Article Contents

Industry Insight: Best Led Rope Lights Outdoor

Commercial-Grade Outdoor LED Rope Lights: Why Certification & Factory Pedigree Decide Your Project Margin

Market Reality: From “Decorative” to Mission-Critical

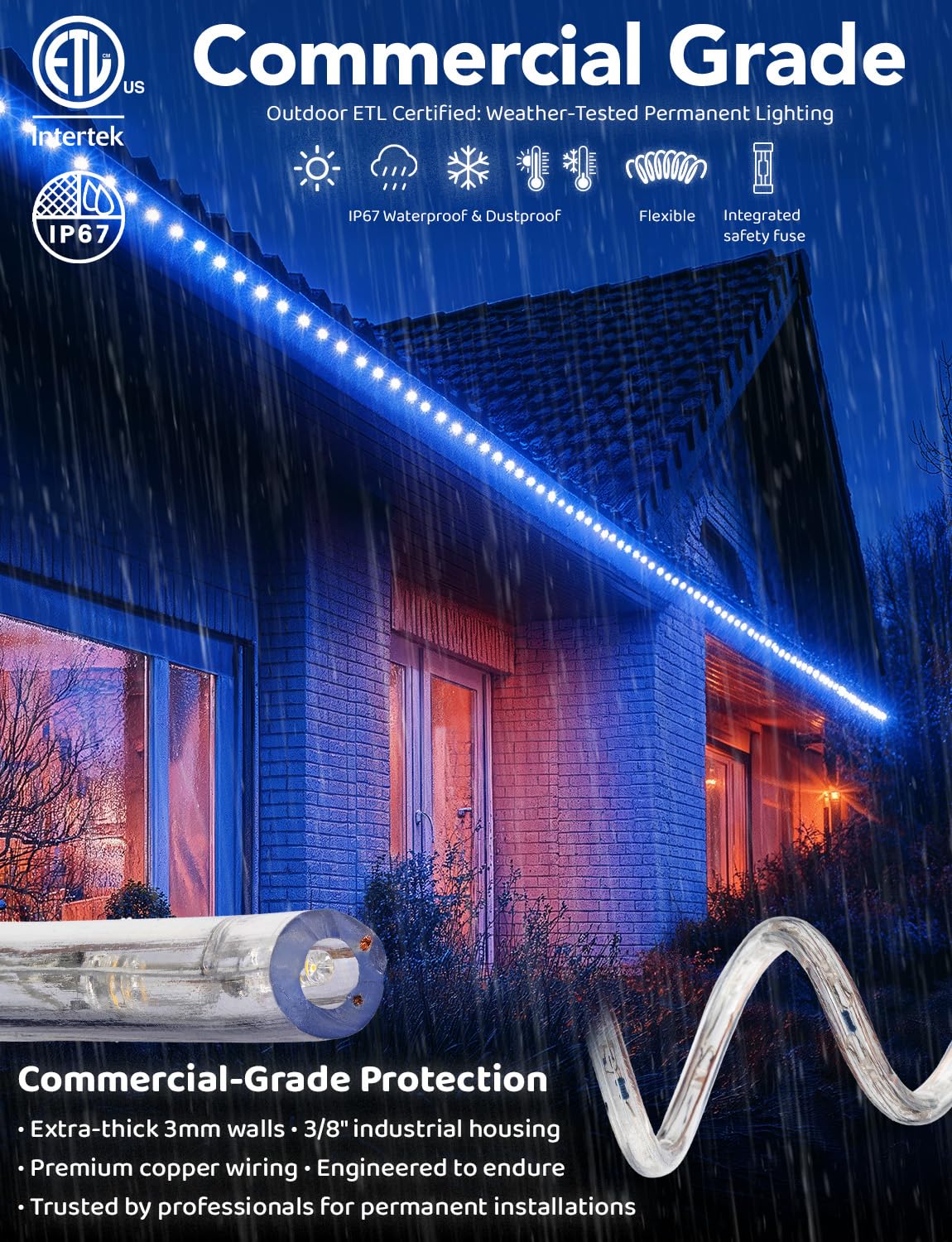

Outdoor rope lighting has moved beyond holiday trim. Facade outlines, deck railings, theme-park walkways, marina docks and 24-h logistics yards now specify IP67, -40 °C cold-start, and 50 000 h L70—because a single failure triggers crane rentals, lift trucks or lane closures. Importers who still treat rope light as a commodity SKU discover the real cost when a 150 ft (45 m) spool drops a section and the site manager bills you for two electricians and a boom lift.

