Article Contents

Industry Insight: Cob Vs Smd

In the evolving landscape of commercial and industrial lighting, the choice between COB (Chip-on-Board) and SMD (Surface-Mounted Device) LED technologies continues to shape performance, efficiency, and long-term reliability. As facility managers, lighting designers, and electrical contractors seek optimal solutions for high-bay fixtures, warehouse lighting, and large-scale indoor environments, understanding the nuanced advantages of each technology is critical. COB LEDs offer superior lumen density and uniform light distribution, making them ideal for applications requiring high-intensity illumination with minimal glare. On the other hand, SMD LEDs provide greater design flexibility, improved thermal management, and cost-effective scalability across a wide range of commercial installations.

Regulatory compliance further influences these decisions, with certifications such as ETL and CE playing a pivotal role in ensuring product safety, electromagnetic compatibility, and adherence to North American and European market standards. These certifications are not just benchmarks for quality—they are essential for project approvals and code compliance in industrial settings.

At Beauty (STC) Manufacturing Co., Ltd., established in 1998, we have been at the forefront of LED innovation, delivering high-performance lighting solutions tailored for demanding commercial and industrial environments. With decades of engineering expertise and a commitment to rigorous testing and certification, Beauty STC provides reliable, energy-efficient COB and SMD lighting systems that meet the highest international standards. Our products are designed to deliver lasting value through superior optical control, thermal stability, and certification readiness—ensuring peace of mind for specifiers and end users alike.

Technical Specs & Certifications

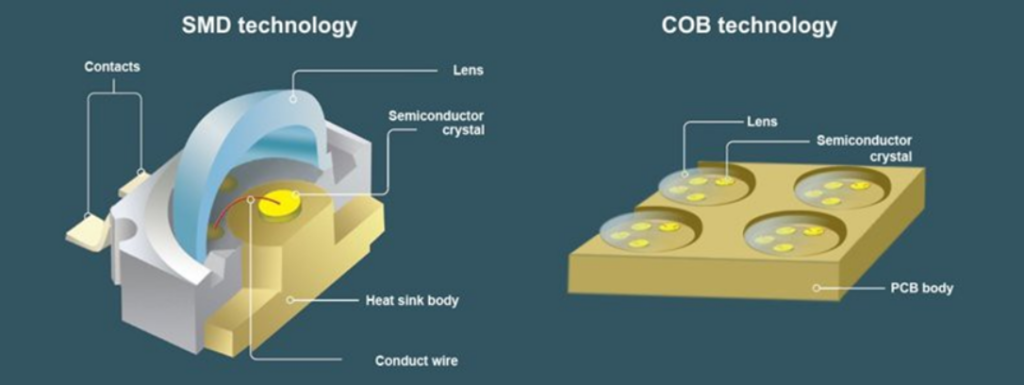

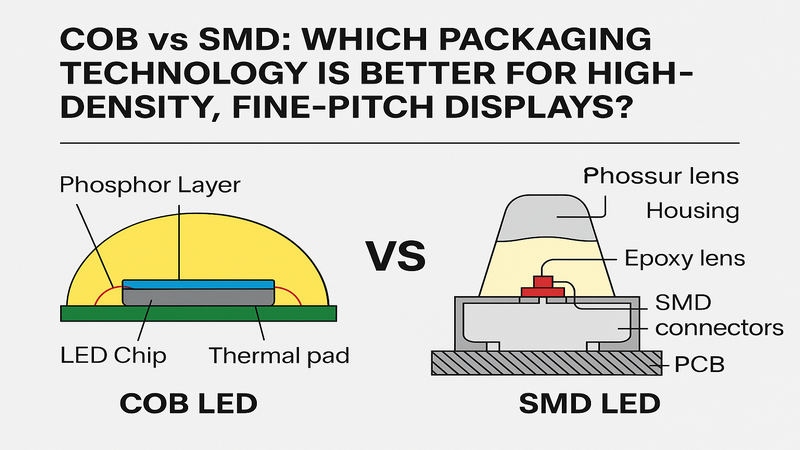

COB (Chip-on-Board) and SMD (Surface-Mounted Device) represent fundamentally different LED packaging technologies, each with distinct performance characteristics relevant to high-quality lighting applications. Understanding their technical specifications is critical for selecting the appropriate solution, especially when prioritizing efficiency, color fidelity, and environmental resilience. Beauty STC Manufacturing Co., Ltd. rigorously engineers both platforms to exceed industry benchmarks, ensuring reliability and performance consistency in demanding environments.

