Article Contents

Industry Insight: Connectors For Led Lights

In the rapidly evolving landscape of commercial and industrial lighting, the reliability and safety of every component are critical—nowhere is this more evident than in the role of connectors for LED lighting systems. As facilities increasingly transition to energy-efficient LED solutions, the demand for high-performance, code-compliant connectors has surged. These components are essential for ensuring secure electrical connections, enabling quick installation, and supporting the long-term durability of lighting installations in demanding environments such as warehouses, manufacturing plants, and large-scale retail spaces. With stringent safety standards in place across North America and Europe, certifications such as ETL and CE have become non-negotiable benchmarks, verifying that connectors meet rigorous requirements for electrical safety, temperature resistance, and environmental resilience.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-quality connectors tailored specifically for commercial and industrial LED lighting applications. With over two decades of engineering expertise, Beauty STC combines innovation with compliance, delivering products that meet both ETL and CE standards while addressing the practical needs of lighting manufacturers and installers worldwide. As the industry continues to prioritize efficiency, scalability, and safety, Beauty STC remains at the forefront, providing dependable connectivity solutions that empower the next generation of intelligent, sustainable lighting infrastructure.

Technical Specs & Certifications

Connectors for LED lighting systems are critical components that enable electrical and mechanical integration but do not themselves generate light. Therefore, metrics such as Lumens per Watt (lm/W) and Color Rendering Index (CRI) are properties of the LED light source or module, not the connectors. It is essential to clarify this distinction to avoid technical misrepresentation. Connectors instead influence system performance by ensuring reliable power delivery, signal integrity, and environmental protection, which indirectly support the LED system’s ability to maintain its specified lm/W and CRI values over time. Beauty STC rigorously designs and tests connectors to uphold these performance standards without deviation.

Lumens per Watt quantifies the efficacy of the LED light engine, reflecting how efficiently electrical power converts to visible light. While connectors do not produce lumens, Beauty STC’s connectors are engineered to minimize voltage drop and resistive losses through high-conductivity copper alloys and precise contact geometry. Our standard connectors maintain contact resistance below 3 milliohms per contact point, ensuring that the LED driver’s output reaches the light source with minimal energy loss. This design directly supports the fixture’s overall lm/W target by preventing parasitic power dissipation in the connection points. We validate this through thermal imaging during 100% production testing, guaranteeing connectors operate within 5°C of ambient under full load to avoid efficacy degradation.

Color Rendering Index values exceeding 90 indicate exceptional color fidelity, a specification determined solely by the LED phosphor formulation and driver stability. Beauty STC connectors contribute to sustained CRI >90 performance by providing stable, low-noise electrical connections that prevent current fluctuations. Our connectors utilize gold-plated contacts (0.8μm thickness minimum) to eliminate oxidation-induced resistance variance, which could otherwise cause chromaticity shifts in sensitive high-CRI LEDs. Rigorous 500-cycle mating endurance tests and humidity exposure validation per IEC 60068-2-78 ensure consistent electrical contact over the product lifecycle, directly supporting the LED system’s ability to maintain its rated CRI without color drift.

IP Ratings define ingress protection against solids and liquids, where connectors play a direct role. Beauty STC offers connectors rated IP67, IP68, and IP69K per IEC 60529 standards. Our IP68-rated connectors undergo 10-meter water submersion testing for 72 hours at 25°C without leakage, utilizing dual silicone sealing gaskets and precision-molded polycarbonate housings (UL94 V-0 rated). For outdoor or wet-location applications, we implement stainless steel locking mechanisms and UV-stabilized materials to maintain seal integrity under thermal cycling from -40°C to +105°C. Each connector batch undergoes mandatory IP verification via differential pressure testing, not just spot checks, ensuring every unit meets the specified rating before shipment. This prevents moisture ingress that could corrode contacts or damage LEDs, thereby protecting the entire system’s photometric performance.

Beauty STC’s quality commitment is embedded in every connector through ISO 9001-certified manufacturing processes. We enforce 100% automated contact resistance testing, 100% visual inspection via AI-powered cameras, and batch-level validation for flammability, tensile strength, and thermal endurance. Our connectors exceed IEC 60309 and UL 498 requirements, with traceable lot numbering for full supply chain transparency. This uncompromising approach ensures that Beauty STC connectors not only meet but consistently exceed industry reliability benchmarks, forming the foundation for high-performance LED lighting systems that deliver on lumen maintenance, color accuracy, and environmental resilience as specified.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is equipped with advanced surface mount technology (SMT) production lines, ensuring high-precision assembly of LED lighting components. These SMT machines are automated and capable of handling fine-pitch components, enabling efficient and reliable placement on printed circuit boards used in LED applications. The integration of automated optical inspection (AOI) systems further ensures product quality and consistency throughout the manufacturing process.

