Article Contents

Industry Insight: Cob Leds

COB (Chip-on-Board) LED technology has emerged as a transformative force in commercial and industrial lighting, delivering exceptional luminous efficacy, superior thermal management, and a compact design that enables high-intensity illumination from minimal footprint fixtures. Widely adopted in warehouses, manufacturing facilities, retail spaces, and cold storage environments, COB LEDs offer uniform light distribution with reduced glare—critical factors for safety, productivity, and visual comfort in demanding applications. As energy efficiency standards tighten and building operators seek long-term ROI, the demand for reliable, code-compliant lighting solutions has never been greater. Leading the charge is Beauty (STC) Manufacturing Co., Ltd., an industry innovator established in 1998 with a proven track record in high-performance LED lighting systems. Beauty STC’s COB LED products are engineered for durability and performance, rigorously tested to meet ETL and CE certification standards, ensuring compliance with North American and international safety and electromagnetic compatibility requirements. With a steadfast commitment to quality and innovation, Beauty STC continues to empower modern commercial and industrial spaces with intelligent, sustainable lighting solutions that perform under pressure.

Technical Specs & Certifications

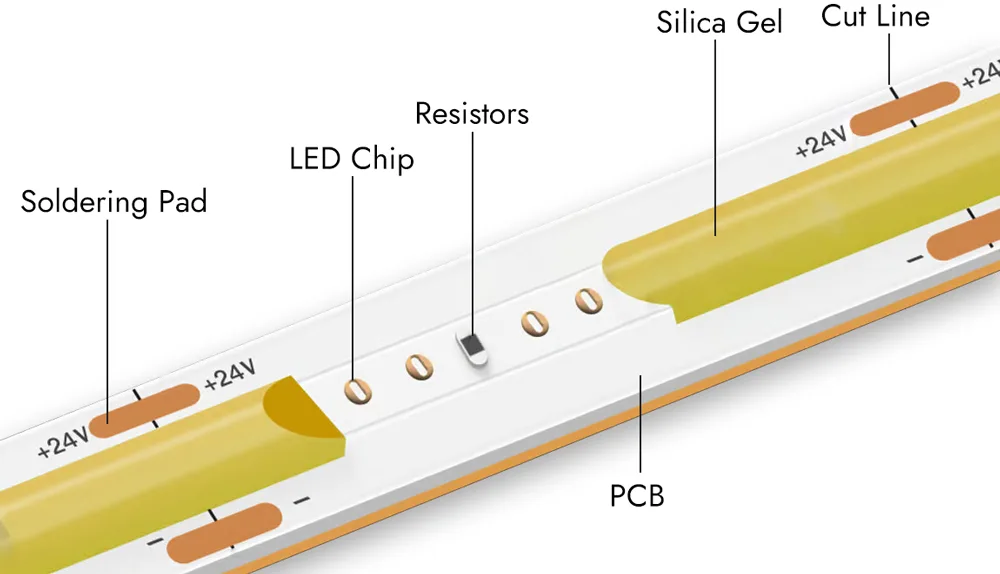

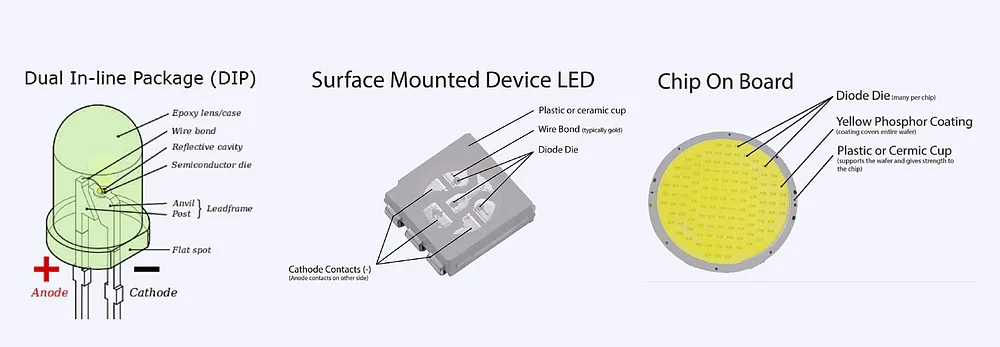

COB (Chip-on-Board) LED technology integrates multiple LED chips directly onto a single substrate, creating a concentrated, uniform light source without individual lenses. This design minimizes shadows and enhances optical control, making it ideal for high-quality architectural, retail, and task lighting applications where precise beam shaping and visual comfort are critical. At Beauty STC, our COB LEDs are engineered to exceed industry benchmarks, particularly in efficacy, color fidelity, and environmental resilience.

Lumens per Watt (lm/W) performance for high-CRI COB LEDs involves a careful balance between efficiency and spectral quality. Our standard high-CRI COB modules achieve 110–130 lm/W at 25°C ambient temperature under typical drive currents (e.g., 700–1050mA). This range reflects the inherent trade-off when targeting CRI >90, as the additional phosphor layers required to broaden the spectral output for accurate color rendering reduce overall photon conversion efficiency compared to lower-CRI alternatives. We optimize thermal management through high-thermal-conductivity MCPCBs (Metal Core Printed Circuit Boards) and precision die-attach processes to maintain stable efficacy across operating temperatures, ensuring minimal lumen depreciation even under sustained high-load conditions.

