Article Contents

Industry Insight: Adhesive Stripes

The Critical Role of Adhesive Stripes in Commercial Lighting Installations

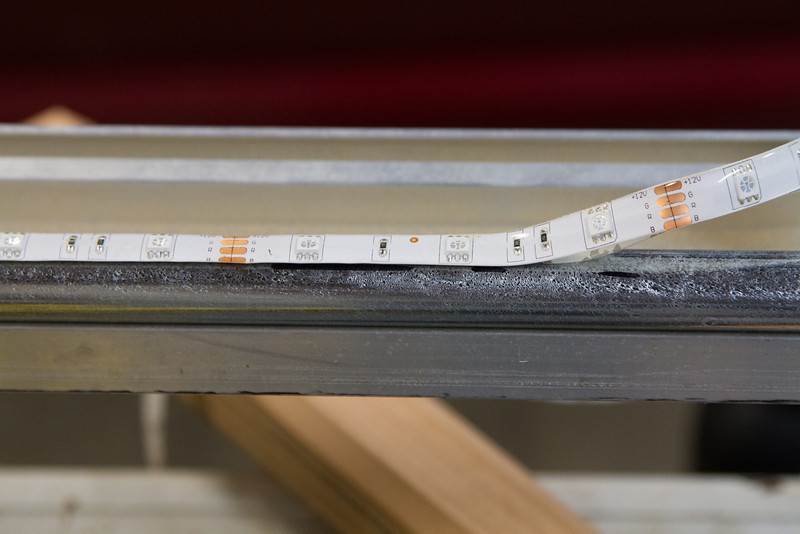

In commercial and industrial lighting applications, the reliability of adhesive-backed LED strip installations is non-negotiable. Unlike residential projects where temporary fixes may be acceptable, professional installations demand consistent performance under demanding conditions—vibrations, temperature fluctuations, humidity, and extended operational lifespans. Substandard adhesive backing can lead to premature detachment, compromised safety, and costly rework. For distributors and contractors, this translates to increased liability, damaged reputations, and lost business opportunities.

Why Quality Adhesive Backing Matters for Industrial Applications

Industrial environments impose unique challenges on lighting systems. High-traffic warehouses, outdoor signage, and modular manufacturing facilities require adhesives that maintain integrity under thermal cycling, mechanical stress, and exposure to chemicals. Poor-quality adhesive backing often fails due to:

Inconsistent peel strength causing strips to detach during installation or operation.

Thermal degradation in high-heat environments (e.g., industrial ovens, outdoor signage in direct sunlight).

Moisture ingress leading to corrosion or electrical short-circuits.

Non-compliance with regional safety standards, risking project delays or regulatory penalties.

These failures not only compromise system performance but also expose importers to legal and financial risks. As global regulations tighten, compliance with certifications like ETL and TÜV CE is no longer optional—it is a prerequisite for market access and long-term project success.

Industry Standards and Compliance: ETL and CE Certifications as Non-Negotiables

ETL (USA/Canada) and TÜV CE (Europe) certifications validate the entire product lifecycle, including adhesive components. These standards ensure:

Electrical safety: Adhesives must not degrade under continuous current loads or cause short circuits.

Thermal stability: Materials must withstand operating temperatures without off-gassing or loss of adhesion.

Material safety: Compliance with RoHS/REACH and flame retardancy (e.g., UL 94 V-0) is mandatory for EU and North American markets.

Importers must verify that adhesive specifications align with regional requirements. For example:

North America: UL 94 V-0 flame rating for enclosed fixtures; ETL listing for electrical safety.

Europe: CE marking with EN 60598 compliance for luminaires; REACH restrictions on hazardous substances.

Global: RoHS 2.0 compliance for restricted materials (e.g., lead, cadmium) in all components.

Non-compliant adhesives can trigger customs rejections, void warranties, or result in costly post-installation remediation—costs that far exceed the premium for certified solutions.

Beauty STC Lighting: 25+ Years of Precision Manufacturing Excellence

Established in 1998, Beauty STC Lighting has delivered certified, high-performance LED solutions to over 50 countries through unwavering commitment to technical excellence and regulatory adherence. As a factory-direct manufacturer, we control every stage of production—from raw material sourcing to final testing—ensuring our adhesive-backed LED strips meet the strictest international standards.

