Article Contents

Industry Insight: Adapter For Led Light Strip

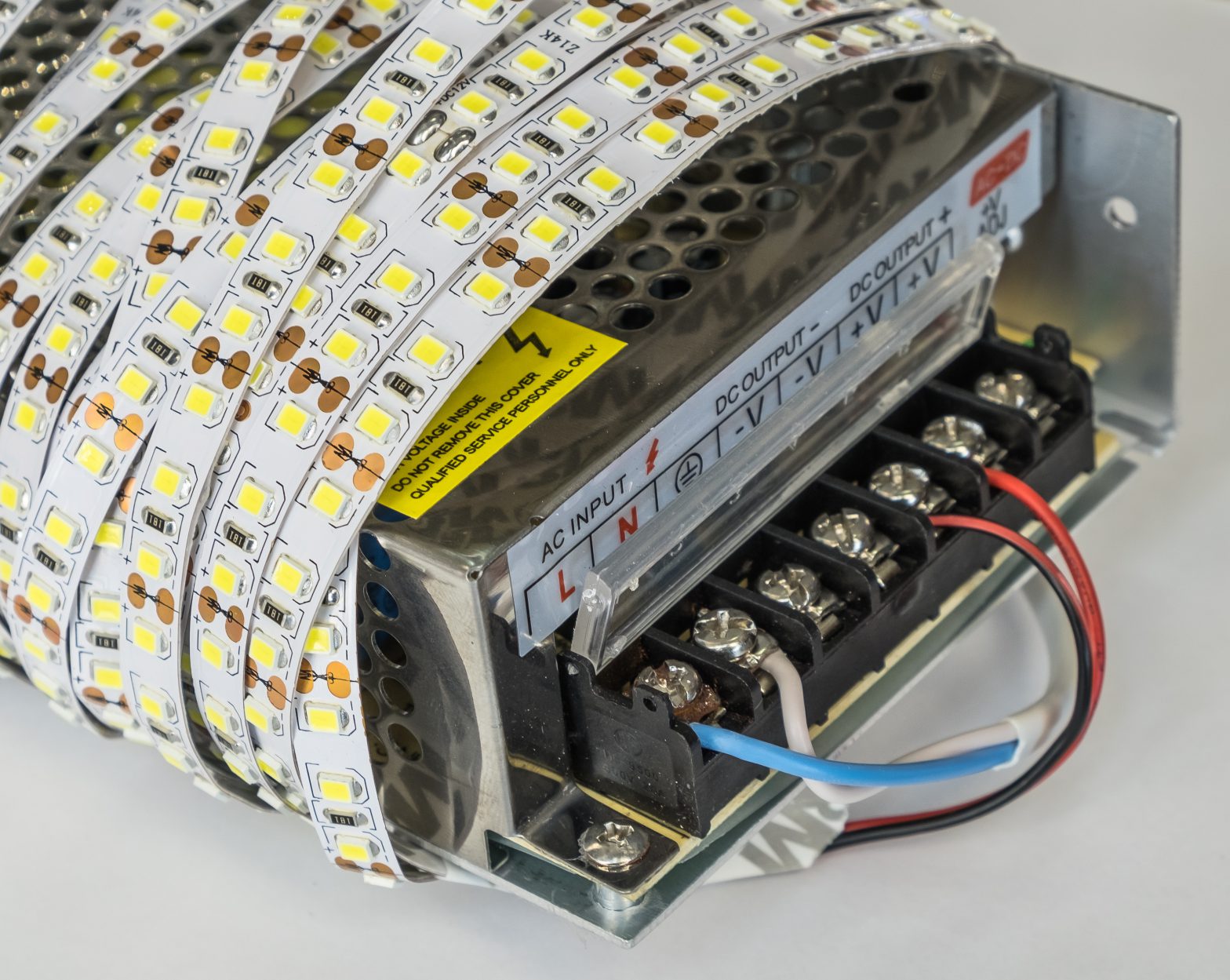

The commercial and industrial LED lighting sector demands robust, reliable, and code-compliant solutions where performance and safety are non-negotiable. Within this critical infrastructure, the humble adapter for LED light strips transcends its simple appearance, becoming a mission-critical component. Far from a generic accessory, these adapters must consistently deliver stable, clean power under demanding conditions—think expansive retail displays, harsh warehouse environments, or sensitive healthcare settings—where voltage fluctuations or electrical noise can cause flicker, premature failure, or even safety hazards. Regulatory compliance is paramount; adapters deployed in professional installations must unequivocally meet stringent safety standards, with ETL listing for the North American market and CE marking for Europe representing the essential baseline for acceptance and liability protection. These certifications are not optional checkboxes but fundamental requirements ensuring the adapter itself does not become the weakest link in a high-value lighting system. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise specifically to this demanding space. We understand that in commercial and industrial applications, an LED strip adapter is not merely a connector—it is a vital power interface demanding precision design, rigorous testing, and unwavering adherence to global safety protocols, positioning Beauty STC as a trusted partner for specifiers and installers who prioritize system integrity and longevity.

