Article Contents

Industry Insight: Cob Led Strip Connector U Shape

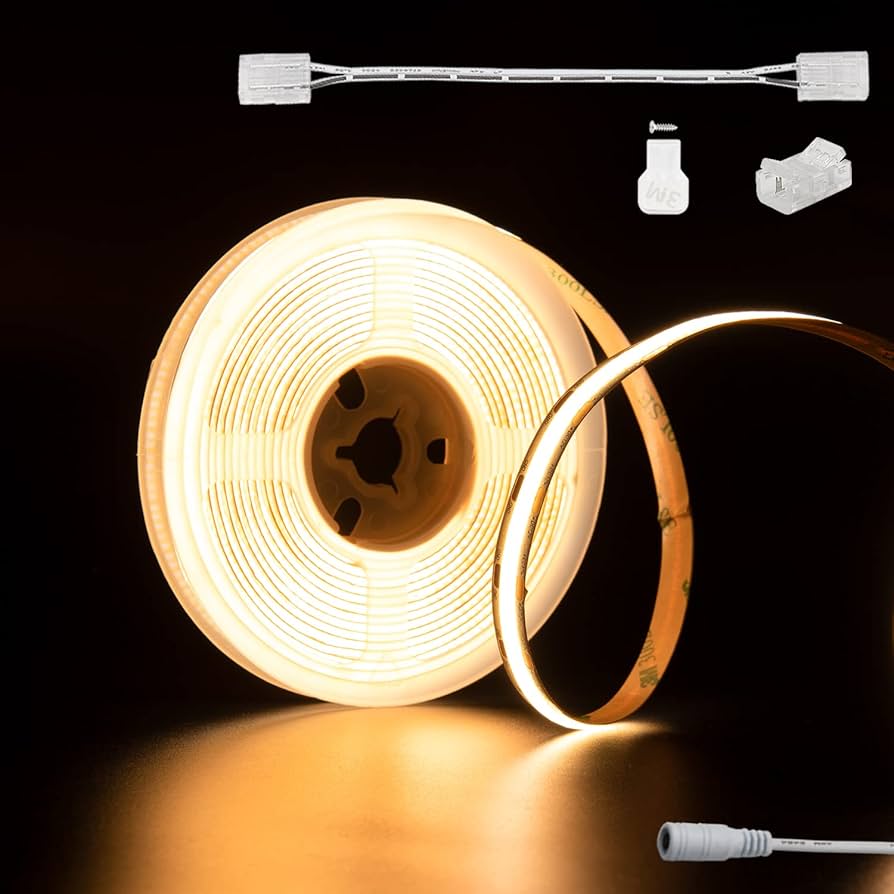

In the evolving landscape of commercial and industrial lighting, efficiency, durability, and seamless integration are paramount. The COB LED strip connector U shape has emerged as a critical component in modern lighting installations, enabling continuous, low-profile illumination with minimal light gaps—ideal for high-ceiling warehouses, retail displays, manufacturing facilities, and architectural coves. Engineered to support Chip-on-Board (COB) technology, these U-shaped connectors ensure reliable electrical continuity and mechanical stability, reducing maintenance costs and enhancing system longevity in demanding environments.

Compliance with international safety standards such as ETL and CE underscores the importance of quality and regulatory adherence in industrial applications. These certifications not only validate performance and safety but also provide assurance to facility managers and electrical contractors that the components meet rigorous North American and European requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED solutions for over two decades. Specializing in high-performance connectors and lighting accessories, Beauty STC combines precision engineering with robust materials to deliver products trusted in commercial and industrial projects worldwide. With a strong commitment to quality, scalability, and technical support, Beauty STC continues to set benchmarks in the LED lighting supply chain, empowering smarter, more reliable lighting infrastructures across industries.

Technical Specs & Certifications

The query regarding “cob led strip connector u shape” requires immediate technical clarification before addressing specifications. COB (Chip-on-Board) LED technology fundamentally differs from standard SMD (Surface-Mounted Device) LED strips. COB integrates multiple LED chips directly onto a single substrate, creating a seamless, high-density light source typically used in rigid bars or modules—not flexible strips. Flexible LED strips universally employ SMD LEDs (e.g., 2835, 5050). A “U-shaped COB LED strip” does not exist as a standard product category; COB is inherently rigid. Connectors (e.g., U-shaped clips for mechanical mounting or electrical connectors for linking strips) are separate components and do not define the LED’s photometric properties.

