Article Contents

Industry Insight: Ballast Compatible Led Bulbs

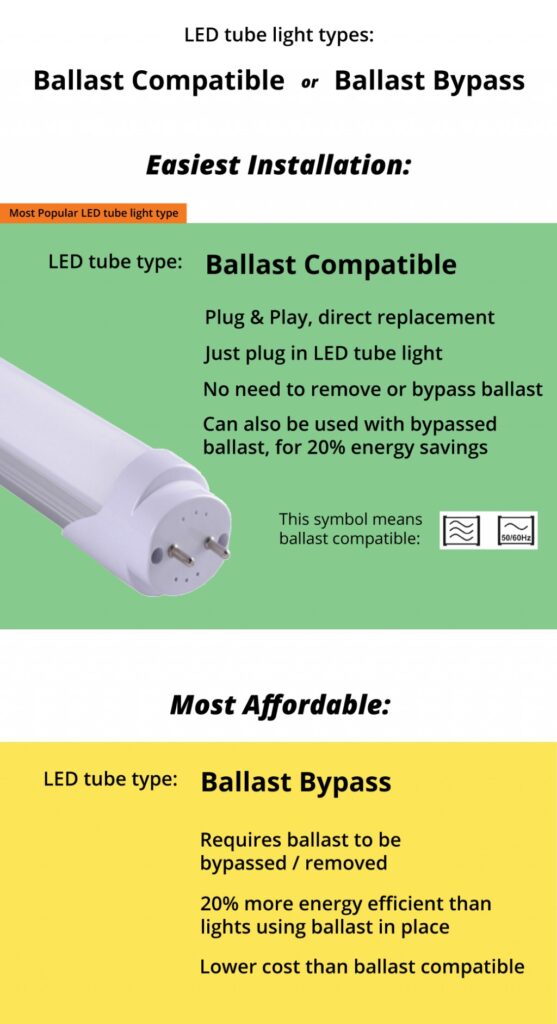

The commercial and industrial lighting sector is undergoing a transformative shift as facility managers and building operators seek energy-efficient, low-maintenance solutions that integrate seamlessly with existing infrastructure. Among the most impactful innovations in this space are ballast-compatible LED bulbs—also known as plug-and-play LED tubes—which offer a simple retrofit alternative to traditional fluorescent lighting systems. Designed to work directly with existing fluorescent ballasts, these LED bulbs eliminate the need for costly rewiring or ballast bypass modifications, significantly reducing installation time and labor costs while achieving substantial energy savings and longer service life.

Compliance with rigorous safety and performance standards is critical in commercial and industrial environments. Leading ballast-compatible LED bulbs are rigorously tested and certified to meet international regulatory requirements, including ETL listing to UL standards in North America and CE marking for the European market. These certifications ensure electrical safety, electromagnetic compatibility, and reliable performance under demanding operating conditions—key considerations for warehouses, manufacturing facilities, office buildings, and retail spaces.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance commercial and industrial lighting solutions, Beauty STC combines advanced optical engineering with robust quality control to deliver products that meet the exacting demands of global markets. With a strong commitment to sustainability, reliability, and regulatory compliance, Beauty STC’s ballast-compatible LED bulbs represent a smart, scalable upgrade path for modernizing legacy lighting systems without compromising safety or performance.

Technical Specs & Certifications

Ballast compatible LED bulbs represent a specialized retrofit solution designed to operate within existing fluorescent luminaires that retain their magnetic or electronic ballasts. At Beauty STC Manufacturing Co., Ltd., we engineer these products to stringent performance and reliability standards while addressing the inherent efficiency trade-offs of ballast compatibility. Key technical specifications for our premium ballast compatible LED bulbs are detailed below, emphasizing the critical parameters you specified.

Lumens per Watt efficacy for ballast compatible LED bulbs is inherently lower than direct-wire LED tube alternatives due to energy losses within the legacy ballast itself. Our engineering focus ensures optimal performance within this constraint. Beauty STC bulbs achieve a typical efficacy range of 80 to 100 lumens per watt when measured at the LED source. However, system efficacy – accounting for the ballast’s power consumption – typically falls between 65 and 85 lumens per watt in real-world operation. This represents a significant improvement over the 50-70 lumens per watt of the original fluorescent systems they replace. We achieve this through high-efficiency driver circuits integrated into the bulb base and premium LED chips, maximizing light output per watt drawn from the ballast output. Our commitment to thermal management using aluminum heat sinks ensures this efficacy is sustained over the product lifetime, avoiding the rapid lumen depreciation common in poorly designed competitors.

