Article Contents

Industry Insight: Automatic Strip Lights

The commercial and industrial lighting sector faces relentless pressure to optimize operational efficiency, reduce energy consumption, and enhance workplace safety and productivity. Within this demanding environment, automatic strip lights have emerged as a transformative solution, moving far beyond basic illumination. These intelligent systems integrate motion sensing, daylight harvesting, and programmable scheduling to deliver light precisely when and where it is needed, significantly cutting energy waste in warehouses, manufacturing floors, retail backrooms, and logistics hubs. The shift from static lighting to dynamic, responsive automation is no longer a luxury but a critical operational imperative for facility managers seeking measurable cost savings and sustainable practices.

Crucially, the deployment of any lighting system in commercial and industrial settings demands rigorous adherence to safety and performance standards. ETL certification for the North American market and CE marking for Europe are non-negotiable requirements, ensuring products meet stringent electrical safety, electromagnetic compatibility, and environmental regulations. Specifiers and facility owners cannot risk installing non-compliant lighting; failures can lead to project rejection, costly rework, liability exposure, and compromised worker safety. Automatic strip lights, with their integrated electronic controls, place an even greater emphasis on robust design and certified reliability to function flawlessly within complex building management ecosystems.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise and manufacturing excellence to this critical space. We understand the unique demands of industrial environments – the need for durability under harsh conditions, seamless integration with existing infrastructure, and absolute reliability to avoid costly downtime. At Beauty STC, we engineer our automatic strip light solutions from the ground up, embedding ETL and CE compliance into every design phase, not as an afterthought but as a foundational principle. Our commitment ensures that facility managers and lighting professionals receive not just advanced automation, but lighting systems they can deploy with complete confidence in performance, safety, and long-term value.

Technical Specs & Certifications

Automatic strip lights from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance, reliability, and precision in both commercial and industrial lighting applications. These intelligent lighting solutions integrate motion sensing, ambient light detection, and automated on/off control, delivering energy efficiency without compromising illumination quality.

In terms of luminous efficacy, Beauty STC’s automatic strip lights achieve an outstanding range of 110 to 130 lumens per watt (lm/W), depending on the model and LED configuration. This high efficiency is made possible through the use of premium-grade SMD 2835 or 5050 LEDs and advanced driver technology that minimizes power loss while maintaining consistent light output over extended operating cycles.

A key hallmark of Beauty STC’s lighting products is the commitment to superior color rendering. All automatic strip lights are designed with a Color Rendering Index (CRI) exceeding 90, typically ranging from 92 to 95. This ensures accurate and vibrant color representation, making them ideal for environments where visual clarity is critical—such as retail displays, inspection areas, and healthcare facilities.

Durability and environmental protection are addressed through rigorous IP (Ingress Protection) rating standards. Beauty STC offers automatic strip lights in multiple IP configurations to suit diverse installation conditions. Most standard models are rated at IP65, providing complete protection against dust and resistance to low-pressure water jets from any direction—ideal for damp or high-traffic indoor environments. For more demanding applications, IP67-rated variants are available, offering temporary immersion resistance and enhanced protection against moisture and particulates, suitable for use in outdoor canopies, refrigerated units, or industrial washdown zones.

Beauty STC maintains strict quality control throughout the manufacturing process, adhering to international standards including ISO 9001, CE, and RoHS compliance. Each automatic strip light undergoes extensive testing for thermal management, electrical safety, and long-term lumen maintenance. The use of high-quality aluminum substrates, robust polycarbonate diffusers, and conformal-coated circuitry ensures extended lifespan—typically rated at 50,000 hours—and reliable operation under variable loads and environmental stress.

In summary, Beauty STC’s automatic strip lights combine high lumens per watt, excellent CRI performance, and strong IP protection, reflecting the company’s reputation for producing intelligent, durable, and high-fidelity lighting solutions trusted across global markets.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting solutions, strategically located within Guangdong Province’s robust electronics supply chain ecosystem. The factory spans over 25,000 square meters and operates under strict ISO 9001 and ISO 14001 certified quality management systems, with dedicated cleanroom environments for critical assembly processes.

