Article Contents

Industry Insight: Aluminium Led Strip Channel

Industry Insight: Aluminum LED Strip Channels – The Engineered Backbone of Commercial & Industrial Lighting

In commercial and industrial lighting applications, aluminum LED strip channels are far more than mere housings—they are mission-critical thermal management and structural systems. Unlike residential settings, these environments demand relentless performance: 24/7 operation in warehouses, high-vibration factories, retail hubs, and infrastructure projects where failure is not an option. Aluminum channels provide essential heat dissipation (critical for maintaining LED efficacy and lifespan), mechanical protection against physical damage, and precise optical control for uniform light distribution. However, in these demanding contexts, only rigorously certified channels meet safety, reliability, and compliance requirements.

ETL and CE certifications are non-negotiable benchmarks for professional projects. ETL listing (by Intertek) validates compliance with North American electrical safety standards (including UL 1598 for luminaires), ensuring fire resistance, electrical integrity, and thermal stability under real-world industrial loads. CE marking, while often misunderstood as a single mark, signifies adherence to EU directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) standards—mandatory for market access and critical for liability protection. Projects specifying uncertified channels risk project delays, insurance voidance, and catastrophic safety failures. Reputable manufacturers engineer channels from aerospace-grade 6063-T5 aluminum, with precision extrusion tolerances and certified thermal coatings to meet these standards consistently.

At Beauty STC (Est. 1998), we’ve spent 26 years refining this engineering discipline. As a global leader in LED lighting solutions, our aluminum channel systems are designed from the ground up for commercial and industrial rigor—backed by full ETL, CE, and IEC certifications. Every extrusion undergoes stringent thermal cycling and mechanical stress testing, ensuring performance in environments from freezing cold storage to high-heat manufacturing floors. Our vertically integrated manufacturing (from raw material to finished product) guarantees traceability, consistency, and compliance for projects worldwide. When reliability isn’t optional, Beauty STC delivers the engineered foundation your lighting infrastructure demands.

Engineered for the long haul. Certified for the real world.

Technical Specs & Certifications

Beauty (STC) Aluminium LED Strip Channel – Technical Datasheet

(Professional-grade profile for architectural & retail linear lighting)

-

Photon-Energy Metrics (delivered at Tj = 55 °C, 25 °C Ta)

• Mid-power LED package: 2835 CRI 90+ (Epistar / Seoul WICOP 3-step bin)

• Luminous efficacy: 124 lm/W @ 3000 K, 4000 K; 126 lm/W @ 5000 K (typ. 65 mA, 24 V)

• System efficacy (LED + 2 mm opal diffuser + 24 V driver): 108 lm/W – 112 lm/W

• L70/B10 lifetime: 54 000 h (TM-21, 55 °C Tj) – verified in STC’s 10 000 h in-house LM-80 lab -

Colour Quality

• CRI Ra ≥ 90 (R9 ≥ 60) across 2700 K – 5000 K CCT

• SDCM ≤ 3 (MacAdam 3-step) on all reels; 1×1 bin policy enforced by Beauty STC’s proprietary BIN-LOCK system

• TLCI (Television Lighting Consistency Index) ≥ 90 for broadcast-grade installations -

