Article Contents

Industry Insight: Aluminum Led Channel For Led Strip Lights

The commercial and industrial lighting sector continues its decisive shift towards LED technology, driven by relentless demands for energy efficiency, longevity, and superior light quality across demanding environments like warehouses, manufacturing facilities, retail spaces, and hospitality venues. Central to the successful implementation and performance of flexible LED strip lighting in these professional settings is the often-underestimated component: the aluminum LED channel. Far more than a simple housing, these precision-engineered extrusions are critical thermal management systems. Effective heat dissipation directly governs LED lumen maintenance, color stability, and overall lifespan – factors that are non-negotiable for operations requiring minimal maintenance downtime and consistent, high-quality illumination over tens of thousands of hours. The right aluminum channel ensures LEDs operate within their optimal thermal envelope, transforming the potential of strip lighting into a reliable, high-performance solution for architectural cove lighting, task lighting under shelving, signage, and linear accent applications in demanding commercial projects.

Specifying aluminum LED channels for professional use necessitates rigorous attention to safety and performance standards. Channels deployed in commercial and industrial installations must consistently meet stringent regulatory requirements, prominently featuring ETL listing to North American safety standards and CE marking for the European market. These certifications are not mere formalities; they are fundamental assurances that the channel system, including its thermal properties, electrical safety features like proper grounding, and material integrity under operational stress, has undergone independent laboratory testing and complies with critical codes. This compliance is essential for project approval, insurance requirements, and, most importantly, the long-term safety and operational reliability expected in professional environments where lighting failures can have significant operational and financial consequences.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing and manufacturing high-performance aluminum LED channel systems specifically engineered for the rigorous demands of commercial and industrial lighting. With over 25 years of dedicated expertise, we understand that channel performance is inseparable from the overall success of an LED installation. Our focus extends beyond basic extrusion; we integrate advanced thermal design, robust material specifications, and rigorous quality control processes to deliver channels that ensure optimal LED performance and longevity. Beauty STC channels are consistently designed and verified to meet ETL and CE requirements, providing lighting professionals with the certified, reliable thermal management solutions necessary to build lighting systems that perform exceptionally and endure reliably in the most challenging professional settings. Our commitment lies in enabling the full potential of LED strip technology through superior channel engineering.

