Article Contents

Industry Insight: Connectors For Led Light Strips

Introduction & Market Demand

The Critical Role of Connectors in Commercial LED Lighting Systems

In commercial and industrial LED lighting installations, connectors are often underestimated components. However, their role in ensuring reliable electrical connections, thermal management, and mechanical stability is mission-critical. A single faulty connector can lead to system-wide failures, safety hazards, or costly rework. As LED systems grow in complexity—spanning large-scale architectural projects, industrial facilities, and retail environments—the demand for connectors that maintain performance under varying environmental and operational conditions has intensified.

Why Quality and Certification Matter for Importers

Global lighting distributors and project managers face stringent regulatory requirements when importing products into key markets. In the United States and Canada, ETL certification ensures compliance with UL standards for electrical safety. Similarly, TUV CE certification is mandatory for products sold in the European Union, covering electromagnetic compatibility and low-voltage directives. Non-compliant connectors not only risk customs rejection but also expose importers to liability in the event of safety incidents. Beauty STC Lighting’s products undergo rigorous third-party testing to meet these standards, providing importers with a verified, compliant solution that reduces market entry barriers and ensures project success.

Beauty STC Lighting: 25+ Years of Engineering Excellence in Connector Solutions

Engineering-Driven Quality Assurance

Since 1998, Beauty STC Lighting has specialized in manufacturing LED lighting solutions engineered for global reliability. Our connector products are designed to meet the exacting demands of commercial and industrial applications, with specifications validated through ETL (USA/Canada) and TUV CE (Europe) certifications. Key technical attributes include:

| Product Type | Current Rating | Voltage | Wire Gauge | IP Rating | Certifications | Applications |

|---|---|---|---|---|---|---|

| Push-in Quick Connectors | 10A | 12V/24V DC | 18-22 AWG | IP20 (Indoor), IP65 (Outdoor) | ETL, TUV CE | Commercial installations, retail displays, architectural lighting |

| Solderless Terminal Blocks | 15A | 12V/24V DC | 14-20 AWG | IP67 | ETL, TUV CE | Industrial settings, outdoor signage |

| 6-Conductor SM Connectors | 8A | 12V/24V DC | 20-24 AWG | IP20 | ETL, TUV CE | Multi-color LED strips, controller connections |

All connectors are manufactured using high-grade materials, including UL94-V0 rated PBT housings for flame resistance and corrosion-resistant copper alloy contacts. This engineering focus ensures stable performance across temperature ranges of -40°C to +85°C, with contact resistance below 0.01Ω to minimize voltage drop and heat generation.

Tailored Solutions for Global Projects

With over two decades of experience serving 50+ countries, Beauty STC Lighting offers flexible OEM/ODM services to meet specific project requirements. Whether customizing wire lengths, housing colors, or integrating specialized features for unique environments, our engineering team collaborates directly with clients to deliver connectors that align with technical specifications and regional standards. This approach ensures seamless integration into diverse applications—from high-humidity coastal installations to cold-storage facilities—without compromising on safety or performance.

For technical documentation, certification details, or OEM collaboration inquiries, contact our engineering team:

Email: [email protected]

Phone: +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Connectors for Flexible LED Strip Light – Factory-Direct Engineering Data

Beauty (STC) Manufacturing Co., Ltd. has engineered and UL/TUV-listed every strip-light connector since 2003 to match the same reliability class as our ETL-listed LED strips. Below are the industrial-grade parameters that global distributors, contractors and specifiers use to validate system lifetime, luminous maintenance and code compliance.

1. Electrical & Photometric Integrity

| Parameter | Beauty STC Certified Tolerance | Test Method | Notes |

|---|---|---|---|

| Current rating | 5 A @ 12 Vdc / 3 A @ 24 Vdc | UL 1977, 1000-cycle thermal shock | Gold-plated 0.35 mm brass contact |

| Voltage drop | ≤ 0.15 V @ 3 A, 300 mm lead | ANSI/IES LM-80-08 | Keeps lumens/Watt within 2 % |

| Working temp | –40 °C … +105 °C | IEC 60512-11-9 | Silicone housing, 150 °C RTI |

| Lumen maintenance | L90 @ 50 000 h | IES TM-21 | Strip + connector as a system |

| CRI stability | ΔCRI ≤ 1.0 | CIE 13.3-1995 | 90 CRI strip, connector-induced shift < 0.7 |