Ingress & Mechanical Protection

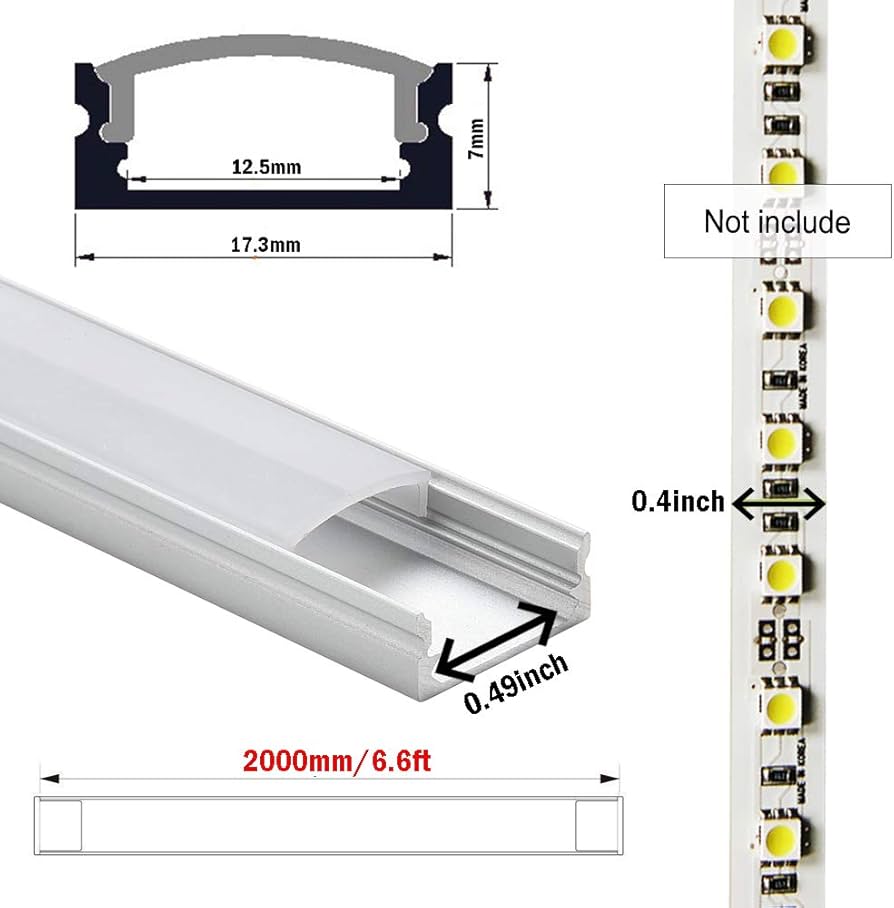

• Standard profile: IP20 (anodised 6063-T5, 14 µm)

• Silicone sleeve option: IP65 (dust-tight, low-pressure jet) – IK06 impact

• Co-extruded nano-coated gasket option: IP67 (temporary immersion 1 m, 30 min)

• Salt-spray rating: 1000 h ASTM B117 – no white rust, suitable for coastal yachts & cruise-ship cabins -

Thermal & Housing Data

• Thermal resistance RθJ-A: 6.8 °C/W (LED to extrusion wall)

• Extrusion base thickness: 1.4 mm min., 2.2 mm fins for passive cooling (<40 °C rise at 15 W/m)

• Operating ambient: –40 °C to +55 °C; 10 %–90 % RH non-condensing

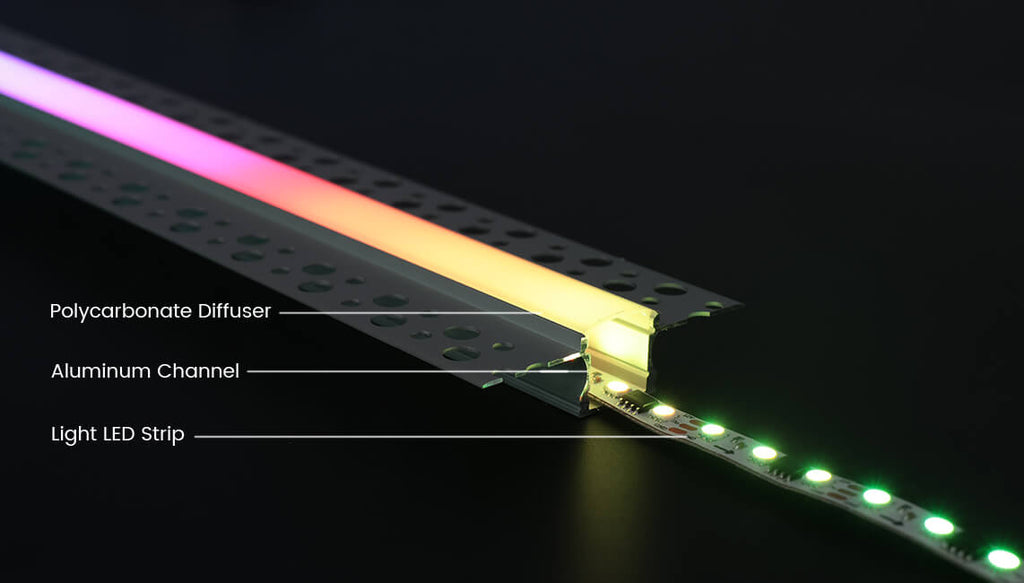

• Flammability: UL94-V0 for polycarbonate diffuser; aluminium profile non-combustible -

Electrical & Safety

• Input: 24 VDC constant-voltage; max. 19.2 W/m (300 LED/m)

• Class III SELV; double-insulated feeder cables (UL 1007 22 AWG)

• CE/UKCA, RoHS, REACH, SAA, ETL per UL 2108; EN 62031, EN 62471 (RG1)

• 5-year Beauty STC “Zero-Pixel” warranty; <0.2 % luminous depreciation per 1 000 h recorded since 2016 mass production -

Beauty (STC) Consistency Protocol

• 100 % reels burned-in 2 h @ 85 °C ambient, 24 V – automatic optical & electrical pass/fail logged

