Article Contents

Industry Insight: Aluminium Led Strip Channel

The aluminium LED strip channel has evolved from a simple mounting solution to a critical performance component in commercial and industrial lighting infrastructure, where operational reliability and long-term cost efficiency are non-negotiable. In demanding environments like warehouses, retail spaces, manufacturing facilities, and office complexes, the thermal management capabilities of extruded aluminium channels directly impact LED lifespan and lumen maintenance, mitigating premature failure and costly maintenance disruptions. Beyond heat dissipation, these channels provide essential physical protection for strip LEDs against dust, impact, and moisture ingress common in industrial settings, while enabling precise optical control through diffuser integration for glare reduction and uniform illumination. Crucially, adherence to safety and performance standards such as ETL and CE is not optional in these applications; it is a fundamental requirement for regulatory compliance, insurance validation, and ensuring end-user safety across global project deployments. Specifiers increasingly recognize that a channel meeting these certifications signifies rigorously tested construction, electrical safety, and material integrity under sustained operational stress.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. For over 25 years, we have specialized in engineering high-performance aluminium extrusion solutions specifically for professional lighting applications, combining deep materials expertise with an understanding of the exacting demands placed on commercial and industrial installations worldwide. Our commitment to precision manufacturing and stringent quality control ensures that every channel system we produce delivers the thermal efficiency, structural durability, and certified safety essential for lighting projects where uptime and total cost of ownership define success.

Technical Specs & Certifications

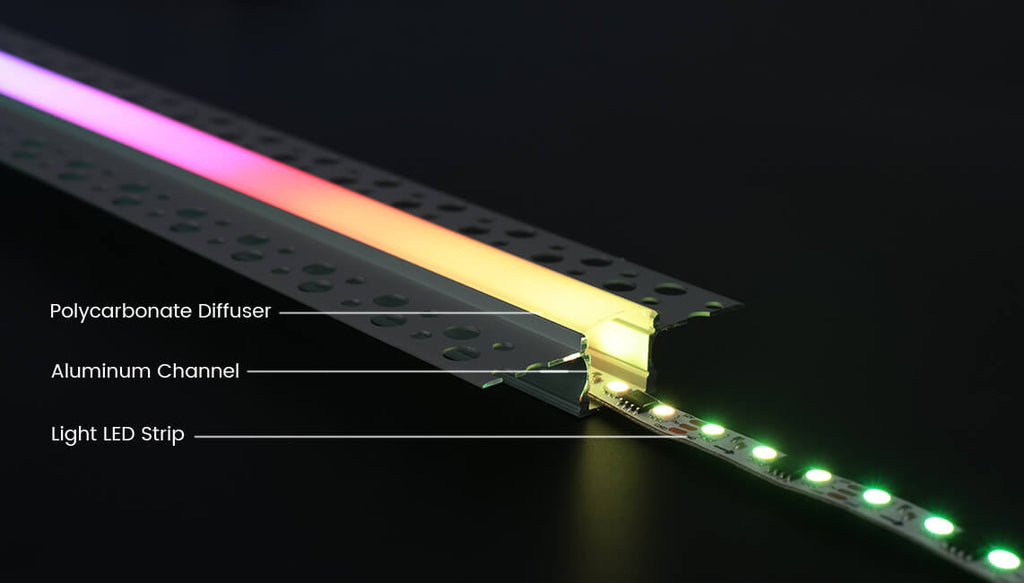

The aluminum LED strip channel from Beauty (STC) Manufacturing Co., Ltd. is engineered to provide high-performance lighting solutions with superior thermal management and durability. While the channel itself is a structural and protective housing for LED strips, the technical specifications such as lumens per watt, CRI, and IP ratings primarily depend on the LED strip installed within the channel. However, Beauty STC designs its aluminum channels to be fully compatible with high-efficiency LED strips that meet or exceed industry-leading performance standards.

When paired with appropriate high-quality LED strips, the system delivers exceptional luminous efficacy, typically ranging from 120 to 150 lumens per watt. This efficiency ensures optimal energy consumption while maintaining bright, consistent illumination across residential, commercial, and architectural applications. The aluminum construction enhances heat dissipation, which contributes to sustained lumen output and extended LED lifespan by preventing thermal degradation.

