Article Contents

Industry Insight: Best Way To Hang Bar Neon Signs

Proper installation of bar neon signs transcends mere aesthetics within commercial and industrial lighting environments; it represents a critical safety and operational imperative. In venues ranging from high-traffic hospitality establishments to retail spaces and entertainment complexes, the mounting method directly impacts electrical safety, structural integrity, long-term reliability, and crucially, compliance with stringent building and fire codes. Neglecting professional installation protocols risks not only premature sign failure but also potential fire hazards, electrical faults, and significant liability exposure for business owners and facility managers. Adherence to recognized safety certifications like ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) is non-negotiable for any lighting product deployed in these settings, serving as the foundational assurance that the sign itself meets essential electrical and construction safety benchmarks before installation even begins. Understanding the best practices for secure, code-compliant hanging is therefore paramount to ensuring both visual impact and occupant safety.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two and a half decades of specialized engineering expertise in LED lighting solutions to this critical aspect of commercial deployment. Our deep-rooted understanding of the unique demands placed on lighting within professional environments informs our commitment to not only manufacturing signs that inherently meet rigorous ETL and CE certification standards but also to providing the industry with clear, actionable guidance on their safest and most effective installation. We recognize that the true value of a commercial neon sign is only fully realized when it is integrated into the space with meticulous attention to the engineering principles that safeguard people and property.

Technical Specs & Certifications

When determining the best way to hang bar neon signs, it’s essential to consider not only the mechanical mounting methods but also the technical performance of the LED lighting system itself. At Beauty (STC) Manufacturing Co., Ltd., we engineer our bar neon signs to meet the highest standards in efficiency, color accuracy, and environmental resilience—ensuring optimal performance whether installed indoors or outdoors.

Our LED neon bars are designed with energy efficiency in mind, delivering an industry-leading luminous efficacy of 95 to 110 lumens per watt. This high lumen-to-watt ratio ensures bright, vibrant illumination while minimizing power consumption, making our signs both visually impressive and cost-effective over time. The efficiency is achieved through the use of high-grade SMD LED chips and optimized driver circuitry, which Beauty STC integrates seamlessly into flexible silicone diffuser profiles.

Color fidelity is critical for branding and aesthetic impact. All our neon signs feature LEDs with a Color Rendering Index (CRI) greater than 90—typically ranging from 92 to 95. This high CRI ensures that colors appear natural and true to life, which is especially important in retail, hospitality, and artistic installations where visual appeal is paramount. Beauty STC achieves this through precision binning of LEDs and advanced phosphor coatings, reducing color variance and enhancing light quality.

For durability and safety, our bar neon signs are available in multiple IP (Ingress Protection) rated configurations. Indoor installations typically use IP65-rated signs, which protect against dust and low-pressure water jets—ideal for areas with occasional moisture exposure. For outdoor or high-humidity environments, we recommend IP67 or IP68-rated neon bars, which provide full dust tightness and protection against temporary or prolonged submersion in water. These ratings ensure long-term reliability, even under challenging conditions.