Color Rendering Index (CRI) is a cornerstone of Beauty STC’s COB LED specification. All high-CRI COB products consistently deliver Ra ≥95, with strong performance in critical R9 (saturated red) values exceeding 90. This is achieved through proprietary multi-phosphor formulations and rigorous binning protocols that ensure spectral continuity across production batches. Unlike generic COBs that may meet Ra>90 but fail in specific color bands, our modules undergo spectroradiometric validation to guarantee accurate rendering of skin tones, textiles, and natural materials—essential for applications in beauty salons, art galleries, and premium retail environments. Extended spectrum coverage (including TM-30 Rf >90 and Rg >98) further distinguishes our offerings, providing designers with tools to achieve both visual accuracy and aesthetic intent.

IP (Ingress Protection) ratings for COB LEDs depend on the fixture integration, as bare COB modules are inherently non-IP-rated components. Beauty STC collaborates closely with luminaire manufacturers to engineer robust environmental protection. For outdoor or wet-location applications, our COB-based fixtures commonly achieve IP65 (dust-tight and protected against low-pressure water jets) or IP67 (submersion up to 1 meter for 30 minutes). This is accomplished through precision silicone encapsulation of the COB array, gasketed optical compartments, and corrosion-resistant housings. All IP-rated assemblies undergo accelerated lifecycle testing, including 1,000-hour salt spray exposure and thermal cycling from -40°C to +85°C, to validate long-term reliability in harsh conditions.

Beauty STC’s commitment to quality permeates every stage of COB LED production. Our vertically integrated manufacturing in China utilizes ISO 9001-certified processes, with 100% automated optical inspection (AOI) for chip placement and phosphor consistency. We enforce strict thermal resistance standards (θj-s ≤ 1.8°C/W) through advanced thermal interface materials and copper-core substrates, directly contributing to industry-leading L90 lifetimes of 50,000 hours at 55°C case temperature (per TM-21 projections). Rigorous in-house LM-80 testing, coupled with real-world field data showing a <0.1% annual failure rate, underscores our reliability. Unlike commodity COBs, Beauty STC modules undergo spectrally resolved aging tests to ensure CRI stability over time, eliminating the common issue of color shift in high-CRI solutions. This uncompromising approach to material science and process control ensures our COB LEDs deliver not just specifications on paper, but sustained performance that protects end-user investments in lighting quality.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and scalability.

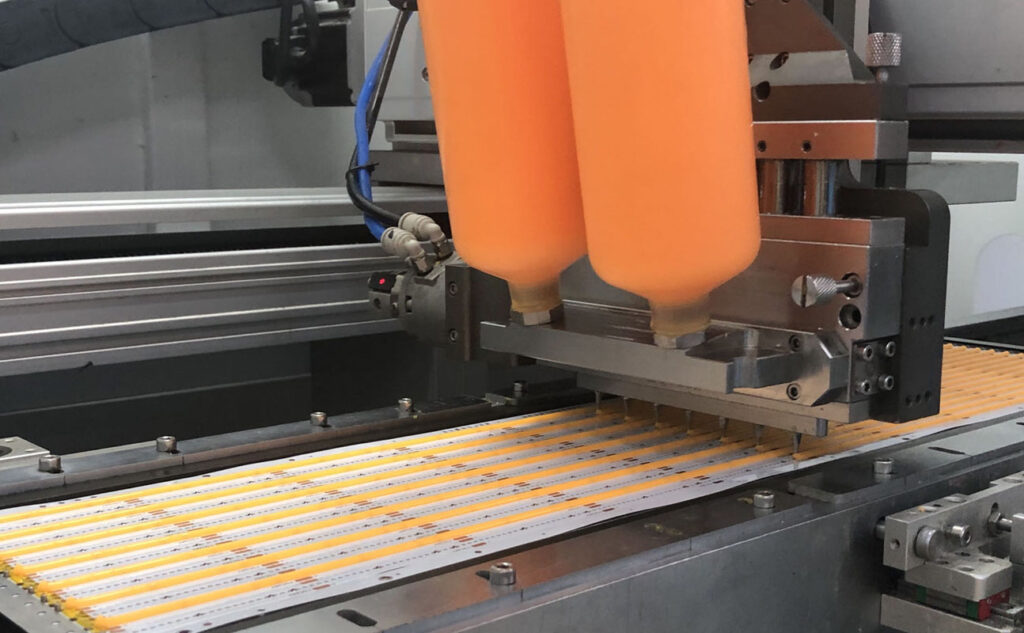

The facility is equipped with advanced Surface Mount Technology (SMT) production lines featuring high-speed, precision SMT machines from leading global manufacturers. These machines ensure accurate placement of components on PCBs, including fine-pitch and high-density designs, which is essential for producing compact and high-performance LED modules. Automated optical inspection (AOI) systems are integrated into the SMT process to verify solder joint quality and component alignment, minimizing defects and ensuring consistent output.