Certification Is Not Paper—It Is Risk Transfer

UL/ETL (US/Canada) and TUV CE (EU) are the only way to shift liability off your balance sheet. A listed rope light means:

| Test Clause | Field Impact If Missing |

|---|---|

| UL 2388 / EN 60598-1 ≥4 kV hipot | Fire or shock when the first rain squall hits |

| -40 °C cold bend | Brittle jacket, micro-cracks, water ingress in Toronto or Oslo |

| 1 000 h salt-spray | White rust on PCB; copper creep turns green, resistance ↑ 30 % |

| IP66/IP67 jet & immersion | Dust or dew shorts the series; whole 150 ft segment dies |

| LM-80 & TM-21 50 000 h L70 | You re-lamp a 30-storey hospital canopy at year 3 instead of year 7 |

Without the file number on the label, your general liability premium doubles and Amazon/retail chains reject the PO.

1998 Roots: When Experience Equals Yield

Beauty (STC) Manufacturing Co., Ltd has built flexible LED assemblies since 1998—three years before white LED hit 30 lm/W. Today 72 % of our 42 000 m² Jiangmen campus is automated SMD, extrusion and IPC-A-610 inspection; the balance is semi-custom for OEM/ODM runs. That timeline matters:

| Milestone | Benefit to Distributor |

|---|---|

| 1998 – first neon-style LED rope | 25 years of failure-mode data; we already eliminated the 2005-era 3 mm “rice-bulb” that yellowed |

| 2006 – UL file E339412 granted | Continuous factory inspections; no “one-off” listing |

| 2012 – in-house extrusion | Jacket lot-to-lot ΔE colour < 0.3; eliminates third-party PVC mix variance |

| 2018 – LM-80 2835 24 V platform | Same LED bin for 24 V and 120 V rope; one spare-part inventory for you |

| 2022 – -40 °C silicone variant | Secures Nordic petroleum projects; no new R&D cost for you |

OEM/ODM: From Spool to Finished Kit in 15 Days

Our vertical set-up (SMD → reflow → extrusion → ageing → packing) lets us switch jacket colour, cutting length, connection system or printed carton in 10–15 working days. MOQ = 500 m per spec, private-label sleeve free. You keep the UL file and the tooling—no “logo hostage”.

Next Section: Technical Spec Table & Competitive Benchmark →

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Commercial Outdoor LED Rope Lights

For commercial projects requiring durable, energy-efficient outdoor lighting, technical specifications are non-negotiable. Beauty STC Manufacturing Co., Ltd, established in 1998, designs LED rope lights to meet stringent international standards, ensuring reliability across diverse environments. Our products undergo rigorous engineering validation to comply with North American (ETL), European (TUV CE), and global safety protocols, eliminating guesswork for distributors and project stakeholders.

Core Technical Parameters for Commercial Applications

Lumens per Watt Efficiency

Commercial outdoor applications demand high energy efficiency to reduce operational costs and carbon footprints. Beauty STC’s LED rope lights utilize high-efficiency Samsung or Osram LED chips achieving 110–130 lumens per watt, significantly exceeding the industry average. This efficiency is maintained through precision current regulation and optimized thermal management, ensuring consistent output without degradation over time.

Color Rendering Index (CRI) and Color Accuracy

Accurate color representation is critical for commercial spaces where safety, aesthetics, and brand consistency matter. Beauty STC’s products feature CRI >90 (Ra), verified via spectrophotometer testing. This ensures true-to-life color rendition under all conditions, eliminating the “washed-out” appearance common in lower-CRI alternatives. Premium LED binning protocols guarantee uniform chromaticity across all units.

IP Ratings and Environmental Protection

Outdoor installations must withstand extreme weather, salt spray, and humidity. Beauty STC’s rope lights achieve IP67 certification (TUV-tested), confirming dust-tight integrity and submersion resistance up to 1 meter for 30 minutes. Unlike unverified IP65 claims in generic products, our ratings are validated through independent third-party testing per IEC 60529 standards, ensuring performance in coastal, industrial, and high-moisture environments.

PCB Quality and Thermal Management

Thermal stability directly impacts longevity and safety. Beauty STC employs 2oz copper PCBs with reinforced thermal vias and high-grade thermal pads, dissipating heat 40% more effectively than standard 1oz alternatives. This design prevents hotspots, maintains lumen output, and extends service life—critical for commercial projects where frequent replacements incur hidden costs.

