Article Contents

Industry Insight: Bendable Led Tape

The commercial and industrial lighting landscape is undergoing a profound transformation, driven by the relentless pursuit of energy efficiency, design flexibility, and operational resilience. Within this evolution, bendable LED tape has emerged not merely as a component, but as a foundational technology redefining how architects, engineers, and facility managers approach illumination in demanding environments. Its inherent adaptability allows for seamless integration into complex architectural forms, tight structural cavities, and dynamic signage applications where rigid fixtures fail, enabling previously impossible lighting solutions that enhance both aesthetics and functionality across warehouses, retail spaces, manufacturing plants, and transportation hubs. Crucially, in these high-stakes settings, performance must never compromise safety or regulatory adherence. Rigorous certifications like ETL and CE are not optional add-ons but absolute prerequisites, ensuring bendable LED tape installations meet stringent electrical safety, electromagnetic compatibility, and environmental standards required for commercial viability and occupant protection worldwide.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands at the forefront of this innovation. With over 25 years of dedicated expertise in advanced LED lighting solutions, we have consistently engineered products that bridge the gap between cutting-edge flexibility and uncompromising industrial reliability. Our deep understanding of the unique challenges within commercial and industrial sectors informs every meter of bendable LED tape we produce, ensuring they deliver superior lumen maintenance, thermal management, and durability under continuous operation while strictly conforming to global safety mandates. As the industry demands more intelligent, adaptable, and trustworthy lighting infrastructure, Beauty STC leverages its legacy of precision manufacturing and technical excellence to provide the certified, high-performance bendable LED tape solutions that power the future of professional illumination.

Technical Specs & Certifications

Beauty STC’s bendable LED tape is engineered for superior performance and reliability in both residential and commercial lighting applications. Designed with flexibility and high efficiency in mind, our bendable LED tape delivers excellent lumen output while maintaining energy efficiency and color accuracy.

The lumens per watt (lm/W) efficiency of Beauty STC’s bendable LED tape ranges from 110 to 130 lm/W, depending on the color temperature and density configuration. This high efficacy ensures optimal light output with minimal power consumption, making it an energy-saving solution ideal for continuous or long-duration operation. The LEDs are built using high-grade SMD 2835 or 3528 chips, which contribute to consistent brightness and thermal management across the strip.

Color Rendering Index (CRI) is a critical factor in lighting quality, and Beauty STC’s bendable LED tape exceeds industry standards with a CRI greater than 90. This ensures accurate and vibrant color representation, making it particularly suitable for retail displays, art galleries, architectural accent lighting, and residential environments where true color perception is essential. The high CRI is achieved through the use of premium phosphor coatings and tightly binned LEDs to maintain uniform color across the tape.

In terms of environmental protection, Beauty STC offers bendable LED tape in multiple IP ratings to suit various installation conditions. Our standard non-coated tape is rated IP20, suitable for dry indoor environments. For damp or outdoor applications, we provide versions with silicone coating rated IP65, offering protection against dust and low-pressure water jets. For fully waterproof performance, such as in outdoor coves, signage, or landscape lighting, our fully encapsulated IP67 and IP68 rated tapes are available, ensuring reliable operation even when submerged or exposed to harsh weather conditions.

Beauty STC is committed to quality and durability. Our bendable LED tapes undergo rigorous testing for thermal stability, solder joint integrity, and long-term lumen maintenance. We use high-purity copper PCBs for enhanced heat dissipation and current carrying capacity, which extends LED lifespan to up to 50,000 hours under normal operating conditions. All products are RoHS compliant and manufactured under ISO 9001-certified processes, reflecting our dedication to consistent quality and environmental responsibility.

With precise bendability along designated cut points, robust construction, and superior photometric performance, Beauty STC’s bendable LED tape stands out as a premium choice for designers and installers seeking reliability, efficiency, and excellent light quality.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant hub for advanced LED lighting production, specifically engineered to meet stringent global quality standards while supporting complex customization demands. The Jiangmen factory is strategically located within a major industrial zone, providing robust infrastructure and logistical advantages for both domestic and international supply chains. This facility is purpose-built for high-volume, precision manufacturing of flexible and rigid LED lighting solutions, with particular emphasis on sophisticated surface mount technology processes essential for modern LED products like bendable tape.