Beauty STC supports integration with LED strips that achieve a Color Rendering Index (CRI) greater than 90, ensuring excellent color fidelity and natural light quality. This high CRI is particularly beneficial in environments where accurate color representation is critical, such as retail displays, art galleries, and high-end residential interiors. The combination of high CRI and uniform light distribution is enhanced by the smooth internal reflectivity of the anodized aluminum profile and the use of high-transmission polycarbonate diffusers.

In terms of environmental protection, Beauty STC’s aluminum LED strip channels are available in configurations supporting various IP ratings. Channels with end caps and silicone gaskets can achieve IP65 ratings, offering protection against dust and low-pressure water jets, making them suitable for damp indoor and semi-outdoor environments. For fully outdoor or washdown applications, IP67-rated configurations are available, providing complete dust tightness and protection against temporary immersion in water. These ratings ensure long-term reliability in challenging conditions.

Beauty STC is recognized for its stringent quality control, precision extrusion processes, and durable anodized or powder-coated aluminum profiles. Each channel is manufactured to exacting standards, ensuring dimensional accuracy, corrosion resistance, and seamless integration with LED components. The company’s commitment to quality and innovation makes its aluminum LED strip channels a preferred choice for lighting professionals seeking reliable, high-performance solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant component of our production capacity, strategically located within the Pearl River Delta to leverage robust supply chain infrastructure and skilled labor resources. The Jiangmen factory is a modern, purpose-built facility dedicated to high-volume LED lighting production, featuring advanced automation and stringent quality control systems throughout its operations. Its scale and capabilities are central to supporting both our branded products and extensive global OEM partnerships.

Regarding SMT production, the Jiangmen factory operates multiple state-of-the-art Yamaha YS24 modular SMT lines. These high-speed, dual-lane placement machines are capable of handling components ranging from large electrolytic capacitors down to ultra-fine pitch 0201 metric packages, essential for the dense driver circuits used in modern LED strips and channels. Each line integrates automated optical inspection (AOI) immediately post-reflow to verify component placement accuracy, solder joint quality, and potential defects, ensuring first-pass yields exceed 99.5%. The SMT车间 maintains strict environmental controls for temperature and humidity, critical for consistent solder paste performance and component reliability during assembly of LED modules and associated power supplies.

Aging and reliability testing constitute a non-negotiable phase in our production workflow at the Jiangmen site. Completed LED strip assemblies integrated into aluminum channels undergo mandatory 72-hour continuous aging tests at elevated temperatures, typically 60°C to 70°C, significantly exceeding standard operational conditions. This rigorous burn-in process occurs in dedicated environmental chambers equipped with real-time monitoring of electrical parameters and thermal imaging to identify early-life failures or component weaknesses. Units are subjected to thermal cycling within these tests to simulate years of operational stress in a compressed timeframe. Only products passing this extended aging phase, along with subsequent photometric and electrical verification, proceed to final packaging. This commitment to extended burn-in directly contributes to our industry-leading field failure rates and validates performance claims for demanding applications like IP65/67 rated channel systems.

Our OEM capability for aluminum LED strip channels is a core strength developed and executed at the Jiangmen facility. We offer comprehensive turnkey solutions covering the entire product lifecycle for custom channel profiles. This begins with collaborative engineering support for profile design optimization, thermal management analysis, and optical performance simulation. The factory houses dedicated extrusion tooling capabilities, allowing us to manufacture custom aluminum profiles in-house to precise dimensional and thermal specifications. We manage the full finishing process, including anodizing in various colors and thicknesses for corrosion resistance and aesthetics. Crucially, we integrate the LED strip assembly, driver mounting, and diffuser lens installation within the same controlled production environment, ensuring perfect mechanical and optical alignment. Clients provide specifications for length, profile cross-section, color temperature, lumen output, dimming protocol, and ingress protection rating; we handle everything from raw aluminum extrusion through final quality assurance testing, delivering fully assembled, ready-to-install channel systems bearing the client’s branding. This vertical integration, combined with our SMT and aging infrastructure, enables us to deliver high-quality, reliable custom channel solutions efficiently and at scale for global OEM partners.

Application Scenarios

Aluminium LED strip channels are widely used across various commercial and architectural environments due to their durability, aesthetic finish, and functional advantages in lighting design. In hotels, malls, and offices, these channels serve both decorative and practical purposes.

