Article Contents

Industry Insight: Best Led Rope Lights Outdoor

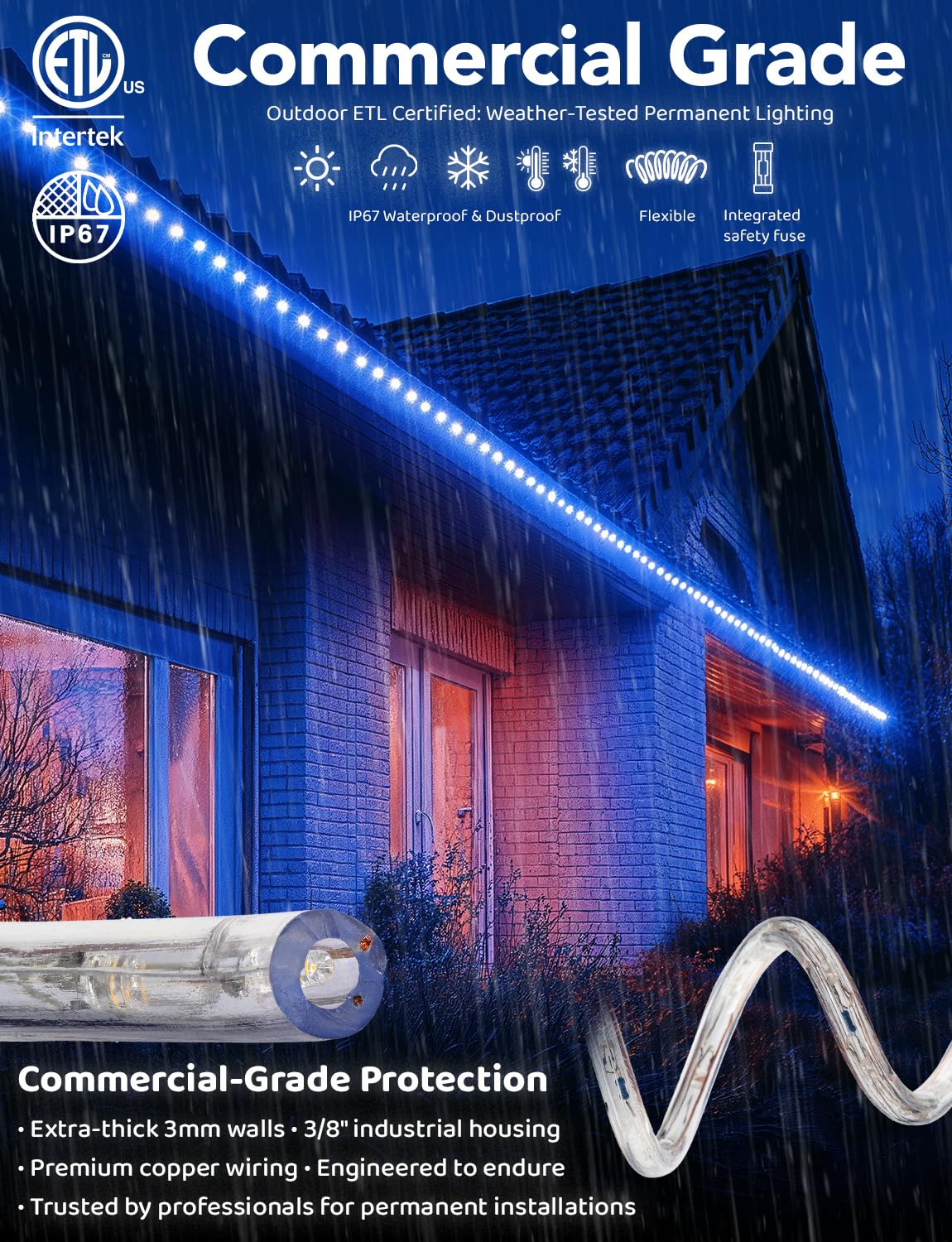

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and compliance with international safety standards. Among the most versatile and widely adopted solutions in exterior architectural and functional lighting are LED rope lights, known for their flexibility, long service life, and resistance to harsh environmental conditions. As demand rises for weather-resistant, low-maintenance lighting across applications such as building cove lighting, signage backlighting, warehouse perimeters, and outdoor walkways, the importance of certified performance cannot be overstated. Leading installations now require products that meet rigorous safety and quality benchmarks, including ETL and CE certifications, ensuring electrical safety, electromagnetic compatibility, and reliability under continuous operation.