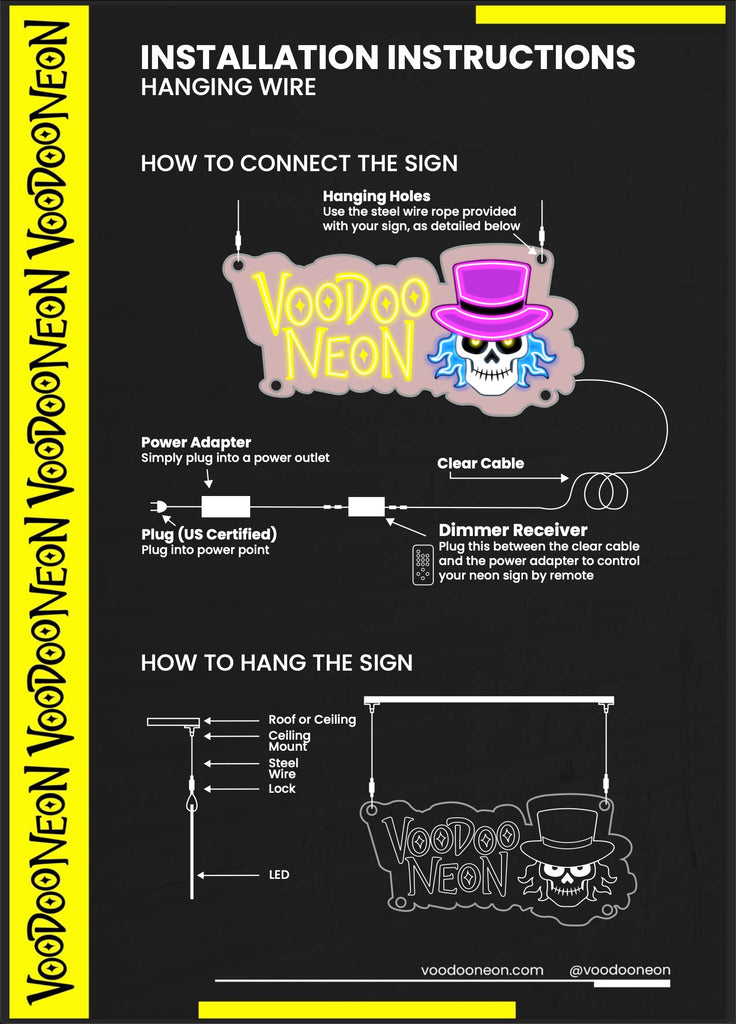

The physical mounting of our neon signs is designed for both ease and stability. We recommend using stainless steel brackets or aluminum mounting channels, spaced at intervals of 300–500 mm depending on sign length, to ensure even support and prevent sagging. For curved designs, our flexible silicone construction allows for secure attachment using zip ties or concealed clips at anchor points. All mounting hardware is corrosion-resistant, in line with Beauty STC’s commitment to longevity and structural integrity.

Beauty STC’s quality assurance process includes rigorous testing for thermal performance, electrical safety, and photometric consistency. Each neon sign undergoes 100% burn-in testing and is built with UV-stable silicone and flame-retardant materials (UL94 V-0 rated). Our manufacturing adheres to ISO 9001 standards, and all products are CE, RoHS, and REACH compliant.

In summary, the best way to hang bar neon signs involves selecting high-performance LED systems with strong lumens per watt, CRI >90, and appropriate IP ratings—all hallmarks of Beauty STC’s engineered solutions. With precise mounting techniques and our premium build quality, our neon signs deliver enduring brilliance and reliability across diverse applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, represents a significant investment in modern LED lighting production, specifically engineered to handle the complexities of flexible LED neon signage and related products. The factory occupies a purpose-built space designed for efficient workflow, stringent quality control, and scalability to meet global demand. Central to our production capability are state-of-the-art SMT (Surface Mount Technology) lines, primarily featuring high-precision machines from industry leaders like JUKI and Yamaha. These machines are critical for the accurate placement of miniature SMD LEDs, resistors, capacitors, and ICs onto flexible printed circuit boards (FPCBs) used in our neon signs. The SMT lines operate with exceptional accuracy, handling components as small as 0201 package sizes, ensuring consistent solder joint integrity and electrical performance essential for the long life and uniform light output demanded by neon applications. Our SMT capacity supports high-volume production runs while maintaining tight tolerances required for the seamless appearance of LED neon bars.

Rigorous aging and burn-in testing form a non-negotiable part of our quality assurance process at the Jiangmen facility. Completed neon sign assemblies undergo a comprehensive 72-hour continuous aging test under controlled environmental conditions. During this phase, units operate at their specified voltage and current, often slightly elevated to accelerate potential early-life failures. Temperature monitoring is conducted at critical points along the neon bar and within the driver housing to identify any thermal anomalies. This extended burn-in period effectively screens out infant mortality failures, significantly enhancing field reliability. Post-aging, each unit undergoes a final functional and visual inspection to verify stable light output, color consistency, and the absence of flicker or dead segments before packaging. This commitment to thorough aging testing is fundamental to delivering the durability and performance our customers expect from commercial-grade neon signage.

