Article Contents

Industry Insight: Candela Vs Lumens

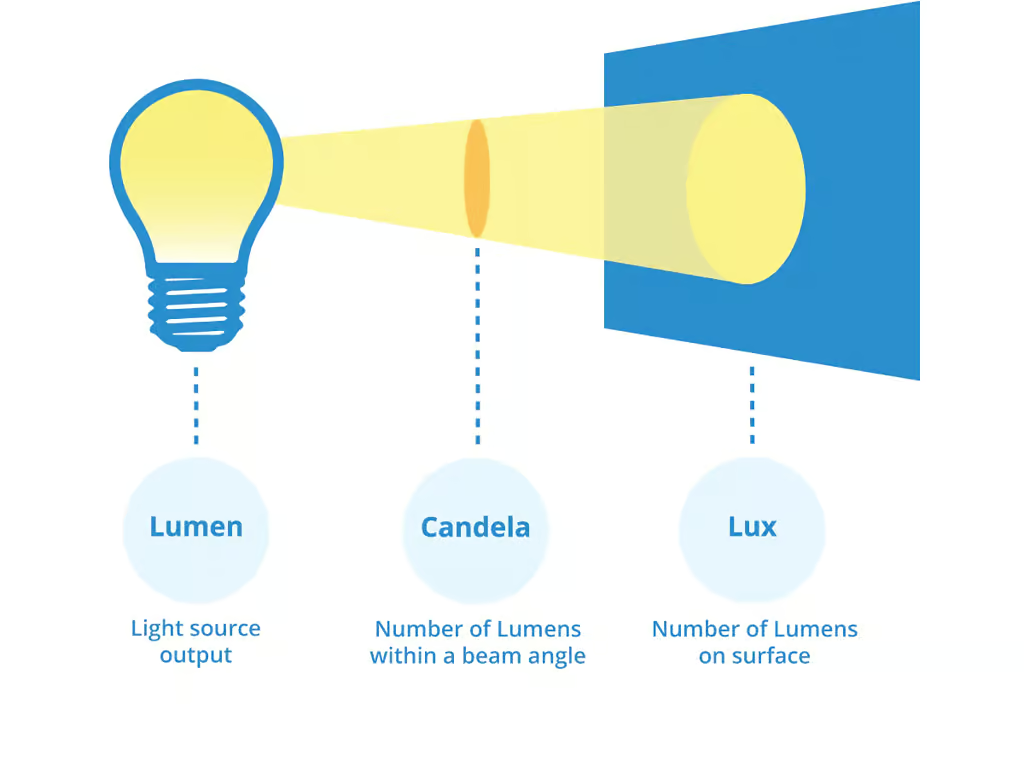

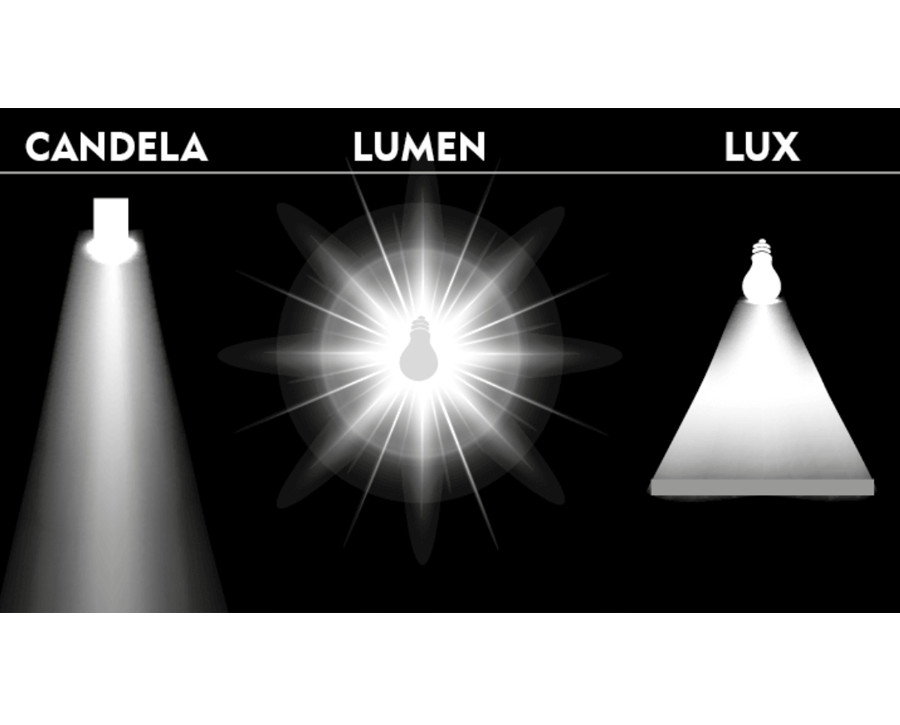

In the commercial and industrial lighting sector, understanding the distinction between candela and lumens is critical for specifying fixtures that deliver both performance and efficiency. Lumens measure the total visible light output of a source—essential for evaluating overall illumination levels across large spaces such as warehouses, factories, and office complexes. Candela, on the other hand, quantifies luminous intensity in a specific direction, making it vital for applications requiring focused lighting, such as high-bay fixtures, task lighting, or outdoor area lighting where beam control impacts safety and visibility. As energy codes tighten and facility managers demand greater precision in lighting design, selecting luminaires that balance lumen output with optimal candela distribution has become a cornerstone of modern lighting strategy.

Compliance with international standards such as ETL and CE further ensures that lighting products meet rigorous safety, performance, and electromagnetic compatibility requirements—non-negotiable elements in commercial and industrial environments where reliability and regulatory adherence are paramount. For over two decades, Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting solutions tailored for these demanding sectors. Combining deep technical expertise with a commitment to quality and compliance, Beauty STC delivers high-performance luminaires engineered to optimize both lumen efficacy and candela distribution, supporting smarter, safer, and more sustainable commercial and industrial lighting installations worldwide.

