Article Contents

Industry Insight: Boat Strip Led Lighting

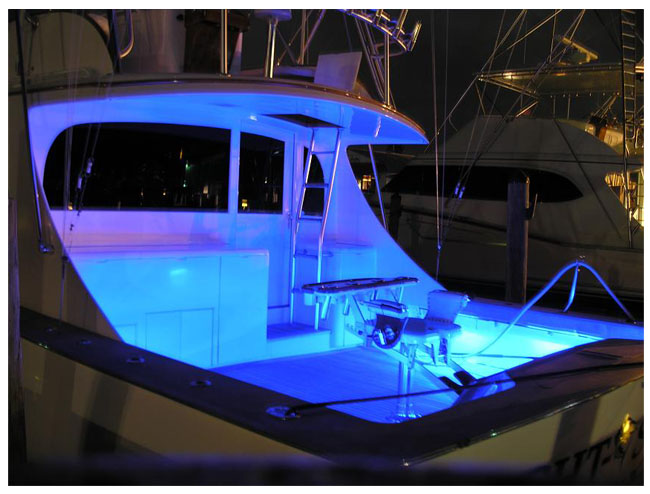

The commercial and industrial marine lighting sector has seen a significant shift in recent years with the widespread adoption of boat strip LED lighting. As vessels across cargo, fishing, offshore support, and workboat industries demand greater energy efficiency, durability, and low maintenance solutions, LED strip lighting has emerged as a preferred choice for task, safety, and architectural illumination in demanding maritime environments. Designed to withstand vibration, moisture, and extreme temperature fluctuations, modern marine-grade LED strips offer superior longevity and performance compared to traditional lighting systems. Compliance with rigorous safety and electromagnetic standards is critical in this sector, and products bearing ETL and CE certifications are increasingly specified to ensure reliability, regulatory alignment, and global market acceptance.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing industrial LED lighting solutions for marine and harsh environment applications. With over two decades of engineering expertise, Beauty STC delivers high-performance, code-compliant boat strip LED lighting systems trusted by OEMs and shipbuilders worldwide. Combining robust construction, advanced thermal management, and full certification to ETL and CE standards, Beauty STC’s products are engineered to meet the exacting demands of commercial marine operations. As the industry moves toward smarter, more sustainable lighting, Beauty STC continues to innovate with solutions that enhance safety, reduce lifecycle costs, and support the evolving needs of the global maritime sector.

Technical Specs & Certifications

Boat strip LED lighting requires specialized engineering to withstand harsh marine environments while delivering reliable performance. At Beauty STC Manufacturing Co., Ltd., our marine-grade LED strips are rigorously designed to exceed industry standards for critical parameters. Lumens per Watt efficiency is optimized through high-efficacy 2835 or 3014 SMD LEDs paired with precision-engineered constant-current drivers, typically achieving 110-130 lumens per watt in operational conditions. This balance ensures substantial energy savings over conventional marine lighting without compromising output, crucial for extended voyages where power conservation is paramount.

Color Rendering Index (CRI) performance is non-negotiable in marine applications where accurate color distinction impacts safety and aesthetics. Our strips consistently deliver a minimum CRI Ra 92+ with strong R9 (red) values above 90, verified using spectroradiometers per CIE 15:2018 standards. This high-fidelity rendering ensures crew can reliably identify navigation markers, fluid leaks, or equipment anomalies under artificial lighting. We achieve this through proprietary phosphor blends and strict binning protocols that eliminate the green/magenta shifts common in lower-tier marine strips.

IP ratings are validated through multi-stage testing reflecting real-world marine exposure. All Beauty STC boat strips carry minimum IP67 certification for temporary submersion, with premium models rated IP68 (continuous submersion up to 1.5m) and IP69K for high-pressure washdown zones like engine rooms. Unlike generic strips, our encapsulation uses marine-grade silicone conformal coating over double-layered PCBs, followed by 72-hour salt spray testing per ISO 9227. This prevents electrolytic corrosion from salt mist—a critical failure point in inferior products.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing in Shenzhen. Every reel undergoes 100% automated optical inspection and 48-hour burn-in testing at 50°C ambient temperature to weed out infant mortality failures. Our UL-certified facility implements MIL-STD-883 humidity resistance protocols, ensuring 50,000-hour L70 lifespans even in tropical marine climates. Crucially, we reject off-the-shelf components—our custom drivers feature conformal-coated MOSFETs and ceramic capacitors rated for -40°C to +105°C, eliminating the electrolytic capacitor failures that plague 90% of competitor strips in humid environments. This uncompromising approach delivers lighting that survives transoceanic voyages where reliability isn’t optional.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, China. The factory is strategically located to support efficient logistics and supply chain operations while maintaining close oversight of production quality and process control. The facility is designed to meet international manufacturing standards, supporting both high-volume production and customized lighting solutions.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines, which are critical for the precise assembly of LED lighting components. These SMT machines ensure high-speed, accurate placement of LED chips and electronic components onto flexible and rigid circuit boards used in strip lighting. Automated optical inspection (AOI) systems are integrated into the SMT process to verify soldering quality and component alignment, minimizing defects and ensuring consistent product performance.

