Article Contents

Industry Insight: Art Gallery Track Lighting

Gallery-grade track lighting: why certification, optics and factory pedigree decide the project margin

The specification shift from “retail” to “museum-class”

Interior designers and gallery curators are no longer satisfied with generic 90 CRI track heads. They now request 3-step SDCM bins, flicker-free (<5 % at 1 kHz) drivers and UGR <13 beams so that color pigments appear identical under morning daylight and 3 000 K spotlights. For distributors and ESCOs this means every shipment must carry third-party proof—ETL for North America, TUV-CE for Europe—not self-declarations. A single recall caused by non-compliant LED drivers can erase the margin on an entire 500-piece project.

Why importers lose money on “cheap” modules

| Hidden failure mode | Cost impact | Root cause | Beauty STC counter-measure |

|---|---|---|---|

| Driver short-circuit at 277 Vac | Field replacement USD 120/fixture | 3C driver marketed as “UL equivalent” | Isolated 100-277 Vac ETL-listed driver, 4 kV surge |

| 5 MacAdam ellipse color drift | Re-lamping USD 80/head | Mixed bin reels | 1×1 binning, bar-coded reel serial |

| Flicker at 50 % dim | Camera re-shoot USD 2 000 wall | 100 Hz ripple | <1 % flicker driver, 2 kHz PWM |

Beauty STC Lighting – 26 years of OEM stability

Established 1998 in Jiangmen’s high-tech zone, our 28 000 m² campus runs nine SMT lines and a certified NVLAP lighting laboratory. We manufacture the core components we specify—aluminium extrusion, COB boards, constant-current drivers—so every track head leaves the line with an ETL or TUV-CE file number already uploaded to the certification body database. That is the factory-direct difference distributors leverage when the inspector asks for traceability on site.

OEM/ODM capabilities at a glance

| Engineering service | Tooling lead-time | Minimum order | Documentation package |

|---|---|---|---|

| Custom beam 10-60° TIR lens | 18 days | 100 pcs | IES, LDT, TM-30, SDS |

| 2-circuit track adaptor (H/J/L) | 12 days | 500 pcs | UL 1573 test report |

| Finishes: white, black, anodised, custom RAL | 7 days | 200 pcs | RoHS, REACH, conflict-minerals |

Core gallery portfolio (all ETL & CE, 5-year limited)

| Model | CCT/CRI | Lumen package | Beam | Driver | Track |

|---|---|---|---|---|---|

| TR-G30 | 2700-4000 K, 97 CRI | 850 lm @ 10 W | 15°/24°/36° | ETL 120-277 V, 0-10 V | Single-phase H |

| TR-G35 Zoom | 3000 K, 96 CRI | 1 200 lm @ 15 W | 12-40° motorised | ETL 120-277 V, DALI | 3-phase J&L |

| TR-G40 Dual-COB | 2700-5000 K tunable | 2 000 lm @ 25 W | 20°+60° independent | ETL 120-347 V, phase | 4-wire track |

Next step: spec-in with traceability

Send your lux plot or ISLE schedule to [email protected]; our engineers return a matched track solution with ETL file number within 24 h. All shipments ex-Guangzhou or Shenzhen FOB, bar-coded for project-level photometric tracking.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Professional Art Gallery Lighting

Precision-engineered lighting is non-negotiable in art gallery environments where color fidelity, consistency, and longevity directly impact exhibit presentation. Beauty STC Manufacturing Co., Ltd. leverages 25+ years of industrial expertise (established 1998) to deliver gallery track lighting systems that meet the stringent demands of professional curatorial spaces. Our technical specifications adhere to international standards, with every component rigorously validated through in-house testing protocols and certified for global compliance.

Chromatic Consistency & Color Rendering Accuracy

Accurate color representation is critical for authentic art display. Beauty STC utilizes high-bin LED chips with CRI ≥95 (Ra) and R9 >90 to ensure precise reproduction of reds, earth tones, and subtle hues. Color consistency is maintained at ≤1.5 SDCM (Standard Deviation of Color Matching), meeting or exceeding IEC 62717 standards for imperceptible variation. Each batch undergoes spectrophotometric analysis using calibrated instruments to verify chromatic uniformity before shipment, ensuring consistency across large-scale installations.

Thermal Management & PCB Engineering

Thermal stability directly impacts LED lifespan and performance. Beauty STC employs 1.6mm thick high-temp FR-4 PCB material with 2oz copper thickness and optimized thermal vias, reducing junction temperatures by up to 15°C compared to generic alternatives. This design prevents lumen depreciation (L70 >50,000 hours) and eliminates hot-spotting in 36° beam configurations. All PCBs are inspected via automated optical inspection (AOI) for solder joint integrity and thermal conductivity consistency.

