements, ensuring electrical safety, electromagnetic compatibility, and regulatory compliance before integration into any professional installation. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of dedicated engineering expertise to this vital segment. We understand that in commercial and industrial contexts, a controller is far more than a switch—it is the operational backbone demanding robustness, seamless integration with diverse building management systems, and unwavering performance under demanding conditions. Our heritage is built on solving the complex challenges inherent in large-scale lighting control, delivering solutions engineered for real-world reliability and certified to meet the highest global safety benchmarks.

Technical Specs & Certifications

The ‘controlador de luces led’ (LED light controller) from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver precise, efficient, and reliable performance when managing high-quality LED lighting systems. While the controller itself does not produce lumens or consume watts directly, it is specifically designed to optimize the operation of LED luminaires that meet stringent performance standards, particularly in terms of lumens per watt (lm/W), Color Rendering Index (CRI), and environmental protection via IP ratings.

Beauty STC’s LED controllers are built to support LED fixtures that achieve high efficacy, typically ranging from 120 to 150 lumens per watt, depending on the luminaire design and LED components used. These values reflect the advanced thermal management and driver compatibility engineered into Beauty STC systems, ensuring minimal energy loss and maximum light output efficiency. The controllers support dimming protocols such as 0-10V, DALI, PWM, or wireless RF, allowing seamless integration with high-efficiency LED modules that maintain consistent lm/W performance across dimming ranges.

A key focus for Beauty STC is color quality, and their lighting systems—paired with compatible controllers—are designed to work with LEDs that deliver a CRI greater than 90. This ensures excellent color fidelity, making the lighting ideal for retail, hospitality, healthcare, and residential applications where accurate color representation is critical. The controllers maintain stable current and voltage regulation, preventing flicker and color shift, which helps preserve the high CRI performance over time.

In terms of environmental durability, Beauty STC designs its LED control solutions to be compatible with luminaires rated at IP65, IP66, and even IP67 for outdoor and demanding indoor environments. The controllers themselves are often housed in robust enclosures with appropriate ingress protection, and all components are manufactured to withstand dust, moisture, and temperature variations. This ensures reliable operation in both commercial and industrial settings.

Beauty STC’s reputation for quality stems from rigorous in-house testing, adherence to international standards (including CE, RoHS, and UL), and the use of premium materials in both electronic and optical components. Their integrated approach to controller and luminaire design ensures compatibility, longevity, and consistent performance, making Beauty STC a trusted name in professional LED lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production capacity. Strategically located within the Pearl River Delta manufacturing hub, the Jiangmen factory benefits from robust infrastructure, skilled labor resources, and efficient logistics networks connecting to major ports. The facility operates under stringent international quality management systems, including ISO 9001 certification, ensuring consistent adherence to global standards across all production stages. Its primary focus is high-volume manufacturing of LED lighting products and critical electronic components, featuring dedicated cleanroom environments for precision assembly processes.

The Surface Mount Technology (SMT) production lines form the technological backbone of the Jiangmen facility. We utilize multiple high-speed, multi-functional SMT machines from leading manufacturers such as Yamaha and Panasonic. These automated lines are capable of placing components with exceptional accuracy down to 0201 package sizes and feature advanced vision systems for precise component alignment. The SMT process encompasses fully automated solder paste printing, high-speed pick-and-place operations, nitrogen-reflow soldering for superior joint reliability, and comprehensive automated optical inspection (AOI) systems. This advanced SMT capability ensures the efficient and reliable assembly of complex printed circuit boards (PCBs) required for modern LED drivers and controllers, supporting both small-batch prototyping and large-scale production runs.

Aging and reliability testing constitute a non-negotiable phase in our quality assurance protocol at the Jiangmen factory. Every batch of LED light controllers undergoes rigorous aging tests within specialized environmental chambers. These tests typically run for a minimum of 48 to 72 hours under controlled conditions that simulate real-world operational stresses, including elevated temperatures and full-load operation. During this period, controllers are continuously monitored for critical parameters such as output voltage stability, thermal performance, efficiency, and functional integrity. Any unit exhibiting deviation from stringent performance specifications is automatically flagged and removed from the production flow. This comprehensive aging process significantly enhances product field reliability and longevity, directly addressing potential infant mortality failures before products reach customers.

Beauty STC possesses extensive OEM capabilities specifically tailored for LED light controllers, known internationally as “controlador de luces led”. Our engineering and manufacturing teams support clients from initial concept through to mass production. This includes custom PCB design and layout optimization, tailored firmware development for specific dimming protocols or control functionalities, and the integration of client-specific components or features. We accommodate diverse requirements for input voltage ranges, output configurations, dimming methods (such as 0-10V, DALI, PWM, or wireless protocols), and thermal management solutions. The Jiangmen factory provides full turnkey OEM services, encompassing component sourcing, SMT assembly, rigorous in-circuit and functional testing, aging verification, and final packaging. Crucially, we support multilingual documentation and labeling, including Spanish language specifications, user manuals, and compliance markings, to meet the specific market needs of our international partners. All OEM controller production strictly adheres to relevant safety certifications such as UL, cUL, CE, and RoHS, ensuring global market readiness.

