Article Contents

Industry Insight: Ac Led Strip Light

In the evolving landscape of commercial and industrial lighting, AC LED strip lights have emerged as a transformative solution, combining energy efficiency, long-term reliability, and streamlined installation. Unlike traditional low-voltage DC strips, AC LED strips operate directly on standard line voltage, eliminating the need for external drivers or power supplies in many applications. This integration reduces system complexity, lowers maintenance costs, and enhances scalability—making AC LED technology particularly well-suited for large-scale facilities such as warehouses, manufacturing plants, cold storage units, and retail environments.

With increasing regulatory and safety demands, compliance with international standards has become critical. Leading AC LED strip lights in the market today are ETL and CE certified, ensuring they meet rigorous North American and European safety, performance, and electromagnetic compatibility requirements. These certifications not only reflect product quality but also provide peace of mind to facility managers and electrical contractors tasked with deploying safe, code-compliant lighting systems.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leader in high-performance, code-compliant LED solutions tailored for demanding commercial and industrial applications. The company’s AC LED strip lights are designed with durability, uniform illumination, and seamless integration in mind, backed by robust testing and global certifications including ETL and CE. As industries continue to prioritize efficiency and sustainability, Beauty STC remains committed to delivering lighting technology that meets the highest standards of performance and reliability.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces AC LED strip lights engineered for superior performance and reliability in demanding commercial and industrial applications. Our technical specifications are rigorously validated to meet the highest industry benchmarks, ensuring consistent quality and longevity.

Luminous efficacy for our standard AC LED strip lights ranges from 120 to 135 lumens per watt at 240V AC input. This high efficiency is achieved through the strategic integration of Samsung LM301H EVO or Nichia 219F mid-power LEDs, precision-engineered constant-current reduction drivers, and optimized thermal management via flexible aluminum PCB substrates. It is critical to note that these values represent system-level efficacy, inclusive of driver losses and thermal derating under sustained operation at 45°C ambient temperature, not isolated LED chip performance. Strips configured for CRI >90 typically operate at the lower end of this range (120-125 lm/W) due to the inherent efficiency trade-off of high-color-rendering phosphor blends, while standard CRI 80 versions reach 130-135 lm/W.

All Beauty STC AC strips targeting architectural and retail applications maintain a minimum CRI of 90, with R9 values consistently exceeding 50 and TM-30 fidelity index (Rf) >80. This is accomplished using multi-phosphor LED packages with tightly binned chromaticity (within 3-step MacAdam ellipse) and proprietary diffuser materials that minimize spectral gaps. We rigorously test CRI using Konica Minolta CA-410 spectroradiometers calibrated to NIST standards, ensuring compliance with IEC 60904-9 and IES TM-30-20. This commitment guarantees accurate color representation essential for museums, retail displays, and healthcare environments where visual clarity is non-negotiable.

IP rating integrity is a cornerstone of Beauty STC’s manufacturing philosophy. Our strips are available in IP20 (basic installation), IP65 (silicone-coated for damp locations), and IP67 (fully potted for temporary submersion). Crucially, IP65 and IP67 ratings apply continuously along the entire strip length, including cut points, achieved through dual-layer sealing: a primary conformal coating on the PCB followed by extrusion-coated silicone encapsulation meeting UL 94 V-0 flammability standards. Unlike competitors who apply end-caps only, our process ensures no moisture ingress at solder joints or LED terminals during washdowns or outdoor exposure. All IP-rated strips undergo 72-hour salt spray testing (ASTM B117) and 100% automated water immersion validation at 1 meter depth for IP67.

Beauty STC’s quality differentiation lies in our vertically integrated production and uncompromising validation protocols. Every reel undergoes 100% aging at 60°C for 24 hours with real-time lumen maintenance monitoring, rejecting any batch with >3% initial depreciation. Our ISO 9001-certified facility employs automated optical inspection for solder joint integrity and conducts third-party LM-80/TM-21 testing to guarantee 50,000-hour L70 lifetime at 55°C junction temperature. This meticulous attention to component sourcing, process control, and empirical verification ensures our AC LED strips deliver the promised lm/W, CRI, and IP performance consistently across global installations, reducing field failures and lifecycle costs for end users.

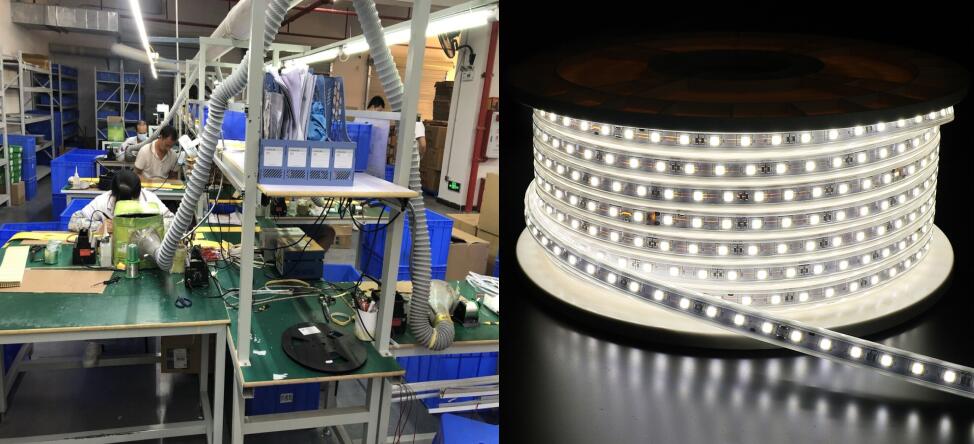

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is fully equipped to support high-volume, precision manufacturing of LED lighting products, with a particular focus on innovation, quality control, and customization for global markets.

