Article Contents

Industry Insight: Bendable Led Strip

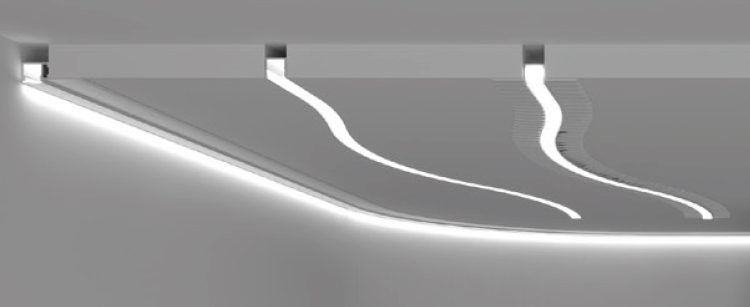

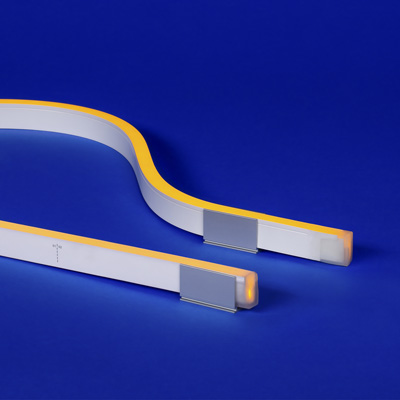

The evolution of commercial and industrial lighting has been significantly shaped by advancements in LED technology, with flexibility, efficiency, and reliability emerging as key drivers in modern lighting design. Among the most innovative solutions to meet these demands is the bendable LED strip—a versatile lighting option that combines dynamic form with high-performance illumination. Engineered to conform to curved surfaces, tight corners, and complex architectural contours, bendable LED strips offer unparalleled design freedom without compromising on light output or thermal management. These attributes make them ideal for a wide range of applications, from retail displays and hospitality environments to industrial signage and structural accent lighting.

In regulated commercial and industrial markets, compliance with safety and performance standards is non-negotiable. Bendable LED strips that carry ETL and CE certifications ensure adherence to rigorous North American and international electrical safety requirements, providing facility managers, lighting designers, and contractors with confidence in their durability and operational integrity. These certifications underscore the importance of quality manufacturing processes and reliable component integration—factors that directly impact long-term performance in demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. With a dedicated focus on commercial and industrial applications, Beauty STC combines engineering excellence with scalable production capabilities to deliver high-performance lighting solutions trusted by professionals worldwide. As a recognized leader in flexible and bendable LED technology, the company continues to set industry benchmarks through certified, energy-efficient products designed to meet the evolving needs of modern built environments.