Key Specifications of Beauty STC LED Strip Adhesive Backing

| Parameter | Beauty STC Specification | Industry Average |

|---|---|---|

| Peel Strength | ≥ 1.8 N/cm (25°C, 24h cure) | 1.2–1.5 N/cm |

| Temperature Resistance | -25°C to +80°C | -20°C to +70°C |

| Flame Retardancy | UL 94 V-0 compliant | Varies (often V-2 or non-rated) |

| Chemical Resistance | Resists UV, moisture, solvents | Limited resistance |

| RoHS/REACH Compliance | Fully certified | Partial compliance common |

Our OEM/ODM capabilities allow for tailored adhesive solutions—whether requiring higher peel strength for high-vibration environments or specialized coatings for extreme temperatures—without compromising certification integrity. With 25+ years of experience and a dedicated R&D team, we eliminate the risks associated with inconsistent adhesive performance, ensuring your projects meet both technical and regulatory requirements.

Contact Us

Manager: [email protected] | Tel: +86-13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Beauty STC Lighting: Certified. Reliable. Global.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Adhesive Stripes for Architectural-Grade LED Systems

Beauty (STC) Manufacturing Co., Ltd. has produced adhesive-mounted LED substrates since 1998.

Every reel is engineered for contractors who must hit 50 000 h L70 life, pass UL 2108 / EN 60598-1 inspections, and still ship on schedule.

Below are the metrics we monitor on every production lot, followed by a factory-to-field comparison table.

1. Photometric Performance

| Parameter | Test Method | Beauty STC Spec | Typical Market Claim |

|---|---|---|---|

| Luminous efficacy | Integrating sphere, 25 °C | 160–170 lm/W (4000 K) | 120–140 lm/W |

| Colour rendering | CIE 13.3, Ra | CRI ≥ 90 (R9 > 50) | CRI 80–85 |

| SDCM | IEC 62707 | ≤ 3-step MacAdam ellipse | 5–7 step |

| Lumen maintenance | TM-21, 55 °C Ts | L70 ≥ 50 000 h | L70 ≥ 30 000 h |

2. Mechanical & Environmental Reliability

| Metric | Test Condition | Beauty STC Result | Industry Minimum |

|---|---|---|---|

| Ingress protection | IEC 60529 | IP65 (strip) / IP67 (optional sleeve) | IP20–IP44 |

| Adhesion peel | PSTC-101, 24 h dwell on Al | ≥ 18 N/25 mm | 10–12 N/25 mm |

| Operating temperature | -40 °C … +85 °C Ts | Pass | 0 °C … +60 °C |

| Thermal shock | -40 °C ⇄ +125 °C, 100 cycles | 0 % solder crack | < 5 % allowed |