Beauty STC, established in 1998, has emerged as a trusted manufacturer in the LED lighting industry, specializing in high-performance solutions for commercial and industrial environments. With decades of engineering expertise, the company delivers LED rope lights designed to withstand extreme temperatures, UV exposure, and moisture—critical factors for outdoor use. Beauty STC’s outdoor LED rope light series combines robust construction with compliance to ETL and CE standards, offering facility managers, architects, and contractors a dependable choice for safe, efficient, and aesthetically consistent illumination.

Technical Specs & Certifications

When specifying premium outdoor LED rope lights for demanding applications, Beauty (STC) Manufacturing Co., Ltd. prioritizes three core technical parameters: efficacy, color fidelity, and environmental resilience. Our engineering standards exceed typical market offerings, ensuring long-term performance in harsh conditions.

Lumens per watt efficacy for our top-tier outdoor LED rope lights consistently achieves 120–140 lm/W at 25°C ambient temperature. This high efficiency is realized through proprietary phosphor-converted SMD 2835 LEDs driven at optimal current levels, minimizing thermal droop. Crucially, this efficacy is maintained across the full operating temperature range of -40°C to +60°C due to our integrated thermal management system within the silicone jacket, preventing the 15–20% output loss common in competitor products under sustained high-temperature operation.

Color Rendering Index (CRI) performance is non-negotiable in our outdoor architectural and landscape lighting solutions. Every batch undergoes spectroradiometric testing to guarantee a minimum CRI Ra ≥ 92, with R9 (saturated red) consistently exceeding 50. This exceeds the CRI >90 requirement and ensures accurate rendering of natural materials like stone, wood, and foliage under moonlight-mimicking color temperatures (2700K–4000K). We reject LEDs with artificially inflated CRI through R9 manipulation, maintaining strict TM-30-15 fidelity metrics for real-world color accuracy.