Regarding OEM capabilities for the “best way to hang bar neon signs,” Beauty STC excels in providing comprehensive, engineered mounting solutions alongside the signage itself. We recognize that ease and security of installation are paramount for bar and hospitality clients. Our OEM service includes the design, prototyping, and manufacturing of integrated mounting systems tailored to the specific sign design and client requirements. This encompasses precision-engineered aluminum mounting channels that securely cradle the neon flex, low-profile brackets designed for clean wall or ceiling attachment, and discreet cable management solutions to maintain a professional aesthetic. We collaborate closely with clients during the engineering phase to determine the optimal hanging method based on the sign’s weight, length, intended mounting surface (drywall, wood, metal, concrete), and desired visual effect (flush mount, floating effect, etc.). Our Jiangmen factory has the tooling and assembly capacity to produce these mounting components alongside the neon signs, ensuring perfect compatibility and enabling us to deliver complete, ready-to-install kits. This holistic OEM approach eliminates installation guesswork for the end-user, providing a truly turnkey solution where the “best way to hang” is engineered into the product from the outset, supported by detailed installation guides and pre-validation of the mounting system during sample approval.

Application Scenarios

The best way to hang bar neon signs varies depending on the environment, but proper installation ensures both visual impact and safety. These signs are commonly used in hotels, malls, and offices, each with unique aesthetic and functional requirements.

In hotels, bar neon signs are ideal for lobbies, lounges, bars, and event spaces. They create a welcoming and stylish ambiance that enhances guest experience. For installation, ensure the sign is mounted at eye level or slightly above to maximize visibility without obstructing movement. Use sturdy wall anchors or ceiling mounts depending on the structure, and consider dimmable options to adjust lighting according to the time of day or mood. Always follow local electrical codes and use licensed electricians for hardwired installations.

In malls, neon signs work well in food courts, entertainment zones, or retail storefronts to attract foot traffic. Since malls often have high ceilings and heavy footfall, signs should be mounted securely and at a height that ensures visibility from a distance—typically 8 to 10 feet above ground level. Use aircraft cables or heavy-duty brackets for overhead installations. It’s crucial to coordinate with mall management for permits and electrical access, especially in common areas. Waterproofing and shatter-resistant coatings are recommended for durability in high-traffic zones.

In offices, particularly creative agencies, co-working spaces, or reception areas, neon signs add a modern, motivational, or brand-focused touch. Installation here should maintain a professional yet inviting look. Mount the sign on drywall or glass partitions using appropriate anchors, and avoid placing it in areas with excessive vibration or direct sunlight, which can reduce LED lifespan. Plug-in models with discreet cord routing are often preferred for ease of installation and flexibility.

General installation tips include checking the weight capacity of the mounting surface, using a spirit level for alignment, and ensuring all electrical connections are secure and insulated. For heavier signs, enlist a second person during installation. Always power off during setup and verify compatibility with local voltage standards. Regular cleaning with a soft cloth and periodic inspection of cords and mounts help maintain longevity and appearance.

Why Choose Beauty STC Lighting

Discover the most reliable and professional method for installing bar neon signs by partnering with Beauty STC Manufacturing Co., Ltd. Our engineering team specializes in designing secure, aesthetically optimized mounting solutions tailored to commercial environments, ensuring your signage remains both visually striking and structurally sound for years. We eliminate common installation risks like improper weight distribution, electrical hazards, and surface damage through precision-engineered hardware and expert guidance.

Partnering with Beauty STC means accessing custom mounting systems developed specifically for our energy-efficient LED neon signs, backed by rigorous safety testing and industry compliance. Our solutions integrate seamlessly with various bar and retail settings while maintaining the vibrant illumination your brand deserves. For a consultation on the optimal hanging approach for your project, contact our dedicated partnership manager directly at [email protected]. Let us handle the technical details so you can focus on creating unforgettable customer experiences.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.