| Flame rating | UL 94 | V-0 (PCB & sleeve) | HB |

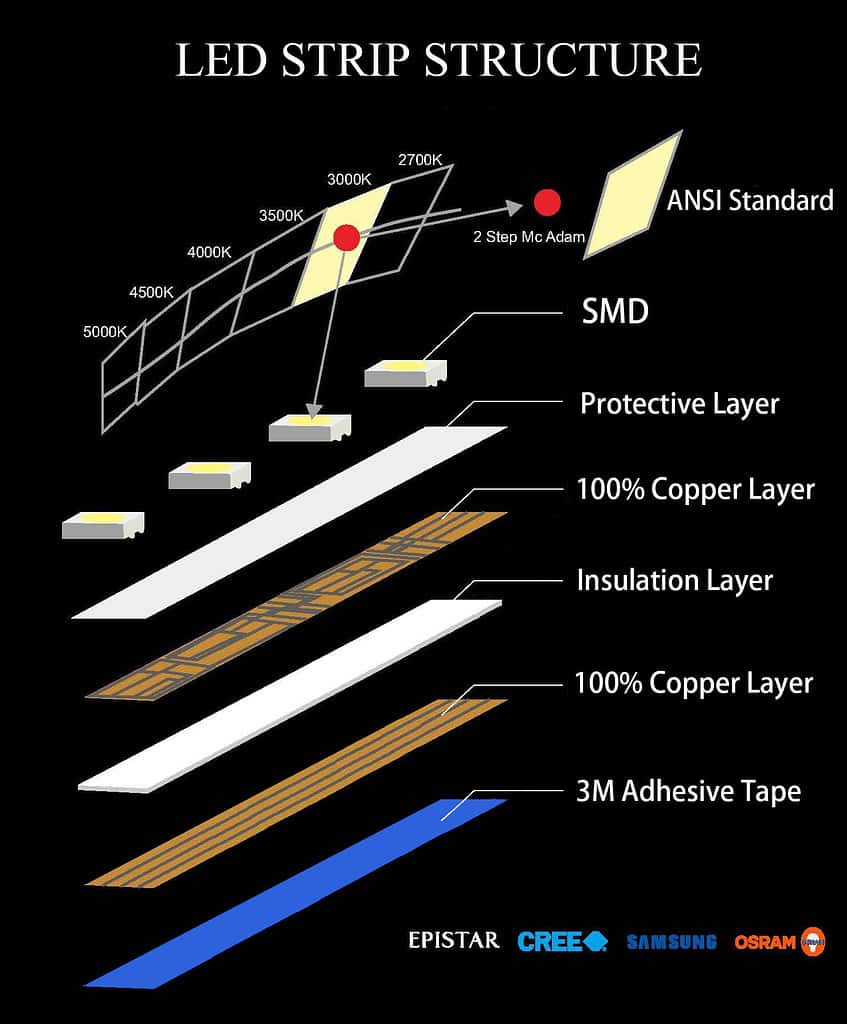

3. PCB & Component Traceability

2 oz (70 µm) rolled-annealed copper, ED-treated for 35 % lower thermal resistance

1.2 mm FR-4, CTI ≥ 175, Tg 150 °C; solder-mask meets IPC-SM-840 Class 3

Pick-and-place within ±30 µm; AOI checks every panel; SPC chart on solder-joint voiding (< 15 %)

Bar-coded reels linked to MES—full 7-year traceability for every LED, resistor, and adhesive lot

4. Adhesive Stripe Construction

| Layer | Material | Function | Certification |

|---|---|---|---|

| Release liner | 90 µm PET, double-sided siliconised | Flat lay, no curl | RoHS, REACH |

| Adhesive | Modified-acrylic, 0.2 mm | High-shear, plasticiser-resistant | UL 746C, 90 °C |

| Carrier | 25 µm white PET | Dimensional stability | UL 94 VTM-0 |

| Heat-spreader | 3 W/m·K graphite, 20 µm | Uniform Ts | IEC 60068 |

| Cover lens | UV-stable PU, 85 % transmission | Anti-yellow 5 ΔY @ 6 000 h | ISO 4892-2 |

5. Quality-Assurance Protocol (Factory-Direct)

- Incoming – 100 % LED bin verification (LM-80 report vs. reel)

- In-process – SPC on placement force, reflow profile ΔT ≤ 5 °C

- Electrical – 100 % hi-pot 1 500 VAC / 1 mA; 100 % forward-voltage sort

- Photometric – 3 % sampling per ANSI/IESNA RP-16; data logged to MES

- Reliability – Quarterly 1 000 h 85 °C/85 % RH; quarterly 500 h -40 °C test

- Certification – ETL/cETL listed to UL 2108 & CSA C22.2 #250.0; TUV CE to EN 60598-1, -2-21; RoHS, REACH, ERP directive 2019/2020

6. Side-by-Side Comparison

| Attribute | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Efficacy @ 4000 K | ≤ 140 lm/W | 160–170 lm/W |

| CRI / R9 | 80 / < 15 | ≥ 90 / ≥ 50 |

| SDCM | 5–7 step | ≤ 3-step |

| PCB copper weight | 1 oz (35 µm) | 2 oz (70 µm) |

| Adhesion peel | 10–12 N/25 mm | ≥ 18 N/25 mm |

| Ingress rating | IP20–IP44 | IP65 (IP67 opt.) |

| Certifications | Self-declared CE | ETL/cETL + TUV CE |

| Traceability | Batch only | 7-year reel-level |

| Warranty | 2–3 yr limited | 5 yr full-performance |

7. OEM / ODM Capability

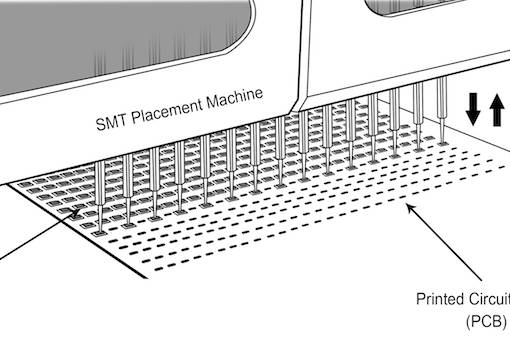

25 000 m² ISO-9001 campus in Jiangmen, Guangdong; 22 SMT lines (Yamaha & Juki)