Technical Specs & Certifications

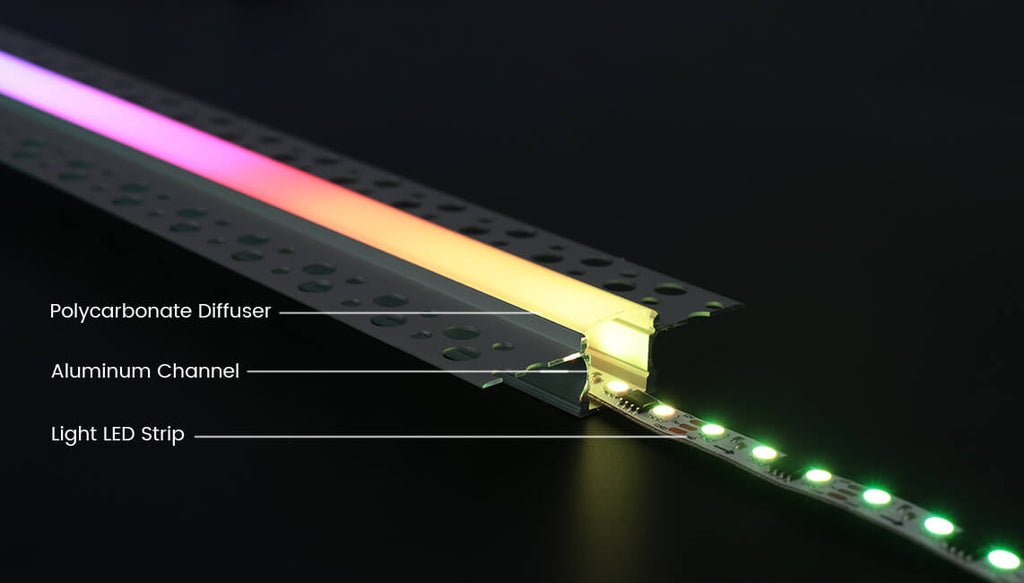

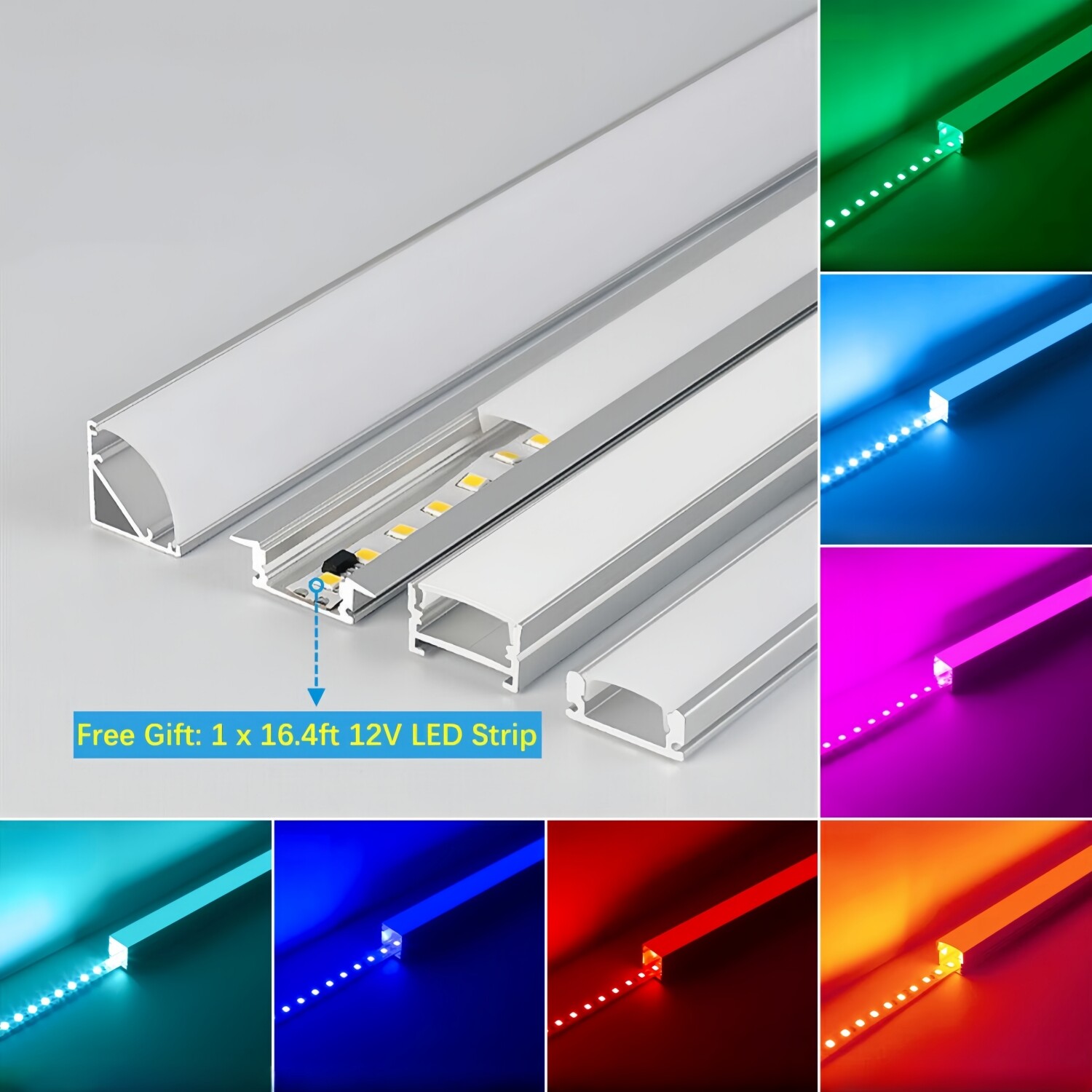

The aluminum LED channel for LED strip lights offered by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver optimal performance, thermal management, and durability for both residential and commercial lighting applications. While the aluminum channel itself is a passive component designed primarily for heat dissipation, protection, and aesthetic integration of LED strips, its compatibility with high-performance LED strips enables systems that achieve excellent lumens per watt (lm/W), high color rendering index (CRI >90), and robust ingress protection (IP) ratings when properly assembled.