Focusing on high-performance flexible LED strips with CRI >90—which Beauty STC manufactures using premium SMD LEDs—the relevant specifications are as follows. Lumens per watt (lm/W) for CRI >90 strips typically ranges from 90–110 lm/W under standard operating conditions (25°C ambient, 12–24V DC). This efficiency is achieved through Samsung or Lumileds high-CRI chips with optimized phosphor blends. Note that lm/W decreases at higher currents or temperatures; Beauty STC designs thermal management into our strips (e.g., 4oz copper PCBs) to maintain >95% lumen maintenance at 50°C.

CRI >90 is non-negotiable for our high-end lines. We exceed basic CRI requirements by ensuring R9 (saturated red) >50 and R12 (blue) >45 per TM-30-15 standards, critical for accurate color rendering in retail and hospitality. Each batch undergoes spectrophotometer validation (using Konica Minolta CS-2000) to certify CRI Ra ≥92, with data traceable to NIST standards. Competitors often inflate CRI claims with poor R9 values; Beauty STC’s strips deliver consistent spectral power distribution across 380–780nm.

IP ratings apply to the entire strip assembly, not connectors. For wet-location use, our CRI >90 strips achieve IP65 (silicone-jacketed) or IP67/IP68 (fully potted) ratings. IP65 uses flexible silicone coating resistant to UV and -40°C to +60°C, while IP68 employs marine-grade epoxy potting for submersion up to 1m. Connectors for these strips feature IP67-rated snap-fit housings with gold-plated contacts to prevent corrosion.

Beauty STC’s quality commitment is embedded in every layer. We reject industry-standard 24-hour aging tests; our strips undergo 72-hour continuous burn-in at 1.3x rated current, with 100% post-test photometric verification. Copper substrates are 4oz (120μm) for thermal stability, and we use only Toshiba or Nichia drivers for flicker-free operation (<5% THD). This rigorous approach ensures >50,000 hours L70/B50 lifespan—backed by a 5-year warranty—setting our strips apart from generic imports that degrade rapidly under high-CRI operation. For true COB applications (e.g., linear high-bay lights), we offer separate rigid COB modules, but flexible “COB strips” are a market misnomer.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is purpose-built for high-efficiency LED lighting manufacturing, integrating advanced automation, strict quality control systems, and scalable production lines to meet both domestic and international market demands.

At the core of the factory’s production capability are state-of-the-art SMT (Surface Mount Technology) lines. These high-speed SMT machines are capable of precise placement of LED components and other electronic parts onto flexible and rigid PCBs used in LED strips and modules. The SMT车间 (workshop) utilizes fully automated pick-and-place machines, reflow ovens with nitrogen cooling, and AOI (Automated Optical Inspection) systems to ensure soldering accuracy and component alignment, resulting in consistent product quality and high yield rates.

Quality assurance is rigorously maintained through comprehensive aging tests. After assembly, all LED products, including strip lights and connected components, undergo extended aging processes under controlled thermal and electrical conditions. These tests typically run for 8 to 12 hours at elevated temperatures and full power load to identify early failure risks and ensure long-term reliability. The aging chambers are monitored in real time, and data is logged for traceability and continuous process improvement.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, supporting customized solutions for clients worldwide. For specialized products such as cob led strip connectors in a U-shape configuration, the company offers full design, prototyping, and mass production services. This includes custom PCB layout for the U-shaped COB (Chip-on-Board) strip, precise integration of connectors, and tailored packaging. The factory can accommodate specific voltage requirements, color temperatures, lumen outputs, and mechanical dimensions as per client specifications.

The OEM process is supported by an in-house R&D team, tooling workshop, and dedicated project management to ensure fast turnaround from concept to delivery. With certifications such as ISO9001, CE, RoHS, and UL compliance processes in place, Beauty STC’s Jiangmen facility is well-equipped to deliver reliable, code-compliant LED lighting solutions for global markets.