Technical Specs & Certifications

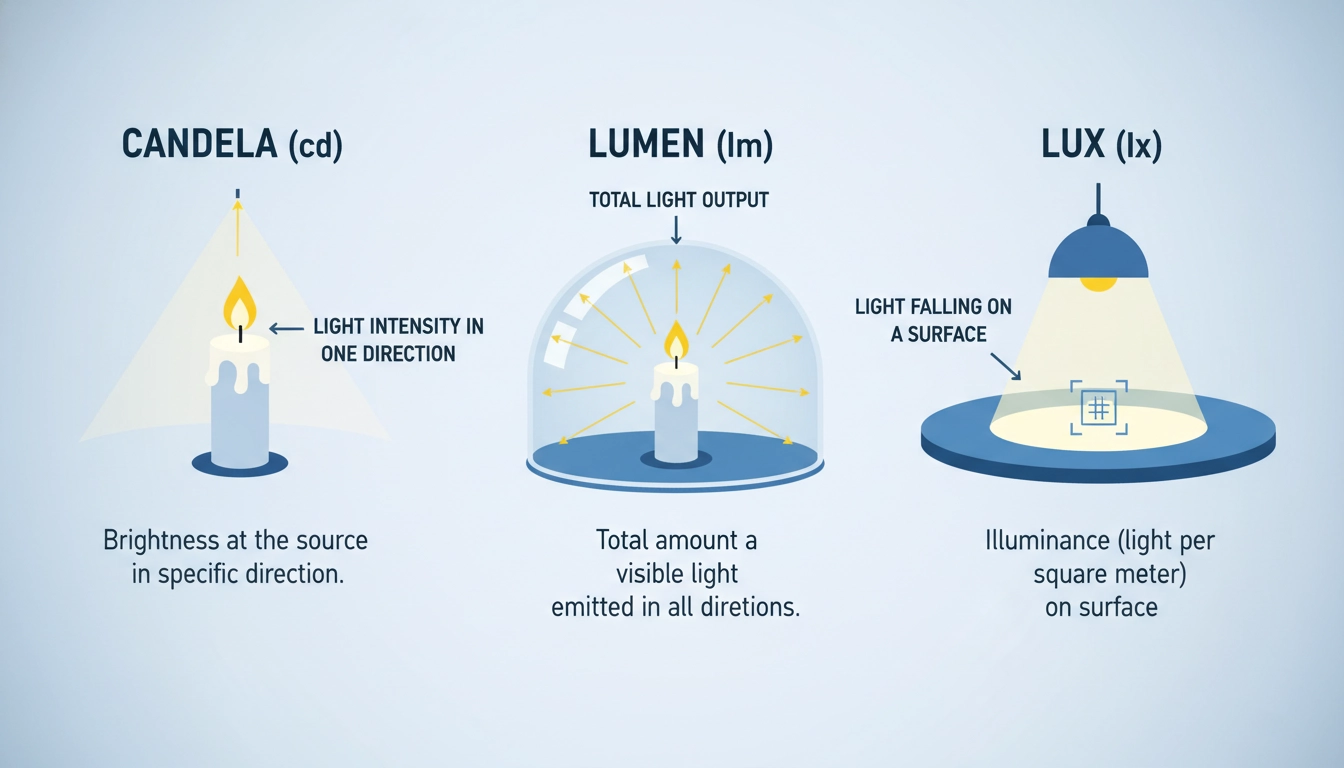

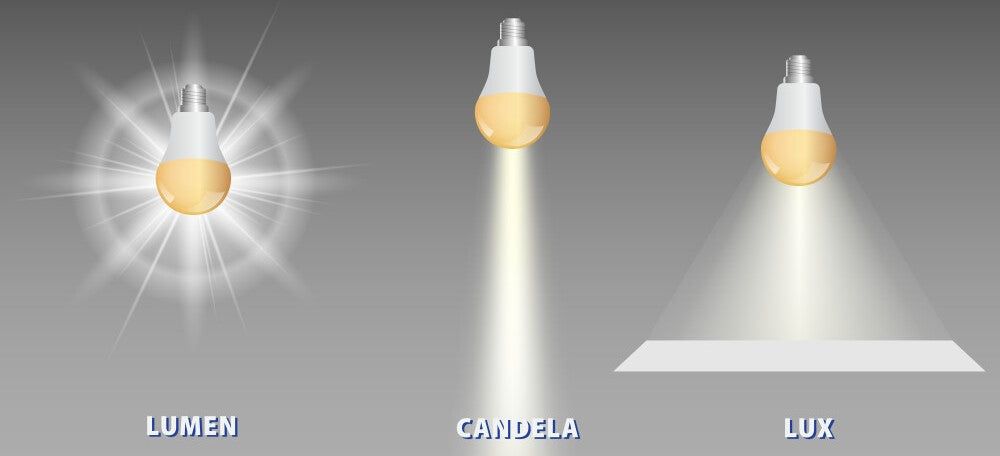

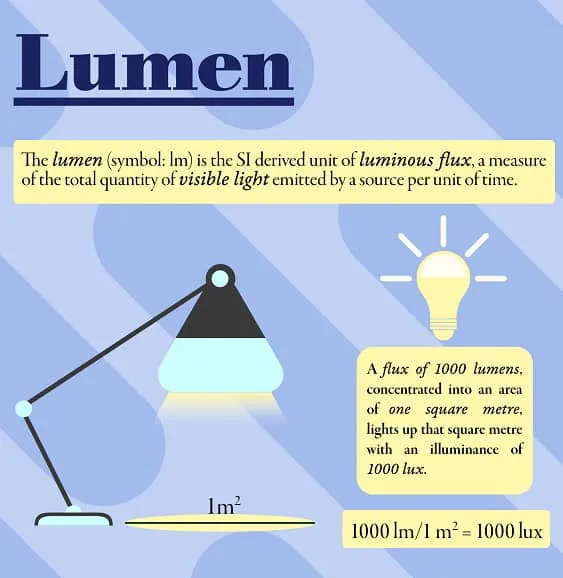

Candela and lumens represent fundamentally distinct photometric quantities requiring precise technical differentiation. Candela (cd) quantifies luminous intensity, defined as the light flux emitted per unit solid angle in a specific direction, per the IEC 60050 standard. It is critical for applications demanding controlled beam distribution such as spotlights or task lighting, where directional intensity directly impacts visual performance. Lumens (lm), conversely, measure total luminous flux – the integrated light output across all directions, representing the overall perceived brightness of a source. This distinction is paramount; a high-candela spotlight may have moderate total lumens, while a diffuse ambient fixture might deliver high lumens with low candela values in any single direction.