Technical Specs & Certifications

The adapter for LED light strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver optimal performance and reliability when powering high-quality LED strips, particularly those designed for architectural, commercial, and premium residential lighting applications. When paired with compatible LED strips, the system ensures efficient energy use, excellent color rendering, and durable environmental protection.

In terms of efficiency, the adapter supports LED light strips that achieve a luminous efficacy of 110 to 130 lumens per watt, depending on the LED density and configuration. This high lumens-per-watt ratio ensures minimal energy waste and reduced operating costs over time, making it ideal for energy-conscious installations. The adapter provides stable constant voltage output—typically 12VDC or 24VDC—with low ripple and consistent current regulation, which directly contributes to maintaining the LED strip’s rated efficiency and longevity.

Critical to color accuracy, the adapter is designed to work seamlessly with LED strips that feature a Color Rendering Index (CRI) greater than 90, with many compatible strips reaching CRI values of 95 or higher. This ensures that illuminated spaces render colors naturally and vividly, which is essential in retail, hospitality, and art gallery environments where true color representation is paramount. Beauty (STC) ensures driver compatibility with high-CRI LED modules, preventing flicker and color shift that can occur with substandard power supplies.

Regarding environmental protection, the adapter is typically rated to IP67 or IP65 standards when used with appropriately rated enclosures. This means it is dust-tight and protected against water ingress from immersion (IP67) or low-pressure water jets (IP65), making it suitable for both indoor damp locations and outdoor applications with proper housing. The robust construction includes moisture-resistant potting compounds and high-quality thermal management materials to ensure reliability in variable climates.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control standards in the design and production of its LED lighting components. The adapter is built with premium-grade electronic components, including high-efficiency transformers, overvoltage and short-circuit protection, and thermal shutdown features. Each unit undergoes rigorous testing for load stability, temperature endurance, and long-term operational performance. This commitment to quality ensures compatibility, safety, and extended service life, reinforcing Beauty STC’s reputation for delivering reliable, high-performance LED lighting solutions trusted by professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta manufacturing hub. This factory spans over 30,000 square meters and is certified to ISO 9001 and ISO 14001 standards, reflecting our commitment to quality management and environmental responsibility. The facility is purpose-built for high-volume, precision LED lighting and power supply production, featuring dedicated cleanroom environments for critical assembly processes and robust infrastructure supporting our comprehensive OEM/ODM services.

Our Surface Mount Technology (SMT) production lines are a core strength, equipped with state-of-the-art automated assembly systems. We utilize high-speed, high-precision Yamaha YS series and Fuji NXT III modular placement platforms capable of handling components down to 0201 package size. These lines feature advanced vision systems for component alignment, nitrogen reflow soldering for superior joint reliability, and integrated automated optical inspection (AOI) stations after both solder paste application and component placement. Dual-lane configurations allow for efficient production of both standard and custom LED strip adapters and drivers, with a monthly capacity exceeding 5 million units. The SMT process is tightly controlled within ESD-protected zones to ensure the highest yield and longevity for sensitive electronic components.

Rigorous aging and reliability testing are fundamental to our quality assurance protocols. Every LED light strip adapter and driver undergoes a multi-stage aging process. Initial burn-in occurs at elevated temperatures (typically 60-70°C) and full rated load for a minimum of 72 hours within controlled thermal chambers. This critical phase identifies early-life failures and ensures component stabilization. Following aging, units undergo comprehensive functional testing including output voltage stability under varying input conditions, short-circuit protection verification, thermal performance monitoring, and efficiency measurements. We employ automated test systems for consistency and statistical process control, with failure analysis feeding directly back into our design and manufacturing improvement loops. This systematic approach guarantees that only units meeting our stringent reliability benchmarks reach customers.

