Article Contents

Industry Insight: Cob Lighting Strip

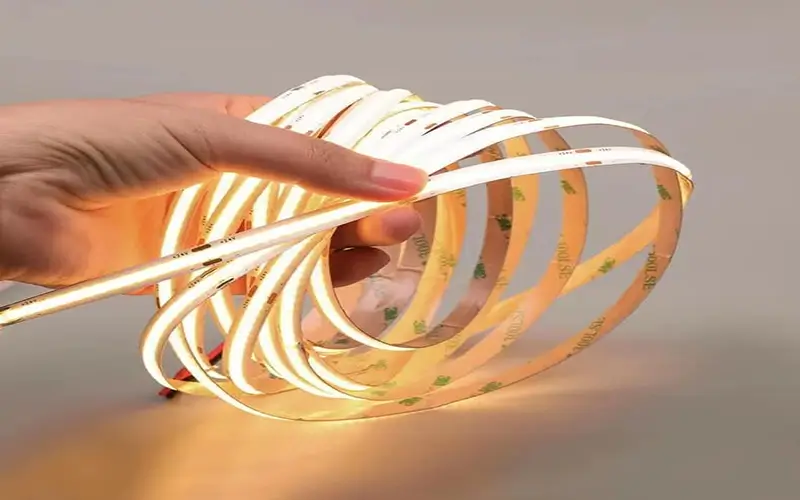

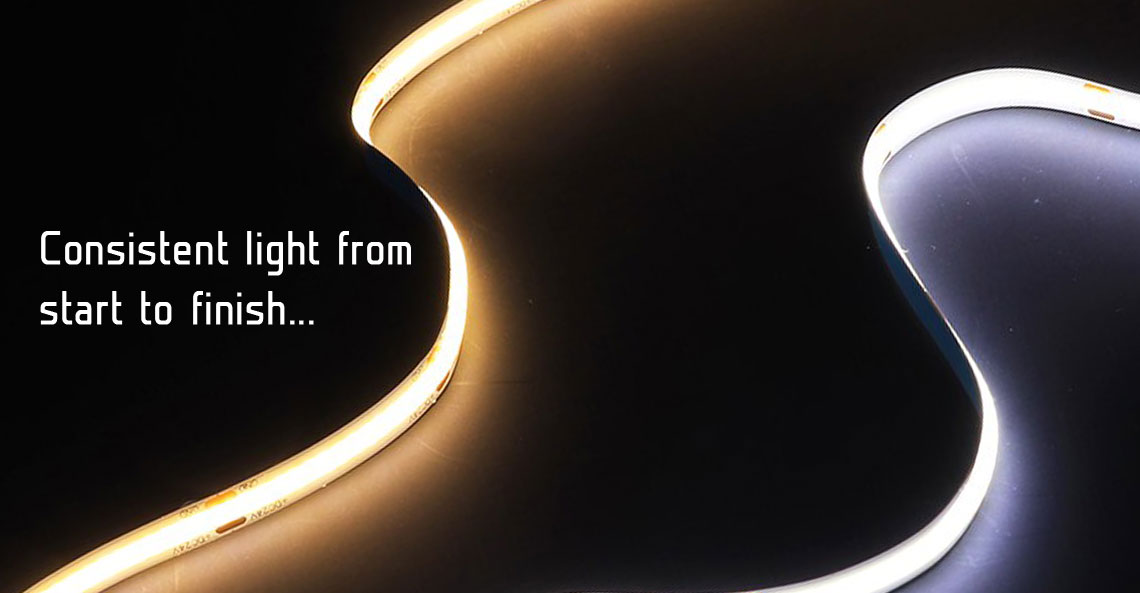

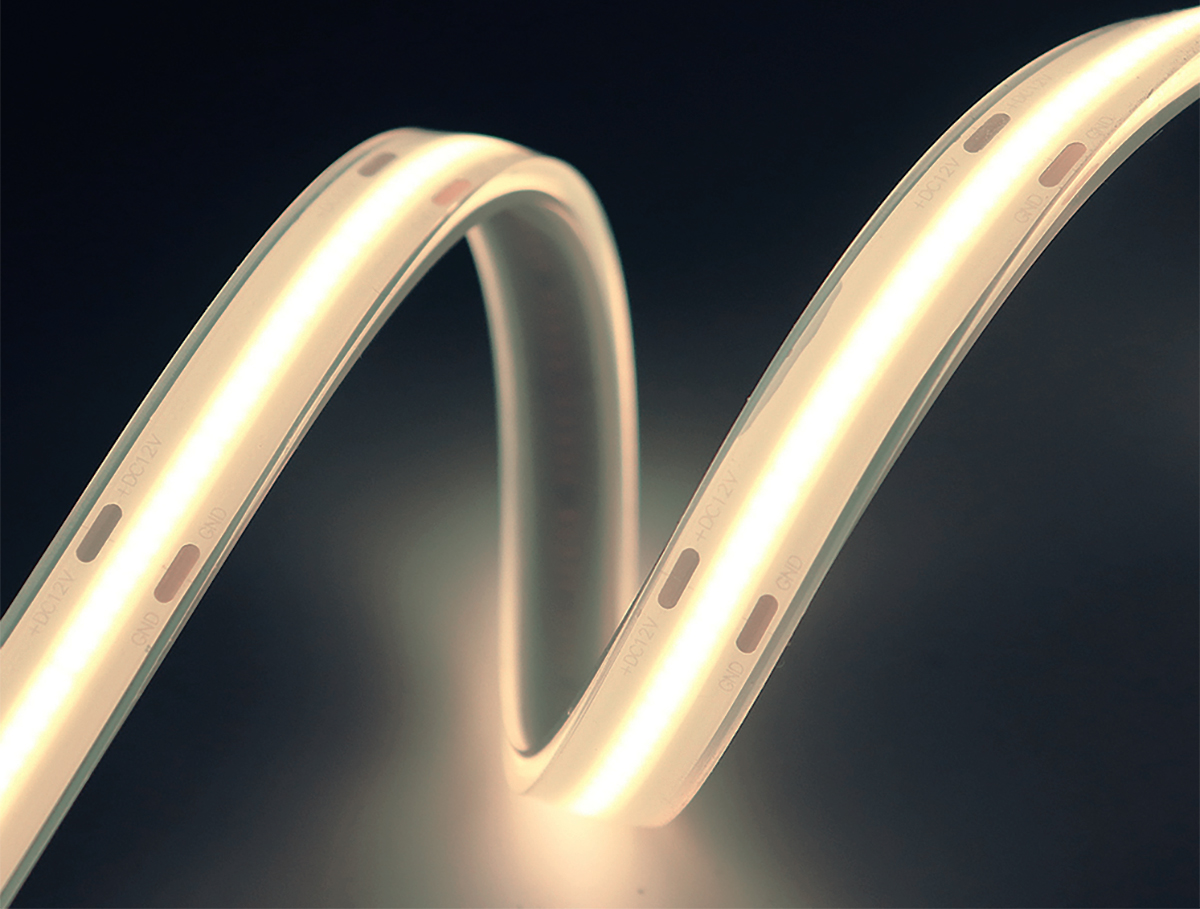

The commercial and industrial lighting sector faces relentless pressure to deliver higher performance, longer lifespans, and significant energy savings while operating in demanding environments. Within this critical landscape, Chip-on-Board (COB) lighting strips have emerged as a transformative technology, moving beyond basic illumination to address core challenges like thermal management, optical control, and visual comfort in high-ceiling warehouses, retail spaces, manufacturing floors, and architectural applications. Their dense, continuous light source eliminates the distracting dotting effect of traditional SMD strips, providing superior uniformity essential for task lighting and aesthetic presentation, while the integrated COB structure enhances reliability and heat dissipation under continuous operation. Crucially, performance claims in this sector demand validation; specifying professionals rightly require products backed by rigorous independent safety and compliance certifications such as ETL and CE, ensuring