Article Contents

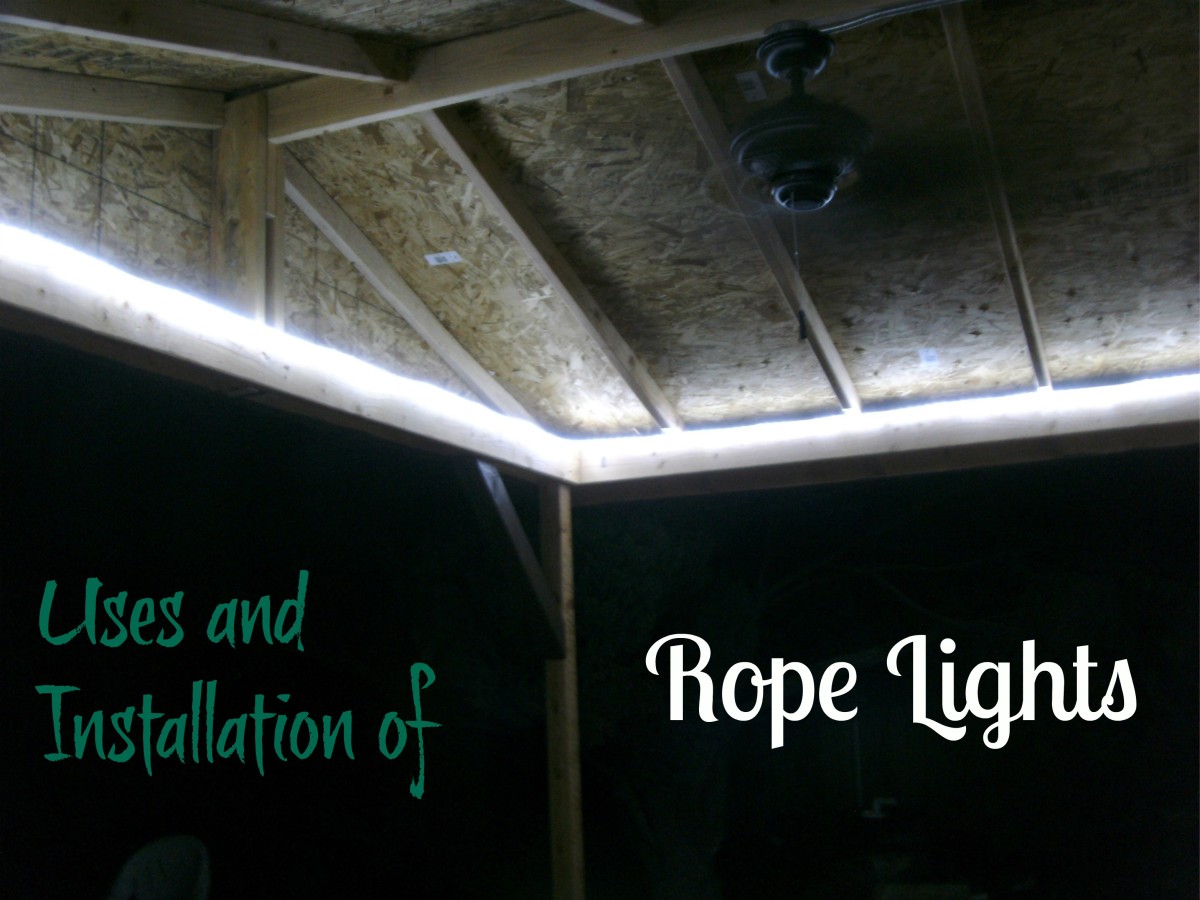

Industry Insight: Ceiling Rope Lighting

Ceiling rope lighting has emerged as a versatile and efficient solution in commercial and industrial lighting applications, where durability, flexibility, and code compliance are paramount. Unlike traditional linear fixtures, rope lighting offers seamless integration into architectural features, high-bay environments, and complex ceiling layouts, making it ideal for warehouses, manufacturing facilities, retail spaces, and transportation hubs. With advancements in LED technology and thermal management, modern ceiling rope lighting delivers uniform illumination, reduced energy consumption, and extended service life—key metrics for facility managers focused on operational efficiency and maintenance reduction.

