Article Contents

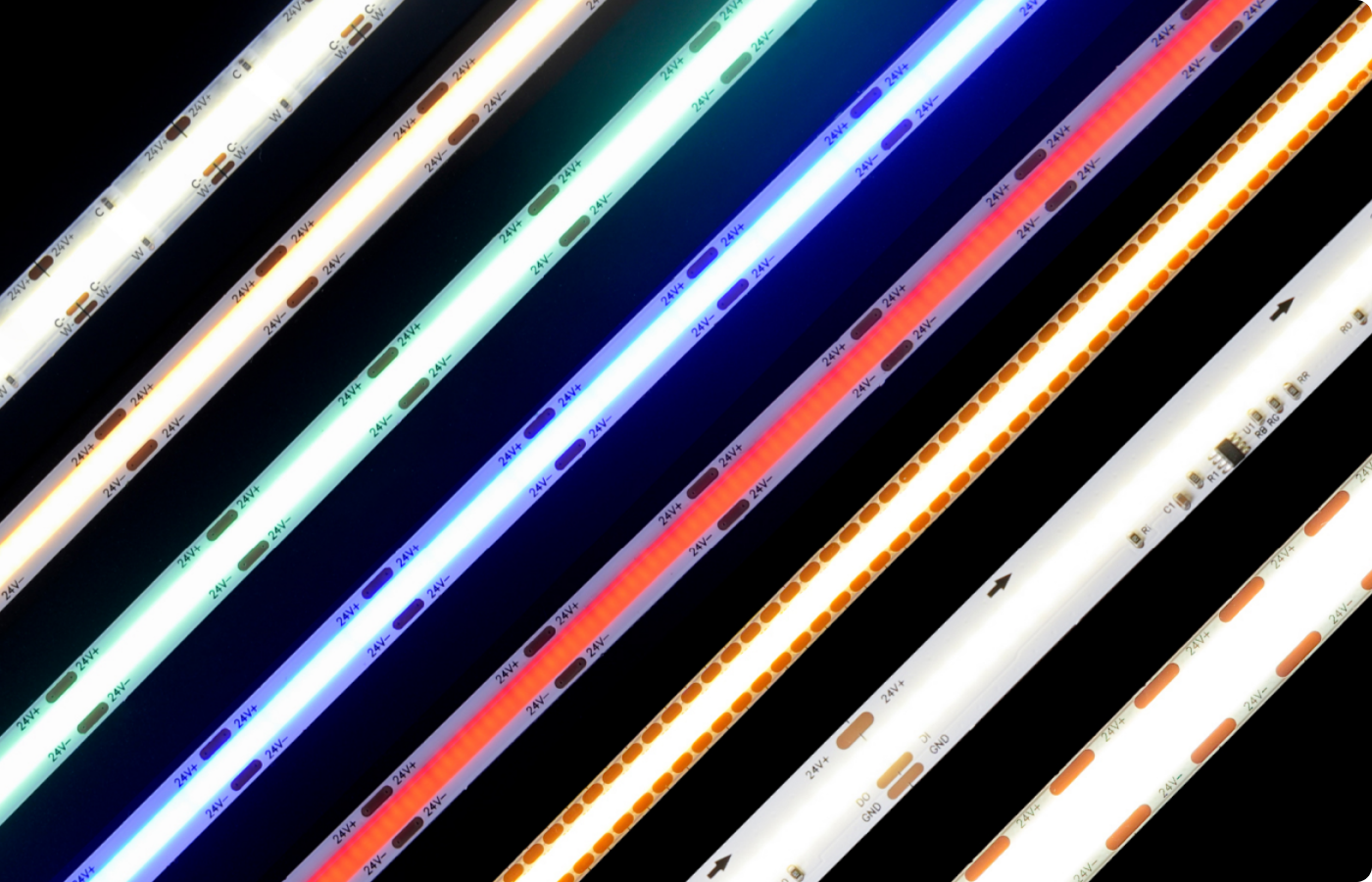

Industry Insight: Best Led Tape

In the rapidly evolving landscape of commercial and industrial lighting, LED tape has emerged as a cornerstone technology for energy-efficient, flexible, and high-performance illumination. As businesses and manufacturers seek sustainable lighting solutions that combine durability with design versatility, the demand for premium LED tape products has surged. Critical to this market are certifications such as ETL and CE, which ensure compliance with rigorous North American and European safety and performance standards—essential for integration into large-scale facilities, production environments, and commercial installations where reliability and code adherence are non-negotiable.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering excellence, Beauty STC has established itself as a leader in developing high-quality, code-compliant LED tape solutions tailored for demanding commercial and industrial applications. By combining advanced thermal management, consistent lumen output, and robust construction with full ETL and CE certification, Beauty STC delivers lighting products that meet the exacting needs of architects, engineers, and facility managers worldwide.