electrical safety, electromagnetic compatibility, and adherence to regional market standards before installation. Beauty STC, established in 1998, brings over 25 years of dedicated LED manufacturing expertise to this evolving field. Our deep understanding of the stringent demands placed on commercial and industrial lighting systems informs every COB strip we engineer, combining innovative thermal solutions, robust construction, and certified compliance to deliver the dependable, high-quality illumination that facility managers and lighting specifiers require.

Technical Specs & Certifications

COB (Chip-on-Board) lighting strips represent a significant advancement in LED technology, offering high-density light output and uniform illumination with minimal hotspots. At Beauty (STC) Manufacturing Co., Ltd., our COB lighting strips are engineered for superior performance, combining efficiency, color accuracy, and durability for both residential and commercial applications.

In terms of efficiency, our COB lighting strips achieve an industry-leading luminous efficacy ranging from 110 to 130 lumens per watt, depending on the color temperature and drive current. This high lumen-to-watt ratio ensures energy savings without compromising brightness, making them ideal for long-term installations where operational cost and sustainability are key considerations.

Color Rendering Index (CRI) is a critical factor in lighting quality, particularly in environments where accurate color representation is essential—such as retail displays, art galleries, and high-end residential interiors. Beauty STC’s COB strips are designed with high-CRI phosphor coatings, delivering a CRI greater than 90, and up to 95 in select models. This ensures vibrant, true-to-life color reproduction, enhancing visual comfort and aesthetic appeal.

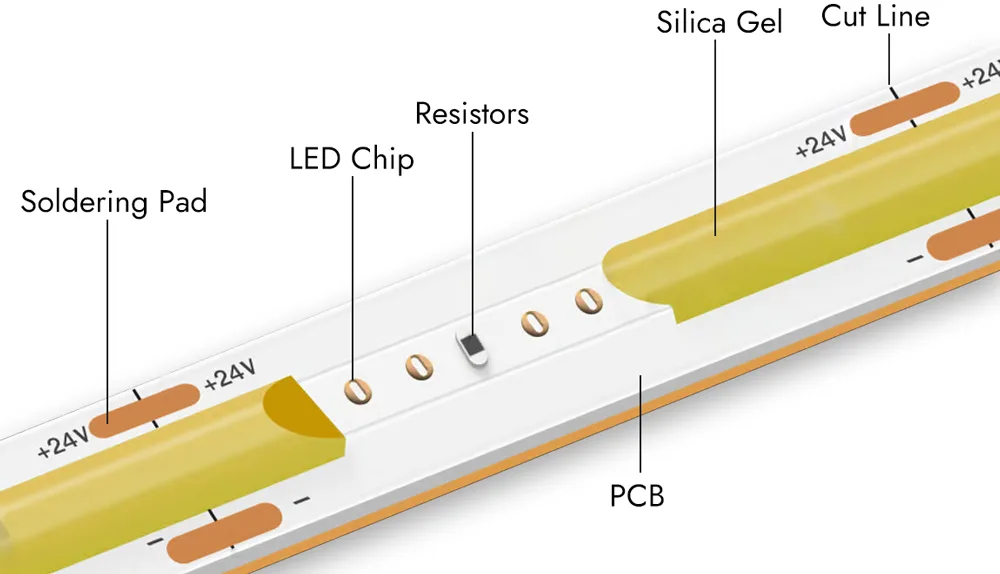

Regarding environmental protection, our COB lighting strips are available in multiple IP (Ingress Protection) ratings to suit diverse installation conditions. Standard non-encapsulated strips typically carry an IP20 rating, suitable for indoor dry locations. For damp or outdoor environments, we offer silicone-coated or fully encapsulated versions with IP65, IP67, and even IP68 ratings. These variants provide robust protection against dust, moisture, and temporary submersion, ensuring long-term reliability in challenging conditions.