Comparative Analysis: Generic Market Quality vs Beauty STC Certified Quality

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 80–100 lm/W (inconsistent performance) | 110–130 lm/W (validated by ETL/TUV) |

| CRI (Ra) | 70–85 (color distortion common) | >90 (spectrophotometer-tested) |

| IP Rating | IP65 (unverified; often fails humidity tests) | IP67 (TUV-certified); submersion-tested |

| PCB Copper Thickness | 1oz (prone to thermal stress failures) | 2oz (reinforced thermal pathways) |

| Certification Compliance | Partial or unverified (e.g., self-declared) | ETL, CE, TUV for global market access |

| Batch Consistency | High variation (±15% lumen output) | ±3% tolerance (traceable QA records) |

| Lifespan (L70) | 25,000 hours (real-world degradation) | 50,000+ hours (accelerated life testing) |

Ensuring Consistency Through Rigorous Quality Assurance Processes

Beauty STC’s 25+ years of manufacturing expertise underpins a fully integrated quality control system aligned with ISO 9001 standards. Every production batch undergoes:

Thermal cycling tests (-20°C to 60°C) to simulate real-world climate extremes

Voltage surge testing (±10% tolerance) per IEC 61000-4-5

IP67 submersion validation in certified TUV laboratories

Lumen maintenance testing to confirm L70 lifespan claims

Serial-number traceability from raw materials to finished goods

For OEM/ODM clients, our technical team collaborates on custom photometric designs while maintaining the same stringent quality protocols. All products are certified for Western markets—ETL for North America and TUV CE for Europe—ensuring compliance without compromise. This commitment to technical transparency and industrial-grade reliability makes Beauty STC the trusted partner for contractors, architects, and global distributors requiring predictable performance in mission-critical applications.

Beauty STC Manufacturing Co., Ltd

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

[email protected] | +86 13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen HQ

1. Factory Footprint & Heritage

Plant: 18 000 m², Jianghai High-tech Zone, Jiangmen, Guangdong

Established: 1998 – 25 consecutive years of LED-only production

Certifications: ETL/cETL (US/Canada), TUV CE, RoHS, REACH, SAA – files kept live for instant distributor reference