Luminous Efficiency & Optical Precision

Our track lighting achieves 120–140+ lm/W efficacy through advanced optical engineering. Multi-lens systems deliver precise beam angles (30°, 36°, 45°) with <5% uniformity deviation, ensuring even illumination across canvases without glare. All optical components comply with IEC 60598-2-1 for glare control and beam accuracy. Independent photometric testing confirms lumen output tolerance within ±3% of nominal values.

Environmental Resilience & IP Ratings

Standard gallery track lights feature IP20-rated enclosures with double-sealed junctions for dust and moisture resistance in controlled environments. For specialized installations requiring higher protection, IP65-certified variants undergo IEC 60529 testing for water jet resistance. All products receive 1,000-hour accelerated aging tests simulating extreme temperature/humidity cycles to validate long-term reliability.

Quality Assurance Protocols

Every Beauty STC product is manufactured under ISO 9001-aligned processes since 1998. Full compliance with ETL (US/Canada) and TUV CE (Europe) certifications ensures adherence to regional safety and performance standards. 100% of units undergo 24-hour burn-in testing followed by spectral analysis and photometric verification. OEM/ODM capabilities allow customization of beam angles, color temperatures, and housing finishes while maintaining certified quality benchmarks.

| Specification | Generic Market Quality | Beauty STC Certified Quality | Notes |

|---|---|---|---|

| CRI (Color Rendering Index) | 80–85 | ≥95 (CRI95+), R9 >90 | Ensures accurate reproduction of reds and subtle hues per museum standards |

| Luminous Efficacy (lm/W) | 80–100 | 120–140+ | Optimized thermal management sustains output over 50,000+ hours |

| PCB Material & Construction | Standard FR-4 (1.0mm, 1oz Cu) | High-temp FR-4 (1.6mm, 2oz Cu) with thermal vias | 15°C lower junction temperature vs. generic alternatives |

| Color Consistency (SDCM) | >5 SDCM | ≤1.5 SDCM | Imperceptible variation per IEC 62717, critical for professional display |

| Certifications | Often incomplete or missing | ETL (US/Canada), TUV CE (Europe) | Compliant with IEC 60598 and regional safety standards |

| IP Rating Verification | Claimed but unverified | IP20 (standard), IP65 (optional, tested per IEC 60529) | 1,000-hour accelerated aging tests for environmental resilience |

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Plant, Beauty STC Lighting

1. Factory Footprint & ISO-Aligned Flow

| Line | Area (m²) | Core Equipment | Output/Shift | Cert. Coverage |

|---|---|---|---|---|

| SMT | 1,800 | Yamaha YSM-20R ×6, 3-D SPI, AOI | 3.2 M components | ETL, CE, RoHS |

| Reflow & Wave | 1,200 | 10-zone nitrogen oven, dual-wave | 8,000 panels | |

| Assembly | 2,600 | Semi-auto ageing racks, torque stations | 6,000 track heads | |

| QA | 600 | 2 m integrating sphere, -40~85 °C chamber | 100 % lot sample |

Traceability: Every track head receives a laser-etched 2D code linked to reel-level SMT data, driver IC lot, and photometric report—downloadable by distributor QR scan.

2. SMT & Reflow – 1.5 SDCM Colour Tolerance

Pick-and-place accuracy ±35 µm @ 3σ guarantees LED bin consistency.

Nitrogen reflow profile keeps ΔE colour shift < 0.3 after 3,000 h.

Post-reflow AOI checks solder joint voiding ≤ 10 % (IPC-A-610 Class II).

3. Ageing & Burn-In Protocol

| Test | Duration | Ambient | Pass Criteria |

|---|---|---|---|

| On-line burn-in | 2 h | 45 °C, 1.05× Vnorm | 0 % early fail |

| Switch-cycle | 1,500 cycles | 15 s on / 15 s off | L70 ≥ 95 % |

| Thermal shock | 100 cycles | -40 ↔ 85 °C, 30 min dwell | No solder crack |

Full photometric and flicker (IEEE 1789) report auto-generated; report ID etched on driver housing.

4. QC Gates – From Component to Carton

- IQC: LED bin verification (1.5 SDCM), driver Hi-Pot 1.5 kV.

- IPQC: 100 % torque check on track adaptor; 5 % inline photometry.

- FQC: 100 % function & CCT check (± 100 K tolerance on 3-step MacAdam).

