Article Contents

Industry Insight: Cob Light Vs Led

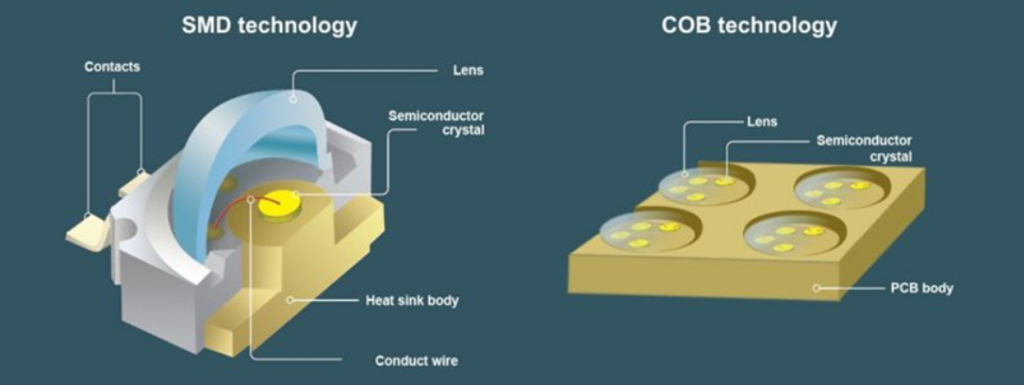

The commercial and industrial lighting sector continuously evolves, demanding solutions that balance performance, longevity, and operational cost efficiency. A critical decision point for facility managers, lighting designers, and electrical contractors involves selecting the optimal LED technology, often framed as a comparison between COB (Chip-on-Board) and traditional multi-SMD (Surface-Mounted Device) LED configurations. While both leverage solid-state lighting principles, their structural differences significantly impact thermal management, light quality, fixture design complexity, and long-term reliability in demanding environments like warehouses, manufacturing floors, retail spaces, and parking structures. Understanding these distinctions is paramount, as the wrong choice can lead to accelerated lumen depreciation, higher maintenance costs, or suboptimal illumination for critical tasks. Crucially, any specification for these professional settings mandates rigorous adherence to safety and performance standards, making ETL certification for North American markets and CE marking for Europe non-negotiable requirements to ensure electrical safety, photobiological safety, and regulatory compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two decades of deep engineering expertise and manufacturing excellence to this complex landscape. We specialize in developing and producing high-performance, certified commercial and industrial LED lighting solutions, including advanced COB and SMD-based fixtures, designed specifically to meet the stringent demands of professional applications while delivering superior energy savings and operational reliability. Our commitment to innovation and quality positions us as a trusted partner in navigating the critical COB versus LED technology considerations for your next project.

Technical Specs & Certifications

When comparing COB (Chip-on-Board) lighting to traditional multi-chip LED solutions, several technical specifications become critical in determining performance, efficiency, and suitability for commercial and industrial applications. Key factors include lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings. Beauty (STC) Manufacturing Co., Ltd. consistently delivers high-performance lighting solutions that meet and exceed industry standards in these areas.

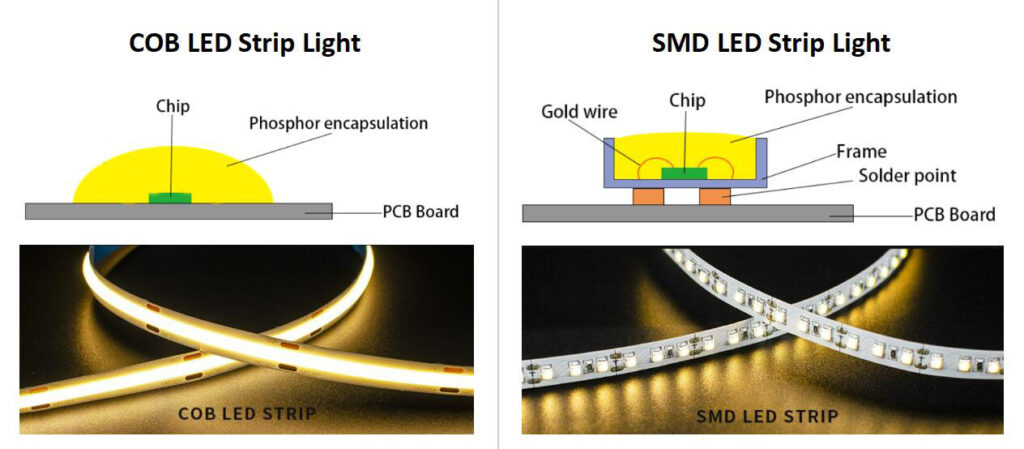

Lumens per Watt (lm/W) efficiency is a measure of how effectively a light source converts electrical power into visible light. COB LEDs typically offer higher lm/W ratios due to their dense array of diodes packed into a single module, allowing for greater light output from a compact source. Modern COB lights from leading manufacturers like Beauty STC achieve efficacies in the range of 120 to 150 lm/W, depending on the driver and thermal design. In comparison, standard SMD (Surface Mounted Device) LED arrays generally deliver between 90 and 130 lm/W. Beauty STC’s proprietary thermal management and driver integration ensure that their COB fixtures operate at peak efficiency, minimizing lumen depreciation over time and maintaining high output throughout the product’s lifespan.