Lumens per Watt (lm/W) efficiency is a key metric for energy-conscious lighting. SMD LEDs, utilizing multiple discrete diodes mounted on a substrate, typically achieve slightly higher peak laboratory efficiencies, often ranging from 140 lm/W to 160 lm/W for top-bin 2835 or 3030 packages under ideal thermal conditions. COB technology integrates numerous LED chips directly onto a single ceramic or metal substrate, creating a unified light source. While COB historically lagged slightly, advanced thermal management and phosphor optimization have closed the gap significantly. Modern high-CRI COB modules from leading manufacturers like Beauty STC reliably deliver 130 lm/W to 150 lm/W. It is crucial to note that real-world system efficiency depends heavily on thermal design, driver quality, and optical components. Beauty STC’s proprietary thermal interface materials and heatsink designs ensure both COB and SMD solutions maintain optimal junction temperatures, maximizing sustained lumen output and preventing premature lumen depreciation, thus delivering the promised lm/W performance throughout the product lifecycle.

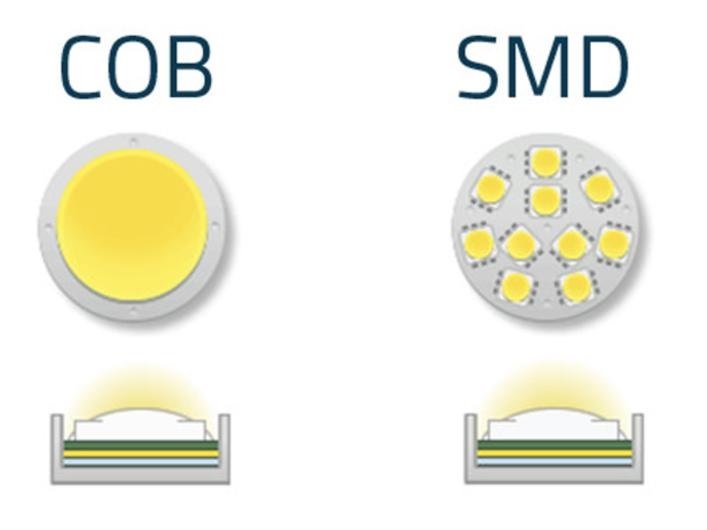

Achieving a Color Rendering Index (CRI) greater than 90, particularly with strong R9 (saturated red) values, is essential for applications requiring true-to-life color representation, such as retail, hospitality, and beauty salons. Both COB and SMD technologies can achieve CRI >90 when utilizing high-quality, multi-phosphor blends and tightly binned LED chips. SMD arrays benefit from precise binning of individual diodes, allowing for excellent color consistency across a fixture. COB’s single, dense light source inherently provides superior spatial color uniformity, eliminating the potential for color variation or “color shadows” sometimes seen in multi-SMD arrays. Beauty STC mandates CRI Ra >92 and R9 >50 across all high-CRI product lines for both COB and SMD platforms. This is achieved through stringent raw material selection, advanced phosphor formulations, and in-line spectroradiometric testing during manufacturing. Our commitment ensures consistent, vibrant color rendering critical for professional environments where color accuracy directly impacts customer experience and decision-making.

IP (Ingress Protection) ratings define resistance to dust and moisture, vital for fixtures used in bathrooms, kitchens, outdoor settings, or industrial environments. The IP rating is primarily determined by the fixture’s overall mechanical design, sealing, and housing, rather than the LED package type itself. Both COB and SMD LEDs can be successfully integrated into luminaires achieving high IP ratings like IP65 (dust-tight, low-pressure water jets) or IP67 (dust-tight, temporary immersion). However, COB’s simpler construction—featuring a single, large emitting surface with fewer solder joints compared to an array of discrete SMDs—can offer inherent advantages in robustness for high-IP applications. Fewer potential entry points for contaminants and reduced susceptibility to stress on individual solder joints under thermal cycling contribute to long-term reliability in harsh conditions. Beauty STC excels in designing and manufacturing IP65 and IP67 rated luminaires using both technologies. We employ rigorous sealing techniques including precision silicone gaskets, high-purity potting compounds for driver compartments, and seamless housing designs. Every high-IP fixture undergoes stringent third-party testing for dust ingress, water resistance, and thermal cycling to guarantee performance in challenging environments, reflecting our adherence to ISO 9001 quality management systems and commitment to exceeding customer expectations for durability.

Beauty STC’s quality differentiation lies in our vertical integration and uncompromising process control. We utilize only Epistar, Samsung, or Nichia LED chips meeting our strict binning criteria for flux and color. Our manufacturing facilities implement automated optical inspection (AOI) and 100% photometric and electrical testing, ensuring every COB module and SMD array meets or exceeds the specified lm/W, CRI >90, and thermal performance targets before integration. Advanced thermal management is core to our design philosophy, utilizing aluminum substrates with optimized thermal vias and high-conductivity thermal pads to minimize thermal resistance. This focus on thermal performance directly translates to sustained high efficiency, exceptional lumen maintenance (L90/B10 > 50,000 hours per LM-80 data), and consistent color quality over time. Beauty STC luminaires carry a minimum 5-year warranty, a testament to our confidence in the reliability and performance of both our COB and SMD-based lighting solutions under real-world operating conditions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, China, strategically located within the Pearl River Delta region known for its robust electronics and lighting supply chain. The factory is equipped with advanced surface mount technology (SMT) production lines, featuring high-precision SMT machines capable of handling complex and high-density printed circuit board (PCB) assemblies. These automated lines ensure consistent placement accuracy, improved throughput, and reliable soldering quality, which are essential for manufacturing high-performance LED lighting products.