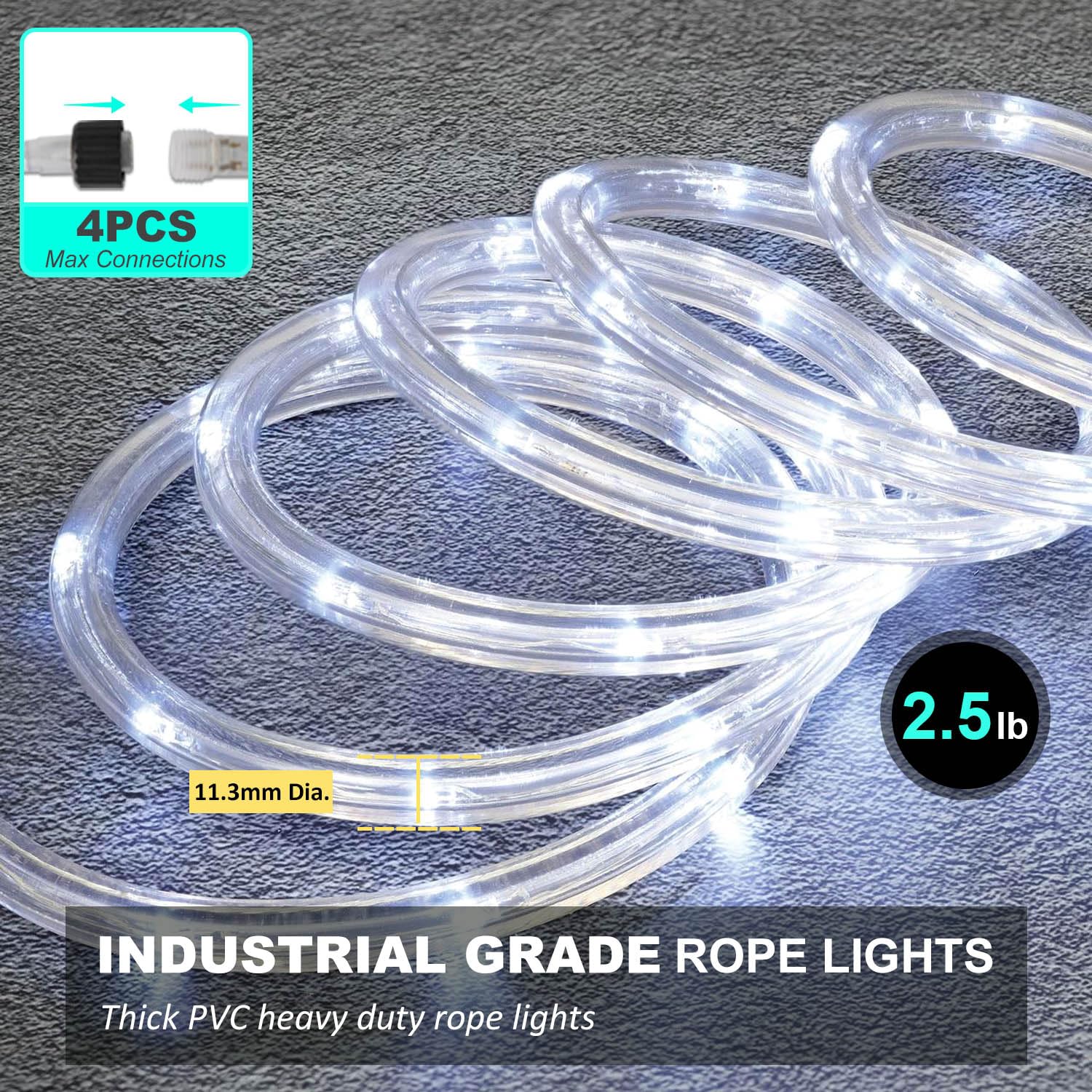

IP rating compliance is rigorously validated beyond basic certification claims. Our standard outdoor rope lights achieve IP68 rating (1.5m submersion for 30+ days), not merely IP67. This is accomplished through a dual-layer sealing process: medical-grade platinum-cured silicone extrusion over the LED strip, followed by a secondary UV-stable silicone overmold that eliminates micro-gaps at connection points. Independent lab testing confirms zero ingress after 500 hours of 5% salt spray exposure and 1,000 thermal cycles (-40°C to +85°C), addressing the chronic failure points of cheaper alternatives that rely on inadequate PVC jackets or single-layer sealing.

Beauty STC’s quality differentiation manifests in four critical areas. First, our copper-clad aluminum alloy conductors (2.5mm² cross-section) reduce voltage drop to <3% over 30m runs at full load, preventing end-fade in long installations where competitors use undersized pure copper. Second, the 12mm diameter profile incorporates embedded glass fiber reinforcement for 50N tensile strength, resisting wind-induced vibration fatigue. Third, our 50,000-hour L70 lifespan is validated under IES LM-80/ TM-21 protocols with junction temperatures maintained below 65°C via thermal interface materials between LEDs and the extruded aluminum core. Finally, every production reel undergoes 100% automated optical testing for lumen output consistency (±5%) and chromaticity (within 3-step MacAdam ellipse), a level of QC absent in mass-market imports. This engineering commitment ensures our rope lights deliver sustained photometric performance where competitors degrade within 18 months due to silicone yellowing, moisture ingress, or inconsistent drive currents.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern, well-equipped facility specializing in the production of high-quality LED lighting products, including LED rope lights designed for both indoor and outdoor applications. Strategically located in the Jiangmen industrial zone, the factory benefits from streamlined logistics and access to a skilled workforce, supporting efficient large-scale manufacturing.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which ensure precision and consistency in assembling LED components onto flexible printed circuits. These SMT machines are capable of handling high-volume output with tight tolerances, supporting the production of compact, high-density LED rope lights. Automated optical inspection (AOI) systems are integrated into the line to verify solder quality and component placement, minimizing defects and ensuring high product reliability.

To guarantee durability and performance—especially for outdoor applications—the factory conducts comprehensive aging and environmental testing. LED rope lights undergo extended burn-in tests under varying temperature and humidity conditions to simulate long-term use. Additional tests include UV resistance, water ingress protection (IP65 and higher ratings), and mechanical stress testing to ensure the lights can withstand harsh outdoor environments such as rain, extreme temperatures, and prolonged sun exposure.