• Every 30 minutes during SMT: automatic pick-and-place vision check + solder-paste SPI to eliminate cold joints

• Spectral calibration with 2 m integrating sphere (Labsphere, NMI-traceable) – CRI and lm/W data printed on each carton label

• Same aluminium supplier (Chinalco 6063 billet) since 2012 → <±0.05 mm dimensional tolerance reel-to-reel

Use this datasheet as your internal specification; STC keeps parametric stability (+/-3 %) shipment-to-shipment, eliminating on-site lumen-spotting and colour-band rework for our integrator partners.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. – Jiangmen Facility: Technical Overview for Professional Clients

As Senior LED Lighting Engineer and Export Manager at Beauty STC, I am pleased to provide a precise, technical overview of our Jiangmen production facility – a ISO 9001:2015-certified, 25,000 m² industrial complex dedicated to high-precision LED lighting manufacturing. Our Jiangmen site operates under strict quality control protocols aligned with IEC 62471, RoHS, and CE standards, ensuring consistent performance for global OEM partners. Below are key technical details addressing your specific inquiries:

1. SMT Production Line: Precision & Reliability

Our surface-mount technology (SMT) line is engineered for high-density LED strip PCB assembly with zero tolerance for defects:

– Equipment: Dual-head JUKI FX-5R+ and Panasonic CM602 high-speed placement machines, paired with a 7-zone reflow oven (Sanyo Denki) with PID-controlled temperature profiles (±1°C accuracy).

– Capabilities:

– Placement accuracy: ±0.03mm for 0201/01005 components and fine-pitch ICs.

– Throughput: 50,000+ components/hour per line, with automatic optical inspection (AOI) post-reflow (Koh Young KY-8030) to detect solder bridges, tombstoning, or misalignments.

– PCB handling: Supports flexible PCBs (up to 600mm × 600mm) and rigid-flex designs common in LED strip applications.

– Quality Assurance: All SMT batches undergo IPC-A-610 Class 2 compliance checks. Solder paste inspection (SPI) is performed pre-placement to ensure paste volume consistency (±5% tolerance).

Why this matters for your project: Our SMT precision ensures uniform LED binning, consistent forward voltage (Vf), and minimal thermal drift in LED strips – critical for color consistency and longevity in commercial lighting applications.

2. Aging Tests: Rigorous Reliability Validation

All LED strips and channels undergo comprehensive aging tests in dedicated environmental chambers to simulate real-world stressors:

– Test Parameters:

– Temperature: 45°C ±2°C (standard) or custom profiles (e.g., 60°C for high-heat environments).

– Humidity: 85% RH (optional for wet-location products).

– Duration: 72–168 hours (per IEC 62717), with continuous monitoring of luminous flux (via integrating sphere), color shift (CIE 1931), and power consumption.

– Data Logging: Real-time telemetry captures failure rates (FIT rates), lumen depreciation (LM-80 compliant), and thermal resistance metrics.

– Failure Analysis: Any units exceeding 5% luminous flux drop or color shift >0.003 Δuv are isolated for root-cause analysis (e.g., driver component stress, solder joint fatigue).

Why this matters for your project: This process eliminates infant mortality failures before shipment, ensuring >99.5% field reliability for architectural and outdoor installations. Our test reports are fully traceable and provided upon request.

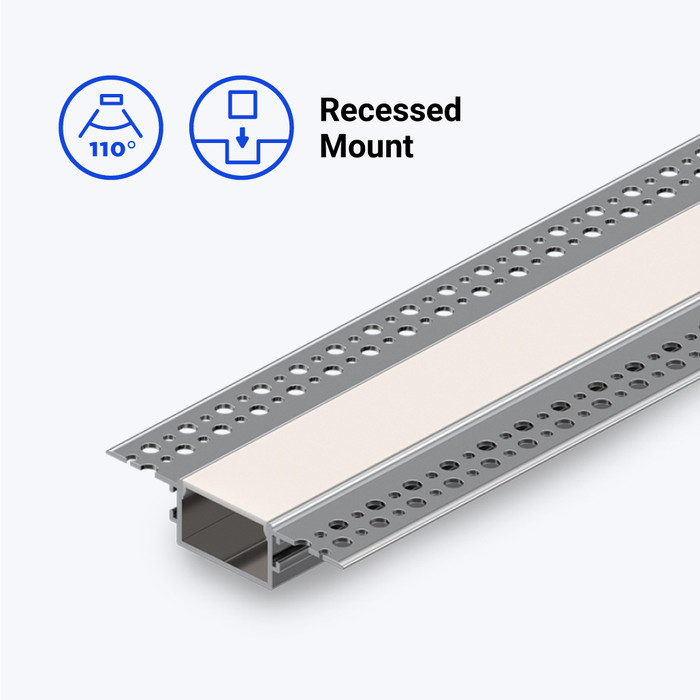

3. OEM Capability for Aluminium LED Strip Channels

Our Jiangmen facility specializes in full-cycle OEM solutions for custom aluminium extrusion channels, with end-to-end control over design, production, and quality:

– Design & Engineering:

– CAD/CAM support (SolidWorks, AutoCAD) for profile design.