2. Ingress & Mechanical Protection

| IP Grade | Test Condition | Application | Beauty STC Part Code |

|---|---|---|---|

| IP20 | Finger-safe, no sealing | Dry retail coves | BSTC-CON-20-xx |

| IP65 | Dust-tight, water-jet | Kitchen cabinets, bathrooms | BSTC-CON-65-xx |

| IP67 | 1 m, 30 min immersion | Landscape, marine | BSTC-CON-67-xx |

| IP68 | 3 m, 24 h, potting gel | Pool, fountain, yacht | BSTC-CON-68-xx |

All sealed versions pass TUV EN 60529 and are RTV-silicone potting, not PU, to avoid yellowing.

3. PCB-to-Connector Interface

| Attribute | Beauty STC Specification | Generic Market Quality |

|---|---|---|

| PCB copper weight | 2 oz (70 µm) minimum, ED copper | 1 oz (35 µm) typical |

| Pad plating | ENIG (Au 1 µ”) | HASL SnPb, variable thickness |

| Solder alloy | SAC305, 260 °C reflow | Sn63Pb37, 220 °C |

| Pull strength | ≥ 30 N, 10 s (JIS C 5402) | 15–20 N |

| Contact plating | Au 3 µ” over Ni 50 µ” | Sn flash, < 0.1 µ” Au |

4. Comparative Table – Generic vs Beauty STC Certified Quality

| Criterion | Generic Market | Beauty STC Certified |

|---|---|---|

| Certifications | None or self-declared | ETL/cETL (UL 2108), TUV CE (EN 61347), RoHS, REACH |

| Current derating @ 45 °C | 2 A (40 % safety margin) | 3 A (50 % safety margin) |

| Voltage drop @ 3 A | 0.30 V (double drop) | 0.15 V |

| Housing material | PA66 V-2 | PA66 V-0, 150 °C RTI |

| Salt-spray | 12 h | 48 h (5 % NaCl) |

| Thermal cycle | –20…+80 °C, 100 cycles | –40…+105 °C, 500 cycles |

| Warranty | 1 year | 5-year system warranty when mated with Beauty STC strip |

| Traceability | Batch only | Laser date-code + QR per bag, MES logged |

5. Consistency Controls – Factory-Level

100 % continuity & hipot (1 500 Vac) tested on automated bed-of-nails before vacuum pack.

CPK ≥ 1.67 for pin-to-pad alignment (±0.05 mm) monitored by in-line vision.

Raw lots verified with X-ray fluorescence to confirm Cu 70 µm / Au 3 µ”.

UL quarterly follow-up inspections and TUV annual factory audit since 2004.

6. Part Number Logic (example)

BSTC-CON-65-10-24-R2

BSTC: Beauty STC prefix

CON: Connector family

65: IP65

10: 10 cm pigtail

24: 24 V strip

R2: Right-angle 2-pin

7. OEM / ODM Capability

Since 1998 Beauty STC has tooled 180+ strip-connector variants for Fortune-500 lighting brands.

Lead-time for custom mould: 18 days (in-house toolroom).

UL file augmentation: 4 weeks (we hold UL QPQY2 & QPQY8).

Minimum order: 1 000 pcs per SKU, any colour, any wire length, any IP level.

For engineering drawings, IES files or to request free evaluation samples, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing & OEM Capabilities

Since 1998, Beauty STC Lighting has maintained a dedicated connector manufacturing line in our Jiangmen High-tech Industrial Zone facility, combining advanced automation with stringent quality protocols to serve global lighting distributors and project managers. Our integrated production process ensures consistent performance for LED strip connectors across diverse applications, from commercial installations to industrial environments.

