Article Contents

Industry Insight: Cob Lighting

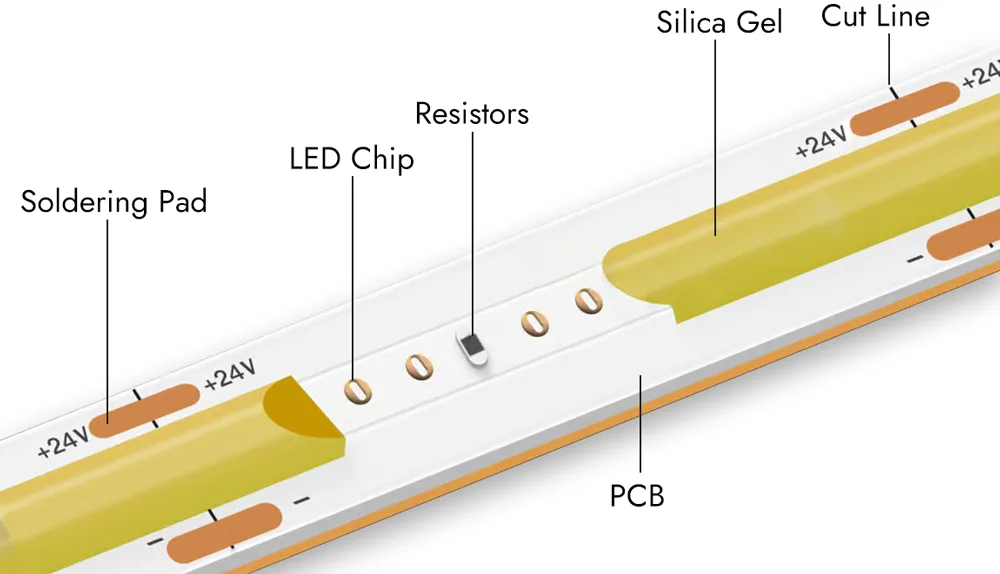

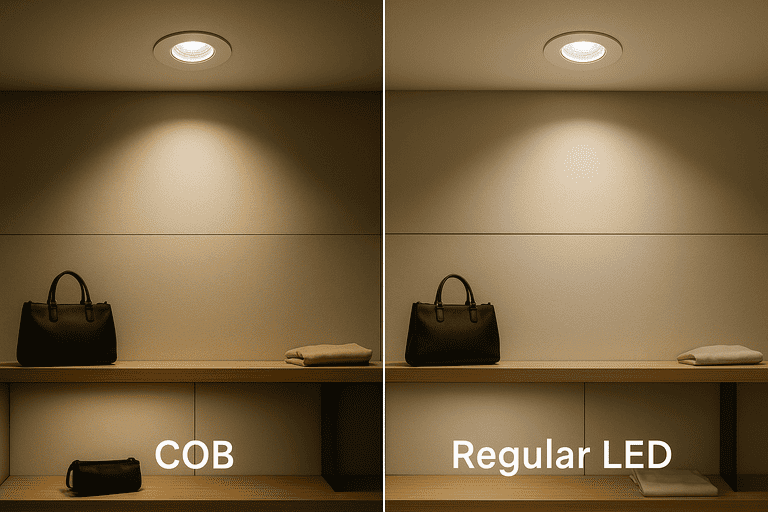

Chip-on-Board (COB) LED technology has rapidly evolved from a niche innovation to a cornerstone solution within the demanding landscape of commercial and industrial lighting. Its fundamental advantage lies in integrating multiple LED chips directly onto a single substrate, creating a compact, high-intensity light source that delivers exceptional lumen density and remarkably uniform illumination without the distracting multiple-point glare common in traditional multi-LED arrays. This characteristic is critically important in environments such as warehouses requiring deep, shadow-minimized coverage for high-bay applications, retail spaces demanding precise and flattering merchandise presentation, manufacturing facilities needing consistent task lighting for safety and productivity, and logistics centers operating around the clock. The inherent thermal efficiency of well-designed COB modules further enhances reliability and longevity – non-negotiable factors when lighting represents a significant operational cost and downtime carries substantial penalties in these sectors. Crucially, specifying COB solutions for such critical infrastructure mandates absolute confidence in safety and performance compliance, making rigorous third-party certifications like ETL (verifying adherence to North American safety standards, often referencing UL requirements) and CE (demonstrating conformity with European health, safety, and environmental protection legislation) not just desirable but essential prerequisites for any reputable manufacturer entering these markets.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over two and a half decades of specialized expertise in advanced LED lighting engineering and manufacturing. Our deep-rooted commitment to innovation, stringent quality control, and unwavering focus on the specific performance demands of commercial and industrial applications positions us as a strategic partner for projects where lighting is integral to operational success. We understand that beyond raw lumens, our clients require solutions built on certified safety, proven durability under continuous operation, and the thermal management precision that defines high-performance COB technology. At Beauty STC, every COB lighting product is engineered from the substrate up with these exacting standards in mind, ensuring seamless integration, reduced maintenance burdens, and superior return on investment for the most challenging professional environments.

Technical Specs & Certifications

COB (Chip-on-Board) lighting is a high-performance LED technology widely used in commercial, industrial, and architectural applications due to its superior lumen density, uniform light output, and thermal efficiency. At Beauty (STC) Manufacturing Co., Ltd., our COB lighting solutions are engineered to meet the most demanding performance standards, combining cutting-edge design with rigorous quality control.

