Article Contents

Industry Insight: Connectors For Led Light Strips

In the rapidly evolving landscape of commercial and industrial lighting, the demand for reliable, efficient, and code-compliant components has never been greater. Among these critical components, connectors for LED light strips play a pivotal role in ensuring seamless integration, long-term durability, and optimal performance across large-scale installations. As facilities increasingly shift from traditional lighting systems to energy-efficient LED solutions, the importance of high-quality connectors—capable of withstanding demanding environments while maintaining electrical integrity—has become a key consideration for engineers, contractors, and facility managers.

Regulatory compliance is paramount in commercial and industrial applications, where safety and performance standards are strictly enforced. Connectors that meet recognized certifications such as ETL and CE are essential to ensure compatibility with regional electrical codes and to provide assurance of rigorous testing for safety, durability, and performance under real-world conditions. These certifications not only facilitate smoother project approvals but also minimize the risk of field failures, downtime, and costly maintenance.

Since its founding in 1998, Beauty (STC) Manufacturing Co., Ltd. has established itself as a trusted leader in the LED lighting components industry. With over two decades of engineering expertise, Beauty STC specializes in designing and manufacturing high-performance connectors tailored for commercial and industrial LED lighting systems. The company’s commitment to innovation, precision manufacturing, and compliance with international standards—including ETL and CE—has made its products a preferred choice for professionals seeking reliability and scalability in their lighting installations. As the industry continues to advance, Beauty STC remains at the forefront, delivering solutions that combine technical excellence with real-world applicability.

Technical Specs & Certifications

Connectors for LED light strips serve a critical mechanical and electrical function but do not possess inherent lumens per watt or CRI specifications. These performance metrics are exclusively properties of the LED light strip itself, determined by the semiconductor chips, phosphor formulation, driver efficiency, and optical design. Connectors are passive components whose role is to maintain the electrical integrity and physical connection between segments of LED strip or to power sources without degrading the strip’s specified performance. At Beauty STC Manufacturing Co., Ltd., we engineer our connectors to ensure they do not introduce voltage drop, signal loss, or thermal issues that could compromise the lumens per watt output or color fidelity of high-CRI LED strips.

When specifying connectors for applications requiring CRI >90 and high lumens per watt efficiency, the connector’s electrical characteristics become paramount. Our connectors utilize high-conductivity copper alloy contacts with 24k gold plating to minimize resistance and prevent oxidation, ensuring stable current delivery. This is essential because even minor voltage drop across a poor connection can reduce the actual lumens output and potentially shift color temperature on sensitive high-CRI strips. Beauty STC connectors are rated for the continuous current load of the connected LED strip, typically supporting 5A to 10A per channel depending on the series, with strict adherence to voltage drop specifications below 0.5% under full load to preserve the strip’s designed efficacy.

IP ratings are a direct function of the connector’s sealing design and materials. Beauty STC offers connectors across the IP spectrum to match the LED strip’s environmental requirements. For indoor dry locations, our basic IP20 snap-connectors provide secure mechanical joining. For damp or outdoor applications requiring IP65, IP67, or IP68 ratings, we utilize precision-molded polycarbonate or silicone housings with integrated EPDM rubber gaskets. These undergo rigorous 30-minute submersion testing at 1 meter depth for IP68 validation. Critical to maintaining high IP ratings is our proprietary double-sealing mechanism on cable entries and mating surfaces, preventing moisture ingress that could cause corrosion, short circuits, or failure of the connected high-CRI LED system. All IP-rated connectors are thermally stable from -40°C to +85°C to withstand environmental stress without compromising the seal.