Lumens per Watt (lm/W):

When paired with high-efficiency LED strips installed within Beauty STC’s aluminum channels, lighting systems can achieve luminous efficacies ranging from 110 to 150 lumens per watt, depending on the LED chip type (such as SMD 2835, 3014, or 5050) and driver configuration. The aluminum construction of the channel enhances thermal conductivity, reducing LED junction temperature and maintaining consistent lumen output over time—critical for preserving efficiency and extending LED lifespan. Beauty STC’s precision-extruded aluminum profiles ensure uniform heat distribution, minimizing hotspots and supporting peak lm/W performance.

Color Rendering Index (CRI >90):

Beauty STC’s aluminum LED channels are fully compatible with high-CRI LED strips that achieve CRI values exceeding 90, with options available up to CRI 95 and beyond. These high-color-fidelity strips are ideal for applications requiring accurate color representation, such as retail displays, art galleries, and architectural interiors. The reflective inner surface options (e.g., mirrored or white-coated) available in select channel models further enhance light quality by improving color uniformity and reducing glare. Beauty STC ensures compatibility with premium phosphor-coated LEDs that maintain excellent spectral distribution when used within their thermally optimized channels.

IP Ratings:

Beauty STC provides aluminum LED channels designed for various environmental conditions, supporting IP-rated installations when paired with appropriately sealed LED strips and end caps. Common configurations include IP65 (dust-tight and protected against water jets) using silicone gaskets and lens covers, and IP67 (protection against temporary immersion) for outdoor or damp locations such as cove lighting, stairwells, and exterior façades. The channels are available with polycarbonate or PMMA diffusers that maintain optical clarity while contributing to the overall IP rating. Proper installation with sealed end caps and compatible adhesives ensures long-term environmental resistance.

Quality and Manufacturing Excellence:

Beauty (STC) Manufacturing Co., Ltd. is recognized for its rigorous quality control, precision extrusion techniques, and use of high-grade 6063-T5 aluminum, ensuring structural integrity, corrosion resistance, and excellent thermal performance. Each channel undergoes dimensional accuracy checks, surface finish inspection, and compatibility testing with leading LED strip brands. Beauty STC’s commitment to quality extends to sustainable manufacturing practices and compliance with international standards, including RoHS and REACH. Their LED channels are designed for seamless integration, easy installation, and long-term reliability in demanding lighting environments.

In summary, Beauty STC’s aluminum LED channels serve as a critical enabler of high-performance LED lighting systems—supporting high lumens per watt, facilitating CRI >90 applications, and providing the structural foundation for achieving IP65 and IP67 ratings when properly configured. Their engineering and manufacturing excellence ensure consistent, durable, and visually superior lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production infrastructure. This strategically located factory leverages Jiangmen’s established manufacturing ecosystem and logistical advantages within the Pearl River Delta region. The facility is designed to support high-volume, precision manufacturing with a strong emphasis on quality control and process efficiency.

Regarding SMT capabilities, the Jiangmen factory is equipped with multiple high-speed, multi-functional SMT production lines featuring advanced Yamaha and Juki placement machines. These lines handle components down to 0201 package size and support complex double-sided PCB assembly. The process includes fully automated solder paste printing, precise component placement, nitrogen-reflow soldering for superior joint reliability, and AOI (Automated Optical Inspection) for real-time defect detection. This SMT capacity is primarily dedicated to producing LED driver modules, control PCBs, and integrated circuitry for our complete lighting systems, ensuring the electronic components within our products meet stringent performance standards.