In terms of efficiency, our COB LED modules deliver an industry-leading luminous efficacy ranging from 110 to 140 lumens per watt, depending on the configuration and thermal management. This high lumens/watt ratio ensures significant energy savings over traditional lighting systems while maintaining excellent brightness and beam consistency. The efficiency is optimized through advanced phosphor coating techniques and thermally enhanced substrates that minimize lumen depreciation over time.

Color Rendering Index (CRI) is a critical metric for applications requiring accurate color representation, such as retail displays, art galleries, and high-end hospitality environments. Beauty STC’s COB lighting consistently achieves a CRI greater than 90, with select high-CRI models reaching Ra 95 or above. This is accomplished using premium-grade phosphor blends and tightly binned LED chips to ensure minimal color variance across fixtures.

Regarding environmental protection and durability, our COB lighting products are available with IP (Ingress Protection) ratings up to IP65 and IP67, making them suitable for both indoor and outdoor use. The IP65 rating ensures complete protection against dust and resistance to low-pressure water jets, ideal for damp or washdown environments. The IP67 rating extends protection to temporary submersion in water, catering to demanding outdoor or industrial installations. Sealing integrity is maintained through precision optical lenses and robust housing designs that also contribute to long-term thermal stability.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality assurance protocols throughout the production process. Each COB module undergoes comprehensive photometric, thermal, and electrical testing to ensure compliance with international standards such as IEC 62717, IEC 62722-2-1, and LM-80. Our commitment to reliability is reflected in extended lumen maintenance (L70 > 50,000 hours) and minimal chromaticity shift over the product lifetime.

By integrating high efficiency, exceptional color fidelity, robust environmental protection, and uncompromising build quality, Beauty STC’s COB lighting solutions stand out as a trusted choice for professionals seeking performance-driven, durable, and visually superior illumination.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen factory serves as our primary manufacturing and R&D hub for advanced LED lighting solutions, occupying a modern 20,000-square-meter facility established in 2015. This purpose-built campus integrates state-of-the-art production lines with rigorous quality control systems under one roof, strategically positioned within the Pearl River Delta electronics supply chain for optimal component sourcing and logistics.

Our SMT production capabilities center on three fully automated Yamaha YS24 modular lines operating in climate-controlled environments. These systems handle components down to 0201 metric size with ±25-micron placement accuracy, supporting high-density COB (Chip-on-Board) substrate assembly through specialized nozzles and vision systems. Each line features nitrogen-reflow ovens maintaining precise thermal profiles for solder joint integrity on thermally demanding ceramic and MCPCB substrates. Daily capacity exceeds 5 million placement points across multiple shifts, with real-time SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection) systems ensuring first-pass yields above 99.2%.