Lumens per watt (lm/W) defines luminous efficacy, indicating energy efficiency in converting electrical power to visible light. Beauty STC achieves industry-leading efficacies exceeding 150 lm/W in commercial-grade LED modules through advanced thermal management systems, proprietary phosphor formulations, and high-efficiency constant-current drivers. Our multi-layer ceramic PCBs and optimized heat sink designs maintain junction temperatures below critical thresholds, preventing lumen depreciation and ensuring sustained efficacy over 50,000+ hours. Unlike budget fixtures where efficacy drops sharply under thermal stress, Beauty STC’s rigorous thermal validation guarantees real-world performance aligns with laboratory specifications, directly reducing operational costs for end-users.

For color quality, Beauty STC mandates CRI (Ra) >95 across all premium architectural and retail lighting lines, with R9 (saturated red) values consistently above 90. This exceeds the requested CRI >90 benchmark and addresses critical limitations of basic CRI metrics. Achieving this requires tight binning of LED chips to ±0.003 on the Planckian locus, coupled with multi-phosphor blends that fill spectral gaps in the 600-650nm range. Our quality control employs spectroradiometers calibrated to NIST standards, verifying CRI under multiple correlated color temperatures (2700K-4000K). This precision ensures accurate color rendering for applications like cosmetic retail or art galleries, where poor R9 values would distort warm tones – a common flaw in CRI 90+ solutions from lesser manufacturers.

IP (Ingress Protection) ratings define environmental resilience per IEC 60529. Beauty STC fixtures undergo certified third-party testing for all claimed ratings. IP65 signifies complete dust protection and resistance to low-pressure water jets from any direction, suitable for outdoor canopies or industrial washdown areas. IP67 adds temporary submersion capability (1m depth for 30 minutes), critical for landscape lighting or marine environments. Crucially, Beauty STC avoids inflated IP claims through robust engineering: silicone gaskets with dual sealing lips, corrosion-resistant housings, and conformal-coated driver electronics. Unlike competitors who achieve IP ratings only in static lab conditions, our fixtures maintain integrity under thermal cycling and UV exposure, validated via 1,000-hour accelerated weathering tests.

Beauty STC’s quality manifests in the integration of these specifications. Our systems engineering approach ensures high efficacy does not compromise CRI – through spectral optimization that minimizes Stokes shift losses – while IP-rated enclosures incorporate thermally conductive yet electrically insulating materials to prevent efficacy degradation. Every production batch undergoes photometric, electrical, and environmental validation against IES LM-79/LM-80 standards, with traceable calibration records. This commitment to technical rigor, from semiconductor-level binning to full-system validation, delivers lighting solutions where photometric performance, color fidelity, and environmental durability are not trade-offs but co-engineered outcomes.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-volume, precision production of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

The production floor is anchored by advanced SMT (Surface Mount Technology) lines, which are critical for the accurate and high-speed placement of LED components onto printed circuit boards. The factory utilizes multiple high-precision SMT machines capable of handling a wide range of component sizes and packaging types, ensuring consistent soldering quality and optimal thermal management. These SMT lines are integrated with automated optical inspection (AOI) systems to detect placement and soldering defects in real time, significantly enhancing product reliability.

A comprehensive aging test process is implemented to ensure product durability and performance. After assembly, LED lighting units undergo rigorous aging procedures under controlled temperature and humidity conditions, typically operating continuously for 8 to 24 hours. During this phase, electrical parameters are monitored to identify early failures, and thermal performance is evaluated to confirm long-term stability. The aging test chamber setup supports batch processing, allowing for efficient screening of large production runs before shipment.

Beauty STC offers robust OEM (Original Equipment Manufacturing) capabilities, supporting customized product development from design to mass production. One notable technical strength is the company’s ability to assist clients in translating photometric specifications, such as converting between candela and lumens based on beam angle and intended application. Engineers at the Jiangmen facility can provide detailed photometric testing and reporting, using integrating spheres and goniophotometers to measure luminous flux (lumens) and luminous intensity (candela). This enables accurate product optimization for clients who specify performance in either unit, whether for directional spotlights (often rated in candela) or general illumination (typically in lumens).