Beauty STC’s quality differentiation lies in our manufacturing rigor and material science expertise. Every connector undergoes 100% automated contact resistance testing and high-potential (hi-pot) dielectric strength verification at 1500V AC. We source only UL94-V0 flame-retardant materials and implement six-sigma process controls in our ISO 9001-certified facilities. Our gold-plated contacts feature a minimum 0.3μm plating thickness—exceeding industry standards—to ensure 50,000+ mating cycles without performance degradation. This precision engineering guarantees that when used with CRI>90, high-efficacy LED strips, Beauty STC connectors maintain the system’s photometric integrity over the product lifetime, preventing the lumen depreciation and color shift that often plague inferior connection solutions. We provide comprehensive compatibility matrices matching our connectors to specific LED strip voltage and density requirements, ensuring optimal performance retention in professional lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern and well-equipped facility specializing in the production of LED lighting components and related electronic assemblies. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from excellent logistics infrastructure and access to a robust supply chain, enabling efficient manufacturing and timely delivery.

The factory is outfitted with advanced SMT (Surface Mount Technology) production lines, which are critical for high-precision assembly of LED light strip components. These SMT machines are automated and capable of placing small electronic components such as resistors, capacitors, and ICs onto printed circuit boards (PCBs) with high speed and accuracy. The use of reflow soldering and automated optical inspection (AOI) systems ensures consistent quality and reliability of the electronic assemblies used in LED lighting products.

A key part of the factory’s quality assurance process is the aging test station. Every batch of products, including connectors for LED light strips, undergoes rigorous aging tests under controlled conditions. These tests simulate extended operation over time to identify early failures and ensure long-term performance and durability. The aging process typically involves powering the products continuously at elevated temperatures for several hours to days, depending on product specifications.