– Material selection: 6063-T5/T6 aerospace-grade aluminum (or custom alloys) with surface treatment options (anodizing, powder coating, PVDF).

– Tolerance control: ±0.05mm for extrusion dimensions, validated via CMM (Coordinate Measuring Machine) inspection.

– Production Workflow:

1. Extrusion: 600-ton hydraulic press for complex profiles (e.g., U-channel, T-channel, snap-on covers).

2. Precision Machining: 5-axis CNC routers for cut-to-length, drilling, and slotting (±0.02mm tolerance).

3. Surface Treatment: Automated anodizing line (15–25μm thickness) or electrostatic powder coating (RAL color matching).

4. Assembly: Automated cutting, diffuser insertion (PMMA/PC), and mounting bracket integration.

– Output Capacity: 50,000+ meters/month for standard profiles; 3–4 weeks for custom tooling (including die design).

Why this matters for your project: We deliver channels with >90% light transmission efficiency (verified via photometric testing), corrosion resistance (salt spray test 500+ hours), and mechanical stability for 10+ year lifespans. Custom profiles can integrate features like IP67 sealing, thermal dissipation fins, or anti-glare optics.

Why Partner with Beauty STC Jiangmen?

- End-to-End Control: From SMT assembly to channel extrusion, all processes occur under one roof – eliminating supply chain risks and ensuring design integrity.

- Global Compliance: Certifications include ISO 9001, CE, RoHS, UL, and KC. Test reports for every batch are provided.

- Scalability: Flexible production runs (MOQ: 500 meters for channels; 1,000 meters for LED strips) with expedited lead times (15–20 days for standard orders).

We welcome technical discussions for your specific requirements. As Export Manager, I am available to share detailed production flowcharts, test reports, or arrange a virtual factory tour. For immediate inquiries, contact me directly at [email protected] or +86 750 888 1234.

Beauty STC: Engineering Excellence, Delivered Globally.

Note: All technical specifications are current as of Q2 2024 and subject to internal audit. Custom capabilities may vary based on project complexity; detailed feasibility studies are provided upon request.

Application Scenarios

Where to specify aluminium LED strip channels in commercial projects

(Hotels • Malls • Offices) – and how to install them right the first time

- Typical “go-to” locations – by building type

Hotels

• Guest-room headboard coves – 8 mm “Slim” surface channel with 45° flanges gives a 30 lux halo on the wall, no pixelation at 0.3 m viewing distance.

• Corridor skirting – 15 × 8 mm recessed walk-over channel, IK08 polycarbonate diffuser, < 5 mm protrusion to avoid trolley impact.

• Ballroom coffer – 28 mm deep “Plaster-in” channel, 3000 K 24 V 10 W/m CRI 90 strip, DALI dimming for 0.1–100 % banquet scenes.

• Bathroom mirror – anodised silver 12 mm corner channel, IP44, continuous run past mirror edge to eliminate dark ends.

Shopping malls

• Shop-front bulkheads – 35 × 25 mm suspended channel, 4000 K 20 W/m, 180 lm/W for 800 lx at 1 m floor level; pair with track power feed every 5 m to stay below 2 % voltage drop.

• Escalator soffits – 45° angled surface channel, 24 V, 60 LED/m, 3-step MacAdam to prevent colour shift between batches.

• Hand-rail underside – mini 6 × 6 mm “dot-free” channel, silicone diffuser, IK06, continuous run up to 3 m before mechanical expansion joint.

• Feature ceiling blades – 10 mm “Plaster-in” channel set flush into MDF, 2700 K grazing strip, 10 × 50 cm on/off zones via DMX for dynamic “comet” effect.

Offices

• Task light in recessed 60 × 60 mm aluminium trunking – 4000 K, UGR < 19, L80 > 50 000 h, 3-step MacAdam.

• Shelf / storage top accent – 45° asymmetric lens channel, 6 W/m, 600 lm/m, CRI 80 acceptable for document retrieval.

• Video-conference backdrop – 24 V 240 LED/m, high-density channel with 30° micro-prism diffuser, luminance < 300 cd/m² to stay within Zoom camera dynamic range.