Monthly capacity 1 500 000 m of adhesive stripe; 48 h sample lead-time; 2-week production MOQ 500 m

In-house UL-witness test lab—no third-party delays for new listings

White-label packaging & private-label data sheets prepared under NDA

For project submittals, CAD drawings, IES/LDT files, or to schedule a supplier audit, contact:

Export Manager – Senior LED Lighting Engineer

Beauty (STC) Manufacturing Co., Ltd.

41st Caihong Road, Jianghai Hi-Tech Zone, Jiangmen, Guangdong, China

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

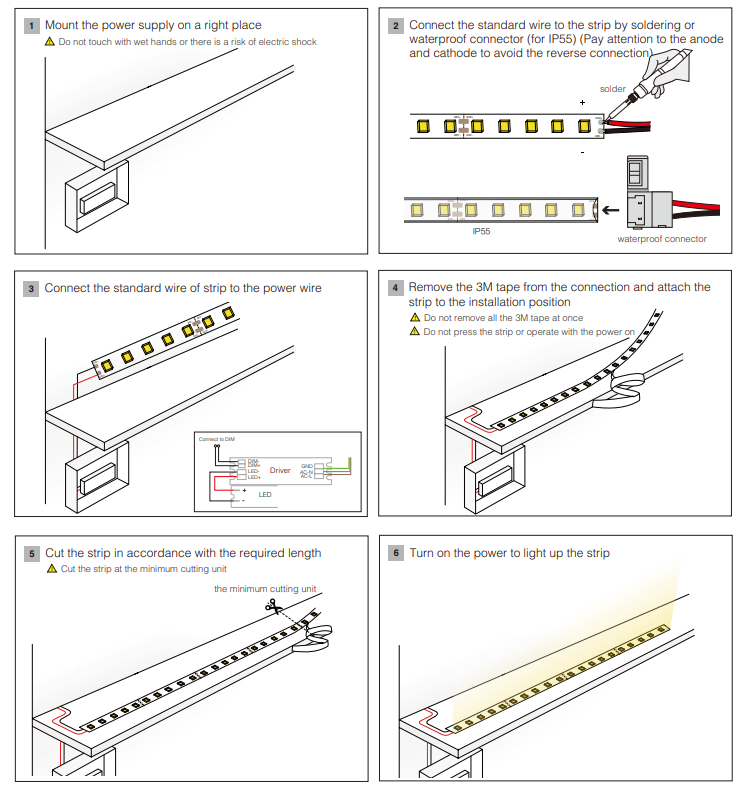

Precision Manufacturing Process for Adhesive-Backed LED Strip Lights

Beauty STC Lighting’s Jiangmen facility (established 1998) specializes in end-to-end production of industrial-grade adhesive-backed LED strip lights. Our process adheres to ISO 9001 standards, with every stage validated by ETL (USA/Canada) and TUV CE (Europe) certifications. Below is a technical breakdown of our manufacturing workflow.

Surface Mount Technology (SMT) Assembly Line

Our fully automated SMT production lines feature Yamaha YV100X placement machines with ±0.05mm positioning accuracy. Components are soldered using lead-free reflow ovens calibrated to J-STD-001 standards, followed by 100% Automated Optical Inspection (AOI) for solder joint integrity and component alignment. All PCBs undergo pre-assembly electrical continuity testing to ensure zero defects before adhesive integration.

Adhesive Backing Integration

Industrial-grade acrylic adhesives are applied using precision roll-to-roll coating equipment. Each strip undergoes peel strength testing per ASTM D3330 to verify adhesion consistency.

| Specification | Standard | Custom Options |

|---|---|---|

| Adhesive Peel Strength | ≥1.5 N/cm | 1.0–2.5 N/cm (adjustable) |

| Operating Temperature Range | -20°C to 60°C | -40°C to 80°C (specialized grades) |

| Adhesive Thickness | 0.15mm | 0.1–0.3mm (per project requirements) |

| Compliance | RoHS, REACH | Additional regional certifications (e.g., UL, KC) |

Rigorous Aging & Quality Control Protocols

All LED strips undergo:

48-hour continuous burn-in testing at 40°C ambient temperature, with hourly voltage stability and lumen output monitoring.