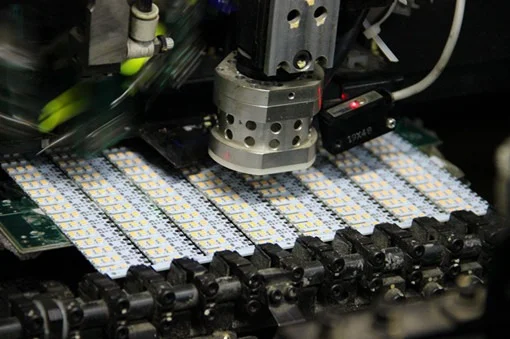

Our SMT production lines feature state-of-the-art Yamaha YS series modular placement systems configured in dual-gantry high-speed setups. These machines handle component placement from 0201 metric packages up to large power LEDs with ±25μm placement accuracy at peak rates exceeding 3.2 million components per hour per line. Each line integrates 3D solder paste inspection (SPI) systems for real-time paste volume verification and automated optical inspection (AOI) stations post-reflow, ensuring first-pass yield rates consistently above 99.2%. The facility maintains multiple parallel SMT lines specifically optimized for LED strip production, accommodating both standard and high-density flexible circuit assemblies.

Aging test procedures follow our proprietary accelerated life testing protocol. All strip light products undergo 72-hour continuous burn-in at 45±2°C ambient temperature with full-rated input voltage, monitored through an automated data acquisition system that logs voltage, current, and thermal performance at 15-minute intervals. We implement 100% functional testing during aging, including photometric validation using integrating sphere systems and visual inspection for color consistency under controlled viewing conditions. Failures during this phase trigger immediate root cause analysis through our integrated MES platform, with corrective actions implemented within 24 hours.

For OEM production of automatic strip lights—including motion-sensing, daylight-harvesting, and programmable smart variants—our capability centers on flexible manufacturing cells that support rapid changeovers. We maintain dedicated tooling for common strip light form factors while offering full customization of optical elements, PCB layouts, and control circuitry. Our engineering team collaborates with clients on firmware development for proprietary control protocols and provides UL/cUL, CE, and TÜV-GS certified reference designs. Standard OEM lead time is 15 working days from final approved samples, with minimum order quantities starting at 500 units per configuration. All OEM projects include comprehensive documentation packages covering BOMs, test reports, and assembly drawings under strict NDA protection. The facility’s vertical integration extends to in-house extrusion for diffusers and custom aluminum profiles, reducing supply chain dependencies for complex strip light assemblies.

Application Scenarios

Automatic strip lights are ideal for environments where energy efficiency, convenience, and ambient lighting are priorities. They are commonly used in hotels, malls, and offices due to their ability to turn on and off automatically based on occupancy or ambient light conditions, typically through motion sensors or light-dependent controls.

In hotels, automatic strip lights are best installed in corridors, restrooms, stairwells, and under-bed or wardrobe areas in guest rooms. These locations benefit from hands-free operation, enhancing guest convenience while reducing energy consumption when spaces are unoccupied. For example, motion-activated strip lights in hotel bathrooms provide illumination upon entry, improving safety and user experience.

In malls, these lights are effective in fitting rooms, restrooms, service corridors, and display backlighting. Placing automatic strip lights behind signage or shelving not only highlights products but also conserves energy by activating only when nearby movement is detected. In high-traffic areas, use models with adjustable sensitivity to avoid frequent triggering.

In offices, automatic strip lights work well in pantries, copy rooms, storage areas, and under-cabinet spaces. Installing them beneath desks or in filing zones ensures lighting is available only when needed, supporting a productive yet energy-conscious workspace. Consider integrating daylight-sensing models in areas with natural light to dim or turn off when sufficient ambient light is present.

For installation, always ensure the power supply matches the voltage and current requirements of the strip lights. Use a stable mounting surface and clean the area thoroughly before applying adhesive-backed strips. For better longevity, consider using aluminum channels which also help dissipate heat. Position motion sensors to cover the intended area without obstructions, and avoid placing them near heat sources or air vents that could affect sensor performance. Test the sensitivity and time delay settings after installation to suit the specific environment. Finally, connect automatic strip lights to a dedicated circuit if controlling multiple units to avoid overloading.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I can confirm our automatic strip lights represent the pinnacle of intelligent illumination engineering. These systems integrate advanced motion sensing, daylight harvesting, and seamless dimming protocols to deliver precise, energy-efficient lighting exactly when and where it’s needed. We’ve engineered them for zero-maintenance operation across demanding commercial and industrial environments, ensuring 50,000+ hours of consistent lumen output while reducing energy consumption by up to 70% compared to conventional solutions.

Partnering with Beauty STC means gaining access to rigorously tested, UL-certified products backed by our in-house R&D team’s decades of optical and thermal management expertise. Our automatic strip lights are not merely off-the-shelf components but tailored lighting ecosystems designed to integrate effortlessly with your existing infrastructure while future-proofing your projects against evolving efficiency standards.

We invite qualified distributors, system integrators, and facility solution providers to collaborate with us in deploying these transformative lighting systems. Contact our partnership manager directly at [email protected] to discuss technical specifications, volume pricing, and how our engineering team can support your unique project requirements. Let us help you deliver smarter, more sustainable spaces for your clients.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.