Overall, the Jiangmen factory reflects Beauty STC’s commitment to manufacturing excellence, technical expertise, and customer-centric service, making it well-suited for both standard and custom LED lighting solutions in domestic and international markets.

Application Scenarios

Candela and lumens serve distinct purposes in lighting design, and understanding their application is critical for achieving functional and aesthetic goals in commercial spaces. Candela (cd) measures luminous intensity in a specific direction, indicating how focused or bright a light beam appears from a particular angle. Lumens (lm) measure the total visible light output emitted by a source in all directions, representing overall brightness. The choice between prioritizing candela or lumens depends entirely on the lighting task and location within the space.

In hotel lobbies and corridors, lumens are the primary concern for general ambient lighting. High-lumen LED panels or downlights ensure uniform illumination across large floor areas, meeting standards like 200-300 lux for safe navigation. However, candela becomes essential for accent lighting. For example, illuminating artwork or reception desks requires directional fixtures with controlled candela ratings to create defined pools of light without glare. A track light with 1500 cd at 30 degrees effectively highlights a feature wall, while the same fixture’s lumen output (e.g., 1200 lm) ensures sufficient total light. Misapplying high-candela fixtures for general lighting causes uncomfortable brightness contrasts, while using high-lumen but low-candela sources for accents results in washed-out, ineffective highlighting.

Malls demand careful candela management in retail zones. Jewelry displays or high-end fashion racks need narrow-beam spotlights (e.g., 3000 cd at 15 degrees) to concentrate light on merchandise, enhancing visual appeal and perceived value. Here, the candela rating directly impacts product visibility and sales. Conversely, broad walkways and food courts rely on high-lumen outputs from suspended LED troffers or high-bays (e.g., 15,000 lm fixtures) to maintain even 300-500 lux across expansive areas. Using high-lumen but uncontrolled candela fixtures near entrances creates hazardous glare for customers transitioning from daylight, while insufficient candela in display areas forces stores to over-light with excessive lumens, increasing energy costs unnecessarily.

Office environments prioritize lumens for task lighting uniformity. Open-plan workspaces require high-lumen LED panels (e.g., 4000-5000 lm) to deliver 500 lux at desk height across large zones, reducing eye strain. Candela considerations arise in specific scenarios: conference room projectors need low-candela ambient lighting to prevent screen glare, while adjustable task lights must direct sufficient candela (e.g., 500 cd) precisely onto documents without illuminating the user’s eyes. Installing high-candela downlights directly over desks causes disabling glare, whereas uniform high-lumen lighting without localized candela control in meeting rooms creates shadowed areas during presentations.

Installation tips begin with verifying beam angles and candela distributions via photometric reports, not just lumen totals. For candela-critical applications like retail displays, ensure fixtures are mounted perpendicular to the target surface and at the manufacturer’s specified distance—tilting a 30-degree beam spotlight by 10 degrees can reduce effective candela by 30%. In offices, align high-lumen panels parallel to desks to minimize screen reflections, maintaining a 1.5:1 uniformity ratio. Always measure illuminance (lux) at task height during commissioning; a 5000-lumen office fixture delivering only 300 lux at desks indicates poor lumen application. For hotels, use dimmable high-lumen systems in lobbies but pair accent fixtures with adjustable mounting hardware to fine-tune candela direction as decor changes. Crucially, never substitute lumen output for candela requirements in directional lighting—no amount of total lumens compensates for incorrect beam focus in display or safety-critical zones.

Why Choose Beauty STC Lighting

Understanding the difference between candela and lumens is essential for choosing the right lighting solution for your application. Candela measures luminous intensity in a specific direction, making it ideal for spotlighting and focused beams, while lumens measure total visible light output, which is critical for general illumination. At Beauty (STC) Manufacturing Co., Ltd., we specialize in delivering high-performance LED lighting solutions engineered with precision based on accurate photometric data.

Partner with Beauty STC to ensure your lighting projects are built on technical excellence and industry expertise. Our team is ready to assist you with custom solutions tailored to your photometric and design requirements. For more information or to discuss your next project, contact us at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.