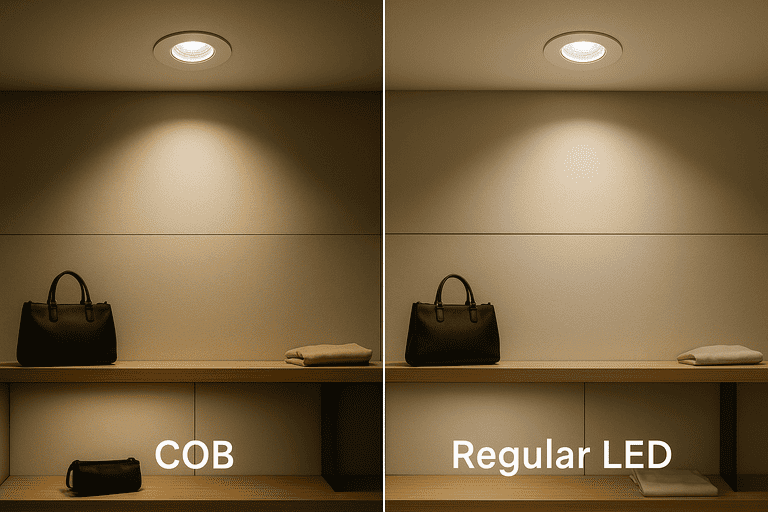

Color Rendering Index (CRI) is essential for applications requiring accurate color representation, such as retail, healthcare, and art galleries. A CRI value greater than 90 indicates excellent color fidelity. Beauty STC’s COB and high-end LED luminaires are engineered with premium phosphor coatings and tightly binned LED chips to consistently deliver CRI values above 90, with select models achieving CRI 95+. This attention to spectral quality ensures that illuminated environments appear natural and vibrant. The compact nature of COB technology further enhances uniformity of light, reducing shadows and glare—advantages that Beauty STC leverages in its downlight and track lighting series.

Ingress Protection (IP) ratings define a fixture’s resistance to dust and moisture, critical for outdoor, industrial, and wet-location applications. Beauty STC designs both COB and LED luminaires with robust sealing and high-quality materials to achieve IP ratings such as IP65, IP66, and IP67. These ratings indicate complete protection against dust and resistance to low-pressure water jets or temporary immersion. Whether in high-humidity environments or outdoor facades, Beauty STC’s fixtures maintain long-term reliability. The integration of COB modules into sealed housings is particularly effective due to fewer solder points and a more compact light source, reducing potential failure points.

Beauty STC’s commitment to quality is evident in every stage of production, from rigorous chip selection and thermal testing to full compliance with international safety and performance standards. Their lighting solutions are designed for durability, energy efficiency, and superior optical performance, making them a preferred choice for projects demanding high CRI, excellent lm/W efficiency, and robust environmental protection. Whether selecting COB or multi-chip LED technology, Beauty STC ensures consistent, premium-grade output tailored to the most demanding applications.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, designed specifically for high-volume, precision LED lighting production. The factory spans over 50,000 square meters and features a fully automated surface mount technology (SMT) production line as its core. We utilize state-of-the-art Fuji NXT III and NXT4 placement machines capable of handling components from 01005 to large LED modules with exceptional accuracy and speed. These machines are supported by nitrogen-reflow soldering systems and automated optical inspection (AOI) stations to ensure solder joint integrity and component placement precision. Our SMT lines achieve a daily throughput exceeding 5 million components, enabling efficient production of complex LED assemblies including multi-die COB modules and standard SMD-based luminaires.

Aging and reliability testing represent a critical phase in our quality control process, conducted within a dedicated environmental testing laboratory at the Jiangmen site. All finished products undergo mandatory aging tests where units operate at full rated power for a minimum of 72 hours under controlled thermal conditions, typically at 50°C ambient temperature. This extended burn-in process identifies early-life failures related to component weaknesses, thermal management issues, or assembly defects. We employ automated data logging systems to monitor lumen output, color shift, and electrical parameters throughout the aging cycle, ensuring only units meeting our stringent IEC 62717 and internal reliability standards proceed to packaging. This rigorous protocol significantly reduces field failure rates and validates the long-term performance claims for our lighting solutions.