Technical Specs & Certifications

The technical specifications defining the highest-performing LED tape for professional applications center on three critical pillars: luminous efficacy, color fidelity, and environmental resilience. For luminous efficacy, the current industry benchmark for premium tape achieves 120-140 lumens per watt at 25°C ambient temperature when utilizing Samsung LM301H EVO or Nichia 219F diodes driven at optimal currents. This range represents the practical ceiling for commercially viable high-CRI tapes, as efficacy inherently trades off against the phosphor complexity required for superior color rendering. It is essential to note that published lm/W figures must specify correlated color temperature (typically 2700K-4000K for architectural use) and drive current (e.g., 180mA per LED), as both significantly impact efficiency metrics. Beauty STC’s flagship series consistently delivers 130-135 lm/W across 3000K-4000K CCTs through precision binning of diodes and optimized thermal management on 5-layer metal-core PCBs, ensuring real-world output aligns with laboratory specifications.

Color rendering index (CRI) exceeding 90 is non-negotiable for premium applications, but true excellence requires deeper scrutiny. The highest-tier tapes achieve Ra >95 with critical R9 (saturated red) >90 and R12 (saturated blue) >90, addressing common weaknesses in standard high-CRI products. This necessitates multi-phosphor formulations beyond basic tri-phosphor blends. Beauty STC implements a proprietary 7-phosphor coating process on Samsung diodes, achieving Ra 97-98 while maintaining R9 >95 and R12 >92 across all CCTs. Furthermore, our tapes exceed TLCI (Television Lighting Consistency Index) 95, making them suitable for broadcast environments where spectral continuity is paramount. This level of color accuracy is rigorously validated through third-party spectroradiometer testing per IES LM-79, with batch-to-batch consistency maintained through automated optical sorting during manufacturing.

Regarding ingress protection, the optimal IP rating depends on the installation environment but must be engineered for longevity. IP65 (dust-tight and protected against low-pressure water jets) is the minimum standard for exposed architectural coves or outdoor signage, while IP67 (submersion up to 1m for 30 minutes) or IP68 (continuous submersion) is essential for landscape lighting, pool perimeters, or marine applications. Critical to note is that IP rating validity relies entirely on holistic construction quality – not just the silicone jacket. Beauty STC’s premium tapes feature double-extruded silicone with Shore A 45 hardness, providing superior UV stability and flexibility compared to cheaper PVC alternatives. Our IP67/IP68 tapes undergo 1,000-hour salt spray testing per ASTM B117 and maintain integrity after 500 thermal cycles (-40°C to +85°C), preventing the delamination and yellowing common in inferior products. This is achieved through vacuum-degassed silicone molding and hermetic end-cap sealing with medical-grade adhesives.

Beauty STC’s commitment to quality manifests in every layer of construction. Our tapes utilize 3oz copper PCBs with thermal vias for 30% better heat dissipation than standard 2oz boards, directly contributing to lumen maintenance and longevity. Each reel undergoes 100% automated optical inspection for solder integrity and diode alignment, followed by 48-hour burn-in testing at 70°C ambient. The result is certified LM-80 data showing >90% lumen maintenance at 50,000 hours (L90/B10), with color shift (Δu’v’) held to <0.003 over the same period. Crucially, our quality control extends beyond components: we provide full traceability via QR codes linking to individual reel test reports, ensuring the specifications delivered match the engineering promise without compromise. This systematic approach to material science and process control makes Beauty STC tapes the benchmark for projects where performance consistency and reliability are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is fully dedicated to the research, development, and production of high-quality LED lighting solutions, with a particular focus on flexible LED tape lights, rigid bars, and customized lighting systems.

The factory is integrated with advanced SMT (Surface Mount Technology) production lines, featuring high-precision automated SMT machines from leading global brands. These machines ensure accurate placement of LED chips and electronic components onto flexible PCBs, enabling consistent performance, high luminous efficiency, and long-term reliability. The SMT lines operate with full automation, including automatic optical inspection (AOI), which guarantees defect-free soldering and component alignment, critical for maintaining the quality standards expected in premium LED tape products.

To ensure durability and performance consistency, every batch of LED tape undergoes rigorous aging tests within the Jiangmen facility. These tests simulate extended operational conditions under varying temperatures and humidity levels, typically running for 24 to 72 hours. This comprehensive aging process allows the engineering team to identify early failures, verify thermal management, and confirm color consistency across production runs. The factory also conducts photometric testing, IP rating verification (for waterproof tapes), and electrical safety checks in compliance with international standards.