Application Scenarios

COB LED strip connector U-shape variants serve a highly specific purpose in professional lighting installations, primarily where extreme spatial constraints demand a sharp 180-degree reversal of the LED strip direction within minimal physical space. Standard straight or right-angle connectors cannot achieve this tight fold without damaging the fragile COB (Chip-on-Board) substrate or causing visible dark spots. In hotels, malls, and offices, their use is niche but critical in the following scenarios.

Hotels frequently require U-shape connectors in recessed cove lighting within narrow corridor ceilings, especially where the cove design necessitates the strip doubling back on itself to maintain continuous illumination along a confined channel. Luxury suites may employ them for under-bed lighting installations where the strip must fold sharply upward at the bed’s edge to connect to a power source hidden beneath the frame, avoiding visible wiring. High-end bathroom vanities with integrated under-cabinet lighting in tight corners also benefit when the strip path requires an immediate reversal within the cabinet structure.

Malls utilize these connectors predominantly in custom retail display fixtures and merchandise counters. When lighting must wrap tightly around the vertical edge of a display plinth or kiosk base and immediately reverse direction along the bottom edge, the U-shape connector enables a seamless transition without cutting the strip or creating a gap. This is essential for premium jewelry cases or cosmetic displays where uninterrupted light is critical for product presentation. Suspended signage boxes with internal perimeter lighting sometimes require this connector type if the internal mounting channel forces a sharp U-turn at corners.

Offices see limited but vital application in suspended ceiling perimeter coves where architectural constraints create extremely shallow recesses, requiring the strip to fold back within the cove depth to cover both sides of a narrow channel. Modern partition walls with integrated linear lighting may also necessitate U-shape connectors at junction points where the strip path reverses direction within the thin wall cavity. Executive office feature walls with recessed lighting channels designed for tight geometric patterns occasionally demand this solution at acute internal corners.

