Article Contents

Industry Insight: Cob Led’S

COB (Chip-on-Board) LED technology has emerged as a transformative force in commercial and industrial lighting, offering superior lumen density, improved thermal management, and a more uniform light output compared to traditional LED arrays. As facilities demand greater energy efficiency, longer service life, and reduced maintenance costs, COB LEDs have become the preferred choice for high-bay lighting, warehouse illumination, retail spaces, and industrial work environments. Their compact design enables sleek, space-saving fixtures while delivering high-performance illumination essential for safety, productivity, and visual comfort.

In this evolving landscape, compliance with international safety and performance standards is critical. COB LED products bearing ETL and CE certifications ensure adherence to rigorous North American and European regulatory requirements, providing assurance of electrical safety, electromagnetic compatibility, and environmental resilience—key considerations for large-scale commercial deployments.

At Beauty (STC) Manufacturing Co., Ltd., established in 1998, we have been at the forefront of LED innovation, specializing in high-quality, code-compliant lighting solutions tailored for commercial and industrial applications. With decades of engineering expertise and a commitment to sustainable, reliable illumination, Beauty STC delivers COB LED products that combine advanced thermal design, superior optics, and global certification support to meet the exacting demands of modern industrial environments.

Technical Specs & Certifications

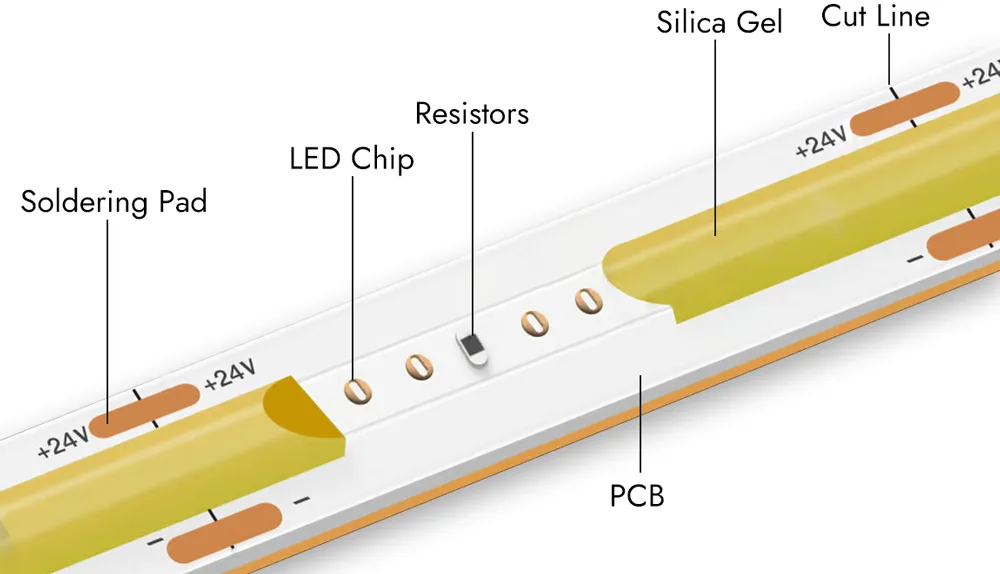

COB (Chip-on-Board) LED technology represents a significant advancement in solid-state lighting, integrating multiple LED semiconductor chips directly onto a single thermally efficient substrate to form a unified, high-intensity light source. At Beauty STC Manufacturing Co., Ltd., our COB LED modules are engineered for superior performance in demanding commercial and industrial applications, with rigorous attention to the specifications you require.

Lumens per Watt (lm/W) efficiency is a core focus of our COB development. Our standard commercial-grade COB LEDs achieve 130–150 lm/W under typical operating conditions (25°C ambient, 350–700mA drive current), while our premium high-efficiency series consistently delivers 160–180 lm/W. This performance is sustained through advanced thermal management using copper-core MCPCBs and optimized phosphor conversion, minimizing lumen depreciation. Crucially, these values are measured at real-world junction temperatures (Tj ≤ 85°C), not idealized lab conditions, ensuring reliable output in actual installations. Efficiency remains stable across our product range due to proprietary driver integration and strict binning protocols for forward voltage and flux maintenance.