2. SMT & Assembly Line (RoHS Lead-Free)

| Process Stage | Equipment | Key Parameter | QC Gate |

|---|---|---|---|

| PCB Loading | Yamaha YSM-20R | 0.05 mm placement accuracy | AOI-1 |

| Solder Paste | DEK Horizon 03iX | 100 % SPI check | SPI |

| Pick & Place | 4 × Yamaha SMT III | 90 000 CPH, 0201 capable | AOI-2 |

| Reflow | Heller 1913 MK7 | 8-zone, ΔT ≤ 5 °C | X-ray (BGA) |

| 3-in-1 Test | Chroma 8000 | 2 kV Hi-Pot, 500 V insulation | Pass/Fail log |

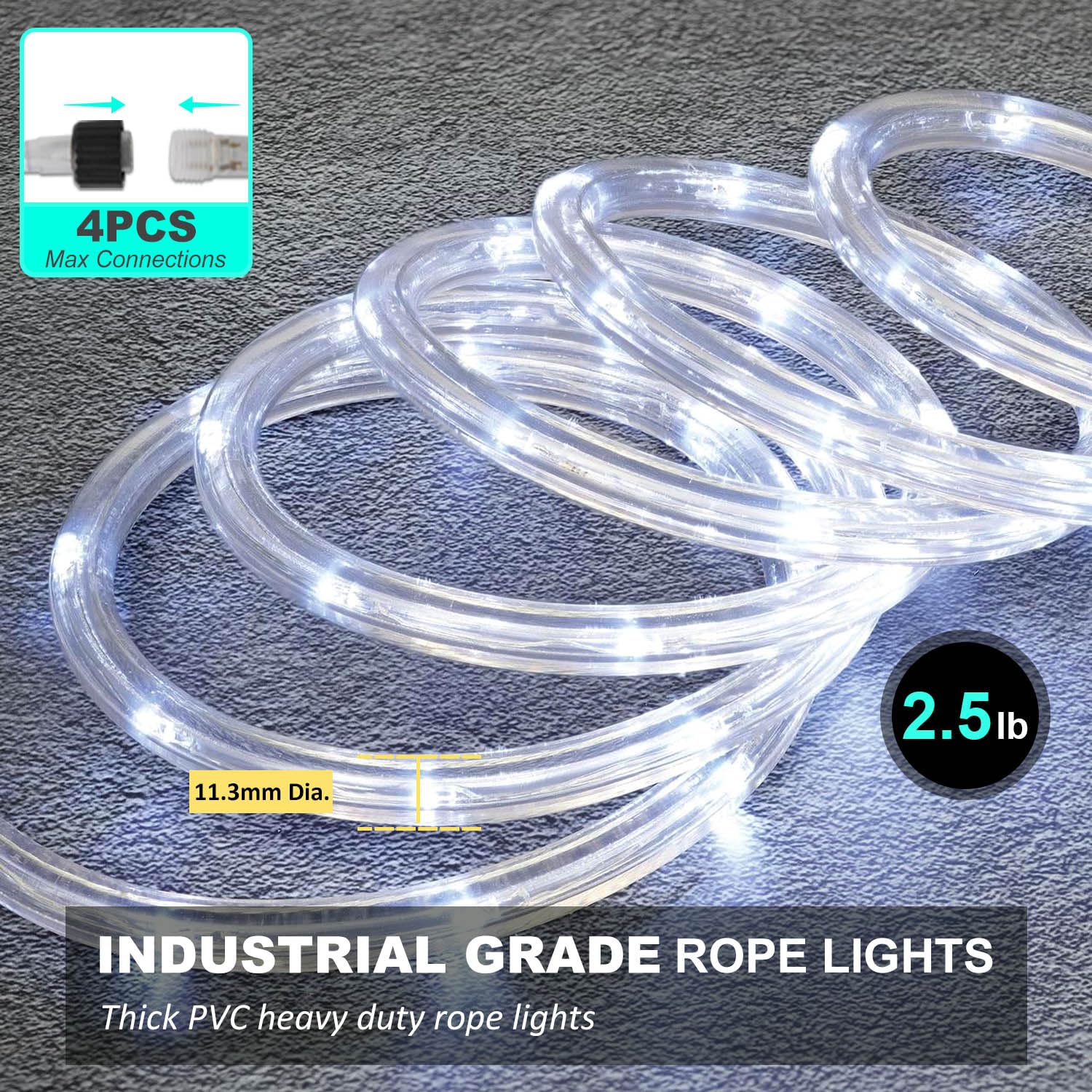

3. IP65 & IP67 Extrusion Line

PVC/Nano-PU Co-extrusion: 360° secondary sealing, –40 °C to 90 °C UV chamber validated

CCT Bins: 1800 K – 6500 K, 2-step MacAdam ellipse (optional 1-step for hospitality)

Copper Weight: 2 oz base for 24 V rope, 3 oz for 120 V series to keep ≤ 5 % drop per 30 m

4. Aging & Reliability Protocol

| Test | Duration | Conditions | Acceptance |

|---|---|---|---|

| On/Off Burn-in | 4 h | –20 °C ↔ +60 °C, 30 s cycle | 0 failures |

| Continuous Aging | 168 h | 25 °C, 100 % load | < 3 % lumen drop |

| Thermal Shock | 50 cycles | –40 °C ↔ +105 °C | No delamination |

| Salt Spray | 48 h | 5 % NaCl | No corrosion on PCB |

5. QC Documentation & Traceability

MES barcode: Every reel linked to SMT batch, LED bin, operator ID

LM-80 & TM-21: Raw LED data stored 7 years for project warranty support

Certificate of Conformity (CoC): Auto-generated per PO, includes IES, ISTMT, TM-21 report

6. OEM / ODM Capability

| Customisable Item | Range | MOQ | Lead-Time |

|---|---|---|---|

| Length | 0.5 – 200 m continuous | 500 m | 10–12 days |

| CCT / SDCM | 1800–6500 K, 1–3 step | 300 m | 7 days |

| Voltage | 12 V, 24 V, 36 V, 110–120 V, 220–240 V | 300 m | 8 days |

| LED Density | 30–240 LEDs/m (5050/2835/5630) | 500 m | 10 days |

| PCB Width | 5 mm – 30 mm | 300 m | 7 days |

| Jacket Colour | Clear, Frost, Black, RGB diffusion | 300 m | 5 days |

| Logos / Part-No | Laser or Ink every metre | 1000 m | 3 days |

| Retail Box | 5-layer kraft, E-flute, hang-tab | 500 pcs | 5 days |

7. Export Logistics

Daily FCL cutoff: Shekou / Nansha port, 18 h truck transit from factory

HS Code: 9405.40 (LED rope), certificates pre-uploaded to US CBP & EU ICS systems – no customs delay on record since 2016