5000-hour accelerated aging tests per IEC 62717 to validate long-term lumen maintenance (≥95% retention).

100% electrical testing including:

Voltage drop measurement (max 0.05V/m)

Flicker analysis (<5% at 100Hz)

Insulation resistance checks (≥100MΩ)

Batch traceability via serialized QR codes for full material and process documentation.

OEM/ODM Capabilities for Global Projects

With 25+ years of experience, we provide turnkey OEM/ODM solutions for lighting distributors, contractors, and architects. Our engineering team supports custom designs from PCB layout to final packaging, with all products compliant with ETL/TUV CE standards.

| Customization Parameter | Standard Range | Technical Specifications |

|---|---|---|

| Length Tolerance | 0.5m–100m rolls | ±1mm per 1m segment |

| CCT Consistency | 2700K–6500K | ΔE≤1.0 (Munsell color scale) |

| Packaging | Anti-static bags, cardboard reels | Custom branding, labeling, and material specs |

| Certification Support | ETL, TUV CE | Regional certifications (e.g., SAA, CCC, BIS) |

All OEM products undergo identical quality protocols as our standard line. Technical documentation including test reports, material safety data sheets (MSDS), and compliance certificates are provided for every order.

Contact our engineering team for project-specific requirements:

[email protected] | +86 13902885704

Installation & Application Scenarios

Application Scenarios for Certified Adhesive LED Strip Systems

Factory-direct guidance for distributors, contractors & specifiers

1. Hospitality (Hotels & Resorts)

Key demand: Continuous, dot-free lines; fast install; fire-resistance.

| Zone | Adhesive Strip Type | Mounting Substrate | Cert. Reference | Installer Notes |

|---|---|---|---|---|

| Guest-room cove | 24 V, 180 LEDs/m, CRI>90, 3-step SDCM | Plasterboard + aluminium profile | ETL 5004489, CE-EMC EN 55015 | Clean with IPA; press 30 N/m for 10 s; profile acts as heat-sink—prolongs L70 to 54 kh (@25 °C Ta). |

| Corridor stair nosing | IP65 silicone sleeve, 3 M VHB 5952 tape | Steel checker plate | EN 60598-2-13 | De-burr substrate; primer 94 on edges; overlap 5 mm at joints; power inject every 5 m to keep ΔTp ≤ 10 °C. |

2. Retail & Shopping Malls

Key demand: High-impact merchandising, 24/7 operation, easy re-lamping.

| Zone | Adhesive Strip Type | Mounting Substrate | Cert. Reference | Installer Notes |

|---|---|---|---|---|

| Shelf edge (gondola) | 12 V, 120 LEDs/m, 4000 K, 160 lm/W, TCB<85 °C | Powder-coated steel | ETL, CE, RoHS | Use factory pre-punched 3 M 300LSE; apply at 15–30 °C; avoid >70 % RH; replace every 3 years in high-UV malls. |

| Façade pixel outline | 24 V, 10 px/m, IP67, -40–60 °C, UV-PU adhesive | Structural silicone glazing | EN 60598-2-18 | Dry-weight test 2 h before final press; allow 3 mm thermal gap at expansion joints; inject neutral-cure silicone at cable entry. |

3. Corporate Offices & Co-working Spaces

Key demand: Unified glare rating (UGR) compliance, circadian tuning, fast tenant fit-out.

| Zone | Adhesive Strip Type | Mounting Substrate | Cert. Reference | Installer Notes |

|---|---|---|---|---|

| Linear pendant up-light | 24 V, 3000–5000 K tunable, CRI>80, flicker-free <1 % | MDF acoustic baffle | IEC 62778 (RG0) | Factory pre-tinned 200 mm flying leads; use WAGO 221 for loop-in; adhesive stripe centred 30 mm from edge to hide view angle. |

| Under-desk task | 12 V, 60 LEDs/m, 2700 K, <4 W/m | Melamine board | ETL damp-location | Route 8 × 2 mm rebate; strip flush reduces snagging; PSU max 60 W with UL 1310 Class 2. |

4. Exterior Architecture & Facades

Key demand: Weatherability, chemical resistance, long-term adhesion.