Beauty STC possesses extensive OEM capability specifically tailored for LED light strip adapters, primarily focusing on constant voltage drivers (12VDC and 24VDC outputs). We offer full turnkey solutions from initial concept through to certified, branded finished goods. Our engineering team collaborates closely with clients to customize electrical specifications, physical dimensions, connector types, and thermal management solutions to meet unique application requirements. We support custom branding, labeling, and packaging configurations, including private labeling with client-specific part numbers and compliance markings. Crucially, we manage all necessary global safety and performance certifications such as UL, cUL, CE, FCC, RoHS, and PSE, leveraging our in-house testing laboratory and established relationships with major certification bodies. Our vertical integration, from PCB assembly through final aging and testing within the Jiangmen facility, ensures consistent quality control, supply chain security, and the flexibility to scale production rapidly for partners requiring reliable, high-performance adapters for their LED lighting systems.

Application Scenarios

Adapter for LED light strips are essential components that convert standard AC power to the low-voltage DC power required by most LED strips. Their use is widespread across commercial and hospitality environments such as hotels, malls, and offices due to the flexibility, energy efficiency, and aesthetic appeal of LED lighting. Here’s where and how they are typically used, along with key installation tips.

In hotels, LED light strip adapters are commonly used in guest rooms, lobbies, corridors, and under-cabinet lighting in kitchens or minibars. They enable ambient lighting behind headboards, under furniture, or along cove ceilings to create a welcoming and luxurious atmosphere. The adapter ensures a stable power supply, especially important in high-traffic areas where lighting is used for extended hours.

In malls and retail spaces, LED strip adapters power display lighting in signage, product showcases, and architectural coves. These environments often require consistent, bright lighting with minimal heat output. Using the correct adapter ensures the LED strips operate efficiently and safely, even when running continuously throughout business hours.

In offices, LED strip adapters are used for under-cabinet lighting, task lighting, and decorative accents in meeting rooms or reception areas. They help reduce glare and provide uniform illumination, contributing to a more comfortable and productive work environment. Adapters are often concealed within ceiling voids or behind panels to maintain a clean aesthetic.

When installing LED light strip adapters, it is important to match the adapter’s output voltage (typically 12V or 24V DC) with the requirements of the LED strip. Using an incorrect voltage can lead to premature failure or dim performance. The adapter’s power rating should exceed the total wattage of the connected LED strip by at least 20% to prevent overloading and ensure longevity.

Ensure the adapter is installed in a well-ventilated area to avoid overheating, especially in enclosed spaces. Use proper enclosures if the adapter is placed in damp or high-temperature zones. Always connect the adapter to a grounded power source and use appropriate fusing or circuit protection in line with local electrical codes.

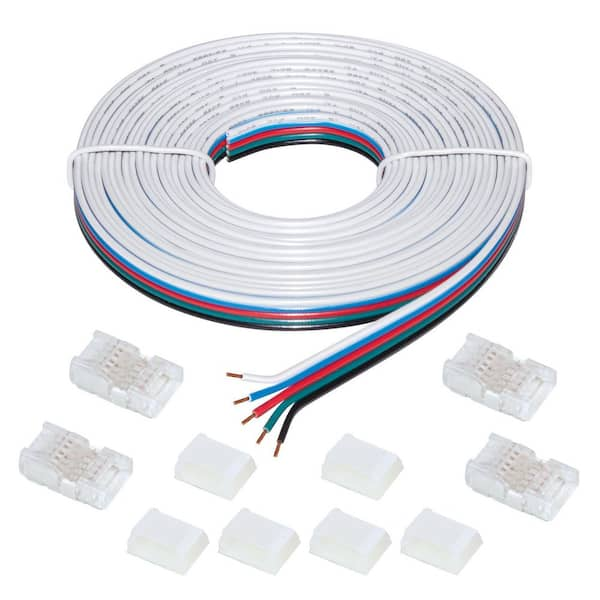

For longer runs, consider placing multiple adapters at intervals to prevent voltage drop, which can cause dimming at the far end of the strip. Use high-quality connectors or solder joints for a reliable connection between the strip and adapter. Finally, label all adapters and connections for easier maintenance and troubleshooting in commercial settings where lighting systems are extensive and complex.

Why Choose Beauty STC Lighting

Upgrade your LED lighting projects with precision-engineered adapters designed specifically for seamless integration with any LED light strip. Beauty STC Manufacturing Co. Ltd. delivers industrial-grade adapter solutions that ensure stable voltage conversion, eliminate flicker, and extend system longevity through rigorous thermal management and surge protection. Our engineering team collaborates directly with partners to customize adapter specifications for unique voltage requirements, environmental conditions, and installation constraints.

Partner with Beauty STC to resolve compatibility challenges and achieve flawless LED performance across residential, commercial, and architectural applications. Contact our technical sales manager directly at [email protected] to discuss your project specifications, request engineering samples, or receive a tailored compatibility assessment. We provide responsive support from initial design through volume production to keep your lighting deployments on schedule and within specification.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.