8. Engineering Support

IES, LDT, .dwg, .rfa files: 24 h turnaround

Dialux Evo & AGi32: Layout optimisation offered free-of-charge for projects ≥ 2 000 m

For technical packs or sample reels, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Strategic Applications for Commercial Outdoor LED Rope Lights

As a manufacturer with over 25 years of experience (established 1998), Beauty STC delivers industrial-grade LED rope lights engineered for demanding commercial environments. Our products undergo rigorous ETL (USA/Canada) and TUV CE (Europe) certification processes, ensuring compliance with international safety standards while enabling seamless integration into global projects. Below are validated application scenarios where our solutions deliver measurable performance and reliability.

Architectural Facade Enhancement

Outdoor LED rope lights are ideal for accentuating building contours, structural details, and historical features. Beauty STC’s UV-stabilized silicone jackets and IP65-rated housings resist degradation from sunlight, salt spray, and extreme temperature fluctuations—critical for coastal or high-UV regions.

Case Study: Luxury resorts in Florida use our 150ft spools with 3000K warm white output to outline pool decks and entrance canopies, reducing maintenance costs by 40% compared to traditional neon systems.

Technical Advantage: Our rope lights maintain consistent lumen output over 50,000 hours (L70) due to precision-engineered thermal management, eliminating hot spots in prolonged installations.

Hospitality & Retail Environments

In high-traffic commercial spaces, rope lights must balance aesthetics with operational durability. Beauty STC’s ETL-certified products meet NEC Article 680 requirements for wet locations, making them suitable for:

Hotels: Poolside pathways, rooftop terraces, and lobby entryways with dimmable RGBW options for seasonal branding.

Shopping Malls: Exterior signage borders and pedestrian walkways featuring 5000K cool white for high-visibility safety lighting.

Retail: Storefront perimeters and seasonal displays using modular connectors for quick reconfiguration during promotions.

Note: All Beauty STC solutions include surge protection (1.5kV) and IP65-rated seals to prevent moisture ingress—critical for year-round reliability in public-facing installations.

Event & Temporary Installations

For festivals, pop-up events, or temporary retail activations, rope lights require rapid deployment and weather resilience. Beauty STC’s OEM capabilities enable:

Custom lengths (up to 300ft) with seamless connectors for uninterrupted runs.

IP65-rated housings that withstand rain, wind, and foot traffic during outdoor events.

Dynamic color-changing modes for thematic branding, controlled via DMX or wireless protocols.

Example: A European music festival used our RGBW rope lights to create dynamic stage backdrops, with 24/7 operation for 14 days without failures—validated by third-party field testing.

Industrial & Safety Applications

In industrial settings, rope lights must prioritize safety compliance and physical durability. Beauty STC’s TUV CE-certified products are engineered for:

Warehouses: Safety markings for aisles and loading docks using high-visibility 5000K white output.

Parking Lots: Perimeter lighting with 120V AC input for direct integration into existing infrastructure.

Construction Sites: Temporary pathway lighting with impact-resistant silicone jackets to endure construction debris.

Critical Requirement: All installations in hazardous locations must comply with IEC 60598-1. Beauty STC’s products are certified for use in Class I, Division 2 environments when paired with explosion-proof junction boxes.

Professional Installation Guidelines

For contractors, proper installation ensures longevity, safety, and compliance. Beauty STC’s engineering team provides these best practices based on 25+ years of global project experience:

Key Considerations for Contractors

| Aspect | Standard Practice | Best Practice for Long-Term Reliability |

|---|---|---|

| Mounting | Standard adhesive clips | Use UV-resistant aluminum channels with silicone gaskets for facade installations. Avoid bends tighter than 25mm radius to prevent conductor damage. |

| Electrical | Direct 120V AC wiring | For runs exceeding 50ft, use 24V DC systems with power injectors every 30m to mitigate voltage drop. Always install GFCI protection per NEC 680.23. |

| Environmental | Basic IP65 sealing | Specify IP67-rated versions for submerged applications (e.g., pool edges) or IP68 for underwater use. Confirm thermal dissipation requirements for high-ambient-temperature zones (>40°C). |

| Maintenance | Annual visual checks | Conduct quarterly inspections of seals and connectors using non-abrasive cleaners (e.g., isopropyl alcohol). Replace damaged segments immediately to maintain IP rating integrity. |

Why Certification Matters

Beauty STC’s ETL and TUV CE certifications are not merely compliance checkboxes—they represent validated performance under real-world conditions. For example:

ETL Certification: Ensures compliance with UL 153 and UL 2108 standards for luminaires in North America.