Compliance with international safety standards is non-negotiable in industrial environments, and leading products in this category are rigorously tested to meet ETL and CE certifications. These accreditations ensure electrical safety, electromagnetic compatibility, and adherence to North American and European regulatory requirements, providing assurance to engineers, contractors, and building owners.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in high-performance commercial and industrial lighting systems, Beauty STC combines engineering precision with scalable manufacturing to deliver reliable, code-compliant products trusted by clients worldwide. With a strong commitment to quality and sustainability, the company continues to advance the role of rope lighting in modern facility design.

Technical Specs & Certifications

Ceiling rope lighting from Beauty STC Manufacturing Co., Ltd. is engineered to meet rigorous performance and reliability standards for both residential and commercial applications. Our specifications prioritize energy efficiency, color fidelity, and environmental resilience, ensuring optimal performance across diverse installation environments.

Lumens per watt (lm/W) efficiency is a core focus in our ceiling rope lighting designs. Beauty STC achieves a typical range of 110–130 lm/W under standard operating conditions, depending on correlated color temperature (CCT) and product configuration. This efficiency is sustained through advanced driver technology and optimized thermal management, utilizing aluminum-clad PCBs to dissipate heat effectively. Higher CCT options (e.g., 4000K–5000K) generally yield the upper end of this range, while warmer tones (2700K–3000K) maintain a minimum of 110 lm/W without compromising output. All products undergo LM-79 testing to validate real-world efficacy, ensuring compliance with stringent energy regulations like DLC and ERP.

Color Rendering Index (CRI) consistently exceeds 90 across our ceiling rope lighting portfolio, with R9 values above 50 to ensure accurate saturation of red tones critical for retail, hospitality, and residential settings. This is achieved through proprietary phosphor blends and strict LED binning protocols, where every emitter is spectrally matched before assembly. Unlike budget alternatives that sacrifice CRI for efficiency, Beauty STC maintains this high standard without significant lm/W trade-offs, typically within a 5–8% reduction compared to standard CRI 80 equivalents. Our Ra95+ options are available for premium applications requiring museum-grade color accuracy.

IP ratings are tailored to installation zones, with IP65 being the standard for bathroom, kitchen, and outdoor-adjacent ceiling applications. This rating guarantees complete dust protection and resistance to low-pressure water jets from any angle, critical for humid environments. For dry indoor zones (e.g., living rooms, offices), IP20 variants offer cost-effective solutions while maintaining electrical safety per IEC 60598. All IP65 models feature seamless silicone encapsulation over the LED strip and connectors, eliminating ingress points without bulky external housings. Rigorous IP validation includes 100% batch testing under IEC 60529 protocols, not just sample checks.

Beauty STC’s quality differentiation lies in our vertical integration and obsessive attention to detail. We manufacture critical components in-house, including custom silicone lenses that prevent yellowing and maintain lumen output over time, unlike epoxy-based competitors. Every reel undergoes 100% aging tests at 50°C for 48 hours, with flux and chromaticity verified post-stress to ensure batch consistency. Our triple-layer PCBs with 2oz copper prevent thermal degradation, contributing to L70 lifespans exceeding 50,000 hours. Rigorous ISO 9001-certified processes govern everything from LED wafer selection to final assembly, with third-party certifications (UL, CE, SAA) validating every claim. This commitment ensures our ceiling rope lighting delivers not just specifications on paper, but sustained performance that reduces long-term maintenance costs and enhances end-user satisfaction.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, vertically integrated facility specializing in the production of innovative LED lighting solutions. Strategically located within the Pearl River Delta, the Jiangmen factory benefits from excellent logistics and access to a skilled manufacturing workforce, enabling efficient production and timely delivery for both domestic and international markets.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-precision automated machines from leading manufacturers. These SMT lines are capable of handling a wide range of LED components with tight tolerances, ensuring consistent product quality and high-density circuit board assembly. The automated placement systems are complemented by automated optical inspection (AOI) equipment to detect soldering defects and component misalignment, resulting in high first-pass yields and reliable electronic performance.

A critical part of Beauty STC’s quality assurance process is the comprehensive aging test chamber located within the Jiangmen facility. After assembly, all lighting products, including ceiling rope lights, undergo rigorous aging tests under controlled thermal and electrical conditions. Products are typically operated at elevated temperatures and full power for extended durations—usually 4 to 8 hours or more—to identify early-life failures and ensure long-term reliability. This process helps maintain consistent performance and supports the company’s commitment to durable, high-quality LED lighting.