Quality is central to Beauty STC’s manufacturing philosophy. Our COB strips are produced using premium-grade epitaxial chips, precision bonding techniques, and rigorous in-line testing. Each batch undergoes thermal cycling, flux maintenance, and color consistency checks to ensure uniform performance across production runs. With excellent thermal management design and stable drivers, our COB lighting strips offer extended lifespans—typically rated at L70 >50,000 hours under normal operating conditions.

In summary, Beauty STC’s COB lighting strips deliver high efficiency (110–130 lm/W), exceptional color rendering (CRI >90), and versatile IP protection (up to IP68), all backed by stringent quality control and innovative engineering. These features position our products as a trusted choice for demanding lighting applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen factory serves as our primary manufacturing hub for advanced LED lighting products, strategically located within the Pearl River Delta region to leverage strong supply chain infrastructure and skilled labor. The facility spans over 20,000 square meters and operates under strict ISO 9001 quality management standards, with dedicated clean rooms for precision electronics assembly.

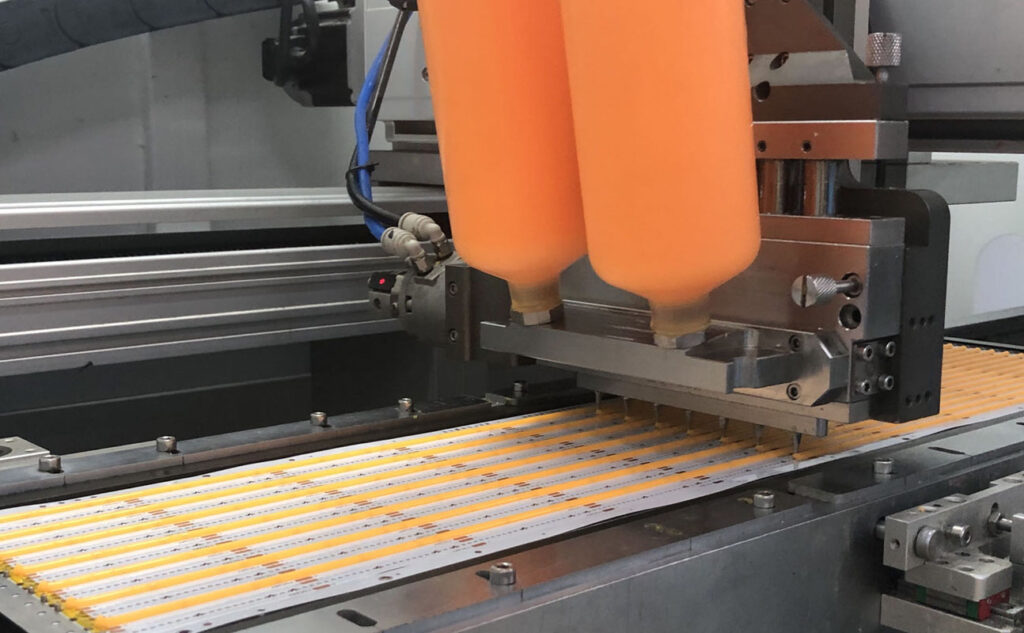

Our SMT production lines are anchored by multiple high-speed Yamaha YS24 series placement machines, complemented by older Yamaha YS12 models for specialized or lower-volume runs. These systems handle components down to 0201 metric size with ±25µm placement accuracy, essential for densely packed COB (Chip-on-Board) lighting strips. The lines integrate fully automated solder paste printers, nitrogen-reflow ovens to minimize oxidation, and 3D AOI systems for real-time solder joint inspection. For COB strip production specifically, we utilize custom feeders and vision systems optimized for flexible PCB handling, ensuring precise die placement and wire bonding alignment critical to lumen uniformity.