Regarding OEM capabilities for COB (Chip-on-Board) technology versus other LED formats, Beauty STC possesses deep expertise in both domains and tailors solutions based on client specifications. For COB-specific OEM projects, we excel in high-density multi-die integration on ceramic or MCPCB substrates, offering custom phosphor coating for precise color rendering and thermal management solutions optimized for compact, high-lumen-output applications like spotlights and downlights. Our COB production leverages the same SMT infrastructure but incorporates specialized handling for bare-die placement and conformal coating processes. For broader LED product lines beyond COB—such as SMD-based linear fixtures, filament bulbs, or standard LED modules—we provide identical engineering rigor in optical design, driver integration, and thermal validation. Crucially, we guide OEM partners on technology selection; COB is recommended for applications demanding superior optical control and minimal glare in directional lighting, while discrete SMD arrays suit diffuse or linear lighting needs where cost efficiency and thermal derating flexibility are priorities. Our engineering team collaborates closely with clients to determine the optimal LED architecture—whether COB, multi-SMD, or hybrid—based on performance targets, form factor constraints, and lifecycle cost analysis, ensuring the final OEM product meets exact market requirements.

Application Scenarios

When deciding between COB (Chip-on-Board) LED and traditional multi-chip LED lighting for commercial applications such as hotels, malls, and offices, understanding the strengths of each technology is key to achieving optimal lighting performance, aesthetics, and energy efficiency.

In hotels, COB LED lights are particularly effective in areas where high-quality, uniform illumination is essential for ambiance and guest comfort. They are ideal for lobbies, hallways, and high-end guest rooms where a clean, glare-free light with excellent color rendering is desired. The compact design and high lumen density of COB LEDs allow for sleek recessed downlights and track lighting that enhance architectural features without visible multiple light sources. Traditional multi-chip LEDs can still be used in service areas, corridors, or back-of-house spaces where precise beam control is less critical and cost efficiency is a priority.

In malls and retail environments, COB LEDs are preferred for display lighting, such as in jewelry stores, fashion boutiques, and product showcases, due to their superior beam quality and minimal shadowing. The ability to produce a smooth, continuous light output without the “dotting effect” seen in some multi-chip LEDs makes COB ideal for accent lighting that enhances product presentation. General mall lighting, such as in walkways and food courts, can utilize traditional LED panels or troffers, which offer sufficient brightness and even distribution at a lower cost.

In office spaces, traditional multi-chip LED panels and troffers are commonly used in drop ceilings due to their wide, uniform light distribution and cost-effectiveness. However, COB LEDs are increasingly used in executive offices, meeting rooms, and modern open-plan designs where focused task lighting or architectural downlighting is required. The higher CRI (Color Rendering Index) and better thermal management of COB LEDs contribute to a more comfortable and productive work environment.

For installation, ensure proper thermal management as both COB and traditional LEDs are sensitive to heat, though COB LEDs typically require more robust heat dissipation due to higher power density. Use compatible drivers and dimmers, especially when integrating with smart lighting controls. When installing COB downlights, maintain adequate clearance above the ceiling to prevent overheating. Align fixtures precisely, particularly in retail or display applications, to achieve the desired beam focus and avoid hotspots. Always follow manufacturer specifications for voltage, wiring, and mounting to ensure safety, longevity, and optimal performance.

Why Choose Beauty STC Lighting

When evaluating COB light versus standard LED solutions for your next project, the technical distinctions in thermal management, lumen density, and beam uniformity significantly impact performance and longevity. At Beauty STC Manufacturing Co., Ltd., our engineering team specializes in demystifying these complexities to deliver application-specific lighting systems that maximize efficiency and reliability. We don’t just supply components—we engineer precision solutions tailored to your operational demands, whether for industrial, commercial, or high-end retail environments.

Partner with Beauty STC to leverage our two decades of R&D expertise in advanced LED architecture. Our collaborative approach ensures you receive not only superior luminaires but also strategic guidance on optimizing light quality, energy consumption, and total cost of ownership. As your dedicated manufacturing ally, we integrate rigorous thermal testing and optical design to transform technical specifications into real-world advantages, eliminating the guesswork in your sourcing decisions.

Contact our Technical Solutions Manager directly at [email protected] to initiate a consultation. Share your project requirements, and we will provide a detailed comparative analysis alongside a customized proposal—proving why Beauty STC is the engineering-driven partner global brands trust for uncompromising LED innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.