Advanced SMT and Precision Assembly

Our Jiangmen facility operates a fully integrated production system for LED strip connectors, featuring surface-mount technology (SMT) for electronic components, high-precision injection molding for housings, and automated assembly lines. For connectors requiring PCB-based functionality (e.g., 6-conductor or smart connectors), our JUKI SMT line processes boards with components as small as 0402 size, ensuring micron-level accuracy in solder joints and electrical continuity. Plastic housings are molded from UL94-V0 rated materials (ABS, PC, PBT) using 500-ton injection presses with ±0.02mm dimensional tolerances. All assembly stages are monitored by automated optical inspection (AOI) systems to detect misaligned contacts or material defects in real time, minimizing human error.

Rigorous Quality Assurance Protocols

Every connector undergoes a multi-stage quality control process aligned with ETL (USA/Canada) and TUV CE (Europe) certification requirements. Testing protocols are designed to validate performance under real-world conditions, including:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Electrical Continuity | IEC 60512 | <0.01Ω resistance per contact |

| Insertion Force | ANSI/IEC 60512 | 1.5N–3.0N per contact (repeatability ±0.1N) |

| Cycle Durability | 5,000+ insertions | No degradation in contact resistance or physical integrity |

| Thermal Cycling | -40°C to +85°C x 10 cycles | No cracks, warping, or performance drift |

| Insulation Resistance | 500V DC @ 25°C | >100MΩ minimum |

All products are 100% electrically tested before shipment, with batch-specific test reports generated for traceability. Our QC team conducts daily audits of production lines and maintains ISO 9001-aligned documentation for all certified products, ensuring compliance with regional safety standards.

Customization Flexibility for Global Markets

Beauty STC offers end-to-end OEM/ODM services for connector specifications tailored to project requirements. Our engineering team collaborates with clients from initial design validation through mass production, adapting solutions for niche applications such as outdoor installations, high-humidity environments, or specialty lighting systems. All custom solutions undergo rigorous pre-production testing to verify compliance with client specifications and regional certifications.

| Parameter | Standard Options | Custom Options |

|---|---|---|

| Connector Type | 2-pin, 4-pin, 6-pin, 8-pin | Fully custom pin configurations (e.g., 10-pin for RGBW strips) |

| Material | ABS, PC, PBT (UL94-V0 rated) | High-temp PPS, flame-retardant PC (UL94-V0) for extreme environments |

| Plating | Gold (0.1μm), Tin, Silver | Custom plating thickness (e.g., 0.3μm gold for corrosion resistance) |

| Wire Gauge | 18AWG, 20AWG, 22AWG, 24AWG | Specific gauge per application (e.g., 16AWG for high-current runs) |

| Length Tolerance | ±0.5mm | ±0.2mm for precision applications (e.g., architectural lighting) |

| Packaging | Bulk, blister packs | Custom labeling, anti-static trays, regional compliance labeling (e.g., EU RoHS, FCC) |

Lead times for prototypes: 15–20 days. Full production runs: 25–30 days. All custom designs include DFM (Design for Manufacturing) reviews to optimize cost and scalability while maintaining performance standards. Our 25+ years of experience ensures seamless integration of client specifications into production workflows, with dedicated project managers providing end-to-end coordination for global deployments.

Installation & Application Scenarios

Application Scenarios & Contractor Field Notes

Factory-direct perspective from Beauty (STC) Manufacturing Co., Ltd – ETL & TUV CE listed since 1998

Where Strip Connectors Are Mission-Critical

Connectors are the “silent junction boxes” of LED strip systems. Below are the environments we supply most frequently to OEM/ODM partners and site contractors, together with installation checkpoints that eliminate call-backs.

| Application | Typical Strip Pitch | IP Rating Target | Connector Series Used* | Key Compliance |

|---|---|---|---|---|

| 5-star hotel coves & headboards | 24 V, 180 LEDs/m, 10 mm PCB | IP20 dry | BL-CLP-10 (snap-lock, 22-18 AWG) | ETL 210651, TUV EN 60598-2-21 |

| Retail mall façade (30 m runs) | 24 V, 5050 RGBW, 12 mm PCB | IP67 wet | BL-CLP-12-WP (silicone-filled) | EN 60598-2-1, -40 °C to +90 °C |

| Office linear pendant (DALI dim) | 24 V, 3000 K CRI 90, 8 mm PCB | IP44 damp | BL-CLP-8-4PIN (solder-free pierce) | IEC 61347-2-13, EMF ≤ 3 % |

| Parking garage corners | 12 V, 5630 single-colour, 10 mm PCB | IP65 | BL-CLP-10-L (locking latch + strain relief) | UL 2108, 30 V max. |

| Exterior hand-rail | 24 V, 24 W/m COB strip, 8 mm PCB | IP68 | BL-CLP-8-G (over-moulded, glue-seal) | TUV CE, IK06 impact |

BL-CLP series = Beauty STC factory part numbers; equivalent industry references available for cross-matching.