The facility incorporates comprehensive aging test procedures as part of its quality control protocol. Completed LED light assemblies and related components undergo rigorous burn-in tests under controlled thermal and electrical conditions. These aging tests typically run for 4 to 24 hours, depending on product specifications, to identify early-life failures and verify long-term reliability. Environmental simulation chambers are also utilized to assess performance under varying temperatures and humidity levels, ensuring products meet international safety and durability standards.

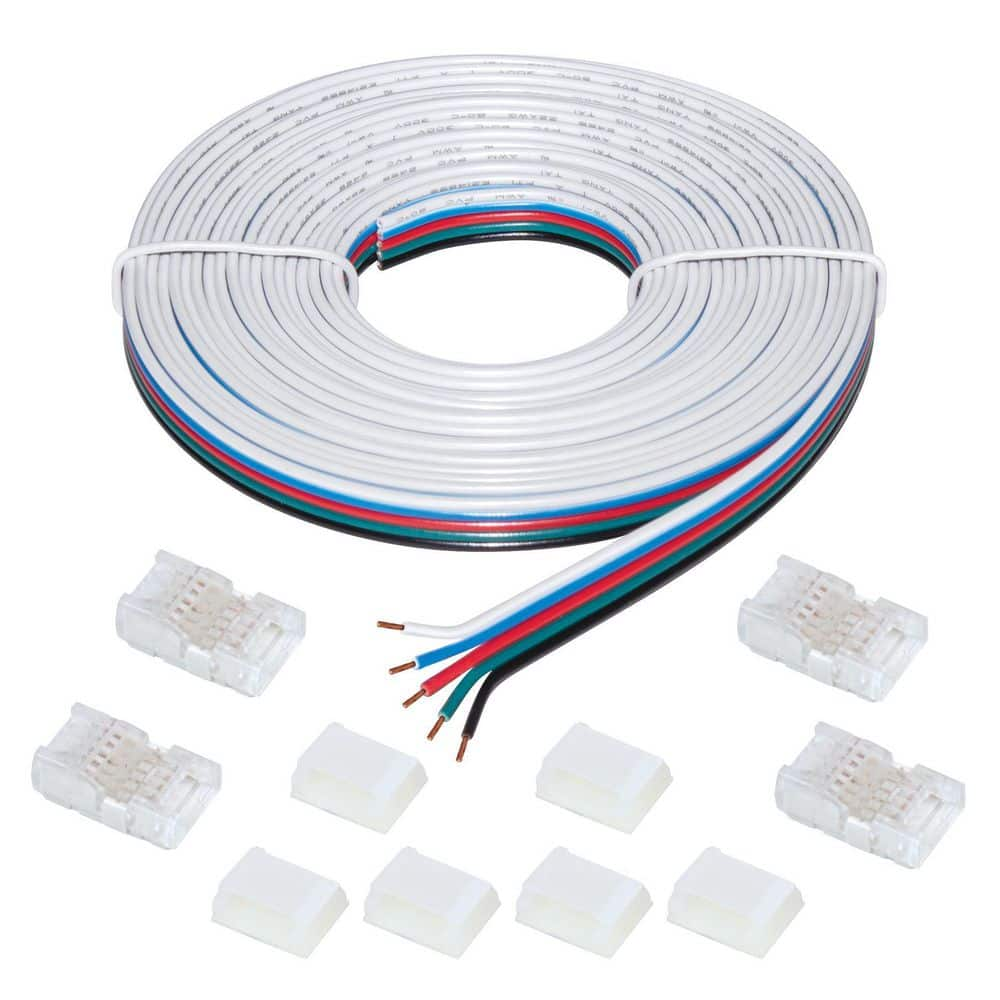

Beauty STC has well-established OEM (Original Equipment Manufacturing) capabilities, particularly in the production of connectors for LED lights. The company supports customized connector development based on client specifications, including variations in pitch, pin count, material selection (such as phosphor bronze or brass with plating), and insulation types for different voltage and temperature ratings. With in-house mold design and plastic injection capabilities, the factory can rapidly prototype and scale production of connectors tailored to specific LED lighting applications, such as strip lights, panels, and downlights. This vertical integration, combined with strict adherence to IPC and IEC standards, allows Beauty STC to deliver high-quality, reliable connector solutions for global lighting manufacturers.