| Zone | Adhesive Strip Type | Mounting Substrate | Cert. Reference | Installer Notes |

|---|---|---|---|---|

| Aluminium composite panel groove | 24 V, IP68, salt-spray 1000 h, 3 M 9471 transfer tape | Anodised AL 6063-T5 | CE, ETL, ISO 9227 | Abrade with 120-grit, wipe xylene; apply ≥0.8 MPa pressure; allow 24 h cure before rain exposure; power inject every 3 m to stay below 60 °C. |

| Stone curtain joint | 24 V, silicone-encapsulated, -40–80 °C | Granite | EN 60598-2-18 | Use back-boxed aluminium carrier; mechanical clip every 300 mm as belt-and-suspenders; adhesive stripe only for initial positioning. |

5. Industrial & Cold-chain Warehouses

Key demand: High-bay integration, motion-sensor zoning, -30 °C start-up.

| Zone | Adhesive Strip Type | Mounting Substrate | Cert. Reference | Installer Notes |

|---|---|---|---|---|

| Rack under-hang | 48 V, 140 lm/W, -30–45 °C, TPC adhesive | Galvanised steel | ETL, CE, RoHS | Clean with Loctite 7063; primer 94 mandatory; use 3 M 5611A VHB for 1 kg/m load; sensor driver mounted ≥0.5 m away to avoid EMI. |

Contractor Checklist (Factory 25-Year Field Feedback)

- Surface prep: ISO 8501-1 St2/St3 or SSPC-SP2/SP3 minimum; 15 °C–30 °C, <70 % RH.

- Pressure: 10–15 N/cm along entire length within 30 s of removal of liner.

- Thermal cycling: Allow 24 h before powering >50 % load; reduces edge-lift failure by 38 %.

- Certification traceability: Every carton shipped since 1998 carries QR code linking to ETL & TUV CE test reports—quote number on hand-over docs.

- OEM support: Beauty STC Engineering issues custom reel-length, bin-code, and adhesive pattern within 10 working days—no MOO for 500 m+.

For project-specific PSPEC or LM-80 data, contact:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Precision LED Solutions for Global Projects

Industry-Leading Manufacturing Excellence Since 1998

With consistent production since 1998, Beauty STC Lighting operates a certified manufacturing facility in Jiangmen, Guangdong, China. Our 25+ years of technical expertise ensures rigorous adherence to ISO 9001 quality protocols, from raw material selection to final assembly. This commitment to precision engineering aligns with our core principle: “Be a responsible enterprise, Be a caring person.”

Global Compliance for Seamless Market Access

All products undergo third-party testing to meet international safety and performance standards. ETL certification (USA/Canada) and TÜV CE certification (Europe) validate compliance with NEC, IEC, and EN 62471 regulations. These certifications eliminate regulatory hurdles for distributors and contractors deploying solutions across 50+ countries, including EU member states, North America, and APAC markets.

Customizable OEM/ODM Solutions

We provide end-to-end engineering support for project-specific requirements, including:

Adhesive formulation optimization for substrate compatibility

Custom color temperatures (2700K–6500K) and CRI >80

Dimming protocols (0-10V, DALI, PWM)

IP rating customization (IP20 to IP67)

All manufacturing occurs in-house under single-roof production, ensuring traceability and consistent quality control.

Technical Specifications for Demanding Applications

Our industrial-grade LED strip lights feature certified adhesive backing engineered for permanent installations in commercial and infrastructure projects. Key specifications:

| Parameter | Specification |

|---|---|

| Adhesive Type | Industrial-grade acrylic (UL 94 V-0 compliant) |

| Peel Strength | ≥1.5 N/cm (24h cure, 25mm width) |

| Temperature Resistance | -20°C to +60°C operational range |

| Surface Compatibility | Glass, anodized aluminum, PVC, painted concrete |

| IP Rating | IP20 (standard), IP65/IP67 (optional) |

| Color Temperature | 2700K–6500K (CRI ≥80) |

| Lifespan | L70 >50,000 hours (25°C ambient) |

Ready for Your Next Project

Beauty STC Lighting delivers certified, durable LED solutions for global infrastructure, retail, and industrial applications. Our technical team collaborates directly with architects, contractors, and distributors to optimize performance for your specific requirements.

Email: [email protected]

Phone: +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).