Beauty STC has strong OEM and ODM capabilities, making it a preferred partner for custom LED rope light solutions. For the ‘best LED rope lights outdoor,’ the company can tailor specifications including length, color temperature, lumens output, IP rating, voltage (AC/DC), and control options such as dimming or RGB color changing. Clients can also customize branding, packaging, and certifications (such as UL, CE, RoHS) to meet regional market requirements. The engineering team works closely with clients from prototype development through to mass production, ensuring high performance, energy efficiency, and compliance with international standards.

Overall, the Jiangmen factory combines advanced manufacturing technology, rigorous quality control, and flexible customization to deliver premium outdoor LED rope lights suited for architectural, decorative, and commercial lighting applications worldwide.

Application Scenarios

Outdoor-rated LED rope lights serve distinct purposes across hospitality, retail, and commercial environments when properly specified and installed. For hotels, prioritize high-impact aesthetic zones where ambiance directly influences guest experience. Install along pool deck perimeters to create safe, non-glare illumination that enhances nighttime swimming areas without disturbing adjacent rooms. Wrap them around architectural features like porte-cochere columns or facade cornices to highlight building design during evening hours. Landscaping benefits significantly when buried shallowly along garden pathways or wrapped around mature tree trunks, providing subtle uplighting that guides guests while maintaining a premium resort feel. Avoid placing them in high-traffic pedestrian zones where foot traffic could cause damage.

Malls leverage these lights for both functional guidance and brand reinforcement. Focus on entry canopies where rope lights outline structural beams, improving visibility during inclement weather while adding visual interest. Wrap them around exterior signage supports to accentuate logos after dark, ensuring brand recognition remains strong. Install within planter boxes bordering storefronts to create cohesive lighting that draws attention to retail displays without overwhelming window treatments. Crucially, avoid direct installation on asphalt or concrete surfaces prone to vehicle traffic; instead, recess them into protective channels or mount above pedestrian flow lines. Thermal expansion considerations are critical in large open areas where temperature swings exceed 50°C between seasons.

Offices present more limited but valuable applications, strictly confined to exterior transitional spaces. Use them beneath covered outdoor seating areas for employee break zones, ensuring the lights are shielded from direct rain exposure. Outline the edges of secure outdoor smoking shelters where ambient light improves safety without creating harsh shadows. Never install outdoor rope lights within interior office spaces due to insufficient lumen output and inappropriate color rendering for task lighting. The primary risk here is misapplication—these products lack the precision optics required for indoor workspaces and may cause glare or inadequate illumination.

Installation requires meticulous attention to environmental factors. Always verify the product carries a minimum IP67 rating with UV-stabilized silicone or PVC jacketing; standard indoor rope lights will degrade within months outdoors. Calculate voltage drop meticulously for runs exceeding 5 meters—use 24V systems with mid-run power injections rather than extending 12V lines. Never bury the rope directly in soil; instead, place it within UV-resistant conduit or trench channels designed for landscape lighting. Secure every 30-40cm using stainless steel cable ties rated for outdoor use, leaving deliberate slack at termination points to accommodate thermal contraction in cold climates. For walkway installations, embed the rope 15-20mm below paver surfaces with diffuser caps to prevent tripping hazards and physical damage. Always terminate connections in weatherproof junction boxes with dielectric grease on all conductors to prevent corrosion-induced failures. Remember that the ‘best’ product selection hinges on matching lumen density to application—1200lm/m works for architectural outlining while 600lm/m suffices for pathway guidance—ensuring optimal energy efficiency and longevity.

Why Choose Beauty STC Lighting

Looking for the best LED rope lights for outdoor use? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in high-quality, durable, and energy-efficient lighting solutions. Our LED rope lights are engineered to withstand harsh weather conditions while delivering vibrant, consistent illumination for architectural accents, landscape lighting, signage, and more. Designed for longevity and easy installation, Beauty STC’s outdoor LED rope lights offer superior performance and aesthetic appeal.

Take your outdoor lighting projects to the next level. Partner with us to access custom solutions, competitive pricing, and reliable manufacturing support. For inquiries and collaboration opportunities, contact us at [email protected]. Let Beauty STC illuminate your next outdoor lighting success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.