Application Scenarios

Connectors for LED lights serve as critical junction points in commercial lighting systems, ensuring reliable electrical continuity while enabling flexibility and serviceability. Their strategic use across hotels, malls, and offices addresses specific operational demands in each environment. In hotels, connectors are indispensable within guest room corridors for linking modular linear LED strips in coves or under cabinets, allowing individual fixture replacement without disturbing entire runs during renovations. They are equally vital in high-ceiling lobbies and ballrooms where track lighting systems require frequent reconfiguration for events; connectors enable quick detachment of pendants or spotlights for cleaning or layout changes. Bathrooms and pool areas mandate IP67-rated waterproof connectors to join downlights or vanity strips, preventing moisture ingress in humid zones.

Malls leverage connectors extensively in suspended track systems spanning multi-story atriums, where high-bay fixtures must be serviced safely from lift platforms; robust connectors simplify removal of heavy luminaires. Retail storefronts use them to interconnect display case lighting, facilitating after-hours bulb changes without disrupting store operations. Emergency exit signage circuits rely on fire-rated connectors to maintain continuity during power failures, while outdoor facade lighting employs UV-stable, IP68 connectors to withstand weather exposure at splices between building-mounted strips.

Offices deploy connectors beneath raised floors for under-desk task lighting strips, allowing IT teams to reposition workstations without rewiring. Suspended ceiling grids utilize low-voltage connectors for troffer replacements or sensor integrations, minimizing ceiling tile disturbance. Open-plan layouts benefit from connectors in flexible partition-integrated lighting, enabling workspace reconfiguration. Critical areas like server rooms require thermally stable connectors rated for continuous 70°C operation to handle dense lighting near heat-generating equipment.

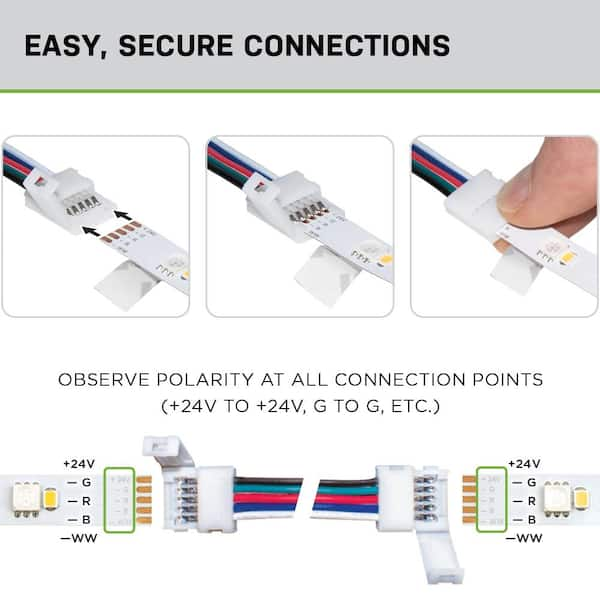

Installation demands precision to prevent field failures. Always verify voltage compatibility between the connector, driver, and LED module to avoid overloading; mismatched 24V connectors on 48V systems cause immediate thermal runaway. Apply dielectric grease to metal contacts in damp locations like hotel pools before mating to inhibit corrosion. Secure cables with strain relief clamps within 50mm of the connector body—unsecured wires induce fatigue fractures in mall atrium installations after repeated servicing. Torque screw terminals to manufacturer specs (typically 0.5–0.8 Nm); under-torqued connections in office partitions generate arcing noise, while over-torquing strips threads. For high-ambient-heat zones like retail kitchen exhaust areas, select connectors with silicone seals rated above 105°C. Finally, conduct a 15-minute operational test at full load before sealing junctions in walls or ceilings—this catches intermittent faults from poor crimping that manifest only after thermal expansion in hotel guest room renovations. Never omit drip loops in vertical cable runs; water tracking into mall facade connectors remains a leading cause of short circuits during monsoon seasons.

Why Choose Beauty STC Lighting

Looking for reliable connectors for LED lights? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting solutions. Our precision-engineered connectors ensure seamless integration, durability, and optimal performance for a wide range of lighting applications. Whether you’re working on residential, commercial, or industrial projects, we provide connectors that meet rigorous industry standards.

Take your LED lighting projects to the next level by collaborating with a team committed to innovation and excellence. For inquiries and personalized support, contact us at [email protected]. Let Beauty STC be your preferred partner in lighting connectivity solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.