Article Contents

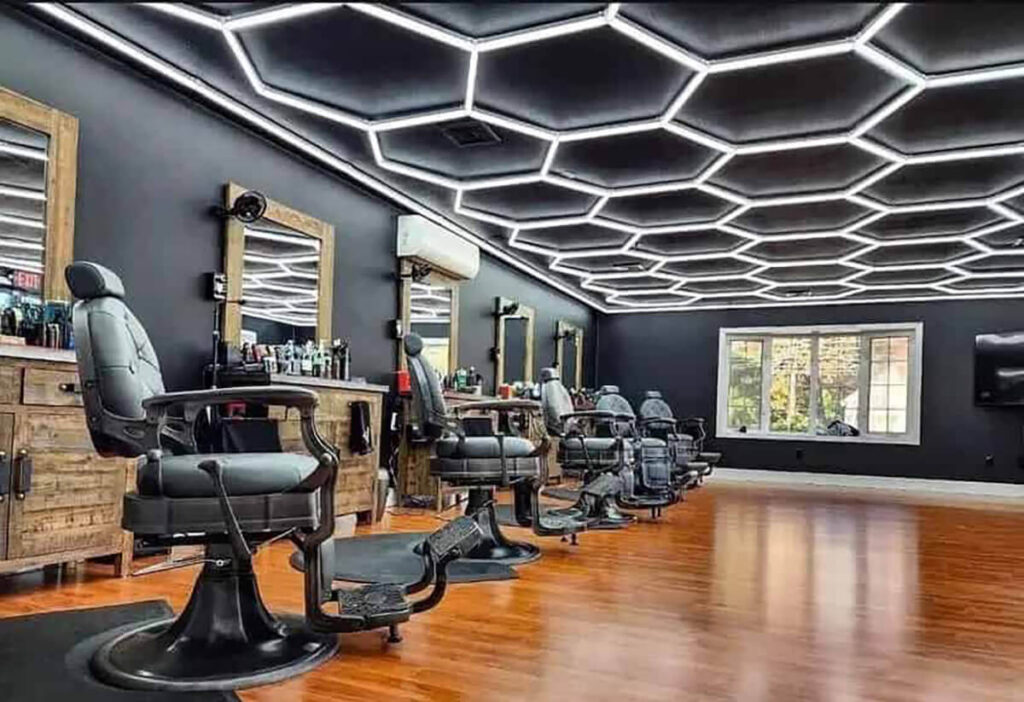

Industry Insight: Barber Shop Lighting

In the commercial and industrial lighting sector, specialized environments demand lighting solutions that combine performance, durability, and aesthetic precision. One such niche is barber shop lighting, where the quality of illumination directly impacts both service accuracy and customer experience. Unlike standard retail or office environments, barber shops require high Color Rendering Index (CRI) lighting, glare control, and optimal color temperature to ensure true-to-life skin and hair tone representation—critical for precision grooming. These requirements place barber shop lighting firmly within the scope of professional-grade commercial lighting systems engineered to meet rigorous safety and performance standards.

Compliance with certifications such as ETL and CE is non-negotiable in this space, ensuring that lighting fixtures adhere to North American and international electrical safety, electromagnetic compatibility, and environmental regulations. These certifications are not only markers of quality but also prerequisites for market access and customer trust in commercial installations. As demand grows for energy-efficient, long-lasting, and code-compliant lighting, manufacturers must balance technical excellence with design flexibility to serve diverse salon layouts and branding needs.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted name in commercial and industrial LED lighting solutions. With over two decades of experience, Beauty STC specializes in engineering high-performance lighting systems tailored to demanding environments—including professional grooming spaces. Leveraging advanced optical design, robust thermal management, and strict adherence to ETL and CE standards, Beauty STC delivers reliable, code-compliant lighting that meets the unique visual and operational demands of modern barber shops.

Technical Specs & Certifications

Barber shop lighting demands precise technical specifications to ensure optimal performance for color-critical tasks like hair coloring, shaving, and skin analysis. At Beauty STC Manufacturing Co., Ltd., our engineered solutions prioritize both aesthetic accuracy and operational efficiency. Key technical specifications begin with lumen efficacy, where our dedicated barbering luminaires consistently achieve 110-125 lumens per watt at full operating temperature. This high efficiency is maintained without compromising color fidelity, achieved through proprietary driver technology and thermal management systems that prevent lumen depreciation under continuous use. Crucially, all Beauty STC barbering fixtures exceed CRI >95 (Ra) with R9 (saturated red) values >90 and full TM-30-15 testing documentation, ensuring true-to-life rendering of hair tones, skin undertones, and cosmetic products. This surpasses basic CRI 90+ claims common in the market, as we validate performance across the entire visible spectrum including critical R12-R15 values for natural skin and hair representation.

For environmental protection, IP ratings are strategically implemented based on zone requirements. General ceiling and wall-wash luminaires utilize IP20 ratings with robust internal conformal coating for basic dust resistance in dry areas. Mirror-mounted task lighting and fixtures near washbasins incorporate IP44-rated sealed optics and gasketed housings to withstand humidity and incidental liquid splashes from styling products or hot towel steam, without over-engineering for unnecessary waterproofing that increases cost. Beauty STC avoids generic IP65 claims for non-wet zones, as excessive sealing traps heat and accelerates LED degradation – our thermal-optimized designs maintain reliability through intelligent airflow management instead.

