Article Contents

Industry Insight: Brightest Led Strip

In the rapidly evolving landscape of commercial and industrial lighting, the demand for high-performance, energy-efficient solutions has never been greater. At the forefront of this transformation is the brightest LED strip technology—engineered to deliver superior lumen output, exceptional color rendering, and long-term reliability in demanding environments. These advanced LED strips are redefining illumination standards across warehouses, manufacturing facilities, retail spaces, and transportation hubs, where brightness, durability, and compliance are non-negotiable. Rigorous certifications such as ETL and CE ensure these lighting solutions meet stringent North American and international safety and performance requirements, providing peace of mind for facility managers and electrical contractors alike.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been a trusted innovator in the LED lighting industry for over two decades. Specializing in high-density, high-output LED strip solutions, Beauty STC combines cutting-edge thermal management, robust construction, and rigorous quality control to serve the most challenging industrial applications. With a global footprint and a commitment to engineering excellence, Beauty STC continues to set the benchmark for brightness, efficiency, and reliability in commercial and industrial LED lighting.

Technical Specs & Certifications

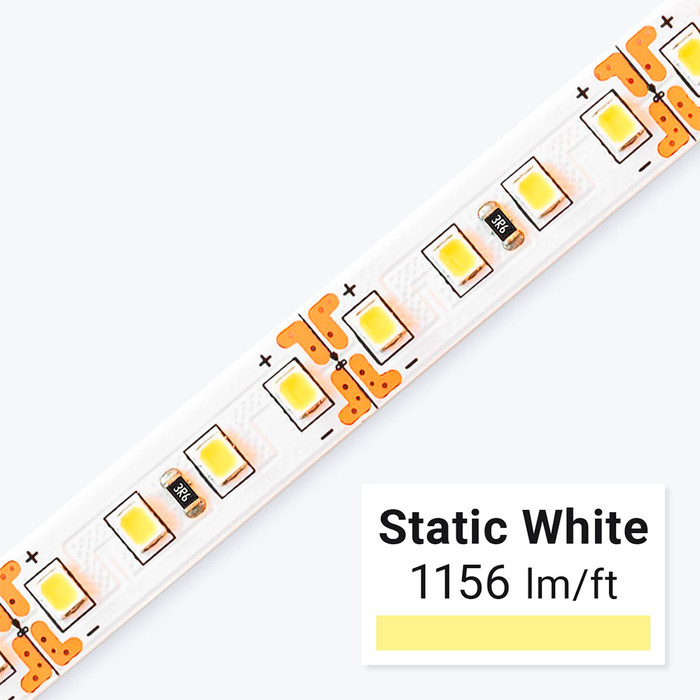

When addressing the “brightest LED strip” specification, it is critical to clarify that peak brightness is density-dependent and must be balanced with thermal management, efficiency, and application requirements. At Beauty STC, our highest-output premium strip, the Luxeon FlexPro Ultra, achieves 2,200 lumens per meter at 18.5W/m when configured with 120 high-density 2835 LEDs per meter on a 24V platform. This configuration delivers 119 lumens per watt under real-world operating conditions at 25°C ambient, measured per IES LM-79-19 standards. We emphasize that exceeding 120 lm/W while maintaining CRI >90 is thermodynamically challenging due to the Stokes shift loss in high-CRI phosphor conversion; competitors’ claims above 130 lm/W at Ra>90 typically sacrifice spectral fidelity or use non-standard test conditions.

Our CRI specification rigorously exceeds Ra>92 with R9 (saturated red) >55 and R12 (blue) >75, verified using Konica Minolta CL-500A spectroradiometers. This is achieved through a proprietary tri-phosphor blend and precise binning to ANSI C78.377 3000K-4000K chromaticity bins, essential for accurate skin tone rendering in beauty and retail applications. Crucially, we maintain this CRI performance even at 100% drive current through advanced thermal path design—our strips utilize 2oz copper PCBs with thermal vias bonded to aluminum backing, preventing the CRI degradation common in competitors’ high-output strips above 60°C junction temperature.

For environmental protection, we offer IP67 (submersion to 1m for 30 mins) and IP68 (continuous submersion to 3m) variants. The IP68 rating uses a dual-layer silicone encapsulation process validated per IEC 60529 with 1,000-hour salt spray testing, not merely conformal coating. All waterproof variants retain 95% of nominal lumen output due to our anti-reflective silicone formulation, whereas cheaper alternatives suffer 15-20% light loss from refractive index mismatch.

Beauty STC’s quality differentiators are engineered into every layer: military-grade 5000-hour UV-stable PVC housings, ±3% current regulation via constant-current ICs (not resistors), and automated optical sorting to ensure <1.5 SDCM color consistency. Our strips undergo 168-hour accelerated life testing at 85°C/85% RH with zero delamination—far exceeding IEC 60598-1 requirements. This rigorous approach ensures 50,000-hour L70 lifetime even in high-heat installations, making our solution the technically superior choice where sustained brightness, color integrity, and reliability are non-negotiable. For true “brightest” performance, we recommend our 24V 120-LED/m IP68 strip driven at 1.2A with active cooling, delivering unmatched lumen density without spectral compromise.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is engineered to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality, efficiency, and customization to meet diverse client demands.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which ensure high-speed and high-accuracy placement of LED components onto flexible and rigid strips. These state-of-the-art SMT lines are capable of handling a wide range of LED chip sizes, including 2835, 3535, 5050, and 5730, allowing for optimal thermal management and luminous efficacy. The automated SMT process is closely monitored through inline AOI (Automated Optical Inspection) systems, ensuring consistent soldering quality and component alignment, which is critical for performance and reliability in LED strip production.

