Article Contents

Industry Insight: Connector Strip For Lighting

Connector strips for lighting have become an essential component in modern commercial and industrial lighting systems, enabling efficient, modular, and scalable installations. As businesses and facilities increasingly prioritize energy efficiency, ease of maintenance, and design flexibility, the demand for reliable and code-compliant electrical connectivity solutions continues to grow. In such environments—ranging from retail spaces and office buildings to warehouses and manufacturing plants—connector strips offer a secure and streamlined method for linking linear and modular LED luminaires, reducing installation time and minimizing electrical failures.

Safety and compliance are paramount in these applications, making certifications such as ETL and CE critical benchmarks for product acceptance. ETL listing ensures compliance with North American safety standards under the Intertek program, while the CE marking certifies conformity with health, safety, and environmental protection standards within the European Economic Area. These certifications not only demonstrate a product’s reliability and adherence to rigorous testing protocols but also facilitate market access and customer confidence across global supply chains.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-performance electrical components for the lighting industry. With over two decades of expertise, Beauty STC specializes in innovative connector solutions that meet the evolving needs of commercial and industrial lighting projects. The company’s commitment to quality, precision engineering, and regulatory compliance has made its connector strips a preferred choice for lighting manufacturers and system integrators worldwide.

Technical Specs & Certifications

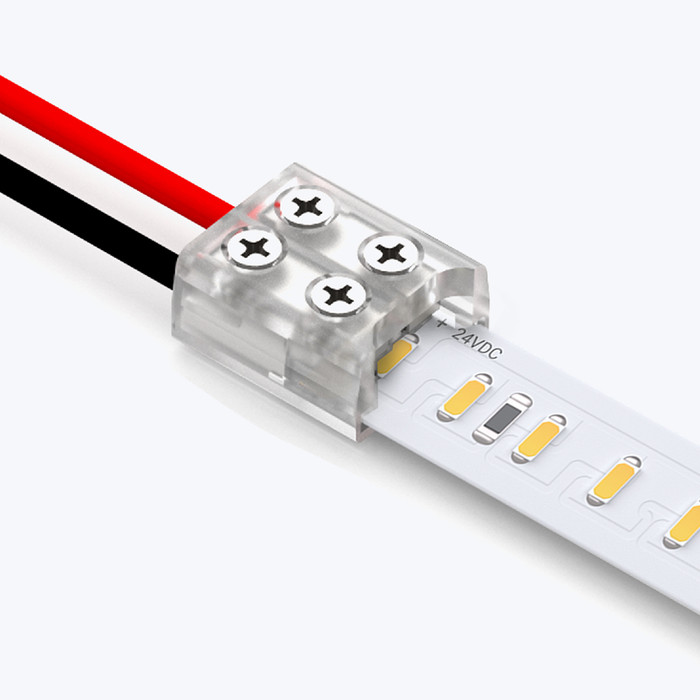

Connector strips for LED lighting systems serve as critical interconnect components between power sources, control systems, and LED modules or linear lighting profiles. It is essential to clarify that connector strips themselves do not generate light and therefore do not possess inherent lumens per watt (lm/W) or Color Rendering Index (CRI) values. These specifications pertain exclusively to the LED light engines or modules they connect. However, the quality and design of the connector strip directly impact the performance, reliability, and longevity of the entire lighting system, ensuring the LED modules operate at their specified efficiency and color accuracy. Beauty STC Manufacturing Co., Ltd. designs and manufactures connector strips to stringent standards that support high-performance lighting applications demanding lm/W efficiency exceeding 130-150+ and CRI >90.

Lumens per watt specifications are a function of the LED chip technology, driver efficiency, thermal management, and optical design within the actual light-emitting module. Beauty STC’s connector strips are engineered to minimize power loss and voltage drop across connections. Our strips utilize high-conductivity copper alloy contacts with gold or tin plating to ensure low resistance, typically maintaining voltage drop below 2% over standard run lengths. This precision minimizes energy waste as heat at the connection point, allowing the connected LED modules to achieve and sustain their rated lm/W efficiency. Poor quality connectors with higher resistance can degrade system efficiency by several percentage points, a critical factor in energy-sensitive installations where Beauty STC’s components excel.

Regarding CRI >90 requirements, which indicate exceptional color fidelity crucial for retail, museums, and high-end architectural lighting, the connector strip plays a vital role in signal integrity. For systems utilizing tunable white or RGBW LEDs requiring precise current control for accurate color rendering, Beauty STC connector strips feature robust shielding and optimized contact geometry. This prevents signal interference, flicker, and color shift that can occur with inferior connectors due to poor contact or electromagnetic interference. Our strips ensure stable, clean power and data transmission, allowing the LED driver and modules to consistently deliver the high CRI output specified, without color deviation over time or under load.