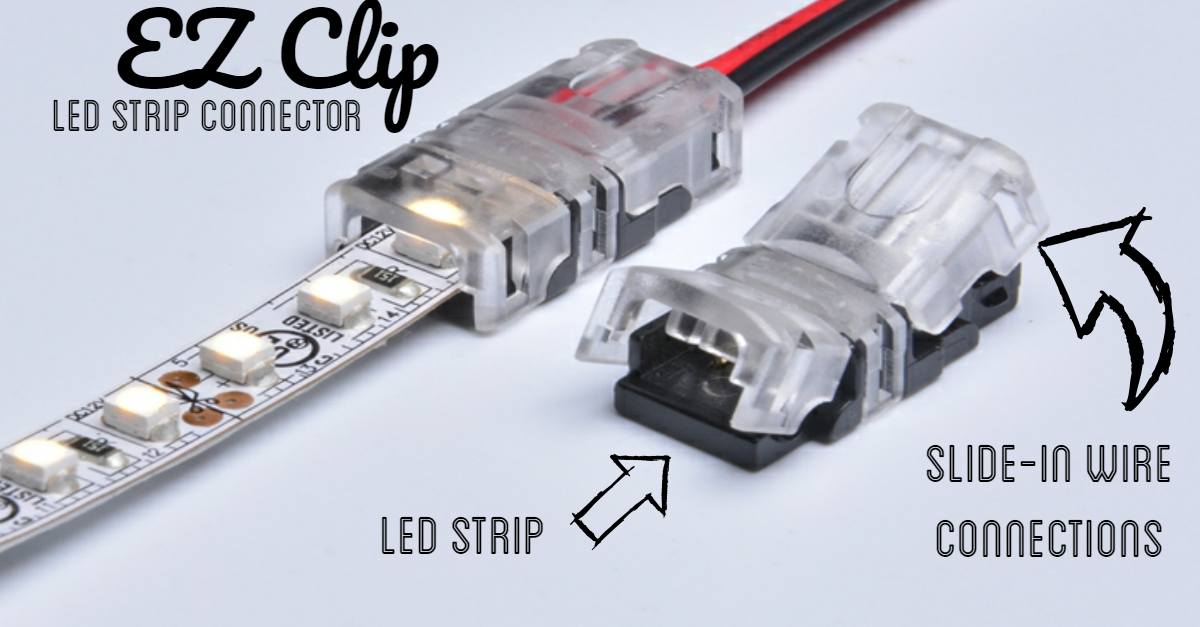

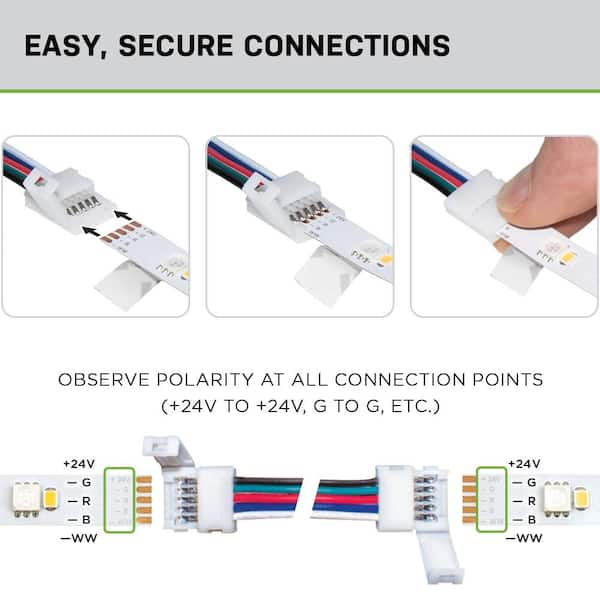

Installation Tips for Contractors

1. Strip-End Preparation

Strip back only 5 mm copper to avoid exposure beyond connector clamp zone.