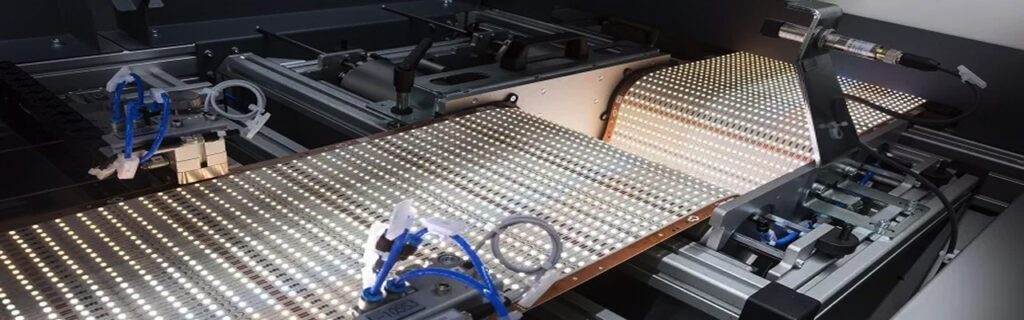

The SMT production lines within the Jiangmen plant are a cornerstone of its operational capability, featuring multiple fully automated high-speed placement systems sourced from leading manufacturers such as Yamaha or Fuji. These lines are configured specifically for the delicate handling of miniature LED components, including the 2835, 3528, and 5050 chip types commonly used in flexible tape assemblies. Each line integrates precision placement machines capable of handling component sizes down to 0201 packages with micron-level accuracy, ensuring consistent solder joint integrity critical for flexible circuit reliability. Supporting this are nitrogen-reflow soldering ovens for void-free thermal profiles and automated optical inspection systems that perform 100% real-time checks on component placement, polarity, and solder quality before the flexible PCBs proceed to further assembly stages. This SMT infrastructure operates under strict ESD-controlled environments to protect sensitive semiconductor devices throughout the manufacturing sequence.

Aging and reliability testing constitute a non-negotiable phase in the Jiangmen factory’s quality assurance protocol, especially for bendable LED tape products where thermal stress and mechanical flexing can accelerate failure modes. The facility maintains dedicated aging chambers with programmable temperature and humidity controls, allowing tapes to undergo extended burn-in cycles typically ranging from 24 to 72 hours at elevated temperatures up to 60°C. During these tests, automated monitoring systems continuously track critical parameters including luminous flux depreciation, chromaticity shift, forward voltage stability, and thermal performance across multiple sample points. Crucially, the aging process for bendable tapes incorporates mechanical stress simulations where samples undergo repeated flexing cycles at specified radii to validate the integrity of solder joints and conductor traces under real-world installation conditions. Any units exhibiting performance deviations beyond predefined thresholds are quarantined for root cause analysis before shipment authorization.

The factory’s OEM capability for bendable LED tape is exceptionally developed, leveraging both its technical infrastructure and engineering expertise to deliver fully customized solutions. Beauty STC supports comprehensive client-driven specifications including but not limited to custom lengths, LED densities (from 30 to 120 LEDs per meter), color temperatures (1800K to 6500K), CRI values (80+ to 97+), and specialized spectral outputs. Material customization extends to flexible PCB substrates with varying thicknesses and bend radii, silicone encapsulation for enhanced durability and IP ratings up to IP68, and client-specific connector configurations. The OEM process begins with collaborative engineering reviews where Beauty STC’s R&D team works directly with clients to validate thermal management solutions, electrical layouts, and mechanical designs ensuring optimal performance in the intended application. This is followed by prototyping with rapid turnaround and rigorous validation against international safety standards including UL, CE, and TÜV. The Jiangmen facility maintains flexible production scheduling to accommodate both large-volume contracts and smaller trial runs, with dedicated quality documentation and packaging tailored to each client’s branding and regulatory requirements. This end-to-end OEM service is underpinned by the factory’s vertical integration capabilities in PCB fabrication, component sourcing, and final assembly, ensuring consistent quality control from raw materials to finished goods.