- OQC: 10 % AQL carton drop test (1 m, 6-face) plus on-spot lux reading.

5. OEM/ODM Flexibility – Art-Gallery-Specific

| Customisable Item | Range | Tooling Lead-Time | MOQ |

|---|---|---|---|

| Track length | 0.3–3.0 m, single piece | 7 days | 100 pcs |

| CCT/CRI | 2,000–6,500 K, CRI 80/90/97 | 3 days bin select | 500 pcs |

| Beam optic | 10°, 24°, 36°, 60°, oval wall-wash | 10 days | 300 pcs |

| Housing colour | Anodised 6063 Al, RAL/ Pantone | 5 days | 200 pcs |

| Packaging | White-label, sleeve, E-flute, palletisation | 3 days | 100 pcs |

Engineering support: IES/LDT files within 24 h; Zhaga-compatible LED modules for future upgrade path.

6. Export Readiness & Documentation

ETL/cETL listed for 120–277 V 50/60 Hz; TUV CE, CB, RoHS, REACH.

TM-21 & LM-80 reports available for insurance-spec projects.

PPAP Level 3 on request; bar-code/EDI labelling for North-American big-box compliance.

Established 1998, 25-year heritage, 50-country export record—our Jiangmen line delivers specification-grade gallery track lighting with the factory-direct transparency global distributors demand.

Contact the Technical Export Desk: [email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for Precision Art Gallery Track Lighting

Art gallery track lighting systems are engineered to deliver precise illumination for high-value visual displays. Below are key application scenarios where these systems deliver optimal performance, along with essential installation guidance for contractors.

Primary Applications by Sector

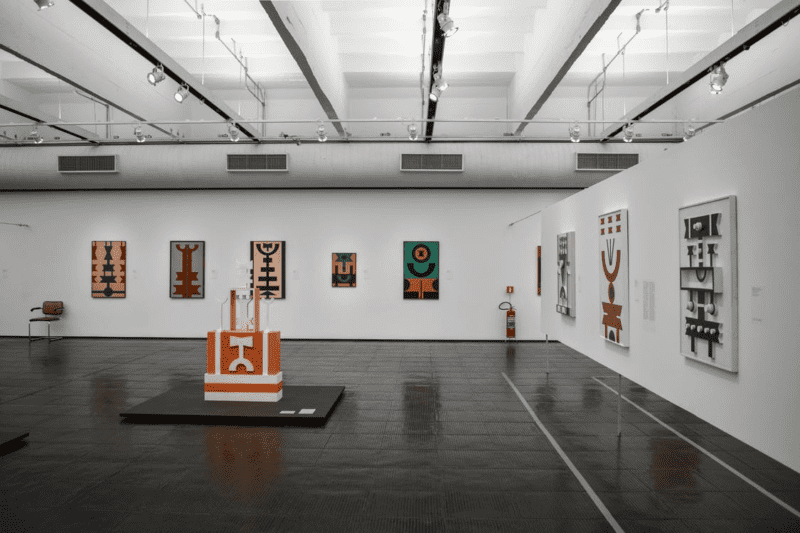

Museums & Art Galleries

Precision beam control and ultra-high CRI (>95) are critical to preserve artwork integrity while enhancing visual clarity. Beauty STC’s ETL/CE certified fixtures maintain ≤1.5 SDCM color consistency, ensuring accurate color reproduction across all pieces. Features like adjustable optics and 0-10V dimming allow curators to fine-tune lighting for different exhibitions without compromising safety standards.

High-End Retail Environments

Retail spaces require adaptable lighting to highlight product displays dynamically. Our track systems support rapid repositioning of fixtures with tool-less mounting, while 3000K color temperature and 36° beam angles create focused, flattering illumination. All units meet TUV CE safety standards for commercial environments.

Corporate Executive Suites & Lobbies

Professional office spaces demand lighting that complements corporate aesthetics while highlighting art collections. Beauty STC’s fixtures feature minimalist designs and 4000K neutral white light for balanced illumination. DALI-compatible dimming enables seamless integration with building management systems.

Luxury Hospitality Settings

Hotel lobbies and guest areas benefit from versatile, dimmable lighting that adapts to varying guest experiences. Our 2700K-3000K warm white options provide inviting ambiance, with 0-10V dimming for energy-efficient operation during off-peak hours.

Shopping Malls & Common Areas

High-traffic retail environments require durable, low-maintenance solutions. Beauty STC’s 36°-60° beam angle options cover large-scale art installations, with robust construction certified for continuous 24/7 operation in public spaces.