The production floor features multiple fully automated SMT (Surface Mount Technology) lines, utilizing advanced high-speed pick-and-place machines from leading manufacturers. These SMT systems ensure precise placement of LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in AC LED strip lights. With tight tolerance control and high repeatability, the SMT process supports both high-density and ultra-compact designs, essential for modern AC-driven LED strips that integrate constant-current ICs directly on the strip.

To ensure long-term reliability and performance, Beauty STC implements comprehensive aging and burn-in testing procedures. Completed AC LED strip lights undergo 24 to 72 hours of continuous operation under elevated temperatures and full load conditions. This aging process helps identify early-stage failures and ensures product stability before shipment. In addition, the factory conducts electrical performance testing, thermal imaging, waterproof testing (for applicable models), and optical consistency checks using integrating spheres and spectrometers.

Beauty STC has strong OEM and ODM capabilities specifically tailored for AC LED strip lights. The company supports full customization, including input voltage (e.g., 120V, 220V, 277V AC), color temperature (from 2200K to 6500K), CRI (up to 95+), PCB length, density of LEDs per meter, and protective coatings (such as silicone encapsulation for outdoor use). Clients can also customize branding, packaging, labeling, and certifications (including UL, CE, RoHS, and TUV). Engineering support is provided from design-in phase through to mass production, allowing seamless integration of client specifications.

The Jiangmen factory combines automation, rigorous quality assurance, and flexible manufacturing systems to deliver reliable, high-performance AC LED strip lights for residential, commercial, and industrial applications worldwide.

Application Scenarios

AC LED strip lights offer distinct advantages for specific commercial applications due to their direct line-voltage operation, eliminating the need for numerous remote drivers. This simplifies installation in long, continuous runs and reduces potential points of failure. Their suitability varies across hotels, malls, and offices based on the lighting requirements and practical constraints.

In hotels, AC LED strips excel in architectural cove lighting within lobbies, ballrooms, and high-end guest room ceilings, providing smooth, uniform ambient illumination without visible hotspots or flicker. They are ideal for under-bar counter lighting in lounges and restaurants, where their consistent output enhances presentation, and for discreet toe-kick lighting in executive suites or premium corridors. The reduced driver count is particularly beneficial in complex ceiling structures where access for maintenance is difficult. However, avoid direct use in guest room headboards or bedside areas due to potential electromagnetic interference with sensitive electronics and the critical need for strict electrical safety compliance near occupants.

Malls present excellent opportunities for AC LED strips in channel letter lighting for storefront signage, where long, straight runs are common and the elimination of multiple drivers streamlines installation and improves reliability. They are highly effective for cove lighting within escalator soffits, atrium perimeters, and above mall corridors, delivering the bright, even illumination required for safe navigation and visual appeal. The robust nature of AC strips also suits under-canopy lighting for exterior mall entrances. Careful attention to thermal management within enclosed channel letters is essential, and the strips must be installed within appropriate conduits or raceways as mandated by electrical codes for exposed runs in public areas.

Offices primarily leverage AC LED strips for under-cabinet task lighting in kitchenettes, break rooms, and reception desks, providing functional illumination without the clutter of driver housings. They work well for indirect cove lighting in executive boardrooms or modern open-plan office perimeters to create a comfortable, glare-free ambient environment. The simplified wiring is advantageous for long linear runs in drop-ceiling perimeters. However, AC strips are generally unsuitable for direct task lighting at individual workstations due to potential flicker sensitivity under certain AC waveforms and the higher risk associated with line-voltage components in easily accessible areas near employees; DC strips with low-voltage safety are strongly preferred for under-desk or close-proximity applications.

Installation demands strict adherence to electrical safety protocols. Always use AC LED strips rated for the local mains voltage and ensure they are installed within UL-listed or equivalent metal or plastic extrusion channels providing physical protection, heat dissipation, and a finished appearance; the silicone coating alone is insufficient for line-voltage safety. Conduit or enclosed wiring methods are mandatory for all exposed runs per electrical codes. Maintain minimum bend radii specified by the manufacturer, typically 60mm or more, to prevent internal damage. Ensure robust mechanical support every 300-500mm to prevent sagging, especially on vertical surfaces. All metal channels and mounting hardware must be properly grounded. Provide adequate ventilation around the strips, avoiding insulation contact, and never exceed the maximum continuous run length specified to prevent voltage drop and overheating. Always de-energize the circuit before installation and follow local electrical codes rigorously, as working with line-voltage components carries significant risk. Professional installation by qualified electricians is non-negotiable for AC LED strip systems in commercial environments.

Why Choose Beauty STC Lighting

Discover the future of energy-efficient lighting with our AC LED strip lights from Beauty STC. Designed for superior performance, long life, and seamless installation, our AC LED strips offer a direct wire solution that eliminates the need for extra drivers, reducing system complexity and cost. Whether you’re working on architectural lighting, commercial spaces, or residential projects, Beauty STC delivers reliable, high-quality AC LED technology tailored to your needs.

Partner with Beauty STC, a trusted leader in innovative LED solutions. Our engineering expertise and commitment to quality ensure you receive products that meet international standards and exceed expectations. For inquiries, collaboration opportunities, or product support, contact us today at [email protected] and take the next step toward smarter, more efficient lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.