Beauty STC has strong OEM/ODM capabilities, particularly for niche products such as ceiling rope lighting. The factory supports full customization, including length specifications, color temperature options (ranging from 2700K to 6500K), dimming functionalities (including DALI, 0-10V, and smart controls), and custom diffuser designs. Clients can collaborate with Beauty STC’s engineering team to develop proprietary designs, packaging, and branding. The company also offers flexible MOQs, making it suitable for both large-scale projects and small-batch custom orders.

Overall, the Jiangmen factory reflects Beauty STC’s dedication to innovation, quality control, and customer-centric manufacturing, positioning it as a trusted partner for advanced LED lighting solutions in residential, commercial, and hospitality applications.

Application Scenarios

Ceiling rope lighting, specifically flexible LED rope lights, serves as a versatile decorative and ambient lighting solution in commercial environments when applied thoughtfully. Its primary role is accentuation rather than task illumination, creating visual interest and guiding spatial perception through soft, linear illumination. In hotels, this lighting excels within lobby ceiling coves to establish a welcoming, high-end ambiance without glare, particularly when using warm white temperatures around 2700K to 3000K. Guest room corridors benefit from discreet under-balcony or soffit installations where low-level illumination aids navigation at night while maintaining a serene atmosphere. High-end spa areas and pool enclosures utilize water-resistant IP67-rated rope lights within architectural coves to enhance relaxation, though direct water contact must be avoided per safety standards. Crucially, rope lighting should never replace required egress or safety lighting in these spaces.

For malls and retail environments, ceiling rope lighting proves effective in defining large volumes. Atrium perimeters and multi-story voids often incorporate rope lights within layered cove details to soften architectural edges and reduce the perceived scale of vast spaces. Food court ceilings use recessed rope lighting above serving stations or seating zones to create intimate pockets within the open layout, though careful positioning prevents direct light spill onto food preparation areas. Retail storefronts and display niches employ colored or tunable white rope lights for dynamic brand expression, but color rendering index (CRI) must exceed 90 for accurate product representation. Installation in high-ceilinged areas demands rigorous voltage drop calculations; runs exceeding 15 meters typically require parallel wiring or mid-run power injections to maintain consistent brightness, especially with 12VDC systems.

Office applications require restraint to avoid visual distraction. Executive boardrooms and premium meeting spaces integrate rope lights within suspended ceiling reveals or above feature walls to denote importance without compromising focus. Open-plan offices may use minimal under-desk or partition-top installations for subtle wayfinding during evening hours, but brightness must stay below 50 lumens per meter to prevent screen glare. Server rooms and technical areas utilize cool white (4000K) rope lighting within equipment rack perimeters for safety marking, provided the fixture carries UL 1598 or equivalent certification for indoor use near electronics.

Installation demands precise execution regardless of venue. Always mount rope lights within extruded aluminum channels with diffuser lenses; this manages heat dissipation critical for LED longevity and provides mechanical protection. Surface temperatures exceeding 60°C significantly reduce lifespan, so channels must have adequate thermal mass and airflow. Power supply selection requires calculating total load plus 20% headroom, with transformers centrally located to minimize voltage drop. For runs over 10 meters, use 24VDC systems instead of 12VDC where feasible. All connections must employ factory-sealed waterproof connectors—not field-soldered joints—to prevent corrosion and failure points. In plenum spaces above ceilings, verify local fire codes; many jurisdictions require conduit or plenum-rated cable runs even for low-voltage systems. Finally, incorporate dimmable drivers compatible with the building management system (0-10V preferred for commercial scale) and ensure maintenance access points every 15-20 meters for future servicing. Never install rope lights in direct contact with insulation or within enclosed thermal pockets, as trapped heat remains the leading cause of premature failure.

Why Choose Beauty STC Lighting

Transform your space with elegant ceiling rope lighting solutions designed for both residential and commercial applications. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality, customizable LED rope lighting that combines durability, efficiency, and modern aesthetics.

Partner with Beauty STC to access OEM and ODM services, competitive pricing, and reliable production capacity. Whether you’re a distributor, contractor, or brand looking to expand your lighting offerings, our team is ready to support your vision from concept to delivery.

For inquiries and collaboration opportunities, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.