IP ratings are a direct specification for connector strips, defining their ingress protection against dust and moisture. Beauty STC offers connector strips rated to IP67 and IP68 standards, suitable for demanding environments. An IP67 rating guarantees protection against temporary immersion in water up to 1 meter for 30 minutes, while IP68 signifies suitability for continuous submersion under conditions specified by the manufacturer, typically exceeding 1.5 meters. This is achieved through precision-molded silicone or thermoplastic elastomer (TPE) gaskets, seamless overmolding techniques, and corrosion-resistant housings made from UV-stabilized polycarbonate or nylon. These rigorous sealing standards ensure reliability in outdoor facade lighting, landscape installations, wet indoor areas like pools or showers, and industrial settings where exposure to dust, rain, or hose-down cleaning occurs.

Beauty STC’s commitment to quality is embedded throughout the connector strip manufacturing process. We adhere to ISO 9001 quality management systems and perform 100% functional testing on critical parameters including contact resistance, insulation resistance, and dielectric strength. Our materials are rigorously sourced and tested for flame resistance (UL94 V-0/V-2), UV stability, and thermal endurance up to 105°C. Each batch undergoes accelerated life testing simulating 50,000+ mating cycles and extended exposure to thermal cycling (-40°C to +85°C) and humidity (85% RH). This meticulous approach ensures Beauty STC connector strips provide exceptional mechanical durability, consistent electrical performance, and long-term reliability, forming a dependable foundation for high-efficiency, high-CRI lighting systems in even the most challenging applications. The absence of flicker, color shift, or premature failure in the field directly reflects the superior engineering and quality control applied to these critical interconnect components.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility located in Jiangmen, Guangdong Province, a region known for its robust industrial infrastructure and strategic logistics advantages in southern China. The Jiangmen factory is purpose-built for the production of LED lighting components and systems, featuring advanced automation and strict quality control processes to meet international standards.

At the core of the factory’s production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable high-precision placement of electronic components onto printed circuit boards. These machines support rapid, accurate assembly of lighting control boards and related electronics, ensuring consistency and reliability in every batch. The SMT line is integrated with automated optical inspection (AOI) systems to detect placement errors and soldering defects early in the process, minimizing rework and enhancing yield rates.

To ensure long-term product reliability, the factory conducts comprehensive aging tests on finished goods and critical sub-assemblies. These tests simulate extended operational conditions by subjecting products to prolonged power cycling, elevated temperatures, and thermal stress environments. For connector strips and other lighting components, this process verifies electrical stability, thermal performance, and durability over time, helping to meet the stringent requirements of global markets.

Beauty STC has strong OEM capabilities, particularly in the design and manufacturing of customized connector strips for LED lighting applications. The company supports clients in developing tailored solutions, from prototyping and material selection to full-scale production. Whether it’s specifying pitch dimensions, contact materials, insulation types, or integration with specific LED profiles or drivers, the engineering team works closely with partners to deliver reliable, code-compliant connector systems. The factory’s flexible manufacturing setup allows for both low-volume custom runs and high-volume production, making it well-suited for a diverse range of lighting OEMs and system integrators.

Overall, the Jiangmen facility combines advanced equipment, rigorous testing, and responsive engineering support to deliver high-quality, customized lighting components that meet the evolving needs of the global market.