Beauty STC’s quality differentiation lies in our holistic engineering approach. Every luminaire undergoes 72-hour burn-in testing at 45°C ambient temperature, simulating extreme shop conditions, with rigorous binning for chromaticity consistency (MacAdam 3-step or tighter). Our proprietary phosphor formulations and constant-current LED arrays prevent the color shift common in cheaper high-CRI solutions, while aircraft-grade aluminum heat sinks ensure L70 lifetimes exceeding 50,000 hours even in high-usage environments. Unlike competitors who prioritize raw lm/W numbers, we balance efficacy with optical control – our asymmetric lens systems deliver 85%+ optical efficiency with UGR<16 glare ratings, eliminating shadows during precise cutting tasks. This commitment to validated performance, backed by IEC 60598 compliance and ISO 9001-certified manufacturing, ensures barbers receive lighting that maintains color integrity shift after shift, directly supporting service quality and client satisfaction.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, a region known for its strong industrial infrastructure and strategic proximity to major supply chain hubs. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products, with a particular emphasis on precision, efficiency, and reliability. The facility integrates advanced automation and stringent quality control processes to meet international standards and support both domestic and global distribution.

At the heart of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable high-speed, accurate placement of electronic components onto printed circuit boards. These machines ensure consistent soldering quality and enable the production of compact, high-performance LED drivers and control modules. The SMT line is supported by automated optical inspection (AOI) systems to detect defects in real time, minimizing errors and ensuring superior product reliability.

To guarantee long-term performance, all lighting products undergo rigorous aging tests within the Jiangmen facility. Completed fixtures are subjected to extended operational runs—typically 4 to 8 hours—at elevated temperatures and full power to simulate years of use. This process helps identify early failures, validates thermal management designs, and confirms the stability of optical and electrical components before products leave the factory.

Beauty STC has robust OEM (Original Equipment Manufacturing) capabilities, particularly tailored for commercial and specialty lighting applications such as barber shop lighting. The company works closely with clients to customize design elements including color temperature (commonly 3000K to 4000K for barber shops), CRI (Color Rendering Index above 90 for accurate skin and hair tones), fixture shape, size, mounting options, and branding. From engineering and prototyping to full-scale production, the OEM process is supported by an in-house R&D team, tooling workshop, and quality assurance department, enabling quick turnaround and compliance with international certifications such as CE, RoHS, and UL.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to innovation, quality, and client-centric manufacturing, making it a trusted partner for branded and private-label LED lighting solutions in professional environments like barbershops, salons, and grooming studios.

Application Scenarios

Barber shop lighting serves a highly specialized purpose focused on precision tasks like hair cutting, coloring, and styling where exceptional color rendering and shadow control are non-negotiable. It is fundamentally unsuited for general ambient lighting in hotels, malls, or offices due to its intense, directional nature and specific photometric requirements. Misapplying this lighting in those environments would create significant functional and aesthetic problems.

In hotels barber shop lighting belongs exclusively within dedicated barbering or grooming suites, not in lobbies, guest rooms, or corridors. Installing it elsewhere would cause excessive glare for guests, disrupt the hotel’s intended ambiance, and waste energy. Similarly within malls this lighting is only appropriate inside tenant-operated barber shops or salons. Using it in common walkways, food courts, or storefront displays would overwhelm shoppers with harsh directional light, create unsafe glare on polished floors, and conflict with the mall’s cohesive lighting scheme. Offices present the strongest mismatch as barber lighting’s high-intensity beams would induce severe eye strain under computer screens, generate distracting hotspots on workstations, and violate occupational lighting standards requiring uniform, diffuse illumination. Its narrow beam angles and high vertical foot-candles are antithetical to open-plan or private office needs.

When correctly installed in barber shops prioritize three critical factors. Position primary lighting fixtures 24 to 36 inches above mirrors at a 30 to 45-degree downward angle to eliminate facial shadows during cutting this requires precise mounting height adjustments based on ceiling height and mirror placement. Always select LEDs with a minimum CRI of 90 and preferably 95+ alongside a correlated color temperature of 4000K to 4500K ensuring accurate hair color discrimination under both natural and artificial light conditions. For safety and functionality maintain strict separation between lighting circuits and plumbing by installing all electrical components at least 3 feet from sinks per NEC/CEC regulations and use IP65-rated sealed fixtures in zones near water sources to prevent moisture ingress and corrosion.

Crucially verify that the lighting layout provides symmetrical illumination across the entire mirror surface without dark zones particularly at the lower third where beard work occurs. Avoid placing fixtures directly overhead of chairs as this creates unflattering top-down shadows on clients’ faces. Instead integrate supplementary vertical wall washing or cove lighting to soften contrasts while maintaining the primary mirror-focused task lighting. Commission each installation with a spectroradiometer to confirm color consistency across all workstations as even minor CCT variations between fixtures will compromise color matching during services. This level of precision ensures the lighting functions as a critical diagnostic tool rather than merely an ambient feature.

Why Choose Beauty STC Lighting

Transform your barber shop with professional, high-quality lighting that enhances every detail of your craft. Partner with Beauty STC, a trusted leader in precision LED lighting solutions tailored for grooming and beauty environments. Our lighting systems deliver true color rendering, optimal brightness, and sleek designs that elevate the client experience. Contact us today to get started—email [email protected] and let Beauty STC illuminate your space with confidence and style.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.