Technical Specs & Certifications

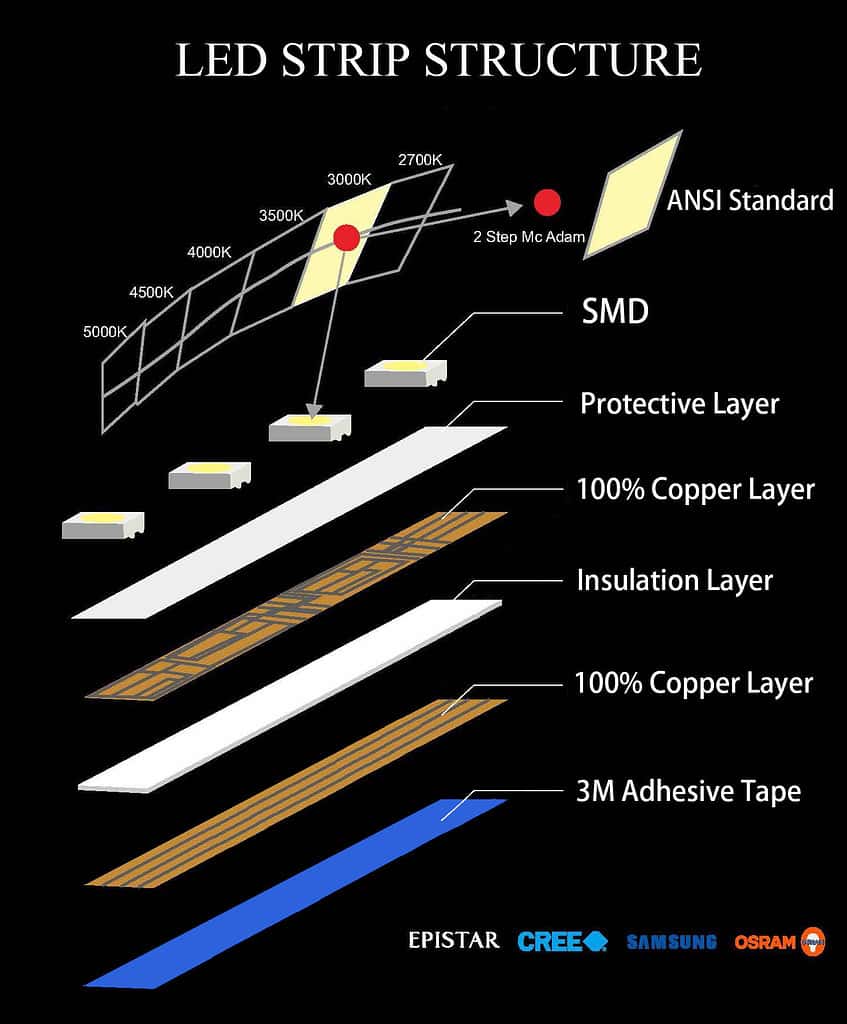

Flexible LED strips, commonly referred to as bendable LED strips, utilize flexible printed circuit boards (PCBs) allowing installation on curved surfaces. At Beauty STC Manufacturing Co., Ltd., our high-performance bendable strips are engineered for superior optical quality and reliability, specifically meeting demanding specifications for professional lighting applications. Lumens per watt efficacy is a critical efficiency metric where our standard 120 LED per meter (3014 or 2835 SMD) warm white (3000K-4000K) strips typically achieve 115-130 lumens per watt under standard test conditions at 25°C ambient temperature. Higher density configurations such as 240 LEDs per meter generally operate in the 105-120 lumens per watt range due to increased thermal density, though our optimized thermal management design minimizes this efficiency drop. All efficacy figures are measured at 700mA drive current with industry-standard integrating sphere methodology per LM-79, ensuring real-world applicability.

Color rendering is rigorously controlled to exceed CRI Ra >90 across all standard color temperatures, utilizing premium Samsung or Epistar 2835 LED chips with meticulously binned phosphor coatings. We emphasize that our CRI >90 specification includes strong R9 (saturated red) values consistently above 50, which is essential for accurate skin tone and material rendering in retail, hospitality, and residential settings where color fidelity is paramount. This high CRI performance is maintained across production batches through our stringent in-line spectrophotometer verification system, preventing the common industry issue of marginal CRI compliance with weak R9 values.

Regarding environmental protection, Beauty STC offers bendable strips in multiple IP-rated configurations validated through third-party testing. Our IP20 standard strips are designed for dry interior environments with no ingress protection. For damp locations, IP65-rated strips feature a continuous silicone encapsulation over the LEDs and PCB, protecting against low-pressure water jets from any direction, verified per IEC 60529 standards. For outdoor or washdown applications, IP67 strips withstand temporary immersion up to 1 meter depth for 30 minutes, while true IP68 variants (submersion beyond 1 meter for extended periods) utilize advanced dual-layer silicone coating and sealed end caps, tested to 1.5 meters for 72 hours. Crucially, our IP65/67/68 ratings apply only to fully assembled strips with our certified end connectors and power supplies, as improper installation compromises the ingress protection.

Beauty STC’s commitment to quality differentiates our bendable LED strips in the competitive market. We implement a proprietary 5-layer flexible PCB construction with 3oz copper thickness, significantly reducing voltage drop over long runs compared to standard 2-layer/1oz alternatives. All soldering is performed via nitrogen-reflow SMT lines with 100% AOI inspection, eliminating cold joints that cause premature failure. Our silicone encapsulants are UV-stable and halogen-free, preventing yellowing even under continuous high-temperature operation. Every production batch undergoes accelerated life testing at 65°C ambient with 720-hour burn-in, guaranteeing L70 (70% lumen maintenance) beyond 50,000 hours. This rigorous quality control, combined with UL/cETL safety certification and RoHS compliance, ensures our bendable strips deliver consistent photometric performance and longevity expected in premium architectural and commercial installations where reliability is non-negotiable.

Factory Tour: Manufacturing Excellence

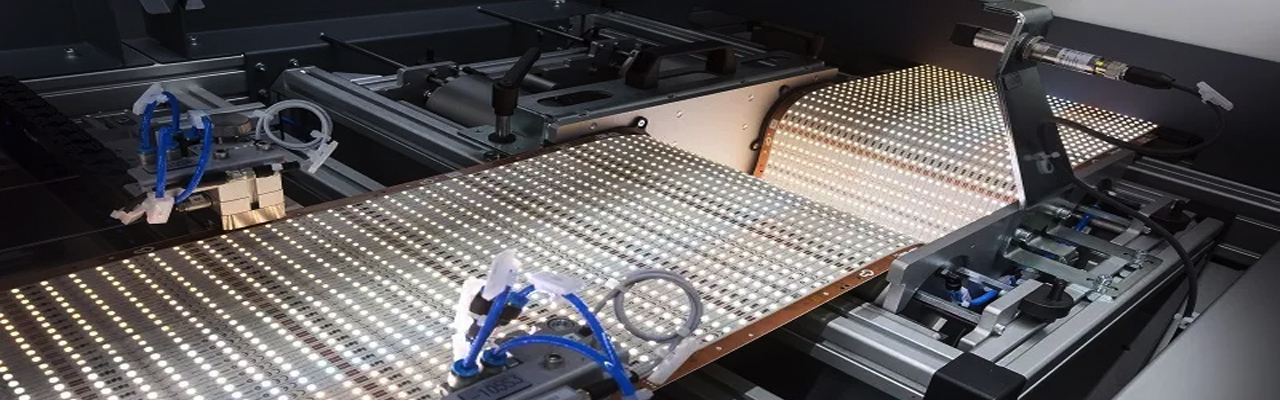

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, China, strategically located to support efficient production and logistics for both domestic and international markets. The Jiangmen factory is designed to meet high standards of quality and productivity, with a strong emphasis on automation, precision, and reliability in LED lighting manufacturing.