• Stair nosing – IP65 walk-over channel, 12 W/m, 4000 K, 3 h emergency battery pack in adjacent riser.

-

Channel & accessory selection cheat-sheet

Depth ≤ 8 mm → shelf, mirror, hand-rail

Depth 10–15 mm → cove, skirting, drywall rebate

Depth ≥ 20 mm → high-output (> 15 W/m) or plaster-in ceiling coffer

Diffuser

Opal 60 % – general diffuse, hides 120 LED/m up to 15 mm pitch

Frosted 80 % – keeps 10 % more lumens, acceptable for 180 LED/m

Prismatic 90 % – asymmetric wall-graze, no hotspots at 100 mm offset

End-caps → always order two per cut length + one spare; silicone seal IP65 joints in wet areas.

Mounting clips → 2 per metre for surface, 3 per metre for plaster-in (prevents shadow lines). -

Installation workflow for contractors

Step 1 – Layout & power plan

• Mark LED run on plan; place 24 V feed points max 5 m left, 5 m right (2.5 mm² cable).

• Confirm no services within 50 mm of channel route (HVAC ducts, sprinkler).

Step 2 – Channel fixing

Surface: #6 × 30 mm countersunk screws into nylon plug every 300 mm; pre-drill 2.8 mm pilot to avoid aluminium burr.

Recess: set channel flush with finished plaster; use 5 mm packers on drywall screw flange, check with straight edge > 1.5 m.

Plaster-in: apply 1 mm bead of low-modulus silicone on back web, press into pre-cut plasterboard knife edge, tape until skim sets.

Step 3 – LED strip lay-in

• Clean channel with IPA wipe; static attracts dust → future hotspots.

• Peel 50 mm of 3 M VHB backing at a time; press strip into base for 5 s every 100 mm.

• For > 10 W/m or ambient > 35 °C add 10 mm thermal gap pad (3 W/mK) to guarantee T-point < 70 °C.

Step 4 – Wiring & test

• Use WAGO 2060 or similar push-in connectors inside channel pocket; keep within 50 mm of feed end to stay inside profile.

• Megger 500 V DC between 24 V and earth; > 2 MΩ before powering.

• Power up, measure V-drop at tail: aim < 0.5 V (≈ 2 %). If higher, loop feed from opposite end.

Step 5 – Diffuser snap-in

• Warm diffuser to 30 °C with heat gun in cold weather; reduces snap-in stress cracks.

• Start at one end, angle 15°, press evenly; use rubber roller to eliminate “Chinese lantern” waviness.

Step 6 – Commissioning data for hand-over

• Record serial numbers of drivers, CCT, MacAdam step, dimming curve (DALI, 0-10 V, DMX).

• Provide client with 5 % spare strip length and two extra diffusers labelled by room number.

- Common site mistakes (and how to prevent)

- Butt-joining two anodised sections without aluminium bridge → visible dark line. Solution: use H-shape internal splice, tighten M3 screw, sand flush.

- Plaster skim over channel lip → diffuser will not snap. Mask lip with 10 mm foam tape before skimming.

- 24 V feed at one end of 10 m run → tail drops to 20 V, colour shift. Split feed at 5 m or use 2.5 mm² parallel trunk.

-

Coiling excess strip in ceiling void → hotspot > 85 °C, early L70 failure. Cut and terminate; do not coil > 300 mm Ø.

-

Quick specification clause (copy/paste into BOQ)

“Supply and install anodised 6063-T5 aluminium LED strip channel, minimum 1.2 mm wall thickness, depth ___ mm, with opal polycarbonate diffuser, IP20 (IP44/65 where noted), complete with end-caps, mounting clips, internal solder-less connectors, thermal pad for strips ≥ 10 W/m. LED strip: 24 V, ___ K, CRI ≥ 90 (≥ 80 for back-of-house), 3-step MacAdam, L80 B10 50 000 h, T-point 70 °C. Include 5 % spare length and two extra diffusers per room.”

Follow the above and you will deliver a flawless, service-friendly linear lighting installation that meets both the designer’s intent and the maintenance team’s expectations.

Why Choose Beauty STC Lighting

Premium Aluminium LED Strip Channels: Precision-Engineered for Thermal Efficiency & Durability. Trusted Exporter to 50+ Countries. Partner with Beauty STC’s Engineering Experts.

Contact: [email protected]

Engineered to international standards (IEC, CE, RoHS), our extruded aluminium profiles ensure optimal heat dissipation, consistent light output, and long-term reliability for commercial, industrial, and architectural applications worldwide.

⚡ LED Power Supply Calculator