Aging and reliability testing are rigorously enforced across all COB lighting strip batches. Every production run undergoes mandatory 24-hour continuous burn-in at 1.2x rated voltage in temperature-controlled chambers (45°C ambient). For clients requiring enhanced validation, we offer accelerated 72-hour aging with thermal cycling between -20°C and 60°C. Each strip is monitored via automated photometric sensors tracking lumen maintenance, chromaticity shift, and thermal performance at 15-minute intervals. Failures trigger immediate root-cause analysis with our in-house LED physics lab, where we perform cross-sectioning and SEM analysis of solder joints or phosphor degradation. Statistical process control data from these tests is shared with OEM partners via our cloud-based quality portal.

Regarding OEM capabilities for COB lighting strips, our Jiangmen facility offers end-to-end customization from concept to packaged product. We support client-specific requirements including custom lengths (50mm to 5m per reel), CRI 80-98 options, CCT ranges from 2200K to 6500K, and specialized beam angles via secondary optics integration. Engineering services cover thermal management redesign using our Ansys simulation suite, driver compatibility validation, and bespoke mechanical packaging for architectural or industrial applications. Clients provide spectral or mechanical targets, and we deliver functional prototypes within 30 days. All OEM projects include NDA-protected design ownership, with production scaling from 500-meter pilot batches to 50,000+ meters monthly. Our UL Recognized lab in Jiangmen also facilitates direct certification support for North American and European market entries, reducing time-to-market for partner products.

Application Scenarios

Cob lighting strips are ideal for environments where uniform, glare-free illumination with a high quality of light is essential. In hotels, these strips are particularly effective in guest rooms, hallways, and lobbies where a soft, continuous light enhances the ambiance. Their seamless light distribution makes them perfect for cove lighting, under-cabinet lighting in hotel suites, and indirect lighting in reception areas. The warm and consistent glow contributes to a welcoming and luxurious atmosphere, which is critical in hospitality settings.

In malls, cob lighting strips are well-suited for display lighting, signage backlighting, and architectural highlighting. Their ability to produce a smooth, shadow-free beam makes them excellent for illuminating retail displays, fashion boutiques, and feature walls without the distracting dots or striations commonly seen with traditional LED strips. They can also be used in escalator soffits or ceiling coves to guide customer movement with a modern, elegant glow.

For offices, cob lighting strips are beneficial in meeting rooms, reception areas, and under-shelf or task lighting applications. They provide a clean, professional appearance and reduce eye strain due to their uniform light output. In open-plan offices, they can be integrated into suspended ceiling details or partition coves to create a balanced ambient light that supports productivity and comfort.

When installing cob lighting strips, ensure the mounting surface is clean, dry, and smooth to promote proper adhesion. Always use a constant current or constant voltage driver that matches the specifications of the cob strip to prevent flickering or premature failure. It is advisable to install the strip with a diffuser or lens to further enhance light uniformity and protect the delicate circuitry. Avoid sharp bends and never cut the strip except at designated cut points. For optimal thermal management, mount the strips on aluminum channels which also act as heat sinks—this is especially important in enclosed spaces or high ambient temperature environments. Finally, test the installation before finalizing the setup to confirm consistent brightness and color temperature across the entire run.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s industry-leading COB lighting strips, engineered for superior uniformity, exceptional color rendering, and unmatched thermal management. As a specialist in high-performance LED solutions, we deliver COB strips that eliminate visible dots and harsh shadows, ensuring seamless illumination ideal for demanding architectural, retail, and display applications. Partner with Beauty STC to access rigorously tested products built on decades of manufacturing excellence and cutting-edge R&D. Our dedicated engineering support and flexible customization options ensure your specific project requirements are met with precision and reliability. Contact our Lighting Solutions Manager today at [email protected] to discuss how our COB technology can enhance your product offerings and strengthen your market position. Let us collaborate on a strategic partnership that drives innovation and value for your clients.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.