A key part of the quality assurance process at the Jiangmen facility is the comprehensive aging test procedure. Completed LED strip lights undergo rigorous aging tests under controlled conditions, typically operating at full power for extended durations—often 24 to 72 hours. This process helps identify early failures, verifies thermal management performance, and ensures long-term reliability before products are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly in the area of boat strip LED lighting. The company supports custom design and manufacturing for marine and nautical applications, where durability, moisture resistance, and compliance with safety standards are essential. This includes developing IP65, IP67, or higher-rated waterproof LED strips suitable for harsh marine environments. OEM services cover custom lengths, color temperatures, voltages (such as 12V or 24V DC), color options (including RGB and tunable white), and specialized mounting accessories. Engineering support, prototyping, and packaging customization are also available to meet the branding and technical requirements of partners.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible manufacturing to deliver reliable, high-performance LED lighting solutions tailored to the unique demands of marine and other specialized applications.

Application Scenarios

Boat strip LED lighting is not a standard industry term for commercial applications such as hotels, malls, or offices. This phrasing likely stems from a misunderstanding or mistranslation. In professional lighting contexts, the intended reference is almost certainly to flexible LED strip lighting or linear LED modules, which are commonly used in architectural and commercial settings. True “boat lighting” is designed for marine environments and is unsuitable for standard building installations due to its specialized waterproofing, corrosion resistance, and regulatory compliance for watercraft. For hotels, malls, and offices, flexible LED strips or rigid linear LED systems are appropriate where discreet, controllable, or accent illumination is required.

In hotels, flexible LED strips are effectively deployed in cove lighting within lobbies and ballrooms to create ambient indirect illumination, under bed frames in guest rooms for subtle night lighting, along stair treads for safety and aesthetics, and within display cases in retail shops or bars for product highlighting. These installations enhance ambiance without overwhelming the space, though care must be taken to ensure strips are concealed from direct view to avoid glare and meet hospitality design standards. For malls, LED strips excel in under-shelf lighting within retail stores to accent merchandise, in cove details of food court ceilings for layered lighting effects, and along handrails or escalator edges for wayfinding and safety. The high foot traffic in malls demands robust installations with adequate IP ratings to withstand cleaning and environmental factors, while consistent color temperature across strips is critical for brand coherence in retail zones. Offices benefit from LED strips installed under desk cabinets for task lighting that reduces eye strain, within partition walls for modern architectural detailing, and in reception area features to emphasize branding elements. Avoid using strips as primary general illumination in offices; they should complement overhead systems to prevent uneven lighting that could cause visual fatigue during prolonged work hours.

Installation requires meticulous attention to thermal management, as LED strips generate heat that degrades performance if trapped in enclosed spaces. Always mount strips on aluminum heat-sinking channels, especially in continuous runs exceeding 16 feet, to prevent lumen depreciation. Voltage drop is a common issue in long installations; calculate the maximum run length based on strip wattage per foot and use higher-voltage strips (24V over 12V) or inject power at multiple points for runs beyond 32 feet. Conceal all drivers in accessible locations—never within walls or ceilings—per electrical codes, and use dimmable drivers compatible with the building’s control system. For cove or recessed applications, ensure the strip faces the reflective surface at a 30-degree angle to diffuse light evenly and avoid hotspots. In high-moisture areas like hotel pool decks or mall food courts, select strips with a minimum IP65 rating and seal all end caps and connections with silicone. Finally, verify local fire codes; many jurisdictions require LED strips to be covered by a thermal cutoff device or installed only in non-combustible housings when concealed. Always engage a licensed electrician for final connections to comply with safety regulations and warranty requirements.

Why Choose Beauty STC Lighting

Upgrade your marine lighting with high-quality boat strip LED lighting designed for durability, efficiency, and superior performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions for marine and industrial applications. Our boat strip LED lights are built to withstand harsh environments while delivering brilliant, energy-efficient illumination.

For partnership opportunities, product inquiries, or custom lighting solutions, contact our sales manager at [email protected]. Let Beauty STC power your next project with reliable, innovative LED technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.