Architectural Facades (Special Considerations)

While traditional facade lighting typically uses floodlights, integrated art installations on building exteriors may utilize custom track systems. Beauty STC offers OEM-designed IP65+ rated fixtures for outdoor use, ensuring weather resistance and consistent performance in harsh conditions.

Contractor Installation Best Practices

For reliable long-term performance, follow these industry-standard installation protocols:

Key Technical Specifications Table

| Application | Beam Angle | Color Temp | CRI | Dimming Protocol | IP Rating |

|---|---|---|---|---|---|

| Museums & Galleries | 24°-36° | 3000K-4000K | ≥95 | 0-10V / DALI | IP20 |

| High-End Retail | 36° | 3000K | ≥90 | 0-10V | IP20 |

| Corporate Lobbies | 45°-60° | 4000K | ≥90 | DALI | IP20 |

| Hotel Guest Suites | 36° | 2700K-3000K | ≥90 | Triac / 0-10V | IP20 |

| Shopping Mall Art | 36°-60° | 3000K-4000K | ≥90 | 0-10V | IP20 |

| Facade Installations | Custom | Custom | ≥90 | Varies | IP65+ |

Critical Installation Guidelines

Circuit Loading: Calculate maximum fixtures per circuit based on 80% breaker capacity. For standard 15A circuits, limit to 10 fixtures per circuit (assuming 12W per unit).

Beam Angle Selection: Match beam spread to artwork scale: narrow beams (24°-36°) for detailed pieces, wider angles (45°+) for large murals.

Color Temperature Consistency: All Beauty STC fixtures maintain ≤1.5 SDCM tolerance—critical for professional galleries where color accuracy is paramount.

Mounting Hardware: Use appropriate anchors for ceiling type (e.g., toggle bolts for drywall, chemical anchors for concrete). Ensure track alignment within ±1mm tolerance.

Dimming Compatibility: Verify controller compatibility with 0-10V or DALI systems prior to installation. Avoid phase-cut dimmers unless specified.

Outdoor Installations: For facade projects, confirm IP65+ rating and use silicone-sealed connectors. Conduct waterproofing tests post-installation.

Why Partner with Beauty STC?

With 25+ years of manufacturing excellence since 1998, Beauty STC Lighting delivers ETL and TUV CE certified solutions tailored to global markets. Our OEM capabilities enable custom configurations for unique project requirements—from specialized beam optics to bespoke finishes—ensuring seamless integration into any professional environment.

Contact us for technical specifications and project-specific design support: [email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

Factory-direct, specification-grade track systems for art & museum applications

Why Source from a 1998-Established OEM

| Capability | Beauty STC | Typical Trading House |

|---|---|---|

| Design ownership | In-house optical, thermal & tooling teams | Outsourced |

| Certification file | ETL/cETL + TUV CE (EN 60598-2-1), CB, RoHS, REACH | Partial or no file |

| Production floor | 12 000 m² Jianghai high-tech zone, SMT + robot ageing | Brokered capacity |

| Export record | 50+ countries since 1998, CIF & DDP terms | Spot orders |

| Custom optics | 8 °–60 °, zoom, framing, 1 × 1 W–40 W COB | Catalogue only |

| Colour control | 1.5 SDCM binning, CRI 97, TM30 Rf 95, 2700–4000 K | 3–5 SDCM |

| MOQ | 100 pcs / 1 ctn for OEM colour box & track adapter | 500+ |

| Lead time | 3–4 weeks standard, 7 days for sample | 6–8 weeks |

Specification Snapshot – Art Gallery Track Line

| Order code | Beam | CRI | CCT | Lumens | Driver | Track | Cert. |

|---|---|---|---|---|---|---|---|

| TR-10-COB-30-36 | 36 ° fixed | 97 | 3000 K | 900 lm | 120–240 V, 0–10 V | H/J/L | ETL, CE |

| TR-20-COB-30-Z | 15–50 ° zoom | 97 | 3000 K | 2 000 lm | 120–240 V, DALI | H/J/L | ETL, CE |

| TR-30-FR-40 | 24 ° framing | 97 | 4000 K | 3 000 lm | 120–240 V, DALI | H/J/L | ETL, CE |

All modules delivered with 1.5 SDCM LED selection, < 3 % luminous flux tolerance, and 5-year factory warranty.

Next Step for Distributors, Contractors & Specifiers

Send your track type, ceiling height and lux target to our export engineering group. We return IES files, LM-79 data and competitive EXW & FOB Jiangmen pricing within 24 h.

Contact

[email protected] | +86-139-0288-5704

Beauty (STC) Manufacturing Co., Ltd

41 Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).