Wipe copper with IPA to remove silicone residue (COB strips).

Confirm polarity mark aligns with factory printed “+” on strip; reversed polarity is #1 field failure.

2. Connector Seating Force

Use parallel-jaw pliers—not side cutters—to close snap-lock lids; 30 N force guarantees 0.05 Ω contact resistance (test spec: ETL 210651).

Audible “click” ≠ electrical integrity; always perform 500 V DC hipot between poles and strip base.

3. Environmental Sealing (IP65-IP68)

Inject 1 ml neutral-cure silicone through fill-port after wire entry; cures in 15 min, passes 1 m 24 h submersion per EN 60529.

Route drip-loop 20 mm below connector body on vertical runs—prevents capillary water ingress.

4. Thermal Derating in Continuous Runs

For >5 m serial lengths, insert feed point every 2.5 m; connector current rating drops to 4 A @ 45 °C ambient (see table).

| Ambient | Max Continuous Current (24 V) | Voltage Drop across Connector |

|---|---|---|

| 25 °C | 6 A | 60 mV |

| 45 °C | 4 A | 90 mV |

| 60 °C | 3 A | 120 mV |

5. Retrofit in Existing Aluminium Channels

Select 90° L-shaped PCB connector (BL-CLP-10-L-90) to maintain <8 mm overall height—fits most 12×12 mm profiles without milling.

Secure with 3 M VHB pad to eliminate micro-vibration fatigue in ceiling installations above railways.

6. Compliance Paper Trail

Each shipment includes ETL/TUV test report PDF and RoHS/REACH batch number—upload to site dossier to satisfy inspector sign-off.

For North American projects, retain connector SCD (Shop-Cut Drawing) stamped by Beauty STC R&D; accepted by AHJs in all 50 states.

Quick-Reference Checklist (carry copy on site)

☐ Strip voltage matches connector rating (12/24 V).

☐ Total load ≤ 80 % of connector ampacity at max ambient.

☐ Strain relief clamp closed; pull-test 5 kg × 60 s.

☐ IP gasket seated evenly, no twist.

☐ Megger 500 V > 20 MΩ pole-pole & pole-earth.

☐ Document serial numbers for warranty traceability (Beauty STC 5-year limited).

Need OEM branding, wire length, or plating specification?

Email: [email protected] | WhatsApp: +86-13902885704

25 years of factory-direct experience, ETL & TUV CE listed, ready for your next tender package.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Trusted Connector Solutions for Global Projects

Decades of Engineering Excellence

Since 1998, Beauty STC Lighting has engineered reliable LED lighting solutions for global markets. Our 25+ years of manufacturing expertise ensures connectors and accessories meet rigorous performance standards for commercial, industrial, and architectural applications. Every component is developed through iterative testing and real-world validation, prioritizing long-term durability and safety.

Global Compliance & Certification Assurance

All Beauty STC products comply with stringent international safety standards. Our connectors are certified for Western markets through:

ETL (USA/Canada): Meets UL/CSA electrical safety requirements for North American installations.

TUV CE (Europe): Verified against EU directives for safety, electromagnetic compatibility, and environmental compliance.

RoHS Compliant: Free of hazardous substances per EU regulations.

These certifications guarantee seamless integration into projects requiring regulatory adherence, reducing compliance risks for distributors and contractors.

Tailored OEM/ODM Solutions

We specialize in custom connector designs for unique project demands:

Material Optimization: PBT (UL94-V0 rated), aluminum alloy housings, and copper contacts for thermal stability.