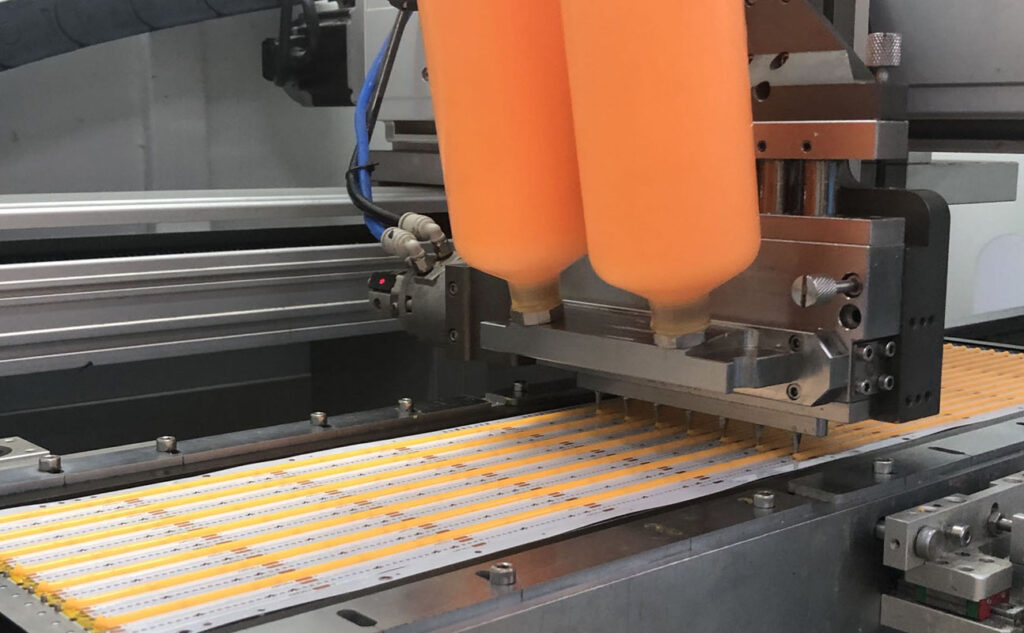

Achieving a Color Rendering Index (CRI) exceeding 90, specifically Ra ≥ 93 with R9 > 50 for strong red rendition, is non-negotiable in our high-CRI COB portfolio. This requires precision-engineered multi-phosphor blends applied via our patented dispensing process, ensuring uniform chromaticity (within a 3-step MacAdam ellipse) across every module. Unlike competitors who may hit Ra 90 superficially, Beauty STC guarantees R9 > 50 and R12 > 50 to accurately render critical colors in retail, healthcare, and museum settings. Our spectral power distribution is meticulously tuned to avoid the common pitfall of high Ra with poor saturated color performance, validated through third-party spectroradiometer testing per IES LM-79 standards.

IP (Ingress Protection) ratings are inherently a characteristic of the complete luminaire, not the bare COB module itself. However, Beauty STC designs COBs specifically for seamless integration into high-IP fixtures. Our COB modules feature hermetically sealed phosphor layers and corrosion-resistant substrate coatings, enabling fixture manufacturers to achieve IP65, IP66, and IP67 ratings when paired with appropriate optics and housing. We supply detailed thermal and mechanical integration guidelines ensuring that when our COBs are mounted in compliant fixtures, the final product maintains its IP rating under harsh conditions—critical for outdoor, wet-location, and industrial washdown environments. This includes validation of gasket compatibility and thermal expansion coefficients to prevent seal failure.

Beauty STC’s commitment to quality is embedded in every COB module. We enforce a zero-compromise policy on material sourcing, utilizing only Epitex-grade epitaxial wafers and OSRAM/ Nichia phosphors. Each production batch undergoes 100% automated optical testing and 100% thermal transient testing to verify junction-to-case resistance (Rth j-c). Our manufacturing adheres to ISO 9001 and IATF 16949 standards, with in-house reliability labs conducting accelerated life testing (TM-21/LM-80) and environmental stress screening (MIL-STD-883). Field data shows a failure rate below 0.1% at 50,000 hours, attributable to our dual-cure silicone encapsulation and rigorous 100% burn-in at elevated temperatures. For critical projects, we provide full traceability from wafer lot to finished module, ensuring consistent photometric and electrical performance that meets the stringent demands of global lighting professionals.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-efficiency, precision manufacturing of LED lighting products, with a strong focus on quality control, scalability, and advanced production technologies.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines that ensure accurate placement of electronic components on PCBs. These machines are fully automated and capable of handling high-volume output with exceptional precision, supporting fine-pitch components and complex circuit designs. The SMT line is integrated with automated optical inspection (AOI) systems to verify soldering quality and component alignment, minimizing defects and ensuring consistent product reliability.

