Article Contents

Industry Insight: Construction Led Strip Light

The commercial and industrial lighting sector increasingly demands robust, high-performance solutions capable of withstanding demanding environments while delivering significant energy savings and operational longevity. Within this critical landscape, construction-grade LED strip lights have emerged as a transformative technology, moving far beyond simple decorative applications. These purpose-built systems are now fundamental for task lighting in warehouses, accentuating architectural features in retail spaces, illuminating production lines, and providing reliable egress lighting in industrial facilities. Their success hinges not just on efficiency and flexibility, but on rigorous adherence to safety and performance standards; ETL and CE certifications are non-negotiable prerequisites, ensuring products meet stringent electrical safety requirements and electromagnetic compatibility regulations essential for mission-critical commercial deployments. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. With over 25 years of dedicated engineering expertise in LED lighting solutions, we understand the unique challenges of commercial and industrial settings. Beauty STC focuses on developing construction LED strip lights engineered for durability, consistent optical performance, and seamless integration into demanding infrastructure projects, providing specifiers and facility managers with reliable, certified lighting systems built to last.

Technical Specs & Certifications

The Construction LED Strip Light from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and durability in demanding environments. Designed specifically for construction and industrial applications, this LED strip delivers exceptional efficiency and color fidelity. It achieves a luminous efficacy of up to 130 lumens per watt, ensuring optimal energy savings without compromising brightness. This high lumens/watt ratio reflects Beauty STC’s commitment to energy-efficient lighting solutions that meet rigorous operational standards.

Color Rendering Index (CRI) is a critical factor in construction and task lighting, where accurate color representation enhances safety and precision. The Construction LED Strip Light features a CRI exceeding 90, enabling true-to-life color visualization. This high CRI ensures materials, wiring, and surfaces are seen with clarity and accuracy, reducing errors and improving work quality on site.

For environmental protection, the strip light is available in multiple IP (Ingress Protection) ratings to suit various construction conditions. Standard models offer IP65 protection, providing resistance to dust and low-pressure water jets, making them ideal for semi-exposed or indoor construction zones. For more demanding environments, IP67-rated versions are available, offering complete dust tightness and protection against temporary immersion in water—suitable for outdoor or high-moisture areas.

Beauty STC maintains strict quality control across all production stages, adhering to international standards such as ISO 9001 and IEC certifications. The Construction LED Strip Light is built with high-grade SMD LEDs, durable flexible PCBs, and robust silicone or PVC jackets, ensuring long service life even under mechanical stress and temperature fluctuations. With rigorous testing for thermal management, electrical safety, and optical consistency, Beauty STC’s LED strips reflect superior craftsmanship and reliability trusted in professional lighting applications worldwide.

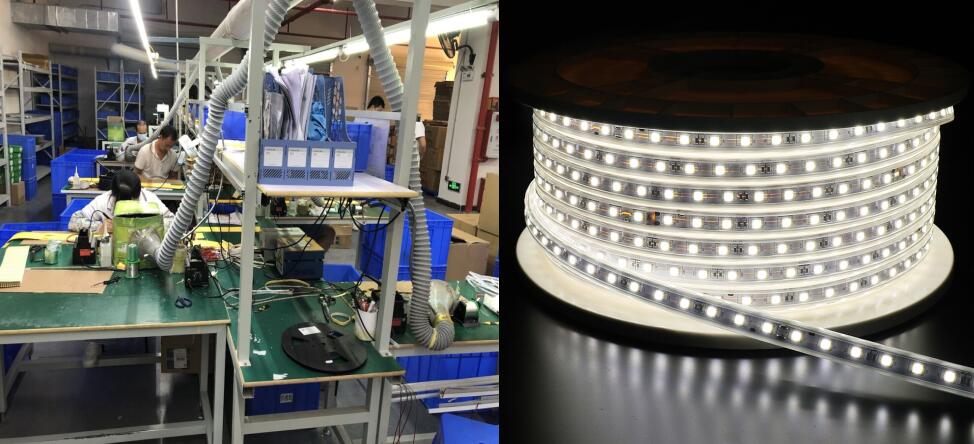

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, is a strategically located production hub within the Pearl River Delta region, leveraging excellent logistics access to ports and major supply chains. The factory is purpose-built for high-volume, precision LED lighting manufacturing, with a particular focus on industrial-grade products like Construction LED strip lights.