Application Scenarios

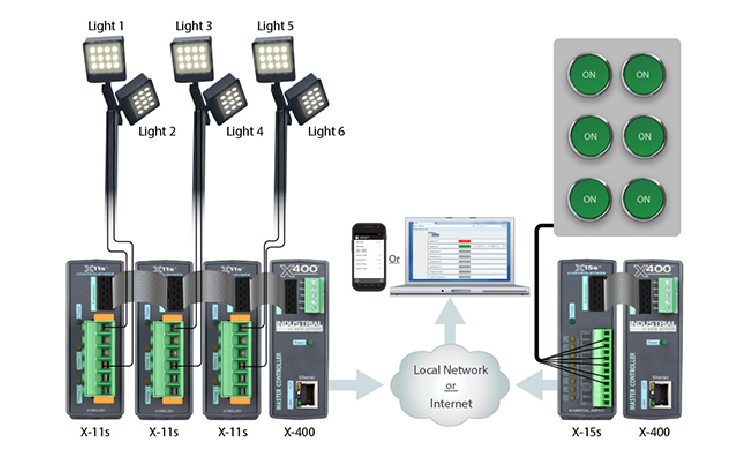

The term controlador de luces led refers to an LED lighting controller, a device used to manage the intensity, color, timing, and sometimes the direction or pattern of LED lighting systems. These controllers are widely used across various commercial and industrial environments due to their energy efficiency, flexibility, and ability to enhance ambiance and functionality.

In hotels, LED controllers are essential for creating dynamic lighting environments that improve guest experience. They are commonly used in lobbies, guest rooms, hallways, ballrooms, and outdoor areas. For example, in guest rooms, controllers allow guests to adjust lighting for relaxation, reading, or sleep, often integrated into smart room systems. In event spaces like ballrooms, LED controllers enable customizable lighting scenes for weddings, conferences, or banquets. The use of dimming and color-tuning features helps establish the desired mood while reducing energy consumption during low-occupancy periods.

In shopping malls, LED lighting controllers play a crucial role in both aesthetic appeal and operational efficiency. They are used in common areas, food courts, retail corridors, and exterior facades. Controllers allow mall operators to program lighting schedules that align with business hours, reduce brightness during daylight, and create eye-catching light displays during holidays or promotions. Zoning capabilities enable different lighting settings for various sections, supporting both security and visual merchandising. Additionally, integration with occupancy sensors helps conserve energy in restrooms, storage areas, and parking lots.

In office buildings, LED controllers contribute to a productive and comfortable work environment. They are used in open-plan offices, meeting rooms, lobbies, and conference centers. Controllers support daylight harvesting by automatically adjusting artificial light levels based on natural light availability, reducing energy use and minimizing glare. In meeting rooms, programmable scenes can be set for presentations, video conferences, or collaborative sessions. Integration with building management systems (BMS) allows centralized control and monitoring, simplifying maintenance and enabling data-driven energy optimization.

When installing LED lighting controllers, several best practices should be followed to ensure reliable and efficient operation. First, verify compatibility between the controller, LED drivers, and fixtures—especially when using DALI, 0–10V, PWM, or wireless protocols like Zigbee or Bluetooth. Mismatched components can lead to flickering or failure. Second, plan the control zones logically based on room function, occupancy patterns, and natural light exposure. This allows for more effective automation and user control. Third, ensure proper electrical grounding and use shielded cables in environments with high electromagnetic interference to prevent signal disruption. Fourth, position controllers in accessible, dry, and well-ventilated locations to facilitate maintenance and reduce heat buildup. Finally, label all circuits and zones clearly during installation to simplify troubleshooting and future upgrades.

For optimal performance, consider working with certified electricians and using controllers from reputable manufacturers like Beauty (STC) Manufacturing Co., Ltd., which offers robust and scalable solutions tailored for commercial applications. Proper commissioning and user training are also key to maximizing the benefits of any LED control system.

Why Choose Beauty STC Lighting

Elevate your LED lighting projects with precision control solutions engineered for performance and reliability. Beauty STC Manufacturing Co., Ltd. specializes in advanced LED light controllers designed for commercial and industrial applications, delivering seamless dimming, robust compatibility, and energy-efficient operation across diverse environments. As a trusted manufacturer with over 15 years of expertise, we prioritize technical excellence and customizable engineering to meet your specific project demands.

Partner with Beauty STC to access rigorously tested controllers that integrate effortlessly with global lighting standards while ensuring long-term durability. Our dedicated engineering team collaborates closely with partners to refine specifications, accelerate time-to-market, and provide comprehensive technical support from prototyping to large-scale production.

For tailored solutions and partnership opportunities, contact our Business Development Manager directly at [email protected]. Let us engineer the control behind your next lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.