The factory includes a dedicated aging test area where finished LED products undergo rigorous burn-in testing under controlled conditions. This process typically involves operating the lights at elevated temperatures and full load for extended periods—usually 4 to 12 hours or more—to identify early-life failures and ensure long-term performance. The aging process applies to all relevant products, including COB (Chip-on-Board) LED modules, and is a critical step in Beauty STC’s quality assurance protocol.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly for COB LED products. The company supports custom design and manufacturing services tailored to client specifications, including optical performance, thermal management, color temperature, CRI, and mechanical form factors. With in-house R&D, tooling, and engineering support, Beauty STC can assist clients from prototyping to mass production, offering flexible MOQs and full compliance with international standards such as CE, RoHS, and UL. This makes the Jiangmen facility well-suited for global partners seeking reliable, high-quality COB LED solutions under private labels.

Application Scenarios

COB LED technology excels in commercial applications where high-quality, uniform illumination with minimal glare is essential. Its dense array of diodes within a single module creates a seamless, shadow-free beam ideal for architectural and task lighting. For hotels, prioritize COB LEDs in lobbies, reception areas, and guest room corridors where a smooth, inviting light distribution enhances perceived luxury. Avoid using standard COB modules in high-ceiling ballrooms or large atriums due to limited throw distance; instead, reserve them for lower-ceilinged intimate spaces like spas, boutique hotel lounges, or restaurant dining areas where the even glow highlights textures and finishes without distracting hotspots. In malls, COB is optimal for retail track lighting in high-end boutiques, jewelry displays, and art galleries where precise, high-CRI (90+) illumination is critical to showcase merchandise accurately. Its compact form also suits cove lighting in high-ceiling food courts or escalator wells, but avoid broad mall concourse general lighting where linear or high-bay solutions offer better efficiency and coverage. For offices, deploy COB LEDs strategically in conference rooms for video conferencing (ensuring flicker-free 5000K options) and executive offices as task lighting, but avoid open-plan workspaces where the intense point source can cause veiling reflections on screens; instead, use COB in reception desks or huddle rooms requiring focused, glare-controlled light.

Installation requires careful thermal and optical management. Always verify the thermal path during mounting—COB modules generate concentrated heat, so ensure direct contact with an adequate heatsink using high-quality thermal interface material; never install into insulated ceilings without a thermal-rated housing. Maintain minimum clearance from combustible materials per local codes, typically 50mm. For glare control in hospitality and retail, use baffles or lenses matched to the beam angle—30-degree optics suit wall washing in hotel corridors, while 15-degree spots highlight retail displays. Conduct a mock-up before full rollout; test installed units at night to assess beam spread, color consistency, and potential ceiling discoloration from heat. In offices, pair COB downlights with dimmable drivers compatible with the building management system and ensure a minimum 0.5-meter spacing from workstations to prevent visual discomfort. Crucially, confirm all drivers are housed remotely in accessible locations—never embed them within sealed ceiling cavities—as COB drivers require ventilation and eventual replacement. Finally, specify units with consistent chromaticity bins (within a 3-step MacAdam ellipse) across all fixtures in a space to avoid visible color variation, especially critical in high-end retail and hotel environments.

Why Choose Beauty STC Lighting

Discover the power of high-performance COB LEDs and elevate your lighting solutions to the next level. At Beauty STC, we specialize in advanced COB LED technology designed for superior brightness, efficiency, and reliability across a wide range of applications. As a trusted manufacturer with years of expertise, we deliver innovative, cost-effective lighting products tailored to your needs.

Partner with Beauty STC and gain access to cutting-edge COB LED solutions backed by exceptional engineering and global support. Whether you’re developing commercial, industrial, or specialty lighting systems, our team is ready to help you succeed.

For collaboration opportunities or technical inquiries, contact us today at [email protected] and take the first step toward a brighter future.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.