Our SMT production lines are centered around multiple high-speed Yamaha YS series surface mount technology machines. These systems are configured for optimal throughput and precision handling of ultra-small components, including 0201 metric LEDs and miniature passive components critical for dense, high-output LED strips. The lines feature automated optical inspection (AOI) systems integrated post-reflow to verify component placement accuracy, solder joint integrity, and potential defects, ensuring first-pass yield rates exceed 99.5% for complex strip light assemblies.

Rigorous aging and reliability testing form a non-negotiable part of our quality control protocol for Construction LED strip lights. Every production batch undergoes a minimum 72-hour continuous aging test under controlled elevated temperature conditions, typically at 50°C, simulating years of operational stress. This process occurs on dedicated aging racks with real-time monitoring of voltage, current, and thermal performance. We specifically monitor for lumen maintenance degradation, color shift, and driver stability under sustained load, with strips failing any parameter immediately quarantined for root cause analysis. This ensures only strips meeting our stringent 50,000-hour L70 lifetime specification proceed to packaging.

Our OEM capabilities for Construction LED strip lights are comprehensive and tailored to demanding industrial applications. We support full customization including bespoke lengths, cut-point intervals, specialized PCB constructions (such as 2oz or 3oz copper for high thermal management), and integration of robust connectors rated for harsh environments. Clients can specify exact color temperatures, CRI values, and lumen outputs, with our engineering team providing validation through LM-79 photometric reports. We accommodate private labeling, custom packaging configurations, and critical certifications including UL/cUL, DLC, and IP67 ratings, managing the entire compliance process. The factory maintains traceability from raw material lot numbers through final test data, enabling full production lot tracking essential for construction project documentation and warranty support. This integrated approach ensures OEM partners receive a finished Construction LED strip light product engineered for reliability, compliance, and seamless integration into their specific project requirements.

Application Scenarios

Construction LED strip lights are ideal for architectural and structural applications where durability, flexibility, and long-term performance are essential. These lights are commonly used in commercial and institutional environments such as hotels, malls, and offices due to their robust design and ability to integrate seamlessly into both aesthetic and functional lighting schemes.

In hotels, construction LED strip lights are often installed in cove lighting along ceilings, under reception desks, within stair treads, and in corridors to provide ambient or accent lighting. Their rigid construction and high ingress protection make them suitable for areas requiring reliable performance with minimal maintenance. They enhance guest experience by creating a welcoming atmosphere while maintaining energy efficiency.

In malls, these LED strips are used in display lighting, column wraps, under handrails, and in architectural features such as archways or soffits. Their durability allows them to withstand high-traffic environments and varying temperatures. The consistent light output helps highlight retail spaces and guide foot traffic effectively, contributing to a visually appealing shopping environment.

In offices, construction LED strip lights are typically employed for indirect lighting in drop ceilings, under cabinets, and along walkways or meeting room features. They support a professional and modern aesthetic while improving visual comfort and reducing glare. Their long lifespan reduces the need for frequent replacements, which is advantageous in hard-to-reach areas.

For installation, ensure the mounting surface is clean, dry, and free of debris to promote strong adhesion. Use mounting clips or aluminum channels to secure the strip, especially in high-vibration or high-traffic zones. Aluminum channels also assist with heat dissipation, extending the LED’s life. Always follow the manufacturer’s bending radius specifications to avoid damaging the strip. Connect the strip to a compatible constant-voltage LED driver, and ensure all electrical connections are properly insulated and compliant with local electrical codes. For outdoor or high-moisture areas, use IP65 or higher rated strips and protect connections with waterproof junction boxes. Finally, test the system before finalizing the installation to verify uniform illumination and secure connections.

Why Choose Beauty STC Lighting

Transform your construction site illumination with Beauty STC’s rugged Construction LED Strip Lights engineered for resilience in demanding environments. Our strips deliver consistent high-lumen output, withstand dust and moisture with robust IP65+ ratings, and feature flexible installation to adapt to complex structural layouts—reducing labor time while ensuring worker safety and project compliance. Partner with Beauty STC to integrate lighting solutions trusted by industry leaders for durability, energy efficiency, and seamless scalability across temporary or permanent installations. Contact our dedicated partnership team today at [email protected] to discuss tailored support, volume pricing, and technical collaboration for your next project. Let us help you build brighter, safer worksites with lighting engineered where performance meets precision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.