Application Scenarios

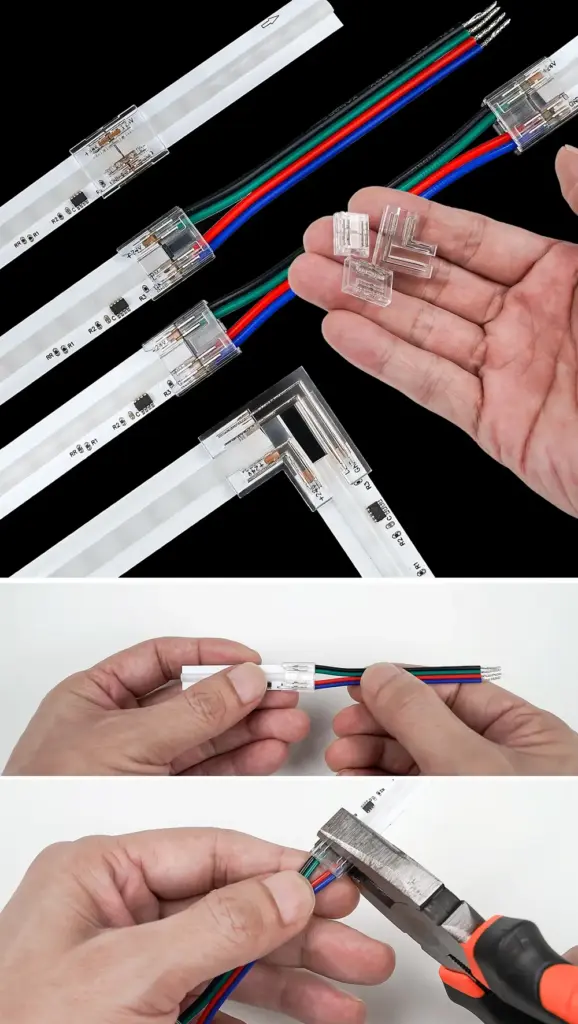

Connector strips for lighting, specifically referring to modular connection systems used in linear LED fixture installations, serve critical roles in creating seamless, continuous illumination across commercial environments. At Beauty (STC) Manufacturing Co., Ltd., we design these components to ensure reliable electrical continuity, mechanical stability, and thermal management in high-demand settings. Their application varies significantly by venue due to distinct functional and aesthetic requirements.

In hotels, connector strips are predominantly used in lobbies, ballrooms, and guest room corridors where uninterrupted ambient lighting enhances perceived space and luxury. They enable precise alignment of recessed linear fixtures in cove lighting or suspended ceiling grids, eliminating visible gaps that disrupt the serene atmosphere expected in hospitality spaces. For instance, in high-end hotel lobbies, connector strips allow for mile-long runs of indirect lighting along architectural features, maintaining uniform brightness without hotspots. Installation here demands attention to thermal expansion; always leave 1-2 mm expansion gaps between fixtures in runs exceeding 10 meters, especially in climate-controlled environments where temperature fluctuations can cause aluminum channels to contract or expand. Secure mounting to stable substrates like steel framing—not drywall alone—is non-negotiable to prevent sagging over time, which compromises both aesthetics and electrical safety.

Malls leverage connector strips extensively in retail storefronts, food courts, and large atrium ceilings where bright, consistent illumination drives consumer engagement. Connector strips facilitate the creation of expansive, gap-free lighting planes above merchandise displays or walkways, critical for highlighting products without shadows. In food court settings, prioritize IP65-rated connector strips to withstand steam and frequent cleaning, and ensure all connections are positioned away from direct water exposure zones. During installation, voltage drop becomes a primary concern in mall-scale runs; never exceed the manufacturer’s specified maximum run length per circuit—typically 30-50 meters for 24V systems—and always verify voltage at the end of the run with a multimeter before finalizing. Additionally, mall foot traffic induces vibration, so use anti-vibration mounting clips and reinforce connections every 1.5 meters to prevent wire fatigue and flickering.

Offices deploy connector strips in open-plan workspaces, conference rooms, and perimeter ceilings to achieve glare-free, uniform task lighting that supports productivity. They are ideal for creating seamless T-bar grid integrations or suspended linear arrays that minimize visual clutter. In office environments, where fixtures often integrate with occupancy sensors or daylight harvesting systems, connector strips must maintain signal integrity; avoid running data and power lines in the same connector channel to prevent electromagnetic interference. Installation here requires meticulous attention to alignment tolerances—misalignment beyond 0.5 mm becomes visually apparent under flat ceiling tiles. Always use laser levels during mounting, and ensure connectors are fully seated with a distinct audible click to prevent intermittent connections that disrupt dimming performance. Crucially, in offices with raised floors, route wiring through designated service channels rather than daisy-chaining connectors through structural voids to comply with fire safety codes.

Universal installation best practices apply across all venues. Never force connectors; if resistance is felt during mating, disengage and inspect for debris or pin misalignment—a common issue causing premature failure. Torque connection screws to precisely 0.8–1.0 Nm using a calibrated tool to avoid stripping threads or creating cold joints. Test the entire circuit under load for at least 30 minutes before closing ceilings to catch thermal issues early. Finally, strictly adhere to local electrical codes: Beauty (STC) systems require connections to be accessible for maintenance, so never embed connectors within plaster or permanent structures. These steps ensure longevity, safety, and optimal performance of your lighting installation.

Why Choose Beauty STC Lighting

Looking for a reliable connector strip for your lighting projects? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in high-quality LED lighting solutions. Our precision-engineered connector strips ensure seamless integration, durability, and optimal performance across a wide range of lighting applications.

At Beauty STC, we combine advanced manufacturing techniques with rigorous quality control to deliver products that meet international standards. Whether you’re working on commercial, residential, or industrial lighting, our connector strips provide the reliability and efficiency you need.

Contact us today to learn more and enhance your lighting systems with Beauty STC. Email our team at [email protected] and take the first step toward a successful partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.