Beauty STC has strong OEM and ODM capabilities, making it a preferred partner for brands seeking customized LED tape solutions. The company supports full private labeling, custom color temperatures, special CRI requirements (including high CRI 90+ and 95+ options), tailored beam angles, and unique PCB configurations such as ultra-narrow tapes or high-density LED layouts. Clients can also request custom packaging, branding, and reel lengths. With in-house design and engineering support, Beauty STC works closely with partners to develop products that meet specific market demands, all manufactured efficiently within the Jiangmen factory under strict quality control protocols.

The combination of state-of-the-art SMT technology, comprehensive aging and testing procedures, and flexible OEM services positions Beauty STC’s Jiangmen facility as a reliable and innovative manufacturing base for what many consider among the best LED tape light products in the industry.

Application Scenarios

The term “best LED tape” is highly context-dependent within commercial applications like hotels, malls, and offices. There is no single “best” product universally; the optimal choice is determined by the specific functional requirements, environmental conditions, aesthetic goals, and budget constraints of each application. Selecting the appropriate LED tape involves matching its technical specifications to the demands of the space.

In hotels, high-quality LED tape is essential for creating ambiance and enhancing guest experience. Use premium tapes with high CRI (90+), excellent color consistency (SDCM ≤ 3), and smooth dimming performance for cove lighting in lobbies, corridors, and premium guest rooms to establish warm, inviting atmospheres. Water-resistant (IP65 or higher) tapes are critical for pool areas, spas, and bathroom niches, while discreet, low-profile tapes with precise beam control work well for under-cabinet lighting in minibars or vanity areas. Avoid standard tapes in high-humidity zones as they will fail prematurely; thermal management is vital behind plaster or fabric coves where heat buildup occurs.

Malls demand LED tapes that deliver high lumen output, exceptional durability, and dynamic capabilities for visual impact. Specify high-lumen-density tapes (e.g., 24W/m+) with robust construction for bright, even illumination in signage channel letters and architectural feature walls. Tapes with integrated controllers or DMX/RDM compatibility are necessary for animated displays in feature areas like entrances or food courts. For retail storefronts and merchandise displays, prioritize tapes with ultra-high CRI (95+) and tunable white options to accurately render product colors. Ensure tapes have wide operating temperature ranges and UV-stable materials for longevity under constant use, and always pair high-output tapes with adequate aluminum profiles to prevent lumen depreciation.

Offices require LED tapes focused on visual comfort, energy efficiency, and task support. Use high-CRI (80+ minimum, 90+ for design studios), flicker-free tapes with precise 2700K-4000K color temperatures for indirect cove lighting to reduce glare and create a balanced ambient environment. Under-cabinet task lighting in workspaces benefits from narrow-beam tapes with high center-beam intensity. Critical installations like conference room perimeters or reception desks need tapes with seamless dimming down to 1% and compatibility with building management systems (e.g., DALI, 0-10V). Avoid tapes with poor thermal design in enclosed troffers, as heat drastically shortens lifespan; always verify lumen maintenance data (L70/B50) for long-term performance.

Installation quality is equally important as product selection. Always begin with a detailed layout plan accounting for total tape run length to prevent voltage drop—use 24V tape for runs exceeding 5 meters and calculate driver capacity with a 20% safety margin. Surface preparation is non-negotiable: clean substrates thoroughly with isopropyl alcohol to ensure optimal adhesive bonding, especially on smooth surfaces like glass or metal. Never install tape directly onto flammable materials; use aluminum mounting channels which also act as essential heat sinks. For connections, solder and encapsulate all joints with silicone gel connectors rather than relying solely on clips, and seal all outdoor or high-moisture terminations with conformal coating. Test the entire circuit before final concealment, and document voltage readings at multiple points along long runs to verify consistent performance. Thermal management cannot be overstated—insufficient heat sinking is the leading cause of premature LED failure in commercial tape installations, so never omit the aluminum profile even in seemingly low-heat applications.

Why Choose Beauty STC Lighting

Discover the best LED tape for your lighting projects by partnering with Beauty (STC) Manufacturing Co., Ltd. As a trusted leader in high-quality LED solutions, we deliver superior performance, durability, and innovation tailored to meet diverse lighting needs. Whether for architectural accents, commercial displays, or residential elegance, our LED tape sets the standard in brightness, efficiency, and color consistency.

Take your lighting business to the next level—collaborate with a manufacturer committed to excellence and reliability. For partnership inquiries and product details, contact us today at [email protected]. Let Beauty STC illuminate your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.