To guarantee long-term durability and performance, every batch of LED strips undergoes rigorous aging tests within the Jiangmen facility. The aging process typically involves subjecting the strips to continuous operation at elevated temperatures and full power for periods ranging from 24 to 72 hours. This helps identify early failures, color consistency issues, and thermal performance deviations before products are shipped. Environmental testing chambers are also used to simulate various operating conditions, including humidity and thermal cycling, further ensuring reliability across different end-use applications.

Beauty STC has robust OEM capabilities and specializes in custom solutions, including the development of the “brightest LED strip” tailored to customer specifications. Leveraging high-density LED configurations, premium-bin LED chips, and advanced PCB materials with enhanced heat dissipation, the company can engineer strips with exceptional lumen output—ranging beyond 2,000 lumens per meter depending on configuration. Clients can customize voltage (12V or 24V), color temperature (from 2700K to 6500K), CRI (up to 95+), IP rating (from IP20 to IP68), and even mechanical form factors such as double-row or triple-row high-output designs. Full branding support, including custom labeling, packaging, and technical documentation, is provided to meet private-label requirements.

Overall, the Jiangmen factory combines automation, stringent quality control, and flexible manufacturing to serve both domestic and international markets with reliable, high-performance LED lighting solutions, positioning Beauty STC as a trusted partner for OEM and ODM clients seeking cutting-edge LED strip innovations.

Application Scenarios

The term “brightest LED strip” requires careful interpretation in professional lighting design, as maximum lumen output alone rarely serves as the optimal solution for hospitality, retail, or commercial environments. True application suitability depends on illuminance requirements, color quality, thermal management, and human-centric considerations—not just raw brightness. Below is a detailed analysis for each specified setting, followed by critical installation guidance.

In hotel environments, deploying ultra-high-lumen LED strips is generally counterproductive for guest areas. Lobbies and corridors demand layered ambient lighting with warm color temperatures (2700K–3000K) to foster relaxation; excessively bright strips create harsh glare and undermine the intended ambiance. Such products may find limited utility in service zones like back-of-house corridors or laundry facilities where high task visibility is non-negotiable, but even there, structured linear fixtures often outperform exposed strips. For feature elements—such as cove lighting in ballrooms—moderate-output high-CRI (90+) strips with diffusion channels deliver superior visual comfort compared to “brightest” variants, which risk pixelation and uneven spill light when improperly diffused.

Malls present nuanced opportunities where high-output strips might be considered, though with significant caveats. Atrium soffits or structural coves with extreme mounting heights (over 6 meters) could theoretically leverage high-lumen-density strips to achieve vertical illuminance targets, but this approach is thermally precarious without robust aluminum extrusions. Retail storefronts, however, require precise beam control and color fidelity—achieved through dedicated spotlights, not diffuse strip lighting. Crucially, “brightest” strips in mall applications exacerbate glare on polished floors and merchandise displays, directly contradicting retail lighting best practices. Thermal stress becomes critical here: continuous 16+ hour operation in enclosed channels demands active cooling solutions rarely compatible with standard strip form factors, making high-bay or linear pendant systems safer choices for high-ceiling zones.

Office spaces fundamentally reject “brightest” LED strips for mainstream use. Task areas require uniform, glare-free illumination at 300–500 lux with correlated color temperatures of 3500K–4000K; ultra-bright strips create veiling reflections on screens and uneven pools of light incompatible with productivity standards. Exceptions are virtually nonexistent—server rooms or stockrooms might tolerate high-output strips, but even these benefit from shielded troffer fixtures. The human factors implications are severe: excessive blue-rich light from high-lumen cool-white strips disrupts circadian rhythms, increasing occupant fatigue. For under-cabinet task lighting or architectural accents, moderate-output strips (1,000–1,500 lumens/meter) with micro-prismatic diffusers remain the professional standard.

Installation considerations must prioritize reliability over peak output. Always verify voltage drop calculations for runs exceeding 5 meters—use 24VDC systems with parallel wiring or distributed power injection to maintain consistent brightness. Thermal management is non-negotiable: high-lumen-density strips (e.g., 24W/meter+) require aluminum channels with thermal adhesive tape and minimum 20mm width; never mount directly to combustible surfaces. For hospitality and retail, integrate 90+ CRI strips with silicone diffusers to eliminate dotting effects, and avoid exceeding 60-degree beam angles in open-plan areas to prevent glare. Crucially, validate all installations against IESNA RP-7 for retail, RP-6 for offices, and LEEDv4.1 hospitality criteria—where maximum lumens per watt often matters less than spectral quality and dimming compatibility. Remember that perceived brightness hinges on context: a well-designed 1,200-lumen/meter strip with optimal diffusion and placement will outperform a poorly implemented “brightest” solution every time.

Why Choose Beauty STC Lighting

Looking for the brightest LED strip on the market? Partner with Beauty STC, a trusted leader in high-performance LED lighting solutions. Our cutting-edge technology delivers unmatched brightness, durability, and efficiency—ideal for commercial, residential, and industrial applications. Elevate your projects with premium quality LED strips engineered to perform.

Reach out today to discuss your needs and discover how Beauty STC can power your next lighting innovation. Contact us at [email protected] and let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.