Aging and reliability testing follow a dual-stage protocol critical for COB lighting validation. All COB modules undergo mandatory 48-hour continuous burn-in at 60°C ambient temperature, with automated monitoring of lumen maintenance and chromaticity shift at 12-hour intervals. We utilize 120-channel programmable aging racks capable of simulating real-world thermal cycling from -20°C to 85°C. Post-aging, statistical samples undergo destructive physical analysis including X-ray inspection of wire bonds and cross-sectioning of phosphor layers. Our accelerated life testing lab conducts TM-21 projections based on IES LM-80 data, with failure modes tracked in a proprietary database for continuous process refinement.

For COB lighting OEM projects, we provide end-to-end customization from wafer-level specification to finished modules. Our engineering team collaborates with clients to define optical parameters including CCT (1800K-6500K), CRI (Ra>90), and beam angles (15°-120°), leveraging in-house phosphor coating and lens design capabilities. The Jiangmen facility maintains dedicated COB production cells with class 10,000 cleanrooms for die-attach and encapsulation processes. Clients receive full design-for-manufacturability support, with prototyping cycles typically completed within three weeks. We accommodate volume production from 5,000 to 200,000 units monthly under strict IP protection agreements, with all COB modules complying with IEC/EN62031 safety standards and providing full traceability through our ERP system. This integrated approach ensures seamless transition from concept to certified, high-reliability COB lighting solutions.

Application Scenarios

COB (Chip-on-Board) lighting is highly versatile and well-suited for a range of commercial environments due to its high lumen output, excellent color rendering, and compact design. In hotels, malls, and offices, COB lighting can be effectively used to enhance both functionality and aesthetics.

In hotels, COB lighting is ideal for accentuating architectural features, illuminating lobbies, and providing ambient lighting in guest rooms and hallways. Recessed COB downlights are commonly used in ceilings to provide a clean, modern look with uniform light distribution. They are especially effective in creating a warm and inviting atmosphere in lounges, restaurants, and spa areas when paired with warm color temperatures (2700K–3000K).

In shopping malls, COB lighting excels in retail display areas, corridors, and high-ceiling atriums. The high brightness and focused beam angles make COB lamps perfect for spotlighting merchandise and guiding foot traffic. Track-mounted or adjustable COB spotlights allow retailers to highlight featured products with precision. In common areas, evenly spaced COB downlights ensure consistent illumination, improving safety and visual comfort.

In office environments, COB lighting supports productivity by delivering bright, glare-free illumination. It is commonly installed in drop ceilings or as part of suspended panel lights. COB panels provide excellent uniformity and are often used in meeting rooms, workstations, and reception areas. Cool white COB lights (4000K–5000K) are preferred in offices as they promote alertness and clarity.

When installing COB lighting, proper thermal management is critical. Ensure adequate heat dissipation by using fixtures with built-in heat sinks and avoid enclosing COB modules in poorly ventilated spaces. Always follow the manufacturer’s recommended mounting distances to prevent glare and achieve optimal light spread. Use high-quality drivers compatible with the COB specifications to ensure longevity and stable performance. For adjustable installations such as track lighting, aim the beams carefully to highlight intended areas without creating hotspots. Finally, consider dimmable COB solutions to allow flexibility in lighting control, enhancing both ambiance and energy efficiency.

Why Choose Beauty STC Lighting

Elevate your lighting solutions with industry-leading COB technology engineered for superior performance and reliability. Beauty STC Manufacturing Co., Ltd. specializes in precision COB lighting systems designed to deliver exceptional lumen density, thermal management, and optical control for demanding commercial and industrial applications. Our engineering expertise ensures products that exceed market standards in efficiency and longevity, providing your business with a tangible competitive edge.

Partner with Beauty STC to integrate cutting-edge COB lighting into your product lines or projects. We offer comprehensive technical collaboration, scalable manufacturing capabilities, and dedicated support to meet your specific requirements. Let our engineering team help you achieve optimal lighting performance while reducing time-to-market and total system costs.

Contact our partnership manager today to discuss how Beauty STC’s COB lighting solutions can advance your business objectives. Reach out via email at [email protected] to initiate a technical consultation and explore tailored collaboration opportunities.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.