A critical part of the factory’s quality assurance process is its comprehensive aging test chamber setup. After assembly, LED products undergo rigorous aging tests under controlled thermal and electrical conditions, typically operating at elevated temperatures for 24 to 72 hours. This process helps identify early-life failures, validates thermal management performance, and ensures long-term reliability. The aging test protocols follow industry best practices and can be customized based on client requirements.

Beauty STC has strong OEM capabilities, particularly in the design and production of COB (Chip-on-Board) LED solutions. The company supports full turnkey OEM services, including custom optical design, thermal management engineering, driver integration, and mechanical housing development. Clients can provide specifications or performance targets, and Beauty STC’s engineering team will develop tailored COB LED products optimized for applications such as downlights, spotlights, track lighting, and industrial lighting. The factory can handle small-batch prototyping as well as large-scale mass production, offering flexible manufacturing options to meet diverse market demands.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and deep technical expertise to deliver high-quality, reliable LED lighting solutions through both standard and custom OEM manufacturing pathways.

Application Scenarios

COB (Chip-on-Board) LED technology excels in commercial applications requiring high lumen density, superior optical control, and a visually smooth, uniform light output without discernible individual points of light. Its integration of multiple LED chips onto a single substrate makes it particularly suitable for specific scenarios within hotels, malls, and offices where these qualities are paramount.

In hotels, COB LEDs are ideal for high-impact guest experience areas. Utilize high-output COB downlights in grand lobbies to provide bright, even illumination on reception desks and flooring while minimizing glare on polished surfaces. Install narrow-beam COB spotlights within display niches or above artwork in corridors to create dramatic accent lighting that highlights textures and colors without hotspots. For premium restaurant and bar settings, select COB fixtures with a CRI of 90+ to render food and beverages accurately and enhance ambiance. COB linear strips concealed within cove lighting throughout guest room corridors or suite living areas deliver seamless, shadow-free illumination that feels luxurious and modern. Avoid placing COB downlights directly above beds in guest rooms unless using very wide flood optics to prevent uncomfortable glare.

Malls benefit significantly from COB technology in areas demanding both high light levels and precise beam control. Deploy high-lumen COB downlights in multi-story atriums to effectively penetrate large vertical spaces and illuminate central features from considerable mounting heights. Use adjustable COB track heads or recessed spots in retail storefronts to create tightly focused beams that draw attention to high-value merchandise displays, leveraging the COB’s crisp beam edge for professional presentation. Install COB linear fixtures within architectural soffits or above escalator landings to provide uniform wall washing that enhances spatial perception and safety. For mall entrances and covered walkways, select IP65-rated COB floodlights to ensure consistent, glare-controlled illumination across expansive floor areas, even in varying weather conditions.

Within office environments, COB technology shines where visual comfort and task performance are critical. Implement COB-based flat panel luminaires in standard suspended ceiling grids for open-plan workspaces; their uniform surface luminance drastically reduces eye strain compared to multi-die LED panels. Choose dimmable COB troffer replacements in conference rooms to enable smooth transitions from bright presentation mode to softer collaboration settings without color shift. Apply narrow-beam COB downlights in executive offices to spotlight desks effectively while maintaining lower ambient light levels for video conferencing. For reception areas and executive lobbies, COB cove lighting or bespoke COB linear elements within custom millwork create a sophisticated, high-end appearance free from distracting dotting effects. Always prioritize fixtures with appropriate UGR (Unified Glare Rating) values below 19 for general office tasks.

Critical installation considerations begin with thermal management, as COB modules generate concentrated heat. Ensure fixtures have adequate heat sinking and are never installed in non-IC rated or tightly enclosed housings unless explicitly certified for such use; verify manufacturer specifications for maximum ambient temperatures. Match the driver output voltage precisely to the COB module’s requirements—common configurations include 36V or 72V DC—and maintain wiring within voltage drop limits, especially for long cable runs to high-power arrays. Select beam angles meticulously: narrow spots (10°-24°) for accenting, floods (36°-60°) for general area lighting, and wall washers (asymmetric beams) for vertical surfaces. Use high-quality thermal interface material between the COB substrate and heat sink during serviceable installations. Provide accessible maintenance points for high-bay or cove installations, as COB modules, while long-lasting, may eventually require replacement. Finally, engage licensed electricians who understand low-voltage DC systems and adhere strictly to local electrical codes and safety standards.

Why Choose Beauty STC Lighting

Discover high-performance COB LEDs designed for superior brightness, efficiency, and thermal management. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in advanced LED solutions. Our COB LED products are engineered to meet the highest industry standards, making them ideal for commercial, industrial, and architectural lighting applications.

Elevate your lighting projects with reliable, innovative technology backed by expert support. Contact us today to discuss your requirements and explore customized COB LED solutions.

Reach out to our sales manager at [email protected] and take the first step toward a successful partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.