The facility is outfitted with advanced SMT (Surface Mount Technology) production lines, which are essential for the accurate and high-speed placement of LED components onto flexible and rigid circuit boards. These SMT machines are state-of-the-art, enabling precise assembly of small and complex LED packages used in bendable LED strips. The use of automated optical inspection (AOI) systems integrated into the SMT lines ensures consistent quality by detecting placement errors or solder defects in real time, minimizing rework and enhancing yield.

A critical part of the factory’s quality assurance process is the comprehensive aging test station. After assembly, all LED strips—especially bendable variants—undergo rigorous aging procedures under controlled thermal and electrical conditions. These tests typically run for 24 to 72 hours at elevated temperatures and full operating voltage to identify early-life failures and verify long-term performance. The aging process ensures that only reliable, stable products reach customers, which is particularly important for flexible LED strips that may be used in demanding environments.

Beauty STC has robust OEM (Original Equipment Manufacturer) capabilities, allowing for full customization of bendable LED strip lights according to client specifications. This includes custom PCB designs that enhance flexibility and bending radius, tailored color temperatures, special diffusers or silicone coatings, cut marks, voltage requirements (such as 12V or 24V DC), and even private labeling and packaging. The factory supports low to high-volume production runs, with engineering and R&D teams available to assist in product development, prototyping, and compliance testing for international standards.

Overall, the Jiangmen factory combines automated manufacturing, stringent quality control, and flexible OEM services to deliver high-performance bendable LED strip solutions tailored to a wide range of commercial, residential, and industrial applications.

Application Scenarios

Bendable LED strips offer unique advantages in commercial environments where curved surfaces, tight spaces, or dynamic lighting effects are required. Their flexibility allows for seamless integration into architectural features that rigid lighting cannot accommodate, making them ideal for specific applications in hotels, malls, and offices. In hotels, prioritize guest experience and safety. Install bendable strips under curved reception desks to create a soft ambient glow that enhances the welcome area without glare. They are excellent for illuminating the inside edges of circular or oval bathtubs in premium suites, providing both functional step lighting and a luxurious aesthetic. Wrap them around the contoured headboards in guest rooms for adjustable backlighting that reduces eye strain during late-night use. Additionally, integrate them along the inner curves of stair treads in grand lobbies to ensure safe navigation while adding subtle drama. For malls, focus on visual merchandising and spatial definition. Use bendable strips inside the curved edges of high-end jewelry or watch display cases where tight radiuses require lighting to follow the product contour, eliminating shadows on precious items. Apply them along the rounded soffits of escalator handrails to guide customer flow with continuous lines of light. They work well for outlining the organic shapes of modern art installations or curved partition walls in common areas, creating zones without physical barriers. In offices, emphasize functionality and well-being. Install bendable strips under the curved undersides of ergonomic standing desks to provide localized task lighting that minimizes glare on screens. They are perfect for tracing the contours of reception area sofas or lounge furniture, adding warmth without overwhelming the space. Wrap them around the curved edges of collaborative huddle room partitions to subtly define spaces while maintaining an open feel. Avoid direct overhead use in workstations due to potential glare; instead, focus on architectural accents that support circadian lighting goals when paired with tunable white systems.

Installation requires meticulous attention to detail to ensure longevity and performance. Always prepare the mounting surface thoroughly by cleaning it with isopropyl alcohol to remove dust, oils, or residues that compromise adhesion; a contaminated surface is the leading cause of strip detachment in high-traffic areas. Never exceed the manufacturer’s specified minimum bend radius—typically 30-50mm for most flexible strips—as sharp kinks can fracture solder joints or damage LEDs. For curved installations, aluminum mounting channels are non-negotiable; they provide critical heat dissipation that prevents lumen depreciation and color shift, especially in enclosed coves common in hotels and offices. Cut the strip only at designated scissor marks to avoid short circuits, and verify polarity meticulously when connecting segments. Power injection is essential for runs exceeding 5 meters: feed power from both ends or at intermediate points to prevent voltage drop, which causes dimming and inconsistent color at the far end of the strip. In humid areas like hotel bathrooms or mall food courts, use only IP67-rated strips with silicone encapsulation and seal all connection points with dielectric grease. Finally, test the entire run at full brightness for 15 minutes before final concealment to identify any thermal or electrical issues, as trapped heat in coves accelerates failure. Remember that bendable strips demand more precise thermal management than rigid alternatives—never install them in uninsulated cavities with ambient temperatures above 40°C.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s innovative bendable LED strip—designed for seamless adaptation to curves, corners, and complex surfaces. Whether for architectural accents, signage, or creative installations, our flexible technology delivers consistent, high-quality illumination. Partner with Beauty STC, a trusted leader in advanced LED solutions, and bring your most dynamic designs to life. For collaboration opportunities and product support, contact our team at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.