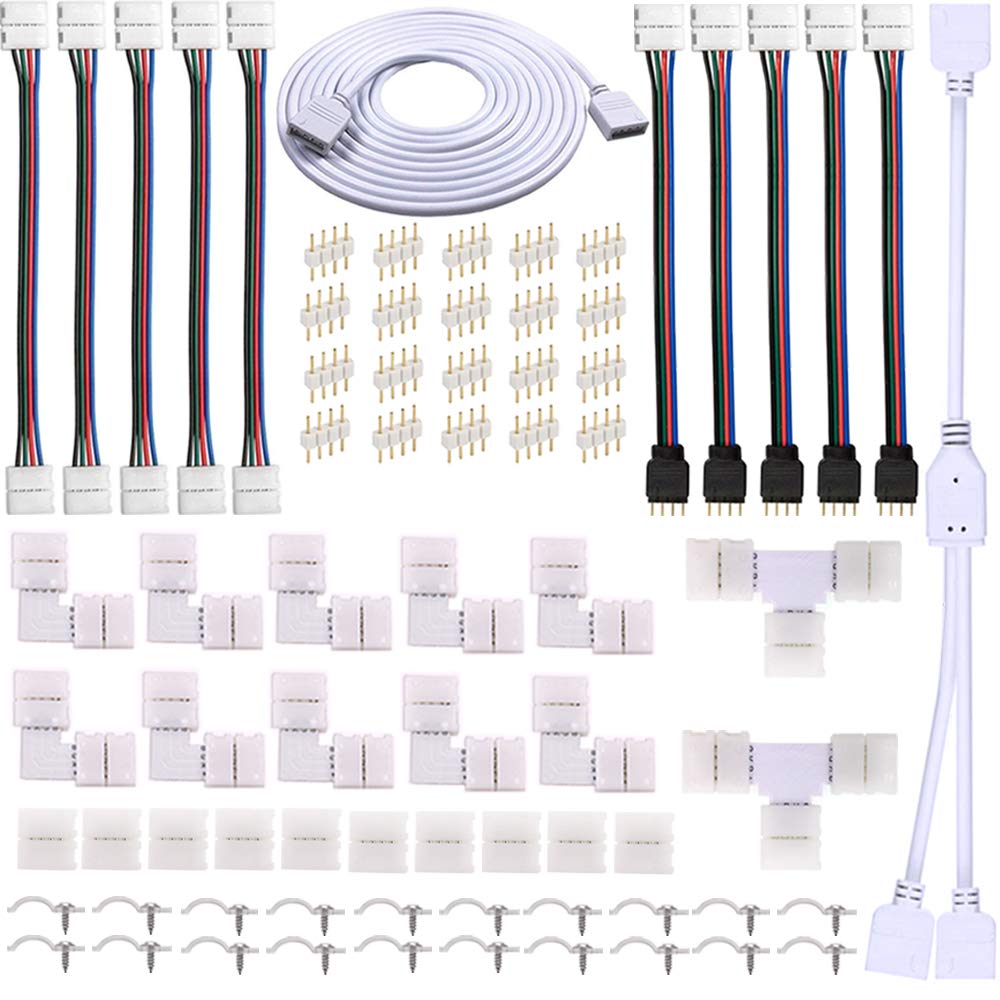

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities and actively supports custom manufacturing for clients. For connectors used in LED light strips, the company can customize design, size, pin configuration, material selection (such as phosphor bronze or brass with nickel or gold plating), and packaging to meet specific client requirements. The factory’s engineering team works closely with clients to develop prototypes, perform testing, and scale up to mass production efficiently. This flexibility, combined with in-house tooling and molding support, allows Beauty STC to deliver tailored solutions with short lead times.

Overall, the Jiangmen factory combines advanced automation, stringent quality control, and responsive OEM services to serve a wide range of customers in the LED lighting industry, particularly those requiring reliable and customized connectors for flexible LED strips and other lighting applications.

Application Scenarios

Connectors for LED light strips serve as critical junction points in professional lighting installations across hospitality, retail, and commercial environments. Their strategic use ensures electrical continuity, simplifies maintenance, and maintains aesthetic integrity where direct soldering or hardwiring is impractical. In hotels, connectors are essential for guest room ambient lighting within crown molding coves, headboard niches, and vanity mirror perimeters where disassembly for bulb replacement is impossible. They enable modular service access behind reception desks and concierge areas without dismantling entire architectural features. High-end resorts also utilize waterproof connectors in pool perimeter channels and spa steam rooms where IP68-rated strip segments require secure, tool-free separation points for filter access.

Malls deploy connectors extensively in suspended ceiling coves for indirect illumination along walkways, allowing segmented power distribution that isolates faults in high-traffic zones. Retail signage applications rely on right-angle connectors to link strip sections within lightbox frames, accommodating tight bends around letter contours while enabling individual sign module replacement. Critical usage occurs in display window mannequin spotlights where vibration-resistant connectors withstand frequent seasonal set changes, and within merchandise shelving where under-shelf strips connect to vertical accent strips at display corners without visible wiring.

Office environments mandate connectors for under-cabinet task lighting in kitchenettes and pantry areas where staff frequently reconfigure layouts. They prove indispensable in modular desk partitions where LED strips illuminate cable management troughs, permitting workstation reconfiguration without rewiring entire floors. Conference rooms use low-profile connectors within suspended ceiling baffles to join strips forming linear glare shields over presentation walls, while executive suites employ them in floating ceiling reveals where maintenance access panels necessitate demountable strip sections.