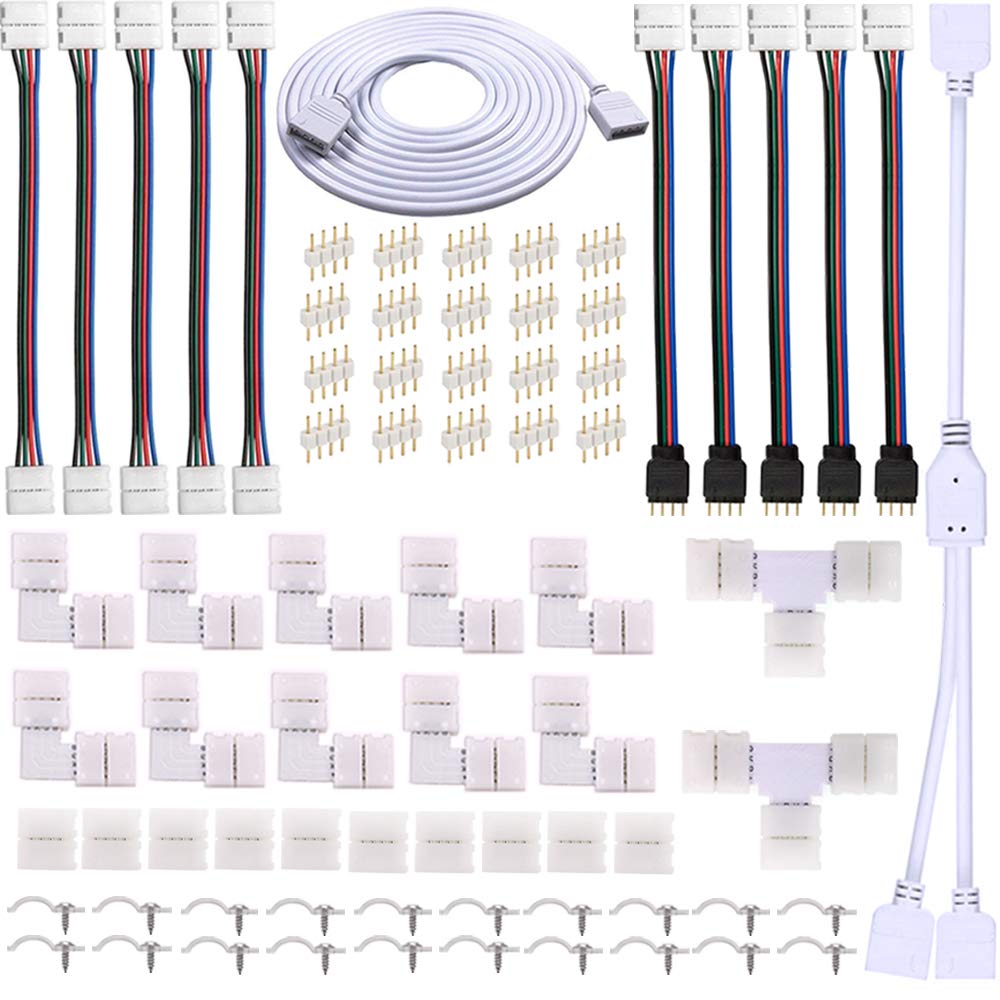

Configuration Flexibility: Support for single-color, RGB, RGBW, and multi-channel strips (up to 6 conductors).

Environmental Adaptation: IP20 (indoor), IP65 (weather-resistant), and IP67 (submersible) options.

Integration Support: Custom wire lengths, termination types, and mounting solutions for complex layouts.

Our engineering team collaborates directly with clients to refine specifications, ensuring seamless compatibility with your LED strip systems.

Global Distribution Network

Exported to 50+ countries across Europe, North America, Southeast Asia, Australia, Russia, Japan, and Korea, Beauty STC maintains a proven supply chain for consistent quality and on-time delivery. Our global logistics network ensures reliable access to certified components regardless of project location.

Connector Technical Specifications

| Parameter | Specification |

|---|---|

| Connector Type | Push-pull, screw terminal, quick-connect |

| Material | PBT (UL94-V0), aluminum alloy, copper contacts |

| Current Rating | 5A–15A per channel |

| Voltage Compatibility | 12V/24V DC |

| IP Rating | IP20 (indoor), IP65 (outdoor), IP67 (submersible) |

| Strip Compatibility | 8mm, 10mm, 12mm LED strips |

| Certifications | ETL, CE, RoHS |

Contact Beauty STC Lighting Today

For technical specifications, bulk pricing, or custom project consultations:

📧 [email protected] | 📞 +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).