Application Scenarios

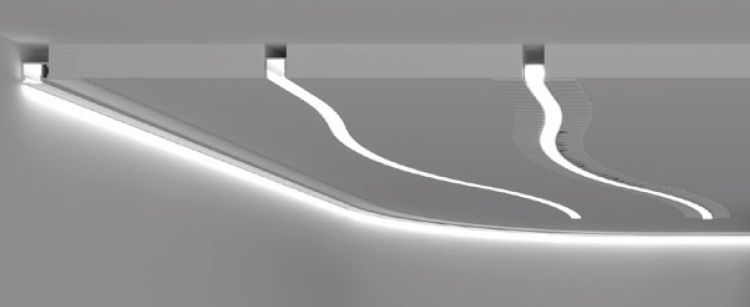

Bendable LED tape is a versatile lighting solution ideal for a range of commercial environments including hotels, malls, and offices due to its flexibility, ease of installation, and ability to create dynamic, visually appealing lighting effects. In hotels, bendable LED tape is commonly used to highlight architectural features such as cove lighting in lobbies, under-bed or headboard lighting in guest rooms, accent lighting in corridors, and within custom reception desks. The soft, continuous glow enhances ambiance and contributes to a luxurious guest experience.

In shopping malls, this type of LED tape is effective for illuminating signage, display windows, ceiling perimeters, and stair edges. Its ability to bend around curves makes it perfect for creative installations in modern, flowing designs often found in mall interiors. Retail areas within malls also benefit from using bendable LED tape to spotlight products or guide foot traffic with subtle linear lighting.

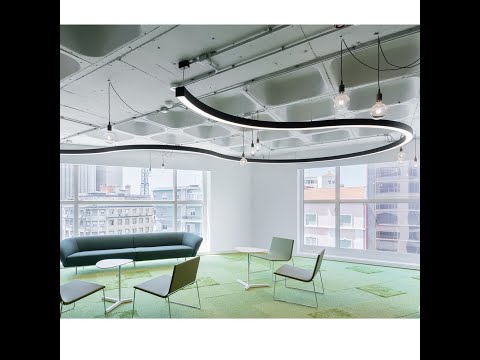

Offices utilize bendable LED tape for both functional and aesthetic purposes. It can be installed under shelves, in ceiling coves, or behind partitions to provide indirect lighting that reduces glare and creates a more comfortable work environment. It’s also used in conference rooms to highlight branding elements or in reception areas to convey a professional and modern image.

When installing bendable LED tape, it is important to start with a clean, dry surface to ensure proper adhesion. Most tapes come with a self-adhesive backing, but for long-term reliability in high-traffic or temperature-variable areas, consider using aluminum channels which also help with heat dissipation and protect the tape. Always cut the tape only at the designated cut marks to avoid damaging the circuitry. For curved installations, gently bend the tape incrementally to prevent creasing or breaking the solder joints. Use compatible LED drivers and ensure proper voltage matching—most bendable LED tapes operate on 12V or 24V DC. For longer runs, avoid overloading by connecting segments in parallel rather than in series to maintain consistent brightness. Finally, test the tape before final installation and seal the ends with provided caps or silicone to protect against moisture and dust, especially in areas with varying humidity levels.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s advanced bendable LED tape, engineered for precision and durability in demanding installations. Our flexible solutions eliminate common issues like cracking and solder joint failure, ensuring flawless performance around tight curves and complex architectural features. Ideal for seamless cove lighting, furniture integration, and custom design applications, our tape maintains consistent output even under rigorous bending. Partner with Beauty STC to integrate superior bendable technology into your next project and deliver exceptional results. Contact our engineering team directly at [email protected] to discuss specifications, volume pricing, and technical support tailored to your requirements. Let us help you achieve lighting excellence through innovation and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.