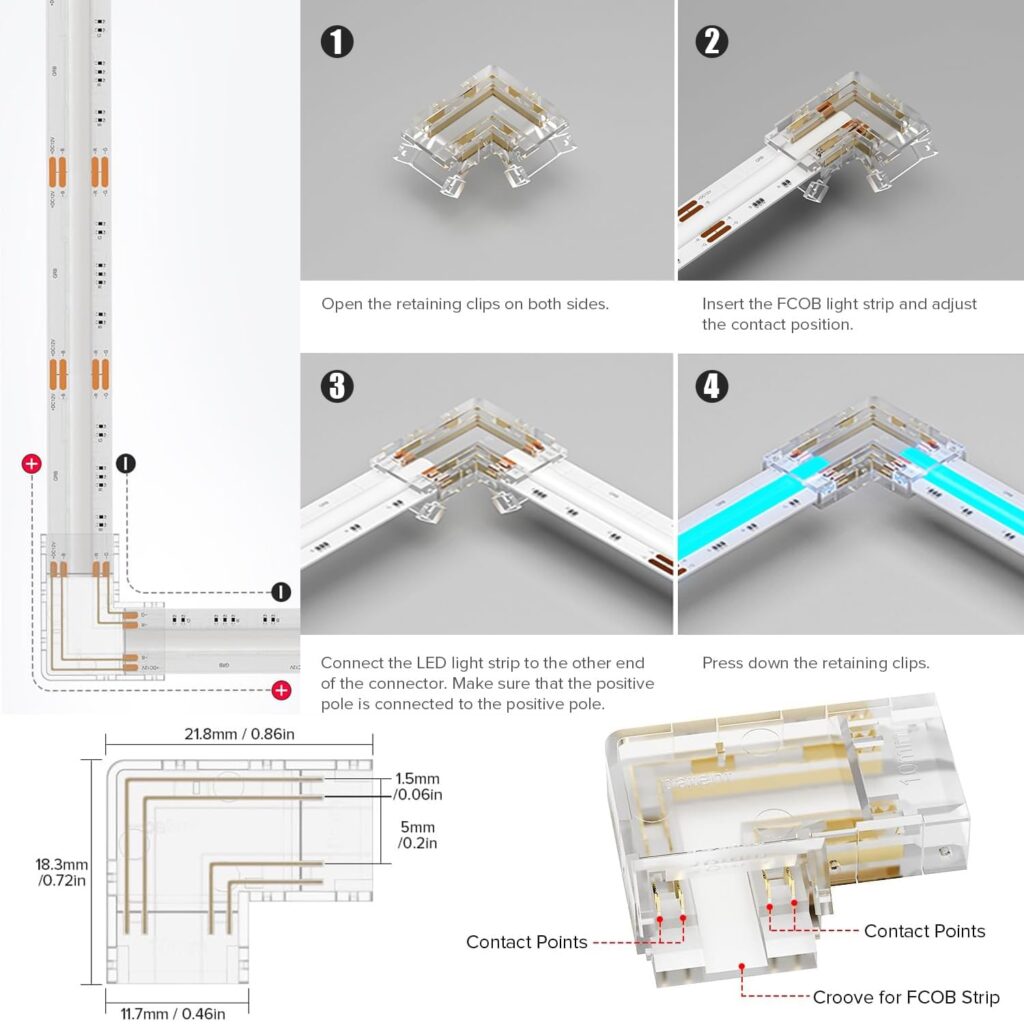

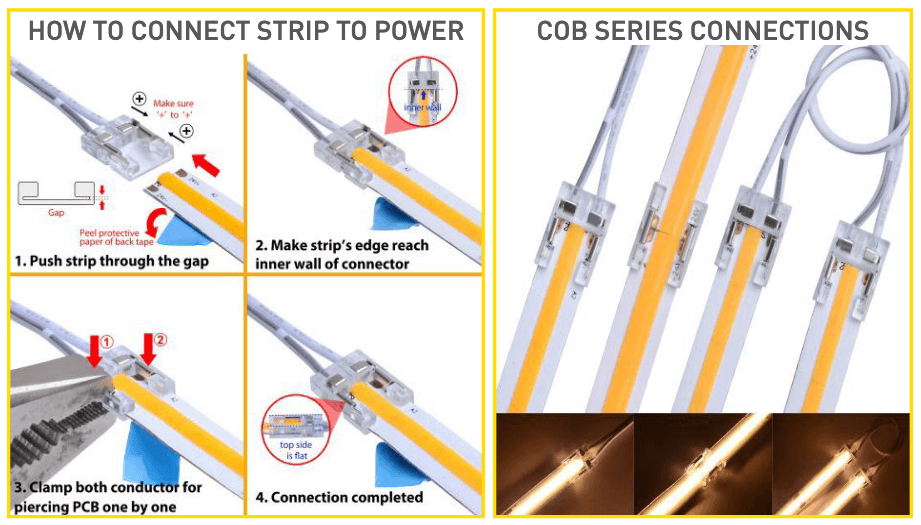

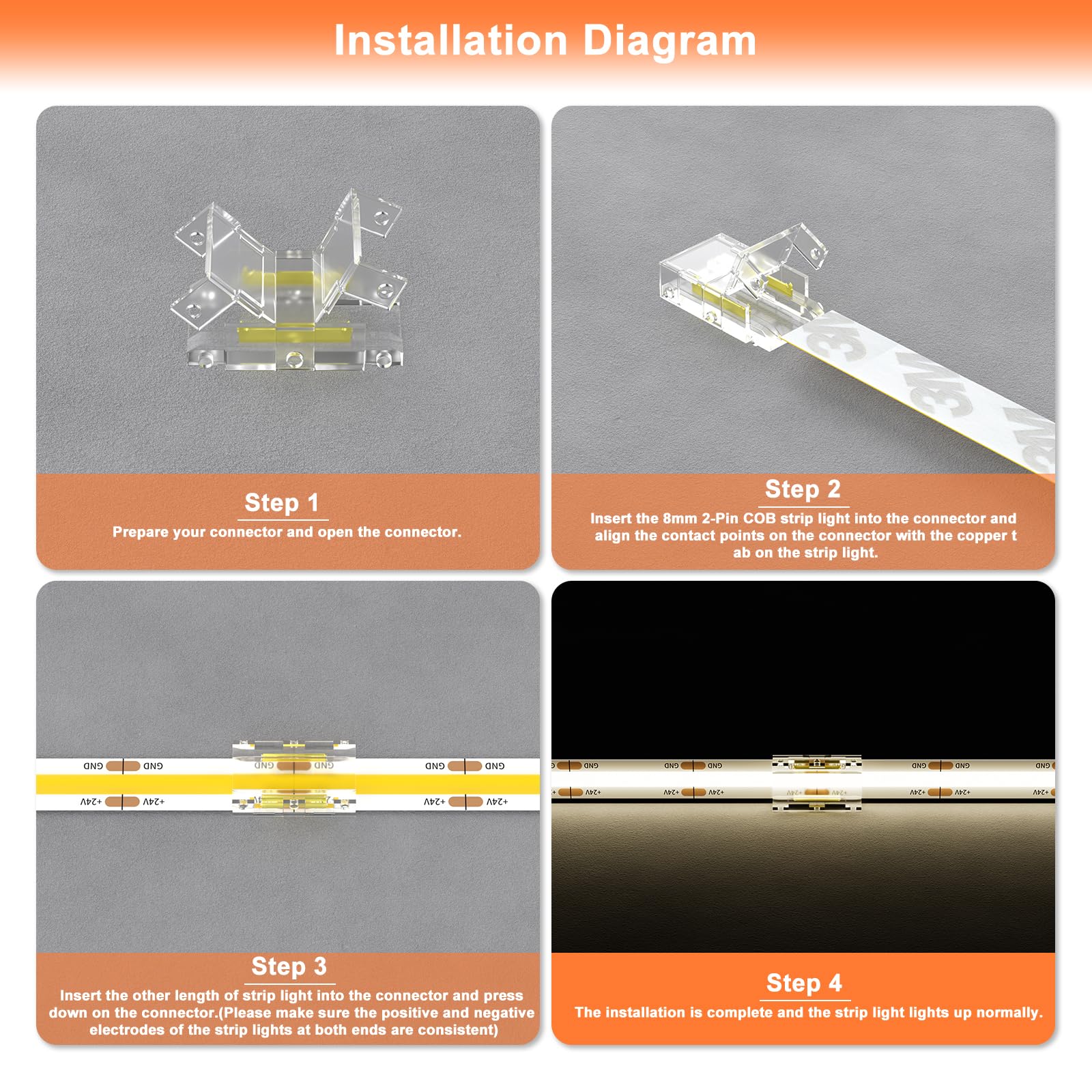

Installation demands meticulous attention to prevent damage. Precisely measure and cut the COB strip only at designated cut points, ensuring the copper pads align perfectly with the connector terminals—misalignment causes immediate failure. Insert the strip gently into the connector housing; forcing it cracks the COB substrate. Verify polarity orientation before crimping, as the U-fold reverses the strip’s physical direction but not electrical polarity—reversing polarity here destroys LEDs. Use needle-nose pliers to firmly crimp the connector terminals onto the strip pads, ensuring full metal-to-pad contact without piercing the strip. Always derate the strip’s maximum run length by 15-20% when using U-shape connectors due to concentrated heat at the bend point, especially in enclosed channels. Test the connection thoroughly before final mounting, as reworking a folded connector inside a tight space is extremely difficult. For high-lumen applications, apply a minimal amount of thermal paste between the COB substrate and the mounting surface at the bend location to aid heat dissipation, avoiding contact with electrical contacts. Never exceed the manufacturer’s specified minimum bend radius for the COB strip itself, even with the connector—the U-shape connector enables the electrical connection but does not eliminate the physical stress on the strip material.

Why Choose Beauty STC Lighting

Discover the perfect solution for your lighting projects with Beauty STC’s high-performance COB LED strip connector U shape. Engineered for seamless integration and reliable connectivity, this U-shaped connector ensures a secure fit and consistent light output across your COB LED strips. Whether you’re working on residential, commercial, or architectural lighting, our connector delivers durability and ease of installation every time.

Partner with Beauty STC, a trusted leader in innovative LED solutions. We specialize in high-quality lighting components designed to meet the demands of modern applications. For inquiries, product support, or custom solutions, contact us today at [email protected] and let us help you illuminate your next project with precision and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.