Color Rendering Index (CRI) performance is a cornerstone of Beauty STC’s quality commitment. All our ballast compatible LED bulbs consistently deliver a minimum CRI of Ra 92, with many models exceeding Ra 95. Crucially, we prioritize high R9 values (saturated red rendering), typically achieving R9 > 90, which is essential for applications requiring accurate color representation like retail, healthcare, and hospitality. This superior color quality stems from our proprietary multi-phosphor blend technology applied to high-CCT tolerance LED chips, rigorously binned and tested during manufacturing. Unlike cheaper alternatives that may meet Ra 90 on paper but fail in critical color points, Beauty STC bulbs undergo spectrophotometric validation to ensure full spectrum fidelity across all eight standard test colors and the vital R9 red.

Regarding Ingress Protection (IP) Ratings, ballast compatible LED bulbs primarily target installation within existing fluorescent luminaires, which are typically rated IP20 for indoor dry locations. Consequently, the standard rating for Beauty STC ballast compatible bulbs is IP20, protecting against solid objects larger than 12mm and offering no moisture protection – appropriate for the enclosed fixture environment. It is critical to note that the bulb itself cannot elevate the IP rating of the entire luminaire; the fixture’s rating governs overall protection. For applications requiring damp location use such as certain outdoor canopies or indoor wet areas, Beauty STC offers specific ballast compatible bulb variants rated IP44. These incorporate enhanced sealing at the base and along the glass tube to withstand splashing water, but they remain dependent on the fixture housing also providing adequate IP protection. True IP65 or higher ratings are generally unattainable for standard ballast compatible bulb form factors due to thermal constraints and the need for ventilation in enclosed fixtures, a limitation we transparently communicate to customers.

Beauty STC’s quality differentiation is engineered into every aspect of these bulbs. We utilize only A-grade Epistar or Samsung LED chips with proven lumen maintenance, coupled with Mean Well or equivalent high-reliability drivers specifically tuned for stable operation across diverse legacy ballast types. Our rigorous 50,000-hour L70 lifetime testing, conducted under real-world thermal and electrical stress conditions with actual ballasts – not just simulated loads – ensures exceptional longevity. Comprehensive safety certifications (UL/cETL, CE, RoHS) are standard, backed by in-house environmental testing for thermal cycling, surge immunity, and humidity resistance. Most significantly, our bulbs undergo compatibility testing against a vast library of common ballasts, including problematic older magnetic types, to guarantee flicker-free operation and eliminate premature failures. This commitment to robust engineering, component selection, and validation testing ensures Beauty STC ballast compatible LED bulbs deliver sustained high performance, safety, and reliability, providing a truly cost-effective and hassle-free fluorescent-to-LED upgrade path.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The factory is designed to support high-volume, precision manufacturing of LED lighting products with a strong emphasis on quality control, efficiency, and compliance with international standards.

At the core of the production process are advanced Surface Mount Technology (SMT) lines, which ensure precise and reliable assembly of LED components onto printed circuit boards. These SMT machines are fully automated and capable of handling a wide range of component sizes and densities, enabling high-speed placement with excellent accuracy. The integration of automated optical inspection (AOI) systems within the SMT lines allows for real-time defect detection, ensuring consistent product quality from the earliest stages of production.

To guarantee long-term performance and reliability, every batch of LED bulbs undergoes rigorous aging tests. The factory is equipped with dedicated aging chambers that simulate extended operational conditions, typically running products under elevated temperature and voltage stress for periods ranging from 4 to 12 hours or more, depending on product specifications. This process helps identify early failure modes and ensures that only robust, stable products proceed to packaging and shipment.