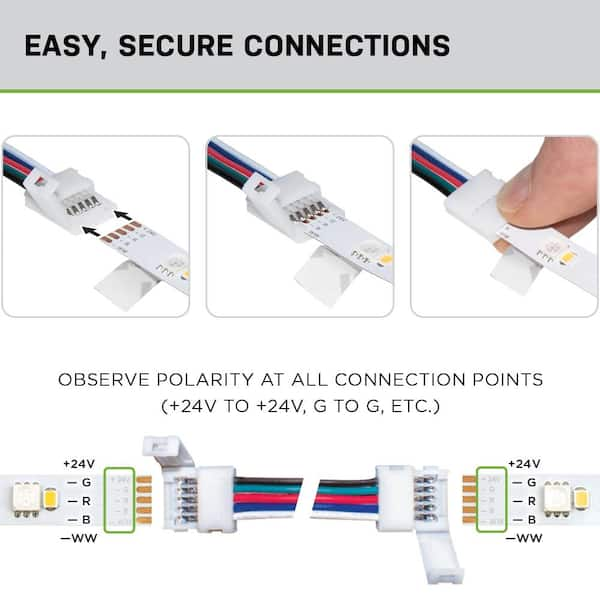

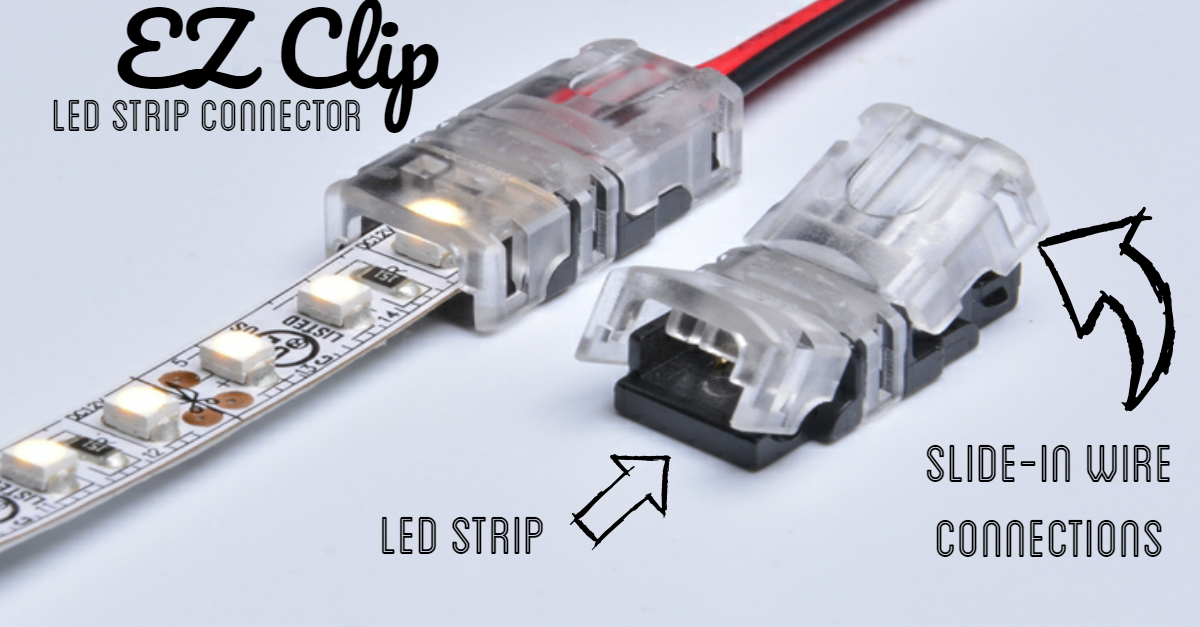

Installation requires strict adherence to electrical specifications. Always verify connector current rating exceeds the strip’s maximum draw by 20% to prevent thermal runaway; a common oversight occurs when linking multiple strips through a single connector rated only for one segment. For indoor dry locations like offices, use insulated push-in connectors with strain relief clamps, ensuring the strip’s copper pads make full contact before locking the housing—partial insertion causes arcing. In humid hotel bathrooms or mall food courts, specify silicone-sealed connectors with IP67 minimum rating and apply dielectric grease to terminals before assembly to prevent corrosion. Never exceed the manufacturer’s maximum daisy-chain length through connectors; voltage drop accumulates at each junction, causing end-of-run dimming in long mall corridor installations. When mounting in aluminum extrusions, confirm the connector body doesn’t bridge the extrusion’s grounding path to avoid short circuits. Finally, document all connection points with labels during installation—this reduces troubleshooting time during hotel renovations where maintenance crews often unknowingly cut live connectors during ceiling work.

Why Choose Beauty STC Lighting

Looking for reliable connectors for LED light strips? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting solutions. Our precision-engineered connectors ensure seamless installation and long-lasting performance for any lighting project. Whether you’re working on residential, commercial, or industrial applications, we deliver durability and consistency you can count on.

Take the next step in enhancing your product line with superior connectivity solutions. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your business goals.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.