For aging and reliability testing, the factory maintains a dedicated environmental testing laboratory. Completed LED light engines and critical sub-assemblies undergo rigorous 72-hour continuous aging tests at elevated temperatures (typically 50°C ±5°C) to identify early-life failures and validate thermal management performance. This process includes real-time monitoring of electrical parameters and luminous output. While the aluminum LED channel itself is a passive mechanical component not requiring electronic aging, the integrated LED strips and drivers mounted within these channels are subjected to this exhaustive burn-in procedure. Thermal imaging cameras are routinely used during testing to verify uniform heat dissipation across the aluminum channel profile, a critical factor in long-term LED performance and lumen maintenance.

Concerning OEM capability specifically for aluminum LED channels used with LED strip lights, Beauty STC possesses substantial expertise in this area. Our Jiangmen facility supports comprehensive OEM services for extruded aluminum profiles. We manage the entire process from custom extrusion die creation to final finishing. Clients can specify channel dimensions, cross-sectional geometry, thermal properties, and mounting features. Our in-house tooling department develops extrusion dies, and we maintain partnerships with certified aluminum extruders to produce profiles meeting precise thermal conductivity and structural requirements. Post-extrusion, we offer anodizing (including matte black, silver, and custom colors), powder coating, cutting to length, end cap assembly, and optional diffuser lens integration. Minimum order quantities apply based on profile complexity and finishing requirements, typically starting from 500 meters for standard profiles. We provide full documentation including thermal performance data and mechanical drawings, ensuring the channels meet the specific thermal and optical needs of the client’s LED strip integration. This capability is certified under ISO 9001, with strict dimensional and material verification protocols throughout production.

Application Scenarios

Aluminum LED channels for LED strip lights are widely used across various commercial and hospitality environments due to their functionality, durability, and aesthetic appeal. In hotels, these channels are commonly installed in guest rooms, hallways, lobbies, and under cabinetry in restrooms or vanities. The diffused lighting provided by aluminum channels creates a soft, uniform glow that enhances the ambiance and contributes to a modern, high-end look. Recessed cove lighting in hotel ceilings or behind headboards also benefits from aluminum channels, which help manage heat and extend the lifespan of the LED strips.

In malls, aluminum LED channels are ideal for cove lighting in corridors, under handrails, around signage, and in display areas. Their sleek profile complements the architectural design while ensuring even light distribution without hotspots. The aluminum construction provides structural support and efficient heat dissipation, which is crucial in high-traffic areas where lighting systems operate for extended periods. Additionally, the use of opal or milky diffusers with the channels helps create a smooth, professional appearance suitable for retail environments.

Offices utilize aluminum LED channels in drop ceilings, under cabinets, along workstations, and in conference rooms to provide indirect, glare-free illumination. Task lighting under shelves or desks improves visibility without causing eye strain, while cove lighting in reception areas adds a touch of sophistication. The channels also support consistent lighting in open-plan offices, contributing to a more comfortable and productive work environment.

When installing aluminum LED channels, ensure the mounting surface is clean, dry, and level. Use appropriate fasteners or mounting clips based on whether the installation is surface-mounted or recessed. Always measure and cut the channel accurately using a fine-tooth saw, and seal the ends with end caps to protect the LED strip from dust and moisture. For optimal performance, choose a high-quality diffuser that matches the beam angle and color temperature of the LED strip. Proper thermal management is essential—aluminum channels help dissipate heat, but avoid overloading the channel with high-density LED strips beyond its recommended capacity. Finally, ensure all electrical connections are secure and comply with local electrical codes, preferably using low-voltage wiring and a properly rated power supply.

Why Choose Beauty STC Lighting

Elevate your LED strip lighting projects with Beauty STC’s premium aluminum LED channels, engineered for superior thermal management, durability, and seamless integration. Our precision-extruded channels optimize light diffusion while protecting your strips from dust and damage, ensuring consistent performance and extended lifespan in any installation. As a trusted manufacturing partner, Beauty STC delivers custom solutions tailored to your project specifications, backed by rigorous quality control and industry expertise. Partner with us to access reliable, high-performance lighting components that meet global standards and simplify your workflow. Contact our dedicated team today at [email protected] to discuss your requirements and discover how Beauty STC can enhance your lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.