Beauty STC has strong OEM capabilities, particularly in the development and production of ballast-compatible LED bulbs—also known as LED tubes designed to work with existing fluorescent ballasts (plug-and-play solutions). The company supports customized branding, packaging, and electrical specifications tailored to different regional markets, including North America and Europe. Their engineering team works closely with clients to ensure compatibility with various ballast types (electromagnetic and electronic), maintain high power factors, and meet safety and regulatory requirements such as UL, CSA, CE, and RoHS.

Overall, the Jiangmen factory combines advanced automation, strict quality assurance protocols, and flexible manufacturing systems to deliver reliable, high-performance LED lighting solutions under both the Beauty STC brand and private labels.

Application Scenarios

Ballast compatible LED bulbs, often marketed as plug-and-play LED tubes, are designed to work with existing fluorescent magnetic or electronic ballasts without rewiring the fixture. However, it is critical to understand that Beauty (STC) Manufacturing strongly advises against their use in commercial settings like hotels, malls, and offices for significant technical and operational reasons. These products inherit all the reliability issues, energy inefficiencies, and failure modes of the aging fluorescent ballasts they depend on. Ballasts are a primary point of failure in fluorescent systems, and adding an LED tube that relies on this component creates a weak link. Energy savings are compromised because the ballast itself consumes power, typically 5-15% of the total system wattage, negating much of the LED’s potential efficiency. Furthermore, compatibility issues are common; not all LED tubes work reliably with all ballast types or ages, leading to flickering, reduced lifespan, or complete failure. Warranty claims are frequently denied when used with older ballasts, leaving the facility liable for premature replacements. Crucially, safety certifications for the LED tube often become void when installed in a fixture with an incompatible or failing ballast.

While the initial query specifies hotels, malls, and offices, Beauty (STC) recommends avoiding ballast compatible LED bulbs entirely in these environments. Hotels require high reliability for guest satisfaction and safety, particularly in corridors and lobbies where lighting failures are disruptive; ballast-dependent LEDs introduce unnecessary risk. Malls feature vast quantities of fixtures where the cumulative energy waste from ballasts significantly impacts operational costs, and the high density of units magnifies the maintenance burden when ballasts fail. Offices demand consistent, flicker-free light for productivity and occupant well-being; ballast-compatible LEDs are prone to flicker as ballasts age, causing eye strain and discomfort. The perceived installation speed advantage is outweighed by the long-term costs of ballast replacements, higher energy bills, and increased maintenance calls. Instead, Beauty (STC) advocates for ballast-bypass or direct-wire LED tube retrofits as the industry best practice. This approach removes the ballast completely, wiring line voltage directly to the tombstones, eliminating a failure point, maximizing energy savings, ensuring compatibility, and extending the LED system lifespan.

For any retrofit project, strict adherence to installation protocols is non-negotiable, regardless of the LED type selected. Always verify local electrical codes and obtain necessary permits before starting work. The single most critical step is confirming the power is completely isolated at the circuit breaker; use a multimeter to test for voltage at the fixture terminals, not just relying on the wall switch. When installing direct-wire LED tubes, meticulously identify and replace shunted tombstones with non-shunted types as required by the manufacturer’s instructions; using shunted tombstones with line voltage creates a short circuit hazard. Ensure all wire connections are tight and secured with wire nuts rated for the application, tucking them neatly into the fixture housing to prevent contact with the tube or housing. Never install ballast-compatible LED tubes into fixtures with known failing ballasts exhibiting symptoms like humming, flickering, or delayed start; this drastically increases failure risk. For ballast-bypass retrofits, completely remove and cap off the old ballast wires according to electrical code, labeling them clearly for future reference. Finally, retain all manufacturer cut sheets and installation instructions for compliance and warranty validation. Beauty (STC) emphasizes that investing in professional installation of direct-wire LED solutions delivers superior safety, reliability, and total cost of ownership compared to the false economy of ballast-dependent products.

Why Choose Beauty STC Lighting

Upgrade your lighting solutions with ballast-compatible LED bulbs designed for seamless integration and optimal performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED technology. Our ballast-compatible LED bulbs offer energy efficiency, long service life, and hassle-free retrofitting—perfect for modern commercial and industrial applications.

To learn more or discuss a customized lighting solution for your business, contact our sales manager at [email protected]. Let Beauty STC power your next project with reliable, high-quality LED innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.