The production process is supported by comprehensive quality control systems, including rigorous aging tests conducted in dedicated environmental chambers. These aging tests simulate extended operation under elevated temperatures and varying load conditions to verify product reliability, thermal management, and long-term performance. This ensures that every lighting fixture meets or exceeds international safety and durability standards before shipment.

Beauty STC has strong OEM/ODM capabilities, allowing customization based on client specifications. This includes tailored solutions for both COB (Chip-on-Board) and SMD (Surface Mounted Device) LED technologies. COB configurations are favored for high-intensity, uniform light output applications such as downlights and spotlights, while SMDs—particularly 2835, 5050, and 3014 types—offer flexibility in design, color mixing, and are widely used in strip lights, panels, and retrofit lamps. The factory’s technical team works closely with clients to select the optimal LED type, thermal design, driver integration, and optical components based on application requirements, enabling scalable and cost-effective manufacturing for diverse market needs.

Application Scenarios

COB and SMD LED technologies serve distinct purposes in commercial lighting, and their selection for hotels, malls, and offices hinges on specific application requirements, visual priorities, and performance needs. Understanding the core differences is essential: COB (Chip-on-Board) integrates multiple LED chips directly onto a single substrate, producing a seamless, uniform light source with minimal glare and excellent optical control. SMD (Surface-Mounted Device) uses individual LED components mounted on a board, offering greater flexibility in color tuning, higher lumen density in compact formats, and often lower initial cost, but potentially exhibiting visible point sources or “dotting” if not properly diffused.

In hotel environments, COB excels where high-quality ambient and accent lighting is critical for guest experience. Use COB downlights or track heads in lobbies, hallways, and high-end guest rooms where smooth, shadow-free illumination enhances architectural details and creates a premium, relaxing atmosphere; the lack of visible dots prevents visual discomfort in spaces with prolonged occupancy. SMD is better suited for functional areas like back-of-house staff corridors, utility rooms, or budget-conscious standard guest rooms where precise beam control is less critical, and cost efficiency or tunable white options for circadian lighting in meeting rooms may be prioritized. For installation, ensure COB fixtures in insulated ceiling cavities have adequate thermal pathways—avoid burying them under insulation without rated housings—and verify SMD strip lighting in cove applications uses diffusers to eliminate pixelation, maintaining consistent color temperature across all units by using the same manufacturing batch.

Malls demand versatile lighting for both broad area coverage and precise merchandise highlighting. COB is the superior choice for high-bay fixtures in atriums or wide corridors requiring uniform, glare-controlled illumination over large distances, and critically for retail accent lighting on display walls or mannequins where a single, intense beam without hotspots showcases products professionally. SMD shines in linear cove lighting for perimeter illumination, dynamic color-changing feature walls, or narrow aisle task lighting where tight spacing of individual emitters provides even spread, and its compatibility with advanced controls supports promotional color schemes. During installation, prioritize thermal management for high-wattage COB high-bays—mount securely to metal structures for heat dissipation—and for SMD strips in long mall runs, calculate voltage drop meticulously, using thicker gauge wire or distributed power feeds to prevent dimming at fixture ends, while ensuring all drivers are housed in accessible locations for maintenance.

Office spaces require balancing visual comfort, productivity, and energy efficiency. COB is ideal for downlights in private offices, executive suites, or conference rooms where reduced glare and a single-point source mimic natural light, minimizing eye strain during focused work; its superior optical control also benefits wall-washing in reception areas. SMD dominates in suspended troffer panels and linear task lighting across open-plan offices due to excellent diffusion through prismatic lenses, high efficacy, and options for high CRI and tunable white to support occupant well-being, while its modular nature simplifies retrofitting in grid ceilings. Key installation considerations include verifying the Upward Light Ratio (ULR) for SMD troffers to prevent ceiling cavity overheating in tightly sealed grids, and for COB downlights in offices, maintaining strict spacing-to-mounting-height ratios (typically 1.5x ceiling height) to achieve uniform desktop illuminance without pools of light, always using dedicated thermal pads if mounting directly to insulated drywall. Never compromise on thermal interface materials for high-output COB fixtures, as sustained overheating rapidly degrades lumen output and color stability in all these high-occupancy settings.

Why Choose Beauty STC Lighting

Discover the ultimate choice between COB and SMD LED technology for your lighting projects. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-performance, energy-efficient LED solutions tailored to meet diverse industrial and commercial needs. Whether you’re evaluating brightness, thermal management, or longevity, our engineering expertise ensures you get the right fit for your application.

Partner with Beauty STC to leverage cutting-edge innovation, rigorous quality control, and scalable manufacturing capabilities. Our team is ready to support your business with customized solutions and technical guidance.

For detailed insights and collaboration opportunities, contact us today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.