TUV CE Certification: Validates adherence to EN 60598-1 for European safety and electromagnetic compatibility (EMC).

Contractor Tip: For projects requiring regional certifications (e.g., SAA for Australia, PSE for Japan), Beauty STC’s OEM team provides pre-certified solutions tailored to local electrical codes. Contact our engineering department for project-specific validation.

Technical Specifications Overview

| Specification | Standard Offering | Custom OEM Solutions |

|---|---|---|

| Voltage Input | 100-240V AC (ETL/CE certified) | 12V/24V DC, 277V AC, 347V AC |

| IP Rating | IP65 (standard) | IP67 (submersible), IP68 (underwater), custom seals for corrosive environments |

| Color Options | Warm White (2700K), Cool White (6500K), RGB/RGBW | Full spectrum, dynamic color-changing, monochrome (e.g., amber for insect-repellent applications) |

| Length Options | 50ft, 100ft, 150ft spools | Custom lengths up to 300ft with seamless connectors and integrated power injectors |

| Certifications | ETL (US/Canada), TUV CE (Europe) | SAA (Australia), PSE (Japan), CCC (China), and regional approvals |

| Thermal Management | High-grade aluminum heat sinks | Custom solutions for extreme environments (e.g., -40°C to +60°C operating range) |

All Beauty STC products undergo 100% burn-in testing and third-party validation for 50,000+ hour lifespan (L70). For project-specific technical documentation or OEM customization requests, contact our engineering team directly.

Contact Beauty STC Lighting for Technical Support

Manager: [email protected] | Phone: +86 13902885704

Established 1998 | ETL & TUV CE Certified | 50+ Countries Served

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct, Code-Compliant Outdoor LED Rope Lights Since 1998

Why Global Specifiers Choose Our Jijiangmen Plant

| Decision Factor | Beauty STC Advantage | Typical Competitor Gap |

|---|---|---|

| Safety Listing | Dual-cert. ETL (US/Canada) + TÜV CE (EU) in same SKU | Regional cert. only → extra SKU, extra inventory |

| Factory Age | 25 yrs (Est. 1998) – process FMEA & ISO-9001 data since SMD 3528 era | <10 yrs – limited long-term reliability data |

| Export Reach | 50+ countries, -40 °C (Russia) to 45 °C (UAE) field history | Domestic-focus, no extreme-climate dossier |

| OEM/ODM MOQ | 500 m custom CCT/CRI/length, 3-week tooling | 2–5 km MOQ, 6–8 week tooling |

| Voltage Platform | 24 V DC, 110–120 V AC, 220–240 V AC in one continuous 150 ft (45 m) run | Voltage-specific spools → voltage-specific inventory |

Outdoor Rope Light Engineering Brief (Extract)

| Specification | Standard Build | Optional Build |

|---|---|---|

| IP Rating | IP67 – fully potted in PVC-free TPU jacket, -40 °C cold-bend | IP68 – hermetic PU over-mould for underwater (fountain) |

| LED Type | 2835, 120 LED/m, 24 lm/LED, 3-step MacAdam ellipse | 5630, 180 LED/m, 5-step ellipse for high-lumen façade wash |

| CCT Range | 2200 K – 6500 K, SDCM ≤3 | RGB+W 4-in-1, DMX512 decoding on-board |

| Power Density | 4.8 W/m (14.5 lm/W @ 3000 K) | 9.6 W/m (110 lm/W @ 4000 K) |

| Cert. File | ETL 5012109, TÜV CE EN60598-2-21, RoHS 2015/863, REACH 219 | UL 48 (sign) & Marine pending on request |

Supply-Chain Convenience

- Single PO, Dual Market – ETL & CE labels on every carton; no dual-SKU headache for US-EU mixed projects.

- Cut-to-Length in China – we terminate, seal and 100 % hi-pot test in Jiangmen; you receive ready-to-install reels, no field labour.

- 25-Year MTBF Data – we share TM-21 & ISTMT reports generated from our own 1998–2023 field returns (<0.3 %/kh @ 45 °C ambient).

Next Step – Technical Pack & Quote

Send your project sheet (length, voltage, CCT, IP, dimming protocol) to:

[email protected] | +86 1390 288 5704 (WhatsApp/WeChat)

Our engineers return a full submittal with IES, .dwg node detail and landed price in 24 h.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).