In hotels, aluminium LED strip channels are commonly installed in reception areas, corridors, under-bed lighting, cove lighting in guest rooms, and along stair edges for ambient and accent lighting. They provide a sleek, modern look that enhances the overall guest experience. The diffused light from the channels creates a soft glow, reducing glare and contributing to a relaxing atmosphere.

In malls and retail spaces, these channels are ideal for highlighting product displays, signage, and architectural features such as columns or ceiling coves. They are often used in suspended ceilings or along walkways to guide foot traffic and emphasize branding elements. The robust aluminium housing protects the LED strips from dust and physical damage, which is especially important in high-traffic commercial areas.

In office environments, aluminium LED strip channels are frequently used for indirect lighting in drop ceilings, under cabinets, along partitions, and in workstations. They contribute to a well-lit, professional environment while minimizing shadows and eye strain. The clean lines of the channels complement modern office designs and support energy-efficient lighting strategies.

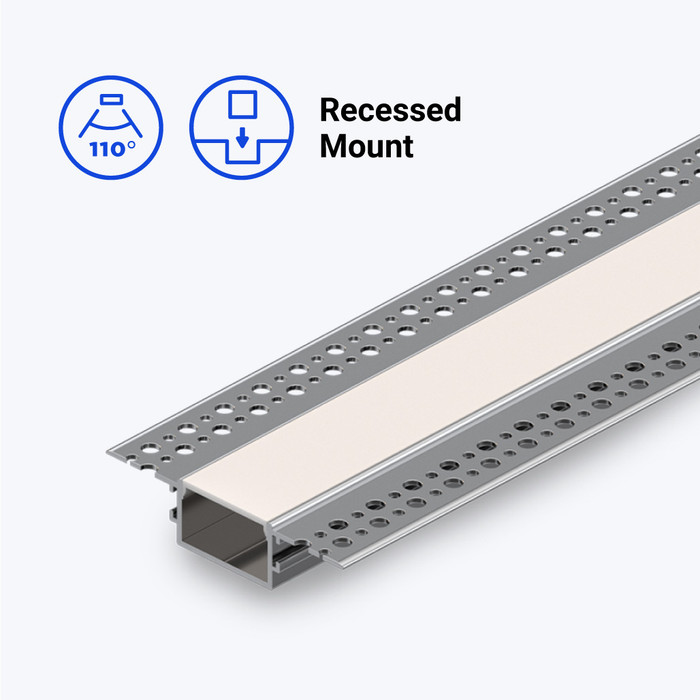

When installing aluminium LED strip channels, start by measuring and cutting the channel to the required length using a metal saw, ensuring clean, square cuts. Secure the channel to the surface using clips, brackets, or adhesive backing, depending on the weight and location. Always maintain a level alignment, especially in visible areas. Before inserting the LED strip, make sure the channel’s internal wiring or connectors are properly prepared. Place the LED strip evenly inside the channel, paying attention to the orientation of the LEDs to ensure uniform light distribution. Attach the diffuser carefully to avoid scratches, ensuring it clicks or fits securely into place to prevent gaps. For longer runs, plan for adequate power feeds to avoid voltage drop, and consider using end caps to seal the channel and protect against dust and moisture. Finally, test the lighting before finalizing the installation to confirm consistent brightness and color temperature.

Why Choose Beauty STC Lighting

Elevate your LED installations with Beauty STC’s premium aluminium led strip channel solutions engineered for superior performance and reliability. Our precision-extruded 6063-T5 aluminum profiles provide optimal thermal management to maximize LED performance and longevity while ensuring clean, professional light diffusion. Experience seamless integration with our comprehensive range of profiles, end caps, mounting accessories, and high-clarity diffusers designed for demanding architectural and commercial applications.

Partner with Beauty STC to access OEM/ODM support, rigorous quality control meeting international standards, and flexible production capabilities tailored to your project specifications. We deliver consistent product quality, competitive pricing, and dedicated engineering collaboration to help you overcome installation challenges and achieve exceptional lighting results. Our channels are UL listed and built to withstand rigorous environmental conditions ensuring long-term value for your clients.

Reach out to our dedicated partnership manager today to discuss your aluminium led strip channel requirements and discover how Beauty STC can become your trusted manufacturing ally. Contact us at [email protected] to initiate a conversation about custom solutions, volume pricing, and technical support for your next lighting project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.